Top 8 Aluminum Machining Services Manufacturers & Suppliers List

1. Hubs – CNC Machining Aluminum Services

Domain: hubs.com

Registered: 1998 (27 years)

Introduction: CNC Machining Aluminum Services: High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density, and natural corrosion resistance. Can be anodized. Available materials include Aluminum 6061-T6, Aluminum 7075-T6, Aluminum 6060, Aluminum 6082, Aluminum 5083-H111, Aluminum 6063, Aluminum 5052, …

2. Reddit – Custom Aluminum CNC Parts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom Aluminum CNC milled parts, one-off parts, CAD file upload, hobby projects, companies mentioned: Xometry, quickparts, local machinists, pricing examples discussed.

3. 3ERP – Aluminum CNC Machining Services

Domain: 3erp.com

Registered: 2000 (25 years)

Introduction: Aluminum CNC Machining Services including CNC Milling, CNC Turning, 5-Axis CNC Machining, and Precision Machining. Capabilities include rapid material removal, high-speed cutting, and fine detailing for both simple and complex parts. Delivery in as fast as 3 days, with options for one-off prototypes or mass production (100K+ parts). Tolerances as tight as ±0.01 mm. No minimum order quantity (MOQ)….

4. PCBWay – CNC Machining & Prototyping Services

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: CNC Machining Service includes precision CNC machining and rapid prototyping parts. Key features include CNC milling (3-, 4-, & full 5-axis), CNC turning, and various 3D printing technologies (FDM, SLA, SLS, MJF, DMLS, PolyJet). The service offers a wide range of materials including metals (Aluminum, Stainless steel, Brass, Copper, Titanium, Mild steel, Alloy steel, Tool steel, Spring steel) and p…

5. eMachineShop – Custom Aluminum Parts

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: eMachineShop offers custom aluminum parts and components, including machining, fabrication, and finishing services. Key features include precision CNC machining, a variety of aluminum grades available, quick turnaround times, and the ability to handle both small and large production runs. The company provides online design tools and instant quotes, ensuring a streamlined ordering process.

6. SendCutSend – Custom Sheet Metal Fabrication

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers custom sheet metal fabrication services including laser cutting, CNC routing, waterjet cutting, anodizing, bending & forming, countersinking, dimple forming, hardware insertion, plating, powder coating, tapping, tumbling, and deburring. They provide instant pricing for custom parts with no minimum quantities and free US shipping on orders over $39. Key materials include cold rol…

7. 3Q Machining – Custom Aluminum CNC Parts

Domain: 3qmachining.com

Registered: 2020 (5 years)

Introduction: Aluminum CNC Machining Service for custom aluminum parts. Key features include: no minimum quantity, starting price as low as $100, fastest delivery in 3 days, design and technique support available. Tolerance as low as +/- 0.005 mm with drawing, ISO 2768 medium without drawing. Alloys offered: 6061-T6, 7075-T6, 7050, 2024, 5052, 6063. Applications include components for automation, automotive, ae…

8. Rapid Axis – Aluminum CNC Machining Services

Domain: rapidaxis.com

Registered: 2018 (7 years)

Introduction: Aluminum CNC Machining Service | Custom Parts | Rapid Axis offers high-precision aluminum CNC machining services for various industries including aerospace, automotive, medical, electronics, and robotics. Key features include:

– Custom aluminum CNC machining for prototypes, low-volume, and high-volume parts.

– Common aluminum alloys used: 6061, 7075, 2024, 5052, 3003.

– Finishing options: Anodizin…

Introduction: Navigating the Global Market for aluminum machining services

In the competitive landscape of international manufacturing, sourcing high-quality aluminum machining services can pose significant challenges for B2B buyers. With various aluminum alloys available, each offering distinct properties and applications, navigating the complexities of these materials while ensuring precision and cost-effectiveness is crucial. This comprehensive guide is designed to assist international buyers, particularly from Africa, South America, the Middle East, and Europe—countries like Nigeria and Germany—in making informed purchasing decisions.

Throughout this guide, we will explore the different types of aluminum machining services, including CNC machining, and their applications across various industries, such as aerospace, automotive, and medical. We will also provide insights on how to effectively vet suppliers, ensuring that they meet the necessary standards for quality and reliability. Additionally, cost considerations will be addressed, equipping buyers with the knowledge to negotiate better terms and understand pricing structures.

By leveraging this guide, B2B buyers can enhance their sourcing strategies and build partnerships with suppliers that align with their operational goals. Whether you are looking for precision components or innovative machining solutions, this resource empowers you to navigate the global aluminum machining market with confidence.

