Top 8 Cnc Milling Services Near Me Manufacturers & Suppliers List

1. Maine Machine Shop – CNC Milling & Metal Fabrication

Domain: mainemachineshop.com

Registered: 2012 (13 years)

Introduction: C&C Machine Shop, located in Ellsworth, Maine, offers a range of services including CNC Milling, Metal Fabrication, Welding, Automotive Machine Shop services, and Machine Part Fabrication. Established in 1987, the shop operates in a 12,000 square-foot facility and specializes in general machining, automotive machining, complete engine rebuilding, and machine repairs. They serve various industries …

2. eMachineShop – CNC Milling Services

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: CNC Milling Services offered by eMachineShop include:

– Capability to produce parts of nearly any shape from various materials including soft metals (aluminum), harder metals (steel), and plastics (acetal).

– Cost-effective service for single parts, batch prototypes, or full production orders.

– Over 50 materials available for selection.

– Free shipping within the USA.

– 100% quality guarantee.

– …

3. Lukens Quality Hardwoods – CNC Milling Services

Domain: lukensqualityhardwoods.com

Registered: 2008 (17 years)

Introduction: CNC Milling Services: High-performance CNC machine for carving or slab leveling, using a Laguna industrial CNC router. Capabilities include 2D and 3D engraving/carving, custom signs. Specifications: Up to 60″ wide, CNC 51″ Drum Sander, 24″ Plainer. Location: Knightstown, Indiana, serving the Midwest.

4. Protolabs – CNC Milling Service

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: CNC Milling Service offers custom milled parts for rapid prototyping and production. Key features include:

– Fast turnaround: Parts can be produced in as fast as 1 day.

– Manufacturing processes: Utilizes 3-axis milling and 5-axis indexed milling.

– Material options: More than 30 engineering-grade plastics and metals available.

– Competitive pricing: More cost-effective at higher quantities.

– Add…

5. Green Wood Milling – CNC Woodworking Services

Domain: greenwoodmilling.com

Registered: 2010 (15 years)

Introduction: CNC Woodworking Services in San Antonio offered by Green Wood Milling Co. include precision CNC cutting, engraving, and routing of wood and other materials. Key CNC capabilities include: 1. Laguna Smart Shop II CNC – 3-axis machine with a 4’ x 8’ cut area for engraving, routing, and flattening. 2. Rotary CNC – specialized for turning spindles up to 42 inches long and 10 inches in diameter for cust…

6. San Antonio CNC Milling – Affordable 7075-T6 Aluminum Services

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: CNC milling service for a small part; material: 7075-T6 Aluminum; dimensions: 33.14 mm x 3.5 mm; location: San Antonio area; willing to pay for service; looking for affordable options compared to big CNC shop prices; flexibility in design changes for milling.

7. JBC Machine – Custom CNC Machining Services

Domain: jbcmachine.com

Registered: 2010 (15 years)

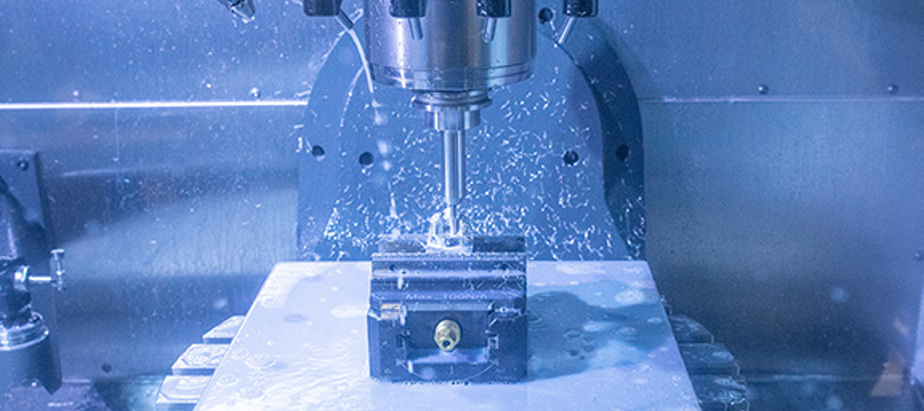

Introduction: Custom CNC Machining Services including 3D Milling, CNC Boring, CNC Drilling, Threading, CNC Turning, and Metal Machining. Materials worked with: Stainless Steel, Aluminum, Bronze, CNC Plastic. Services offered: Prototype Machining, Reverse Engineering of OEM Parts, and Split Anvils. Industries served: Aerospace, Paper Manufacturing, Food Packaging and Processing.

8. Stumptown CNC – Precision CNC Routing & Milling Services

Domain: stumptowncnc.com

Registered: 2016 (9 years)

Introduction: Stumptown CNC offers high-speed precision CNC routing and milling services using a state-of-the-art Thermwood 3-axis CNC router with a 120″ x 60″ cutting area, high flow vacuum table, and a 7-position tool holder. They can fabricate richly detailed parts with tolerances of ± .001″. The materials they most often cut include plywoods, laminated plywoods, hardwoods, softwoods, and MDF.

Introduction: Navigating the Global Market for cnc milling services near me

In today’s competitive landscape, sourcing reliable CNC milling services near me poses a significant challenge for international B2B buyers, particularly those operating in dynamic markets such as Africa, South America, the Middle East, and Europe. With industries ranging from automotive to aerospace and medical, the demand for precision-engineered parts has never been higher. This guide serves as an essential resource, addressing the complexities of finding and selecting the right CNC milling suppliers.

