Top 8 Cnc Pipe Bending Service Manufacturers & Suppliers List

1. Axenics – CNC Tube Bending Services

Domain: axenics.com

Registered: 2005 (20 years)

Introduction: CNC Tube Bending services offered by Axenics include:

– Computer Numeric Controlled (CNC) pipe bending for larger bends and high-quantity tube and pipe bending services.

– Capability to work with major alloys: copper, brass, aluminum, stainless steel, titanium, and Inconel.

– Produces wrinkle-free bends for seamless flow of liquids or gases.

– Process involves clean, dry cuts and precise bendi…

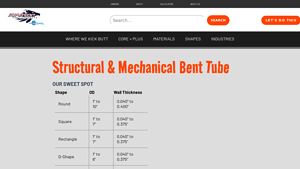

2. Superior Tube Products – CNC & Precision Tube Bending Services

Domain: superiortubeproducts.com

Registered: 1999 (26 years)

Introduction: CNC & Precision Tube Bending Services including Bent Tube, Laser-Cut Tube, Core + Plus, Welding, End-Forming, Milling & Drilling, Tooling, Hydraulic & Mechanical Press Work. Available shapes: Square, Round, Oval, D-Shape, Rectangle, Roll Over Protection System (ROPS), Custom Shape. Industries served: HVAC, Agriculture, Construction, Lawn & Garden, Outdoor Power Equipment, Medical Equipment, Office…

3. Ohio Laser – Precision Tube Bending Services

Domain: ohiolaser.com

Registered: 1999 (26 years)

Introduction: Ohio Laser offers tube bending services that include precision bending of various materials such as stainless steel, aluminum, and carbon steel. The company utilizes advanced CNC bending technology to achieve accurate and repeatable bends. Their capabilities include bending tubes with diameters ranging from 1/2″ to 6″ and wall thicknesses up to 0.120″. Ohio Laser can handle both small and large pr…

4. McKinney Manufacturing – CNC Mandrel Tube & Pipe Bending

Domain: mckineymfg.com

Registered: 2018 (7 years)

Introduction: CNC Mandrel Tube & Pipe Bending and Fabrication services; custom mandrel CNC tube and pipe bending; high-volume production capabilities; uses a steel plug (mandrel) to support the pipe during bending; capable of producing high quality, tight-radius bends; works with round, rectangular, and square tubing from ¼” to 4” outside diameter; specializes in custom-designed OEM and aftermarket exhaust syst…

5. Woolf Aircraft Products – Tube Bending Materials

Domain: woolfaircraft.com

Registered: 1998 (27 years)

Introduction: {‘company_name’: ‘Woolf Aircraft Products, Inc.’, ‘certification’: ‘ISO 9001: 2015 Registered’, ‘contact_number’: ‘734.721.5330’, ‘tube_bending_materials’: [‘Aluminum’, ‘Brass’, ‘Copper’, ‘Inconel’, ‘Chrome Moly’, ‘Copper Nickel’, ‘Carbon Steel’, ‘Titanium’, ‘Stainless Steel’], ‘outer_diameter_range’: ‘0.0625″ to 8″‘, ‘bending_processes’: [‘Rotary Draw Bending’, ‘Compression Bending’, ‘Roll Bendin…

6. Sharpe Products – Custom Tube and Pipe Solutions

Domain: sharpeproducts.com

Registered: 1999 (26 years)

Introduction: Sharpe Products specializes in custom tube and pipe bending, laser cutting, and end forming services for materials ranging from 0.50″ to 6″ OD. They serve various industries including aerospace, agriculture, automotive, construction, food and beverage, medical/healthcare, and recreation. Their services include:

– Tube Bending: Standard and complex tube bending capabilities.

– Tube Laser Cutting: P…

7. Lafarge & Egge – CNC Tube and Pipe Bending Services

Domain: lafargeandegge.com

Registered: 2017 (8 years)

Introduction: Lafarge & Egge offers AS9100/ISO 9001 certified CNC tube and pipe bending services for small and medium diameter tubes (< 3″) with tight tolerances. Key capabilities include CNC tube, pipe, and duct bending, coiling, pressure testing (including autofrettage), flaring, smushing, beading, coping, drilling, notching, deburring, end finishing, and internal/external swaging. They provide complex fabric…

8. Peerless – CNC Tube Bending Services

Domain: peerless-inc.com

Registered: 1997 (28 years)

Introduction: Peerless offers CNC tube bending services for a wide variety of shapes and sizes. The service is characterized by tight tolerances and conformity to customer specifications. Customers can provide drawings, and Peerless will prepare the bent tube assembly according to their needs. Benefits include reduced job costs, time savings during quoting and purchasing, improved service levels, standardizatio…

Introduction: Navigating the Global Market for cnc pipe bending service

In an increasingly interconnected world, sourcing reliable CNC pipe bending services can be a complex endeavor for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The key challenge lies in identifying suppliers who not only meet stringent quality standards but also align with specific project requirements and budget constraints. This guide aims to demystify the CNC pipe bending landscape by providing comprehensive insights into various bending techniques, applications across industries, and essential criteria for supplier vetting.