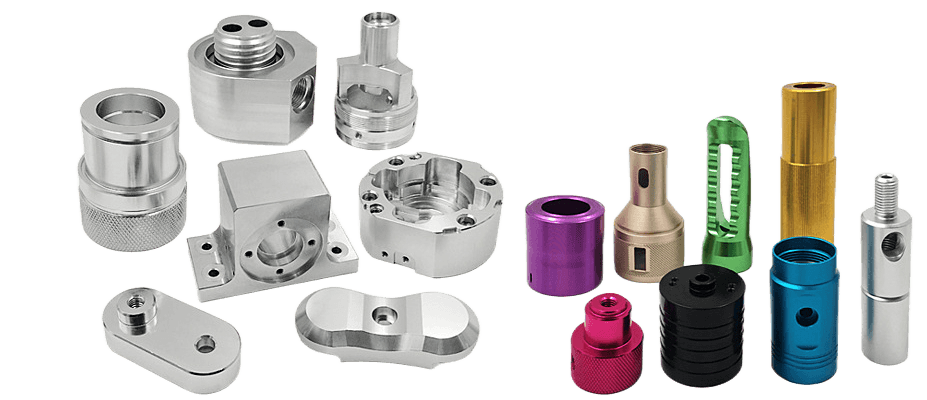

Understanding aluminum machining services Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machining | High precision, automated processes | Aerospace, automotive, medical devices | Pros: High accuracy, repeatability. Cons: Initial setup cost. |

| Die Casting | Molds for complex shapes, high-volume production | Consumer goods, automotive parts | Pros: Cost-effective for large runs. Cons: Limited to specific designs. |

| Extrusion | Continuous shapes, versatile profiles | Construction, furniture, automotive components | Pros: Efficient for long parts. Cons: Requires specialized equipment. |

| Waterjet Cutting | No heat-affected zone, intricate designs | Art, architecture, aerospace components | Pros: Versatile material compatibility. Cons: Slower than CNC. |

| Laser Cutting | High-speed, precise cuts with minimal waste | Electronics, signage, custom components | Pros: Quick turnaround, high detail. Cons: Limited thickness capabilities. |

What Are the Characteristics of CNC Machining Services for Aluminum?

CNC (Computer Numerical Control) machining is a highly precise manufacturing process that employs computer-controlled tools to create intricate parts from aluminum. This type of machining is particularly advantageous for industries such as aerospace and automotive, where tolerances are critical. The automation involved ensures consistency across production runs, making it a preferred choice for high-volume orders. Buyers should consider the initial investment in CNC machinery but can benefit from long-term cost savings due to increased efficiency and reduced waste.

How Does Die Casting Differ from Other Aluminum Machining Services?

Die casting involves forcing molten aluminum into a mold to produce complex shapes. This method is ideal for high-volume production and is commonly used in the manufacturing of automotive parts and consumer goods. The key advantage is the ability to create intricate designs with minimal machining post-production. However, buyers should be aware that die casting can be less flexible in design changes once the mold is made, potentially leading to higher costs if modifications are needed.

What Are the Advantages of Aluminum Extrusion Services?

Aluminum extrusion is a process where aluminum is forced through a die to create long, continuous shapes with uniform cross-sections. This method is particularly well-suited for applications in construction and automotive components where specific profiles are required. The primary advantage of extrusion is its efficiency in producing long parts at a lower cost. However, buyers must consider the need for specialized equipment and the limitations on design flexibility after the die is created.

Why Choose Waterjet Cutting for Aluminum Machining?

Waterjet cutting utilizes high-pressure water to cut through aluminum, allowing for intricate designs without introducing heat that could affect the material properties. This method is versatile and can be used for a variety of materials, making it suitable for artistic applications, architectural elements, and aerospace components. While it offers great detail and flexibility, buyers should note that waterjet cutting can be slower than other methods like CNC machining, which may impact lead times for larger projects.

What Makes Laser Cutting a Preferred Choice for B2B Buyers?

Laser cutting is a high-speed method that uses focused light to cut aluminum with precision. It is particularly effective for creating detailed components in electronics and signage. The benefits of laser cutting include minimal material waste and fast processing times, allowing for rapid prototyping and production. However, buyers should consider the limitations in terms of thickness and material compatibility, as not all aluminum grades may be suitable for this cutting method.