Throughout this comprehensive guide, we will explore various types of CNC milling services, their applications across different sectors, and the critical factors to consider when vetting suppliers. We will also delve into cost considerations, quality certifications, and the importance of technological capabilities, including multi-axis milling and automated processes. By equipping you with actionable insights and practical advice, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Understanding the intricacies of CNC milling services is vital for fostering successful partnerships and ensuring product quality. As you navigate the global market, this guide will help you identify trustworthy suppliers, optimize your procurement processes, and ultimately enhance your competitive edge in your respective industry.

Understanding cnc milling services near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3-Axis CNC Milling | Standard milling with three axes for simple shapes | General manufacturing, prototyping | Pros: Cost-effective, versatile. Cons: Limited complexity compared to multi-axis. |

| 4-Axis CNC Milling | Adds a rotational axis for enhanced machining capabilities | Aerospace, automotive components | Pros: Greater precision, allows for complex geometries. Cons: Higher cost than 3-axis. |

| 5-Axis CNC Milling | Multi-directional machining for intricate designs | Medical devices, aerospace parts | Pros: Exceptional detail and accuracy. Cons: Requires specialized skill and investment. |

| High-Volume CNC Milling | Automated processes for large production runs | Mass production, automotive parts | Pros: Economical for large orders, consistent quality. Cons: Initial setup cost can be high. |

| Precision CNC Milling | Focus on tight tolerances and high-quality finishes | Medical, military, and aerospace industries | Pros: Meets stringent quality standards. Cons: Typically higher prices due to quality requirements. |

What Are the Characteristics of 3-Axis CNC Milling Services?

3-axis CNC milling is the most common type of milling service, where the cutting tool moves along three axes: X, Y, and Z. This setup is ideal for creating simple geometries and flat surfaces, making it suitable for general manufacturing and prototyping. Buyers should consider the cost-effectiveness and versatility of 3-axis milling, but be aware that its limitations in handling complex shapes may necessitate additional processes for intricate designs.

How Does 4-Axis CNC Milling Enhance Production Capabilities?

4-axis CNC milling introduces an additional rotational axis, allowing for more complex machining without needing to reposition the workpiece. This capability is particularly beneficial in industries such as aerospace and automotive, where precision and complexity are paramount. Buyers should evaluate the potential for improved accuracy and reduced setup times against the higher costs associated with 4-axis systems.

Why Choose 5-Axis CNC Milling for Complex Projects?

5-axis CNC milling offers unparalleled precision by allowing the cutting tool to move along five different axes simultaneously. This technology is essential for producing intricate designs found in medical devices and aerospace components. While the benefits include exceptional detail and efficiency, buyers must consider the specialized skills required for operation and the higher investment involved in acquiring such advanced machinery.

What Are the Advantages of High-Volume CNC Milling Services?

High-volume CNC milling is designed for automated production runs, making it ideal for businesses needing consistent and rapid output, such as automotive manufacturers. This method streamlines operations, significantly reducing per-unit costs. However, buyers should weigh the initial setup costs against the long-term savings and quality consistency that high-volume services can provide.

When Is Precision CNC Milling Necessary for Your Business?

Precision CNC milling focuses on achieving tight tolerances and high-quality finishes, making it indispensable in sectors like medical and military manufacturing. This service ensures that components meet stringent industry standards, which is critical for safety and functionality. Buyers should be prepared for higher costs associated with precision milling but can expect superior quality and reliability in their products, which is essential for critical applications.

Key Industrial Applications of cnc milling services near me

| Industry/Sector | Specific Application of cnc milling services near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of precision components for aircraft | Ensures safety and compliance with strict regulations | ISO certifications, material specifications, lead times |

| Automotive | Manufacturing engine components and assemblies | High-volume production with tight tolerances | Scalability, cost efficiency, quality assurance |

| Medical Devices | Creation of intricate parts for surgical instruments | Critical for patient safety and device reliability | Regulatory compliance, material biocompatibility, precision |

| Oil and Gas | Fabrication of components for drilling equipment | Enhances operational efficiency and reduces downtime | Material durability, environmental considerations |

| Renewable Energy | Production of components for solar panels | Supports sustainable energy solutions and innovation | Design specifications, scalability, and cost control |

How Are CNC Milling Services Used in Aerospace Applications?

CNC milling services are crucial in the aerospace industry for producing components that meet stringent safety and performance standards. This sector requires parts like brackets, housings, and structural components that must adhere to tight tolerances and weight specifications. International buyers, particularly from regions like Europe and the Middle East, should prioritize suppliers with ISO certifications and experience in aerospace manufacturing to ensure compliance with industry regulations and quality assurance.

What Role Does CNC Milling Play in Automotive Manufacturing?

In the automotive sector, CNC milling is employed to manufacture complex engine components and assemblies, such as pistons, cylinder heads, and transmission parts. This application allows for high-volume production while maintaining precision, essential for performance and safety. Buyers from South America and Africa should consider suppliers capable of scaling production efficiently and ensuring consistent quality, as this directly impacts vehicle reliability and cost-effectiveness.

Why Are CNC Milling Services Essential for Medical Device Manufacturing?

CNC milling services play a pivotal role in the medical device industry by producing intricate parts for surgical instruments and devices. The precision required in this sector is paramount, as even minor defects can affect patient safety. International buyers, particularly in regions with stringent regulatory environments like Germany, must ensure that their suppliers can meet regulatory compliance and use biocompatible materials to guarantee the safety and efficacy of medical devices.