From understanding the nuances of different materials—such as stainless steel and aluminum—to exploring cost implications and lead times, this resource equips buyers with the knowledge necessary to make informed purchasing decisions. The guide delves into industry best practices, ensuring that buyers can navigate the selection process with confidence. Whether you are involved in construction, automotive, HVAC, or custom manufacturing, this guide will serve as your roadmap to finding the most suitable CNC pipe bending service providers.

By leveraging actionable insights and expert recommendations, international buyers can enhance their procurement strategies, ensuring they partner with suppliers who can deliver high-quality, cost-effective solutions tailored to their unique needs.

Understanding cnc pipe bending service Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Draw Bending | Utilizes a die to form the tube around a mandrel; suitable for complex shapes and tight radii. | Automotive, aerospace, and HVAC systems | Pros: High precision and repeatability; good for intricate designs. Cons: Higher tooling costs and slower production for large volumes. |

| Mandrel Bending | Incorporates a mandrel inside the tube to prevent deformation; ideal for thin-walled tubes. | Medical devices, furniture, and architecture | Pros: Maintains shape and integrity; suitable for tight bends. Cons: More expensive due to additional tooling. |

| Compression Bending | Involves bending by compressing the tube; typically used for larger diameters. | Construction and heavy machinery | Pros: Cost-effective for large volumes; simpler tooling. Cons: Limited to larger diameters and less precision. |

| Three-Dimensional Bending | Allows for bends in multiple planes; complex geometries can be created. | Custom fabrication, art installations | Pros: Versatile for unique designs; reduces welding needs. Cons: More complex setup can lead to longer lead times. |

| Laser Tube Cutting & Bending | Combines cutting and bending in one process; allows for intricate designs with cut features. | Automotive and manufacturing sectors | Pros: Reduces production time; enhances design flexibility. Cons: Higher initial investment in technology and setup. |

What Are the Characteristics and Suitability of Rotary Draw Bending?

Rotary draw bending is characterized by its use of a die and a mandrel to create precise bends in tubes, making it suitable for applications requiring intricate shapes and tight radii. This method is particularly favored in industries like automotive and aerospace, where precision is critical. Buyers should consider the initial tooling costs and longer lead times, but the high repeatability and accuracy make it a worthwhile investment for complex projects.

How Does Mandrel Bending Maintain Tube Integrity?

Mandrel bending involves inserting a mandrel into the tube during the bending process to prevent deformation, making it ideal for thin-walled tubes used in medical devices and architectural applications. This method ensures that the integrity of the tube is maintained, allowing for tighter bends without compromising strength. While it can be more expensive due to the need for specialized tooling, the benefits in quality and performance are significant for critical applications.

What Are the Advantages of Compression Bending for Large Applications?

Compression bending is a straightforward technique that works by compressing the tube to create bends, making it particularly effective for larger diameters commonly used in construction and heavy machinery. Its cost-effectiveness and simplicity in tooling make it a popular choice for high-volume production runs. However, buyers should note that this method is limited in precision and is not suitable for smaller diameters or intricate designs.

Why Choose Three-Dimensional Bending for Custom Fabrication?

Three-dimensional bending allows for the creation of complex geometries by enabling bends in multiple planes. This versatility makes it an excellent choice for custom fabrication projects, including unique art installations. Although it offers the advantage of reducing the need for welding, the complexity of setup can lead to longer lead times. Buyers should weigh the need for custom designs against the potential delays in production.

How Does Laser Tube Cutting Enhance Bending Services?

Combining laser cutting with bending processes allows for intricate designs that include cut features, significantly enhancing flexibility in manufacturing. This method is increasingly used in the automotive and manufacturing sectors, where speed and design complexity are paramount. However, the initial investment in laser technology can be high, so businesses should consider their production volume and design needs when opting for this advanced service.

Key Industrial Applications of cnc pipe bending service

| Industry/Sector | Specific Application of CNC Pipe Bending Service | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Custom structural components for buildings and frameworks | Enhanced structural integrity and design flexibility | Material specifications, delivery timelines, and design compatibility |

| Oil & Gas | Piping systems for refineries and offshore platforms | Increased efficiency and safety in fluid transport | Corrosion resistance, pressure ratings, and compliance standards |

| HVAC | Ductwork and piping for heating, ventilation, and air conditioning systems | Improved energy efficiency and reduced installation costs | Custom dimensions, material selection, and thermal performance |

| Automotive | Exhaust and fuel systems in vehicles | Improved performance, weight reduction, and compliance with emissions standards | Precision tolerances, material strength, and weight considerations |

| Art & Design | Sculptural and artistic metal installations | Unique, customized designs that enhance aesthetic value | Flexibility in design, material options, and production scalability |

How is CNC Pipe Bending Service Used in Construction & Architecture?

In the construction and architecture sectors, CNC pipe bending services are essential for producing custom structural components such as handrails, frames, and supports. This service allows architects and engineers to create designs that are both aesthetically pleasing and structurally sound. The key requirement for buyers in this sector is to ensure that the materials used can withstand various environmental conditions, especially in regions with extreme weather. Additionally, timely delivery is crucial to keep construction schedules on track.

What Role Does CNC Pipe Bending Play in Oil & Gas Applications?