Key Industrial Applications of aluminum machining services

| Industry/Sector | Specific Application of aluminum machining services | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing aircraft components | Lightweight yet strong parts enhancing fuel efficiency | Certification of materials, precision tolerances, lead times |

| Automotive | Production of engine components | Improved performance and reduced weight for vehicles | Alloy selection, machining capabilities, cost efficiency |

| Medical Devices | Creation of surgical instruments | High precision and biocompatibility | Regulatory compliance, surface finish requirements |

| Construction | Fabrication of structural components | Durable and lightweight solutions for building projects | Material grades, sustainability practices, delivery timelines |

| Electronics | Production of heat sinks and enclosures | Enhanced thermal management and device longevity | Design specifications, volume requirements, custom tooling |

How is Aluminum Machining Services Utilized in the Aerospace Sector?

In the aerospace industry, aluminum machining services are pivotal for manufacturing lightweight yet robust components such as aircraft frames, fittings, and brackets. These components are designed to meet strict regulatory standards while optimizing fuel efficiency. For international buyers, particularly in regions like Africa and Europe, sourcing requires a focus on certified materials and adherence to precise tolerances. Suppliers must demonstrate their capability to produce complex geometries while ensuring timely deliveries to align with production schedules.

What Role Does Aluminum Machining Play in Automotive Applications?

Aluminum machining is integral to the automotive sector, where it is used to produce engine components, transmission housings, and structural parts. The lightweight nature of aluminum contributes to improved fuel efficiency and overall vehicle performance. Buyers from South America and the Middle East should consider the alloy selection and the machining capabilities of their suppliers to ensure they meet the specific performance requirements of modern vehicles. Additionally, cost efficiency in production processes can significantly impact profit margins.

How Are Aluminum Machining Services Applied in Medical Devices?

In the medical field, aluminum machining services are essential for creating surgical instruments and medical devices that require high precision and biocompatibility. The ability to manufacture components that meet stringent health regulations is crucial. For international buyers, especially in regions with strict regulatory standards, sourcing from suppliers who can ensure compliance and high-quality surface finishes is vital. These factors influence the overall reliability and safety of medical devices.

What Are the Benefits of Aluminum Machining in Construction?

Aluminum machining services are widely employed in the construction industry for fabricating structural components such as beams, trusses, and frames. The durability and lightweight properties of aluminum make it an attractive choice for modern building projects. Buyers from Europe and Africa should prioritize sourcing practices that consider material grades and sustainability practices, as these elements are increasingly important in construction projects. Timely delivery is also crucial to avoid project delays.

How Does Aluminum Machining Enhance Electronic Applications?

Aluminum machining is utilized in the electronics sector for the production of heat sinks and enclosures that are vital for thermal management in devices. The efficient dissipation of heat enhances device longevity and performance. For B2B buyers in South America and the Middle East, it is essential to communicate design specifications clearly and understand the supplier’s capabilities for custom tooling and volume requirements. This ensures that the final products meet both functional and aesthetic criteria.

3 Common User Pain Points for ‘aluminum machining services’ & Their Solutions

Scenario 1: Inconsistent Quality of Machined Parts

The Problem: One common challenge faced by B2B buyers in the aluminum machining sector is the inconsistency in the quality of machined parts. This inconsistency can lead to significant production delays and increased costs, especially when the parts are critical components in complex machinery or aerospace applications. Buyers often find themselves dealing with parts that do not meet specified tolerances, leading to rework, scrap, and potential safety issues. This situation is particularly frustrating for companies with tight deadlines and high-quality standards.

The Solution: To mitigate the risk of inconsistent quality, buyers should prioritize working with machining service providers that have robust quality management systems in place. It’s advisable to request detailed quality assurance protocols, including certifications like ISO 9001. Before placing large orders, conduct a pilot run to evaluate the provider’s capabilities and quality control measures. Establish clear specifications, including tolerances and surface finishes, and communicate these expectations during the design phase. Frequent communication and feedback loops with the machining partner can also help ensure that the final products meet the required standards. By being proactive in the sourcing process and establishing quality benchmarks, buyers can significantly reduce the likelihood of receiving subpar components.

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem: Many B2B buyers experience frustration due to long lead times associated with aluminum machining services. Extended production times can disrupt supply chains and delay product launches, particularly in fast-paced industries such as automotive and aerospace. Buyers often face the dilemma of balancing the need for high-quality parts with the urgency of their timelines, leading to a compromise in either quality or delivery schedules.

The Solution: To address lead time challenges, buyers should consider establishing long-term partnerships with aluminum machining service providers. These relationships can foster better communication and prioritization of orders. Additionally, buyers should leverage technology, such as instant quoting and ordering systems, which many modern machining services offer. This allows for quicker turnaround times and better planning. When possible, providing accurate forecasts of demand can also help machining partners allocate resources effectively. Furthermore, exploring local or regional machining services can reduce shipping times and facilitate faster responses to urgent needs. By taking these proactive steps, buyers can better align production schedules with their machining service capabilities.