How Do CNC Milling Services Benefit the Oil and Gas Industry?

In the oil and gas sector, CNC milling is utilized to fabricate components for drilling equipment, such as valves, fittings, and casings. The ability to produce durable parts that withstand extreme conditions enhances operational efficiency and reduces downtime. Businesses sourcing these components should focus on suppliers that offer high-quality materials and can demonstrate expertise in meeting the unique challenges of the oil and gas industry, particularly in terms of environmental compliance and material strength.

What Advantages Do CNC Milling Services Offer for Renewable Energy Components?

CNC milling services are increasingly important in the renewable energy sector, particularly for the production of components used in solar panels and wind turbines. This application supports the transition to sustainable energy solutions by enabling the creation of efficient and innovative designs. Buyers, especially from emerging markets in Africa and South America, should seek suppliers who can provide tailored solutions that align with their project specifications while also being cost-effective to support large-scale deployment.

3 Common User Pain Points for ‘cnc milling services near me’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable CNC Milling Providers

The Problem: B2B buyers often struggle to identify trustworthy CNC milling services in their vicinity. This challenge is particularly pronounced in regions with limited options or where new providers frequently emerge. Buyers may encounter issues such as inconsistent quality, lack of certifications, or inadequate customer support, leading to uncertainty about the reliability of potential partners. This dilemma can delay projects and increase costs, as companies may need to conduct extensive vetting processes to ensure they partner with a reputable service provider.

The Solution: To mitigate this challenge, B2B buyers should prioritize sourcing CNC milling services through verified industry directories or associations. Engaging with local manufacturing networks or trade shows can also provide valuable insights into reputable providers. Once potential partners are identified, buyers should conduct thorough due diligence by requesting proof of certifications (such as ISO 9001) and reviewing customer testimonials. Setting up initial consultations can facilitate discussions about quality control processes and lead times, ensuring that the provider aligns with the buyer’s specific needs. Establishing clear communication channels and expectations from the outset can help build a strong working relationship that fosters reliability.

Scenario 2: Managing Production Timelines and Deadlines

The Problem: In the fast-paced world of manufacturing, meeting production deadlines is crucial. However, B2B buyers frequently face challenges with CNC milling services that do not adhere to agreed timelines. Delays can arise from various factors, such as equipment malfunctions, insufficient staffing, or unexpected material shortages. Such setbacks can disrupt supply chains, lead to lost sales opportunities, and damage client relationships, particularly in industries like automotive or aerospace, where timing is critical.

The Solution: To effectively manage production timelines, B2B buyers should prioritize CNC milling services that offer transparent project management systems. This includes real-time updates on project status and proactive communication regarding potential delays. Buyers can implement a phased approach to ordering, starting with smaller batches to evaluate the service provider’s efficiency before committing to larger production runs. Additionally, establishing a detailed contract that outlines timelines, penalties for delays, and quality expectations can create accountability on both sides. This proactive strategy ensures that buyers can better anticipate and respond to production challenges, minimizing risks to their overall project timelines.

Scenario 3: Navigating Complex Specifications and Customization Needs

The Problem: Many B2B buyers require highly customized CNC-milled parts that meet intricate specifications. However, they often find it challenging to communicate their exact needs to milling service providers. Misunderstandings regarding tolerances, materials, or design intricacies can result in costly errors and wasted resources. This issue is exacerbated for companies that operate in specialized sectors, such as medical devices or aerospace, where precision and compliance with regulatory standards are paramount.

The Solution: To effectively navigate complex specifications, buyers should invest time in creating comprehensive technical documentation that clearly outlines their requirements. Utilizing computer-aided design (CAD) files can significantly enhance communication with CNC milling services, as these files provide a visual representation of the parts needed. Buyers should also engage in collaborative design discussions with potential service providers to explore feasible manufacturing methods and material selections that align with their specifications. Establishing a feedback loop during the prototyping phase allows for adjustments based on initial outputs, ensuring that the final products meet the desired standards. By fostering a collaborative environment, B2B buyers can achieve precise outcomes that fulfill their unique requirements while minimizing the risk of errors or miscommunications.

Strategic Material Selection Guide for cnc milling services near me

What Are the Key Properties of Aluminum for CNC Milling Services?

Aluminum is a widely used material in CNC milling due to its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It typically performs well under moderate temperature and pressure conditions, making it suitable for various applications, including automotive and aerospace components. Its lightweight nature facilitates easier handling and reduces shipping costs, which is particularly advantageous for international B2B transactions.

Pros and Cons of Using Aluminum

The primary advantages of aluminum include its durability, ease of machining, and cost-effectiveness. It can be machined into complex shapes with high precision, which is essential for intricate parts. However, aluminum can be more expensive than other materials like steel, and its lower strength compared to some alloys may limit its use in high-stress applications.

Impact on Application

Aluminum is compatible with various media, including water and air, making it ideal for applications like heat exchangers and automotive parts. However, it may not be suitable for environments involving strong acids or alkalis, which could lead to corrosion.

Considerations for International Buyers

B2B buyers should ensure that suppliers comply with international standards such as ASTM and DIN for aluminum grades. Countries like Germany have stringent quality requirements, so understanding local regulations is crucial for successful procurement.

How Does Stainless Steel Perform in CNC Milling Applications?

Stainless steel is recognized for its exceptional corrosion resistance and strength, making it a popular choice for CNC milling, especially in the medical and food processing industries. Its ability to withstand high temperatures and pressures makes it suitable for applications requiring durability and reliability.