CNC pipe bending is vital in the oil and gas industry for fabricating piping systems that transport fluids in refineries and offshore platforms. The service ensures that pipes can be bent to fit complex layouts without compromising structural integrity. Buyers must consider factors such as corrosion resistance and pressure ratings, particularly for offshore applications where safety and durability are paramount. Compliance with international standards is also critical for sourcing decisions.

How is CNC Pipe Bending Beneficial for HVAC Systems?

In HVAC applications, CNC pipe bending is used to create ductwork and piping systems that optimize airflow and energy efficiency. This process allows for seamless transitions in duct design, minimizing air resistance and improving system performance. Buyers should focus on custom dimensions and material choices that enhance thermal performance. Additionally, sourcing partners should be evaluated based on their ability to provide quick turnaround times to meet project deadlines.

Why is CNC Pipe Bending Important in the Automotive Industry?

The automotive industry utilizes CNC pipe bending services to manufacture components such as exhaust and fuel systems that require precise shapes and tolerances. This ensures that vehicles meet performance and emissions standards while also reducing weight for better fuel efficiency. Buyers must consider the strength of materials and the precision of bends, as even minor discrepancies can lead to significant performance issues. Sourcing from suppliers with a strong track record in automotive applications is advisable.

How Does CNC Pipe Bending Contribute to Artistic Designs?

In the realm of art and design, CNC pipe bending allows for the creation of unique sculptural installations and artistic pieces. Artists and designers can leverage this technology to achieve intricate shapes and forms that would be challenging with traditional methods. The flexibility in design and material options is crucial for creative projects, and buyers should prioritize suppliers who can accommodate custom requests and scale production as needed.

3 Common User Pain Points for ‘cnc pipe bending service’ & Their Solutions

Scenario 1: Delays in Project Timelines Due to Bending Specifications

The Problem:

A common challenge faced by B2B buyers in the CNC pipe bending sector is the misalignment between project timelines and the bending specifications provided. When working on large-scale projects, such as construction or manufacturing, any delays can cascade, affecting overall project deadlines. Buyers often find that the CNC bending service provider cannot meet the specific geometric requirements of their designs within the needed timeframe. This can lead to costly delays, missed deadlines, and strained client relationships.

The Solution:

To mitigate the risk of timeline delays, B2B buyers should conduct thorough due diligence before selecting a CNC pipe bending service provider. This includes requesting detailed timelines based on their specific bending needs and ensuring the provider has the capability to handle custom specifications. Engaging in open communication about project requirements upfront can help set realistic expectations. Additionally, buyers should consider suppliers that offer rapid prototyping services. By creating prototypes early in the project, buyers can validate designs and make adjustments before full production begins, thus maintaining project momentum.

Scenario 2: Inconsistent Quality of Bended Pipes Leading to Rework

The Problem:

Inconsistent quality in the finished bent pipes can pose significant issues for B2B buyers, especially in industries like aerospace, automotive, and construction, where precision is crucial. Buyers may receive products that do not meet the required tolerances or are structurally unsound, leading to potential safety hazards and the need for costly rework. This inconsistency can stem from inadequate quality control measures or the use of outdated equipment by the service provider.

The Solution:

To ensure consistent quality, B2B buyers should prioritize working with CNC pipe bending services that emphasize rigorous quality control protocols. This includes asking about the provider’s certification standards, such as ISO certifications, which can indicate a commitment to quality management. Buyers should also request samples of previous work and inquire about the specific bending processes used, such as mandrel bending, which can improve the integrity of the bends. Establishing a partnership with a supplier that provides transparency in their processes and allows for regular quality audits can further enhance product reliability.

Scenario 3: Limited Material Options Affecting Design Flexibility

The Problem:

B2B buyers often encounter limitations in the range of materials available for CNC pipe bending services, which can restrict their design options and lead to compromises in product functionality. For instance, if a buyer requires bends in high-strength alloys or specific stainless steel grades but the provider only offers a limited selection, it can hinder the innovation and effectiveness of the final product. This is particularly critical for industries that demand high performance and durability.

The Solution:

To overcome this challenge, buyers should actively seek CNC pipe bending service providers that offer a broad spectrum of material options. Before initiating a project, it is advisable to compile a list of required materials and discuss these with potential suppliers. This not only ensures that the provider can accommodate specific needs but also opens the door to new design possibilities. Additionally, buyers can explore partnerships with suppliers that offer advanced materials technology, such as alloy customization or composite materials, to enhance the durability and functionality of their products. Engaging in collaborative discussions about material properties and performance expectations can lead to more innovative solutions tailored to the buyer’s specific applications.

Strategic Material Selection Guide for cnc pipe bending service

What Are the Key Properties of Common Materials Used in CNC Pipe Bending Services?

When selecting materials for CNC pipe bending services, it is crucial to consider their properties, advantages, disadvantages, and how they impact specific applications. This analysis focuses on four common materials: stainless steel, aluminum, carbon steel, and alloy steel.

How Does Stainless Steel Perform in CNC Pipe Bending Applications?

Key Properties: Stainless steel, particularly grades 304 and 316, is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. Grade 316 offers superior resistance to chlorides, making it ideal for marine and chemical applications.