Pros and Cons of Using Stainless Steel

The key advantages of stainless steel include its robustness and longevity, which reduce the need for frequent replacements. However, it is more challenging to machine than aluminum, leading to higher manufacturing costs and longer lead times. The complexity of machining stainless steel can also necessitate specialized tooling, which may not be readily available in all regions.

Impact on Application

Stainless steel is widely used in environments that require hygiene and cleanliness, such as medical devices and food processing equipment. Its compatibility with a wide range of chemicals further enhances its applicability in diverse industries.

Considerations for International Buyers

Buyers from regions like Africa and the Middle East should be aware of the specific grades of stainless steel that meet local standards. Compliance with international certifications, such as ISO 9001, is essential for ensuring product quality.

What Are the Benefits of Using Titanium in CNC Milling?

Titanium is renowned for its high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures. This makes it an ideal material for aerospace and military applications where performance and reliability are critical.

Pros and Cons of Using Titanium

The primary advantage of titanium is its unparalleled strength and durability, allowing it to perform well in demanding environments. However, it is one of the more expensive materials to machine due to its toughness, which can lead to higher costs and longer production times. Specialized equipment and tooling are often required, which can limit accessibility for some manufacturers.

Impact on Application

Titanium is particularly suitable for applications involving harsh environments, such as marine or chemical processing. Its biocompatibility also makes it a preferred choice for medical implants and devices.

Considerations for International Buyers

International buyers should consider the availability of titanium grades that comply with ASTM and JIS standards. Understanding the local market dynamics and sourcing capabilities is essential for effective procurement.

How Does Plastic Compare in CNC Milling Services?

Plastics, such as polycarbonate and nylon, are increasingly used in CNC milling due to their lightweight and versatile properties. They offer good chemical resistance and can be engineered for specific applications, making them suitable for a wide range of industries.

Pros and Cons of Using Plastic

The advantages of plastics include low cost and ease of machining, allowing for rapid prototyping and production. However, they may not provide the same level of durability as metals, limiting their use in high-stress applications. Additionally, some plastics can be sensitive to temperature changes, which may affect their performance.

Impact on Application

Plastics are often used in consumer goods, automotive components, and electronic housings. Their compatibility with various media makes them suitable for applications requiring chemical resistance.

Considerations for International Buyers

B2B buyers should be aware of the specific plastic grades that meet local regulations and standards. Understanding the supply chain for plastics in regions like South America can help mitigate risks associated with material shortages.

Summary Table of Material Selection for CNC Milling Services

| Material | Typical Use Case for cnc milling services near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive and aerospace components | Lightweight and corrosion-resistant | Lower strength compared to some alloys | Medium |

| Stainless Steel | Medical devices and food processing equipment | Exceptional corrosion resistance | Higher machining complexity | High |

| Titanium | Aerospace and military applications | High strength-to-weight ratio | Expensive and challenging to machine | High |

| Plastic | Consumer goods and electronic housings | Low cost and easy to machine | Limited durability in high-stress applications | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for cnc milling services near me

What Are the Main Stages of Manufacturing Processes in CNC Milling Services?

CNC milling services encompass a series of well-defined manufacturing stages that ensure precision and efficiency. Understanding these stages can help B2B buyers evaluate potential suppliers more effectively.

How Does Material Preparation Work in CNC Milling?

Material preparation is the first step in the CNC milling process. It involves selecting the right type of raw material, which could range from metals like aluminum and stainless steel to plastics and composite materials. The chosen material is then cut to size, deburred, and cleaned to remove any contaminants. This initial stage is crucial as the quality of raw materials directly impacts the final product’s integrity and performance.

What Forming Techniques Are Used in CNC Milling?

The forming stage is where the actual machining occurs. Using Computer Numerical Control (CNC) technology, the selected material is shaped according to precise specifications. This process typically involves the use of various techniques such as:

- 3-Axis Milling: The most common form, allowing for the creation of flat surfaces and simple shapes.

- 4-Axis and 5-Axis Milling: These advanced techniques enable the machining of complex geometries and intricate features with fewer setups, reducing the risk of errors and enhancing efficiency.

Each technique is tailored to meet the unique requirements of specific industries, whether it’s automotive, aerospace, or medical device manufacturing.

How Is Assembly Managed in CNC Milling Services?

While CNC milling primarily focuses on the machining process, assembly may also be a part of the service. In some cases, multiple components produced through CNC milling need to be assembled into a final product. This could involve joining parts using techniques such as welding, adhesive bonding, or mechanical fasteners. Effective assembly processes ensure that the final product meets operational specifications and quality standards.

What Finishing Techniques Are Essential in CNC Milling?

The finishing stage is critical for enhancing both the functionality and aesthetics of the machined parts. Common finishing techniques include:

- Polishing: This improves surface finish and reduces friction.

- Anodizing: A process often used for aluminum parts, enhancing corrosion resistance.

- Coating: Applying protective or decorative layers to meet specific industry requirements.

These finishing techniques are especially important in sectors like medical device manufacturing, where hygiene and durability are paramount.

How Is Quality Assurance Implemented in CNC Milling Services?

Quality assurance (QA) is a vital aspect of CNC milling services, ensuring that each product meets industry standards and client specifications. For B2B buyers, understanding the QA process can provide confidence in the reliability of their suppliers.

Which International Standards Are Relevant for CNC Milling Quality Control?