Pros & Cons: The durability and aesthetic appeal of stainless steel make it a popular choice for applications in industries such as food processing, pharmaceuticals, and architecture. However, it is more expensive than other materials and can be challenging to bend due to its toughness, requiring specialized tooling and techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it suitable for piping in chemical processing and food industries.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as ASTM A312 or EN 10217. The higher cost may be justified in applications requiring long-term durability.

What Are the Benefits of Using Aluminum in CNC Pipe Bending?

Key Properties: Aluminum, especially the 6061 alloy, is lightweight, corrosion-resistant, and has good mechanical properties. It is easily machinable and can be anodized for additional surface protection.

Pros & Cons: The low weight of aluminum makes it ideal for applications where weight savings are critical, such as in the aerospace and automotive industries. However, it has lower tensile strength compared to steel and may not be suitable for high-pressure applications.

Impact on Application: Aluminum is often used in structural applications, HVAC systems, and transportation, where reduced weight can enhance efficiency and performance.

Considerations for International Buyers: Buyers should be aware of the common standards, such as ASTM B221, and consider the availability of aluminum in their region. Its cost is generally moderate, making it a favorable option for many projects.

Why Choose Carbon Steel for CNC Pipe Bending Services?

Key Properties: Carbon steel is known for its high strength and durability. It is often used in structural applications and can be treated to enhance its properties, such as through galvanization for corrosion resistance.

Pros & Cons: Carbon steel is cost-effective and readily available, making it a popular choice for a variety of applications. However, it is prone to rust and corrosion if not properly treated, which may limit its use in certain environments.

Impact on Application: Carbon steel is commonly used in construction, oil and gas pipelines, and heavy machinery. It is suitable for applications that do not involve corrosive media.

Considerations for International Buyers: Buyers should consider compliance with standards such as ASTM A53 and ensure that the material is treated appropriately for their specific environmental conditions. Its low cost makes it an attractive option for large-scale projects.

What Advantages Does Alloy Steel Offer in CNC Pipe Bending?

Key Properties: Alloy steel, particularly 4130, is known for its high strength-to-weight ratio and toughness. It is often used in applications requiring high performance under stress.

Pros & Cons: Alloy steel is highly durable and can withstand extreme conditions, making it ideal for aerospace and automotive applications. However, it can be more expensive than standard carbon steel and may require specialized bending techniques.

Impact on Application: Alloy steel is commonly used in high-stress applications, including racing cars and aerospace structures, where performance and safety are paramount.

Considerations for International Buyers: Compliance with international standards such as ASTM A519 is essential for buyers in regions like Africa and South America, where quality assurance is critical. The higher cost may be justified by the performance benefits in demanding applications.

Summary Table of Material Selection for CNC Pipe Bending Services

| Material | Typical Use Case for cnc pipe bending service | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals, architecture | Excellent corrosion resistance | Higher cost and bending complexity | High |

| Aluminum | Aerospace, automotive, HVAC systems | Lightweight and corrosion-resistant | Lower tensile strength compared to steel | Medium |

| Carbon Steel | Construction, oil and gas pipelines | Cost-effective and strong | Prone to rust without treatment | Low |

| Alloy Steel | Aerospace, racing cars | High strength-to-weight ratio | More expensive and requires special techniques | High |

This material selection guide equips international B2B buyers with the necessary insights to make informed decisions regarding CNC pipe bending services, ensuring they choose the right material for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc pipe bending service

What Are the Key Stages in the CNC Pipe Bending Manufacturing Process?

CNC pipe bending is a precise and sophisticated manufacturing process that transforms raw materials into complex geometries required by various industries. The process typically involves several critical stages:

-

Material Preparation: The initial step involves selecting the appropriate pipe material, which can range from stainless steel and aluminum to various alloys, depending on the specific application. The raw material is cut to the required lengths and inspected for any defects before it proceeds to the bending phase. This stage is crucial, as the quality of the raw material directly impacts the final product’s integrity.

-

Forming: During this stage, the prepared pipes are loaded into a CNC bending machine. The machine uses programmed instructions to bend the pipe according to the desired specifications. Techniques such as rotary draw bending and mandrel bending are commonly employed. Rotary draw bending allows for both two-dimensional and three-dimensional bends, while mandrel bending is used to maintain the pipe’s internal diameter, preventing deformation during the bending process.

-

Assembly: After bending, the pipes may undergo an assembly process where multiple components are joined together. This is particularly relevant in applications requiring complex frameworks, such as in the construction or automotive industries. Techniques such as welding or mechanical fastening may be used, depending on the design requirements.

-

Finishing: The final stage involves surface treatment, which may include processes like polishing, coating, or painting to enhance the product’s durability and aesthetic appeal. This stage is essential for ensuring that the final product meets the environmental and operational demands of its intended application.

How Is Quality Assurance Implemented in CNC Pipe Bending Services?

Quality assurance (QA) is a fundamental component of the CNC pipe bending process, ensuring that products meet international standards and customer expectations. Here’s a breakdown of the QA measures typically implemented:

-

Adherence to International Standards: Many manufacturers comply with ISO 9001, which outlines criteria for a quality management system, ensuring consistent quality in products and services. In addition, industry-specific standards such as CE marking for safety in the European market and API standards for the oil and gas sector are critical for B2B buyers. Understanding these standards helps buyers assess whether a supplier can meet their specific requirements.

-

Quality Control Checkpoints: The QA process is often divided into several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During manufacturing, real-time inspections are conducted to monitor the bending process and detect any deviations from the specified tolerances.

– Final Quality Control (FQC): After the completion of the bending and finishing stages, a thorough inspection is carried out to ensure that the final product adheres to all specifications and quality standards. -

Common Testing Methods: Various testing methods are employed to verify the quality of the finished products. These may include:

– Dimensional Inspection: Using calipers and gauges to ensure that the dimensions of the bent pipes are within specified tolerances.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or dye penetrant testing are used to detect internal flaws without damaging the product.

– Visual Inspection: A simple yet effective method to check for surface imperfections or defects.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some effective methods to ensure quality:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational standards of potential suppliers. This first-hand observation can provide insights into the reliability and consistency of the supplier’s output.

-

Quality Assurance Reports: Requesting detailed QA reports can help buyers understand the supplier’s quality management practices and any certifications they hold. These reports often include data from IQC, IPQC, and FQC stages, along with details of any non-conformities and corrective actions taken.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can add an additional layer of assurance. These agencies can perform unbiased inspections and provide certification that the products meet specified international standards.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, especially in regions like Africa and South America, several nuances should be considered:

-

Understanding Regional Standards: Different regions may have varying standards and regulations that affect quality assurance processes. Buyers should familiarize themselves with local industry standards, as well as international standards, to ensure compliance.

-

Communication Barriers: Language differences can lead to misunderstandings regarding specifications and quality expectations. Clear communication and the use of detailed specifications can help mitigate these risks.

-

Cultural Differences: Different cultural approaches to business can affect the emphasis placed on quality control. Buyers should be aware of these differences and ensure that their expectations regarding quality are clearly articulated and understood.

By considering these factors, B2B buyers can navigate the complexities of international sourcing for CNC pipe bending services, ensuring that they partner with suppliers who meet their quality expectations and production needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc pipe bending service’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure CNC pipe bending services. By following these steps, you can ensure that you select a reliable supplier who meets your specific technical needs while adhering to quality and delivery standards.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your project, including material type, diameter, wall thickness, and bend radius. This initial step is crucial to communicate your needs effectively to potential suppliers. Providing detailed specifications helps suppliers assess their capabilities and ensures they can meet your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in CNC pipe bending services. Look for companies that have a proven track record in your industry, as they are more likely to understand your unique requirements. Utilize online directories, trade associations, and industry-specific platforms to compile a list of potential suppliers.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s essential to vet suppliers thoroughly. Request detailed information about their machinery, technology, and bending techniques. Pay special attention to their ability to handle multiple bends, tight tolerances, and various materials, as these factors can significantly impact the quality of the final product.

- Key Considerations:

- Types of bending processes offered (e.g., rotary draw, mandrel bending).

- Maximum and minimum sizes and tolerances they can accommodate.

Step 4: Verify Quality Control Measures

Quality assurance is paramount in CNC pipe bending. Inquire about the supplier’s quality control processes, including any certifications they hold (e.g., ISO 9001). A robust quality control system ensures that your products will meet the required standards, minimizing the risk of defects and rework.

Step 5: Request Samples and Case Studies

Ask potential suppliers for samples of their previous work or relevant case studies. This will allow you to assess their workmanship and the quality of their finished products. Observing their capabilities in real-world applications provides insight into how well they can meet your project’s demands.

Step 6: Discuss Lead Times and Pricing

Once you have shortlisted suppliers, initiate discussions about lead times and pricing. Understanding their production timelines is crucial for your project scheduling. Additionally, request detailed quotes that break down costs, including any potential additional fees for custom tooling or expedited services.

Step 7: Establish Communication Protocols

Effective communication is vital throughout the sourcing process. Determine how you will interact with the supplier—whether through regular updates, project management tools, or direct contact. Clear communication channels help ensure that any issues or changes are addressed promptly, contributing to a smoother procurement process.

By following this checklist, you can confidently navigate the sourcing of CNC pipe bending services, ensuring that you select a supplier that aligns with your technical requirements and business goals.

Comprehensive Cost and Pricing Analysis for cnc pipe bending service Sourcing

What Are the Key Cost Components in CNC Pipe Bending Services?

Understanding the cost structure of CNC pipe bending services is crucial for B2B buyers aiming to optimize their sourcing strategies. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials used in CNC pipe bending include stainless steel, aluminum, and alloy steel. Prices vary based on material quality, availability, and market fluctuations.

-

Labor: Skilled labor is essential for precision machining. Labor costs can vary by region, with countries like Germany often having higher labor rates than those in Africa or South America. The complexity of the bending process also influences labor time and costs.

-

Manufacturing Overhead: This includes costs associated with running the facility, such as utilities, equipment maintenance, and administrative expenses. Efficient operations can help keep overhead costs low, which can be a point of negotiation for buyers.

-

Tooling: Custom tooling can be a significant upfront cost, particularly for unique or complex bending projects. Suppliers may charge for the design and fabrication of specialized tools, which can be amortized over larger production runs.