International standards play a significant role in maintaining quality in manufacturing processes. For CNC milling services, two prominent certifications are:

- ISO 9001: This standard focuses on quality management systems, ensuring that organizations consistently meet customer and regulatory requirements.

- AS9100: Specifically tailored for the aerospace sector, this standard incorporates additional requirements to ensure safety and reliability.

Compliance with these standards is a strong indicator of a supplier’s commitment to quality.

What Are the Key QC Checkpoints in CNC Milling?

Quality control is typically executed at various stages of the manufacturing process, often referred to as the “Quality Control Checkpoints.” Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections and measurements are conducted to identify any deviations from standards.

- Final Quality Control (FQC): Once production is complete, final inspections are performed to verify that the finished products adhere to quality specifications.

These checkpoints help identify potential issues early, minimizing waste and ensuring that only high-quality products reach the customer.

What Testing Methods Are Commonly Used in CNC Milling Quality Control?

Several testing methods are employed to ensure the integrity and performance of machined parts. Common methods include:

- Dimensional Inspection: Using tools like calipers and micrometers to measure critical dimensions.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing to detect internal flaws without damaging the component.

- Functional Testing: Ensuring that parts perform as intended under operational conditions.

These testing methods are essential for industries where precision is non-negotiable, such as aerospace and medical devices.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct due diligence when selecting CNC milling suppliers to ensure they adhere to stringent quality standards. Here are several strategies to verify quality control:

What Auditing Practices Should Buyers Consider?

Conducting supplier audits is an effective way to evaluate a potential partner’s quality control practices. Audits can provide insights into the supplier’s processes, compliance with international standards, and overall commitment to quality. Buyers may consider:

- On-site Audits: Visiting the supplier’s facility to observe operations and quality management systems in action.

- Document Reviews: Examining quality control documentation, including inspection reports and certifications.

How Can Buyers Access Quality Reports and Third-Party Inspections?

Requesting quality reports and third-party inspection certificates can offer additional assurance of a supplier’s quality practices. Reputable suppliers often engage independent organizations to conduct audits and provide certifications, which can be shared with potential clients.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

How Do Regulatory Standards Differ Across Regions?

Different regions may have varying regulatory standards that impact quality assurance. For instance, medical devices in Europe must comply with the CE mark requirements, while in the U.S., FDA regulations apply. Understanding these differences is crucial for international buyers to ensure compliance.

What Should Buyers Know About Cultural and Communication Factors?

Cultural differences can affect communication and expectations regarding quality. B2B buyers should establish clear guidelines and maintain open lines of communication with suppliers to ensure that quality standards are understood and met.

Conclusion

For B2B buyers seeking CNC milling services, a comprehensive understanding of manufacturing processes and quality assurance practices is essential. By focusing on the key stages of manufacturing, relevant international standards, and effective quality control measures, buyers can make informed decisions when selecting suppliers. Investing time in due diligence will ultimately lead to successful partnerships and high-quality products that meet industry demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc milling services near me’

Introduction

Navigating the procurement of CNC milling services can be a complex process, especially for international B2B buyers seeking reliable and high-quality solutions. This checklist aims to streamline your sourcing efforts, ensuring you make informed decisions that meet your technical and operational requirements. Follow these actionable steps to identify and engage with the right CNC milling service providers.

Step 1: Define Your Technical Specifications

Clearly outline the specifications of the parts you need, including dimensions, tolerances, materials, and quantities. This step is crucial as it sets the groundwork for your discussions with potential suppliers. Providing detailed specifications helps ensure that suppliers can meet your needs and reduces the likelihood of miscommunication.

- Considerations:

- Type of materials (e.g., aluminum, stainless steel, plastics)

- Complexity of the part design (e.g., multi-axis requirements)

Step 2: Research Local and International Suppliers

Start by compiling a list of CNC milling service providers both locally and internationally. Utilize online directories, trade associations, and industry forums to identify companies with a strong reputation. This research is important for comparing capabilities, pricing, and lead times across different regions.

- Key Resources:

- Industry-specific websites and forums

- Trade fairs and exhibitions in your region

Step 3: Evaluate Supplier Capabilities and Technologies

Assess the technological capabilities of potential suppliers. Inquire about the types of CNC milling machines they use, including the number of axes and any advanced features like automation or specialized tooling. Understanding their technological strengths will help you determine if they can produce the quality and complexity of parts you require.

- Important Questions:

- Do they utilize multi-axis machining?

- What software do they use for design and programming?

Step 4: Verify Supplier Certifications and Quality Standards

Before proceeding, verify that the suppliers adhere to recognized quality standards such as ISO 9001 or AS9100. Certifications provide assurance that the supplier maintains rigorous quality control processes, which is vital in industries like aerospace or medical manufacturing where precision is paramount.

- What to Look For:

- Copies of their certifications

- Evidence of quality management protocols

Step 5: Request Samples and Quotes

Once you have shortlisted potential suppliers, request samples of their work along with detailed quotes. Evaluating samples can give you insights into their manufacturing quality and adherence to your specifications. Quotes should include pricing, lead times, and any additional costs for tooling or setup.

- Considerations:

- Compare pricing models (fixed vs. variable costs)

- Review lead times and availability for your project schedule

Step 6: Check References and Past Performance

Ask for references from previous clients who have similar needs to yours. Engaging with past customers can provide valuable insights into the supplier’s reliability, quality of work, and customer service. This step helps mitigate risks associated with choosing a new supplier.

- Key Questions:

- How satisfied were they with the quality of the parts?

- Did the supplier meet deadlines consistently?

Step 7: Establish Communication and Support Channels

Effective communication is essential for successful collaboration. Ensure that the supplier has clear communication channels and a responsive support team. This is particularly important for addressing any issues that may arise during the production process.

- What to Ensure:

- Availability of dedicated account managers

- Clear processes for handling inquiries and feedback

By following this checklist, you will enhance your ability to find a CNC milling service provider that aligns with your business needs, ultimately leading to successful project outcomes.

Comprehensive Cost and Pricing Analysis for cnc milling services near me Sourcing

What Are the Key Cost Components for CNC Milling Services?

When sourcing CNC milling services, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: The type of material significantly influences the overall cost. Metals like aluminum and stainless steel are commonly used, but exotic materials can drive prices higher. Buyers should consider both the cost of raw materials and the potential for waste during machining.

-

Labor: While CNC machines are automated, skilled labor is still essential for programming, setup, and quality control. Labor costs can vary based on the complexity of the project and the expertise required.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Efficient operations can minimize overhead costs, which is beneficial for both the supplier and the buyer.

-

Tooling: Custom tooling can be a significant upfront investment. Costs vary based on the complexity and durability of the tools required for specific jobs. Buyers should inquire about tooling costs, especially for low-volume projects.

-

Quality Control (QC): Rigorous QC processes are essential, particularly for industries like aerospace and medical manufacturing. The costs associated with testing and inspection should be factored into the overall pricing.

-

Logistics: Shipping and handling costs can add to the total price, particularly for international buyers. Understanding the Incoterms involved can help clarify responsibilities and potential costs.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary widely based on market conditions, competition, and the supplier’s business model.

How Do Price Influencers Affect CNC Milling Costs?

Several factors can influence the pricing of CNC milling services:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Discussing your expected volume can enable suppliers to offer more competitive pricing.

-

Specifications and Customization: Custom parts with unique specifications require additional setup time and tooling, impacting overall costs. Clear communication of requirements can help avoid unexpected charges.

-

Materials: As mentioned, the choice of materials can significantly affect pricing. Opting for standard materials can reduce costs, while specialized materials may require premium pricing.

-

Quality and Certifications: Parts requiring industry-specific certifications (like ISO 9001) may incur additional costs due to the stringent quality assurance processes involved. Understanding the certification requirements relevant to your industry can aid in budgeting.

-

Supplier Factors: The reputation, location, and capabilities of the supplier can influence pricing. Established suppliers may charge a premium for their reliability and quality assurance.

-

Incoterms: International buyers must understand the shipping terms, as they dictate who bears the costs and risks during transportation. This knowledge can prevent unexpected expenses.

What Are the Best Practices for Negotiating CNC Milling Prices?

-

Understand Total Cost of Ownership (TCO): Beyond the initial price, consider maintenance, logistics, and potential downtime costs when evaluating suppliers. A lower initial price may lead to higher long-term expenses.

-

Leverage Volume Discounts: If you anticipate future orders, negotiate for a better rate based on projected volumes. Suppliers may be willing to offer discounts for long-term partnerships.

-

Request Detailed Quotes: Ensure that quotes break down all cost components to identify areas where you might negotiate better terms or find cost-saving opportunities.

-

Explore Multiple Suppliers: Comparing multiple suppliers can provide leverage in negotiations and help you identify the best overall value rather than just the lowest price.

-

Be Culturally Sensitive: When negotiating with suppliers from different regions, be aware of cultural nuances that may affect business interactions, especially in regions like Africa and the Middle East.

What Should International B2B Buyers Consider When Sourcing CNC Milling Services?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be mindful of specific challenges:

-

Currency Fluctuations: Be prepared for potential changes in costs due to currency variations, which can affect pricing over time.

-

Import Duties and Taxes: Understanding local import regulations and costs can prevent unexpected expenses when parts arrive.

-

Communication Barriers: Clear communication is vital to ensure that specifications are understood and met. Consider time zone differences and language barriers when coordinating with suppliers.

-

Quality Assurance Standards: Ensure that the supplier can meet your quality standards, especially if they differ from local requirements.

Disclaimer

The prices and cost structures mentioned are indicative and can vary based on market conditions, specific project requirements, and supplier capabilities. Always consult with multiple suppliers to obtain accurate and tailored quotes for your specific needs.

Alternatives Analysis: Comparing cnc milling services near me With Other Solutions

Exploring Alternatives to CNC Milling Services

When considering manufacturing solutions, it is essential to explore alternatives to CNC milling services. While CNC milling provides precision and efficiency, other technologies and methods may also meet specific needs depending on factors like production scale, material types, and budget constraints. This analysis will compare CNC milling services to two viable alternatives: 3D printing and traditional machining.

| Comparison Aspect | CNC Milling Services Near Me | 3D Printing | Traditional Machining |

|---|---|---|---|

| Performance | High precision and speed | Moderate precision; great for complex geometries | High precision; slower than CNC |

| Cost | Moderate initial investment; competitive for large runs | Lower initial costs; more economical for small batches | Often higher due to labor costs and setup |

| Ease of Implementation | Requires CAD files and skilled operators | User-friendly software; less skilled labor needed | Requires skilled machinists and setup time |

| Maintenance | Regular maintenance needed; costly downtime | Minimal maintenance; generally low overhead | High maintenance; often requires skilled technicians |

| Best Use Case | High-volume, precision parts in automotive, aerospace, and medical sectors | Prototyping and complex designs; low-volume production | Custom parts with specific tolerances; low to medium volume |

Understanding the Pros and Cons of Alternatives

3D Printing

3D printing, or additive manufacturing, allows for the creation of complex shapes and designs that may be challenging to achieve with traditional machining or CNC milling. It uses a layer-by-layer construction method, making it ideal for rapid prototyping and low-volume production runs. However, while 3D printing is cost-effective for small batches, it may not provide the same level of precision and durability required for critical applications in industries like aerospace or medical devices.