-

Quality Control (QC): Ensuring the integrity and precision of bent pipes is critical. QC processes add to the overall cost but are essential for high-quality outputs, especially in industries like aerospace and automotive, where specifications are stringent.

-

Logistics: Shipping costs depend on the distance, weight, and dimensions of the products. International buyers should consider Incoterms, which define the responsibilities of buyers and sellers in shipping arrangements.

-

Margin: Suppliers will typically add a profit margin on top of their costs. Understanding market rates can help buyers gauge whether a quote is competitive.

How Do Price Influencers Affect CNC Pipe Bending Services?

Several factors influence the pricing of CNC pipe bending services:

-

Volume/MOQ: Higher order volumes often lead to lower unit prices due to economies of scale. Establishing a minimum order quantity (MOQ) can also affect pricing and negotiation leverage.

-

Specifications/Customization: Unique designs or stringent specifications may incur additional costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Materials: The choice between standard and premium materials can significantly impact costs. For example, stainless steel 304 is generally less expensive than 316 due to its lower corrosion resistance.

-

Quality and Certifications: Suppliers that offer industry certifications (such as ISO) may charge higher rates due to the assurance of quality. Buyers should weigh the benefits of certified suppliers against their budget constraints.

-

Supplier Factors: Supplier reputation, experience, and location can affect pricing. Established suppliers with a proven track record may charge a premium for their services.

-

Incoterms: Choosing the right Incoterms can influence total costs, including shipping and insurance. Buyers must be aware of their responsibilities in the shipping process to avoid unexpected charges.

What Are Some Buyer Tips for Cost-Efficiency in CNC Pipe Bending Services?

To enhance cost-efficiency when sourcing CNC pipe bending services, consider the following strategies:

-

Negotiate Wisely: Engage suppliers in discussions about pricing, especially for larger orders. Building a good relationship can lead to better terms and pricing over time.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Assess factors like quality, delivery times, and potential rework costs to determine the true cost of a service.

-

Understand Pricing Nuances for International Purchases: Different regions may have varying pricing structures due to local economic conditions, labor costs, and material availability. Conduct market research to benchmark prices across suppliers in different regions.

-

Consider Long-Term Partnerships: Establishing a long-term relationship with a reliable supplier can lead to discounts and preferential treatment in terms of pricing and service.

-

Request Detailed Quotes: Ensure that quotes break down all costs, including materials, labor, and logistics. This transparency will aid in comparing offers from different suppliers effectively.

Disclaimer on Indicative Prices

Prices for CNC pipe bending services can vary widely based on numerous factors, including market conditions, material prices, and supplier capabilities. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing cnc pipe bending service With Other Solutions

When evaluating CNC pipe bending services, it’s essential to consider alternative solutions that can fulfill similar requirements. Different methods may offer unique advantages depending on your project specifications, budget constraints, and desired outcomes. Below, we compare CNC pipe bending services with two viable alternatives: manual pipe bending and tube laser cutting.

| Comparison Aspect | CNC Pipe Bending Service | Manual Pipe Bending | Tube Laser Cutting |

|---|---|---|---|

| Performance | High precision with tight tolerances and complex geometries. | Moderate precision; suitable for simpler bends. | High precision for cutting shapes but not for bending. |

| Cost | Higher initial investment; cost-effective for large runs. | Lower initial costs; labor-intensive and less efficient for large volumes. | Moderate to high; ideal for intricate designs but may require additional bending processes. |

| Ease of Implementation | Requires skilled operators and programming; setup time can be significant. | Simple tools needed; faster setup, but skill-dependent. | Requires advanced machinery and programming; high setup time for complex designs. |

| Maintenance | Regular calibration and maintenance of CNC machines needed. | Minimal maintenance; tools can be easily replaced. | High maintenance on laser equipment; requires specialized knowledge. |

| Best Use Case | Large-scale production with complex designs and high precision needs. | One-off or low-volume projects where speed is prioritized. | Projects requiring intricate cut designs, where bending is a secondary consideration. |

Understanding Manual Pipe Bending as an Alternative

Manual pipe bending utilizes hand-operated tools to achieve bends in pipes. This method is often employed for simpler projects or one-off jobs where the investment in CNC machinery isn’t justified. Pros of manual bending include lower costs and quick setup, making it ideal for smaller operations or rapid prototyping. However, the precision is typically less than that of CNC methods, and the quality may vary based on the operator’s skill level.

Exploring Tube Laser Cutting as a Solution

Tube laser cutting is a technology that can create intricate shapes by cutting tubes rather than bending them. This method is particularly useful for designs that require complex geometries and features like holes or slots. The advantages of tube laser cutting include exceptional accuracy and the ability to produce highly detailed components. Nevertheless, it doesn’t replace bending capabilities, so additional processes may be necessary to achieve the required shapes, which can increase overall production time and costs.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between CNC pipe bending services and alternative methods, consider your specific project requirements, including the complexity of designs, production volume, and budget constraints. CNC pipe bending is optimal for high-volume projects that demand precision, while manual bending suits smaller, simpler tasks. Tube laser cutting can complement bending processes for projects requiring detailed cuts. Evaluating these aspects will help you make an informed decision that aligns with your operational goals and resource availability.