Traditional Machining

Traditional machining encompasses various methods, including turning, drilling, and grinding. This approach can yield high precision and is often favored for custom components with specific tolerances. However, traditional machining typically requires more labor-intensive processes, resulting in higher costs and longer lead times compared to CNC milling. It is best suited for low to medium production volumes where bespoke parts are necessary.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right manufacturing solution requires an understanding of your specific requirements, including production volume, material specifications, and budget constraints. CNC milling services excel in high-volume, precision-driven applications, making them ideal for industries demanding rigorous quality standards. In contrast, 3D printing offers flexibility for design and lower costs for prototyping, while traditional machining may suit specialized needs with lower production runs. By evaluating these aspects, B2B buyers can make informed decisions that align with their operational goals and industry standards.

Essential Technical Properties and Trade Terminology for cnc milling services near me

What Are the Essential Technical Properties for CNC Milling Services?

Understanding the technical specifications of CNC milling services is crucial for B2B buyers to ensure that their manufacturing needs are met with precision and reliability. Here are some key properties to consider:

1. Material Grade

Material grade refers to the classification of materials based on their physical and chemical properties. Common materials used in CNC milling include aluminum, stainless steel, titanium, and various plastics. Selecting the right material grade is vital because it affects the durability, weight, and functionality of the finished part. For example, aerospace applications often require lightweight yet strong materials, while medical devices may need biocompatible plastics.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. It is a critical specification in CNC milling, as it dictates how closely a part must conform to its design specifications. High-precision applications, such as those in the automotive or aerospace industries, may require tolerances as tight as ±0.001 inches. Understanding tolerance requirements helps buyers ensure that the parts will fit correctly and function properly in their intended applications.

3. Surface Finish

Surface finish describes the texture and smoothness of a part’s surface after machining. Common finishes include mill finish, sanded, and polished. The surface finish can influence not only the aesthetics but also the performance of the part, particularly in applications where friction or wear is a concern. For example, medical instruments often require a smooth finish to reduce the risk of bacterial contamination.

4. Machining Speed

Machining speed refers to the rate at which material is removed during the milling process, usually measured in inches per minute (IPM). Higher machining speeds can lead to shorter production times and increased efficiency. However, they must be balanced against tool wear and part quality. Buyers should consider their production timelines and budget when discussing machining speeds with suppliers.

5. CNC Axis Configuration

The axis configuration of CNC milling machines indicates the number of axes in which the machine can operate. Common configurations include 3-axis, 4-axis, and 5-axis milling. A 5-axis machine can create more complex geometries and reduce the need for repositioning parts, thereby enhancing efficiency and precision. Buyers should evaluate the complexity of their designs to determine the appropriate axis configuration for their needs.

What Are Common Trade Terms in CNC Milling Services?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another company under its own brand name. Understanding OEM relationships can help buyers identify suppliers that can meet their specific manufacturing needs while maintaining brand integrity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce for a single order. Knowing the MOQ is crucial for buyers, as it can impact inventory levels and cash flow. Some suppliers may offer lower MOQs for new clients or trial orders.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers asking for pricing and terms on specific products or services. It is a vital step in the procurement process that helps buyers compare offers and make informed decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, ensuring smoother transactions.

5. CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools via a computer. Understanding CNC technology is essential for buyers, as it enables high precision and efficiency in manufacturing, making it a preferred choice for complex parts.

By grasping these technical properties and trade terms, B2B buyers can navigate the CNC milling landscape more effectively, ensuring they select the right partners and solutions for their manufacturing needs.

Navigating Market Dynamics and Sourcing Trends in the cnc milling services near me Sector

What Are the Key Trends Shaping the CNC Milling Services Market?

The CNC milling services market is witnessing transformative changes driven by several global factors. Increased demand for precision engineering across industries such as automotive, aerospace, and medical devices is a primary driver. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (e.g., Nigeria, Germany) seek suppliers capable of delivering high-quality parts, they are increasingly adopting advanced technologies like multi-axis CNC milling. This technology enables manufacturers to produce complex components with high accuracy and efficiency, thus reducing lead times and operational costs.

Another significant trend is the rise of automation and smart manufacturing. Integration of IoT (Internet of Things) and AI (Artificial Intelligence) in CNC machining processes allows for real-time monitoring and predictive maintenance, enhancing production reliability. As international buyers prioritize suppliers that can offer rapid prototyping and flexible manufacturing solutions, CNC milling services are evolving to meet these needs. Additionally, the growing emphasis on just-in-time (JIT) manufacturing is compelling suppliers to streamline their processes and improve supply chain management, thereby ensuring timely delivery.

How Is Sustainability Influencing Sourcing Decisions in CNC Milling Services?

Sustainability and ethical sourcing are becoming integral to the CNC milling services sector. As global awareness of environmental issues rises, B2B buyers are increasingly seeking suppliers who prioritize sustainable practices. This includes minimizing waste through efficient machining processes and utilizing eco-friendly materials. For example, manufacturers can reduce their carbon footprint by opting for biodegradable lubricants and recycled materials in their CNC operations.

Moreover, certifications such as ISO 14001 (Environmental Management) and adherence to green manufacturing practices are becoming essential for suppliers looking to attract international buyers. These certifications demonstrate a commitment to reducing environmental impact and ensuring responsible sourcing practices. Buyers are also showing a preference for suppliers who maintain transparent supply chains, as this builds trust and ensures compliance with ethical standards.

How Has CNC Milling Evolved Over Time to Meet B2B Needs?

CNC milling has undergone significant evolution since its inception, transitioning from manual operations to highly automated processes. Initially, machining relied heavily on manual labor, which was not only time-consuming but also prone to errors. The introduction of Computer Numerical Control in the 1960s revolutionized the industry by allowing machines to operate based on precise digital instructions, greatly improving accuracy and efficiency.

Over the decades, advancements in technology have led to the development of multi-axis CNC machines that can perform complex tasks with minimal human intervention. This evolution has enabled manufacturers to cater to diverse industries with varying needs, from producing intricate aerospace components to high-volume automotive parts. As CNC milling continues to advance, it remains a crucial element in supporting the growing demand for high-quality, precision-engineered products in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc milling services near me

-

How do I assess the quality of CNC milling services near me?

To assess the quality of CNC milling services, examine the supplier’s certifications, such as ISO 9001 or AS9100, which indicate adherence to quality management systems. Request samples of previous work to evaluate precision and finish. Additionally, inquire about their quality control processes, including inspections and testing methods used throughout production. Customer testimonials and case studies can also provide insights into their reliability and service quality. -

What are the key considerations when selecting a CNC milling supplier?

When selecting a CNC milling supplier, consider their experience in your specific industry and their ability to meet your technical requirements. Evaluate their equipment capabilities, such as multi-axis milling, which can enhance precision for complex parts. Assess their customer service and communication practices, as well as their ability to meet deadlines and adapt to changes in your project scope. Finally, confirm their compliance with international standards relevant to your industry. -

What types of materials can be processed with CNC milling services?

CNC milling services can process a wide range of materials, including metals like aluminum, stainless steel, and titanium, as well as various plastics. The choice of material often depends on the application; for instance, medical devices may require biocompatible materials, while aerospace components might need lightweight alloys. Discuss your specific material requirements with potential suppliers to ensure they have the necessary capabilities and experience. -

What are typical minimum order quantities (MOQs) for CNC milling services?

Minimum order quantities (MOQs) for CNC milling services can vary widely depending on the supplier and the complexity of the part. Some suppliers may accept small batch orders, while others may require larger MOQs to justify setup costs. It’s essential to clarify this with your potential suppliers during negotiations, especially if you’re sourcing for niche applications or prototypes. Some suppliers may offer flexibility for first-time orders or ongoing partnerships. -

How do payment terms typically work in CNC milling contracts?

Payment terms in CNC milling contracts often include a deposit upfront, followed by the balance upon completion or delivery of the order. Standard terms may range from 30 to 60 days after invoicing, depending on the supplier’s policies and your business relationship. It’s advisable to negotiate terms that align with your cash flow requirements and establish clear milestones for payments linked to project phases or delivery schedules. -

What should I know about logistics and shipping when sourcing CNC milling services internationally?

When sourcing CNC milling services internationally, consider shipping times, costs, and customs regulations that may impact delivery schedules. Collaborate with your supplier to determine the best shipping methods, whether air freight for speed or sea freight for cost-effectiveness. Understanding Incoterms is crucial, as they define responsibilities for transportation, insurance, and duties. Ensure your supplier is experienced in international shipping to avoid delays and additional costs. -

How can I customize CNC milled parts to meet my specific requirements?

Customizing CNC milled parts typically involves discussing your design specifications with the supplier early in the process. You can provide CAD files or detailed drawings that outline your requirements, including dimensions, tolerances, and surface finishes. Many CNC machining companies offer design assistance to optimize parts for manufacturability. Make sure to clarify any additional costs associated with custom tooling or programming that may arise during production. -

What quality assurance processes should I expect from a CNC milling service?

A reputable CNC milling service should have robust quality assurance processes in place, including in-process inspections and final product testing. They may employ techniques such as coordinate measuring machines (CMM) or visual inspections to ensure parts meet specified tolerances. Additionally, ask about their traceability practices and whether they maintain records for each batch produced. These processes are critical for industries with strict regulatory requirements, such as aerospace and medical manufacturing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc milling services near me

In conclusion, the strategic sourcing of CNC milling services presents a vital opportunity for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By leveraging the precision and efficiency of advanced CNC technologies, companies can significantly enhance production capabilities while maintaining stringent quality standards. The ability to source locally or regionally not only reduces lead times but also fosters stronger relationships with suppliers, ensuring that businesses can adapt swiftly to market demands.

As industries such as automotive, aerospace, and medical continue to evolve, the need for high-quality, customized components will grow. Embracing strategic sourcing practices will empower organizations to stay competitive and responsive in a rapidly changing landscape.

Looking ahead, international buyers are encouraged to explore partnerships with reputable CNC milling service providers who prioritize innovation, quality control, and customer-centric solutions. By doing so, businesses can position themselves at the forefront of their respective markets, driving growth and success in an interconnected global economy. Engage with local CNC milling experts today to unlock the full potential of your manufacturing capabilities.