Essential Technical Properties and Trade Terminology for cnc pipe bending service

What Are the Key Technical Properties for CNC Pipe Bending Services?

Understanding the essential technical properties involved in CNC pipe bending services is crucial for B2B buyers aiming to procure high-quality, precision-engineered components. Here are several critical specifications:

-

Material Grade

The grade of material used in pipe bending directly affects the performance, durability, and cost of the final product. Common materials include stainless steel (e.g., 304 and 316), aluminum (e.g., 6061), and various alloy steels. Each material has unique properties such as corrosion resistance, weight, and strength, which are essential for applications in industries like construction, automotive, and aerospace. -

Bend Radius

The bend radius is the curvature of the pipe at the bend and is crucial for ensuring structural integrity. A smaller bend radius can lead to material stress and potential failure, while a larger radius can affect the design and fit of the assembly. Understanding the required bend radius helps in selecting the appropriate bending method and machine settings. -

Tolerances

Tolerances refer to the allowable deviation from specified dimensions. In CNC pipe bending, tight tolerances (e.g., +/- 0.010 inches for linear dimensions) ensure that parts fit together accurately in assemblies, reducing the need for additional machining or adjustments. For B2B buyers, knowing the tolerance levels is vital for quality assurance and compatibility with existing components. -

Wall Thickness

The thickness of the pipe wall is a critical factor influencing strength and durability. Standard wall thicknesses range from 0.035 inches to 0.188 inches, depending on the material and application. Buyers must specify wall thickness to ensure that the parts can withstand the intended loads and environmental conditions. -

Production Volume

Understanding the scale of production—whether low-volume custom prototypes or high-volume production runs—is essential for cost estimation and lead time. Different processes may be more suitable for varying volumes, affecting pricing and delivery schedules. This knowledge allows buyers to plan their projects effectively.

Which Trade Terms Are Essential for Understanding CNC Pipe Bending Services?

Familiarity with industry jargon can enhance communication and streamline the procurement process. Here are key trade terms relevant to CNC pipe bending services:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source components that meet specific design and performance criteria. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units that can be ordered from a supplier. This term is crucial for buyers, as it affects budgeting and inventory management. Knowing the MOQ helps in planning purchases and avoiding excess stock. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing for specific products or services. It typically includes detailed specifications, quantities, and delivery requirements. For B2B buyers, crafting a clear RFQ can lead to more accurate quotes and faster responses from suppliers. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is vital for B2B buyers engaging in cross-border trade. -

BOM (Bill of Materials)

A BOM is a comprehensive list of raw materials, components, and assemblies required to manufacture a product. It is essential for project planning and inventory control, ensuring that all necessary parts are available for production. -

CNC (Computer Numerical Control)

CNC refers to the automation of machine tools through computer programming. In the context of pipe bending, CNC technology ensures high precision and repeatability, which are critical for meeting the stringent requirements of various industries.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing CNC pipe bending services, ensuring that their projects are successful and cost-effective.

Navigating Market Dynamics and Sourcing Trends in the cnc pipe bending service Sector

What Are the Current Market Dynamics and Key Trends in CNC Pipe Bending Services?

The CNC pipe bending service sector is experiencing significant growth driven by several global factors. One major driver is the increasing demand for customized solutions across diverse industries, including construction, automotive, aerospace, and energy. As businesses strive for efficiency and precision, the adoption of CNC technology has become essential, enabling manufacturers to create complex shapes with minimal waste. Emerging B2B technologies, such as advanced CAD software and automated manufacturing processes, are streamlining operations, allowing for faster turnaround times and enhanced product quality.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Vietnam) are particularly focused on sourcing partners that can provide high-quality, cost-effective solutions. A key trend in sourcing is the shift toward online platforms that offer instant quotes and comprehensive service options, facilitating easier comparisons and decision-making. Buyers are increasingly looking for suppliers that can handle both low and high-volume production runs, further emphasizing the need for flexibility in service offerings.

Additionally, sustainability is becoming a critical factor in supplier selection. Companies are seeking partners who demonstrate a commitment to environmentally friendly practices, which can influence purchasing decisions and long-term partnerships.

How Is Sustainability Impacting the Sourcing of CNC Pipe Bending Services?

The environmental impact of manufacturing processes is under scrutiny, pushing businesses to prioritize sustainability in their sourcing strategies. In the CNC pipe bending sector, this translates into a demand for ethical supply chains and environmentally friendly materials. Buyers are increasingly looking for suppliers who employ sustainable practices, such as waste reduction, recycling, and energy-efficient operations.

Moreover, certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are gaining importance. Suppliers who can provide evidence of these certifications not only enhance their marketability but also appeal to environmentally conscious buyers. The use of ‘green’ materials, such as recycled metals or those with lower carbon footprints, is becoming a differentiator for suppliers aiming to stand out in a competitive market.

As businesses worldwide recognize the importance of corporate social responsibility, the expectation for transparent and ethical sourcing will only grow. Buyers must consider these factors when selecting their CNC pipe bending service providers, as they can significantly impact brand reputation and compliance with international regulations.

How Has the CNC Pipe Bending Service Sector Evolved Over Time?

The evolution of CNC pipe bending services can be traced back to the industrial revolution when manual bending techniques dominated the landscape. The introduction of CNC technology in the late 20th century revolutionized the industry, allowing for greater precision and the ability to produce complex geometries that were previously unattainable. This transition marked a significant shift from traditional methods to automated systems that enhance productivity and reduce labor costs.

As industries continue to evolve, so do the capabilities of CNC pipe bending services. The integration of advanced materials and the development of sophisticated bending techniques, such as mandrel bending, further highlight the sector’s growth. Today’s CNC pipe bending services are characterized by their ability to meet the diverse needs of global markets, offering tailored solutions that align with the rapid advancements in technology and changing consumer demands.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc pipe bending service

-

How do I ensure the quality of CNC pipe bending services?

To guarantee the quality of CNC pipe bending services, start by assessing the supplier’s certifications and quality assurance processes. Look for ISO certifications that demonstrate adherence to international standards. Request samples or case studies showcasing their previous work to evaluate their capabilities. Additionally, inquire about their equipment and technology used in the bending process, as well as their quality control measures, such as inspections and testing methods. Establishing a strong communication channel for ongoing updates and feedback can also enhance product quality. -

What are the most important factors to consider when choosing a CNC pipe bending supplier?

When selecting a CNC pipe bending supplier, consider their experience and expertise in your specific industry, as different sectors may have unique requirements. Evaluate their production capabilities, including the range of materials they can work with and their bending technology. Assess their lead times and ability to meet deadlines. It’s also crucial to examine customer reviews and references to gauge their reputation. Finally, consider their flexibility in handling custom designs and their willingness to accommodate changes during the production process. -

What types of materials can be used for CNC pipe bending?

CNC pipe bending can accommodate a variety of materials, including stainless steel, aluminum, carbon steel, and alloy steel. Each material has distinct properties that may suit specific applications; for instance, stainless steel is preferred for corrosion resistance, while aluminum is favored for its lightweight characteristics. It’s essential to communicate your material requirements to the supplier, as certain materials may require specialized equipment or techniques to achieve the desired bends and tolerances. -

What is the minimum order quantity (MOQ) for CNC pipe bending services?

Minimum order quantities for CNC pipe bending services can vary significantly among suppliers. Some may offer low MOQs for custom projects, while others might set higher limits for economies of scale. It’s advisable to discuss your project requirements with potential suppliers to understand their MOQ policies. If your project involves low volume needs, ask if they can accommodate your request or if they offer prototyping services to test your design before committing to larger quantities. -

How can I effectively communicate my design requirements for CNC pipe bending?

To ensure your design requirements are clearly understood, provide detailed specifications, including dimensions, tolerances, and material types. Use technical drawings or CAD files to convey complex geometries accurately. Discuss your design with the supplier’s engineering team to address any potential manufacturing challenges. It’s also beneficial to outline any specific finishes or treatments required post-bending. Regular communication throughout the design and production phases can help avoid misunderstandings and ensure the final product meets your expectations. -

What payment terms should I expect when sourcing CNC pipe bending services?

Payment terms for CNC pipe bending services can vary based on the supplier and the size of the order. Common arrangements include upfront deposits, progress payments, or payment upon delivery. For international transactions, consider factors such as currency exchange rates and potential tariffs. It’s advisable to negotiate terms that align with your cash flow needs while ensuring the supplier’s financial security. Always review the payment terms in the contract carefully and clarify any concerns before proceeding. -

What logistics considerations should I keep in mind when sourcing CNC pipe bending services internationally?

When sourcing CNC pipe bending services internationally, consider shipping costs, lead times, and customs regulations. Understanding the supplier’s location can impact both logistics and delivery schedules. Ensure the supplier has experience handling international shipping and is familiar with necessary documentation. Discuss options for tracking shipments and handling any potential delays. Additionally, consider the implications of import duties and taxes on your overall project budget. -

How can I verify the reliability of a CNC pipe bending supplier?

To verify a CNC pipe bending supplier’s reliability, start by checking their business credentials, including certifications and industry affiliations. Request references or case studies from previous clients, particularly those in your industry. Look for reviews and testimonials online to gain insights into their performance. Conducting a site visit can also provide a firsthand look at their operations. Finally, assess their communication responsiveness and willingness to address your inquiries, as these factors often reflect their reliability and customer service standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc pipe bending service

In the competitive landscape of CNC pipe bending services, strategic sourcing emerges as a critical driver for success. By aligning with experienced providers who offer a blend of precision, customization, and timely delivery, international B2B buyers can enhance their operational efficiency and product quality. The ability to access advanced technologies, such as CNC bending and custom tooling, allows companies to meet unique project requirements while optimizing costs.

For businesses in Africa, South America, the Middle East, and Europe, the emphasis on building strong partnerships with reputable service providers cannot be overstated. These collaborations not only ensure superior product outcomes but also facilitate innovation and adaptability in a rapidly changing market.

As we look ahead, the demand for high-quality, tailored pipe bending solutions is expected to grow, driven by advancements in manufacturing technologies and the increasing complexity of industrial applications. B2B buyers are encouraged to explore these opportunities, leveraging strategic sourcing to gain a competitive edge and drive long-term success. Engage with leading service providers today to unlock the potential of CNC pipe bending services for your projects.