Scenario 3: Difficulty in Choosing the Right Aluminum Alloy for Specific Applications

The Problem: Selecting the appropriate aluminum alloy for a specific application can be a daunting task for B2B buyers. Each alloy has distinct properties that make it suitable for certain environments and applications, such as strength, corrosion resistance, and machinability. Buyers may struggle with understanding the nuances of different aluminum grades, leading to the potential for selecting an inappropriate alloy that could fail to meet performance expectations.

The Solution: To navigate the complexities of aluminum alloy selection, buyers should engage closely with their machining service providers. They should prepare a detailed project brief that outlines the specific requirements of the application, including environmental conditions, load-bearing needs, and any relevant industry standards. Machining service providers often have extensive experience and knowledge about the properties of various aluminum alloys and can offer valuable insights. Additionally, consulting technical datasheets and material guides can provide clarity on the strengths and weaknesses of each alloy. Buyers should also consider conducting small-scale testing or prototyping with different alloys to evaluate their performance in real-world conditions. By taking a collaborative and informed approach to alloy selection, buyers can ensure they choose the right material that meets their application’s demands while optimizing performance and durability.

Strategic Material Selection Guide for aluminum machining services

What Are the Key Properties of Common Aluminum Alloys Used in Machining Services?

Aluminum machining services leverage various alloys, each with unique properties that cater to specific applications. Understanding these materials is crucial for international B2B buyers to ensure optimal performance and compliance with industry standards.

How Does Aluminum 6061 Stand Out in Machining Applications?

Aluminum 6061 is a versatile alloy known for its excellent machinability, weldability, and corrosion resistance. It features a tensile strength of approximately 276 MPa and a density of 2.7 g/cm³, making it suitable for a wide range of applications, including structural components and automotive parts.

Pros: Its good mechanical properties and ease of fabrication make it a popular choice. It is also relatively cost-effective, allowing for efficient production.

Cons: While it offers decent corrosion resistance, it may not perform well in highly acidic or alkaline environments. Additionally, its strength is lower compared to other alloys like 7050.

Impact on Application: Aluminum 6061 is widely used in the aerospace, automotive, and construction industries, where its balance of strength and weight is essential.

Considerations for International Buyers: Buyers from regions like Africa and Europe should ensure compliance with standards such as ASTM and DIN. Additionally, understanding local availability and pricing can help in making informed decisions.

What Advantages Does Aluminum 5052 Offer for Machining Projects?

Aluminum 5052 is primarily alloyed with magnesium, which enhances its corrosion resistance, making it ideal for marine and automotive applications. It has a tensile strength of about 193 MPa and a density of 2.68 g/cm³.

Pros: Its superior corrosion resistance makes it suitable for environments exposed to moisture. It is also highly formable, allowing for complex shapes.

Cons: The alloy cannot be heat-treated, which may limit its use in high-stress applications. Its lower strength compared to 6061 may not be suitable for all structural applications.

Impact on Application: Commonly used in fuel tanks and marine environments, its resistance to corrosion is crucial for longevity.

Considerations for International Buyers: Buyers should be aware of surface treatment requirements to enhance corrosion resistance, especially in humid climates prevalent in parts of Africa and South America.

Why Is Aluminum 7075 Considered a High-Performance Alloy?

Aluminum 7075 is one of the strongest aluminum alloys available, with a tensile strength of around 490 MPa. It is often used in aerospace applications where high strength-to-weight ratios are critical.

Pros: Its exceptional strength makes it suitable for high-stress applications, and it can be machined to tight tolerances.

Cons: The alloy is less resistant to corrosion compared to others, requiring protective coatings or treatments. It is also more expensive due to its complex manufacturing process.

Impact on Application: Ideal for aircraft structures, military applications, and high-performance components, its strength is a key factor in safety-critical applications.

Considerations for International Buyers: Buyers must ensure compliance with aerospace standards and may need to consider the additional costs associated with protective coatings.

What Makes Aluminum 2024-T3 a Unique Choice for Specific Applications?

Aluminum 2024-T3 is well-known for its fatigue resistance, making it suitable for aerospace applications. It has a tensile strength of approximately 345 MPa but is less corrosion-resistant, often requiring surface treatments.

Pros: Its excellent machinability and fatigue resistance make it ideal for components subjected to cyclic loading.

Cons: Poor weldability and corrosion resistance can limit its use in certain environments, necessitating additional treatments.

Impact on Application: Commonly used in aircraft fittings and structural components, its properties are critical for ensuring safety and reliability.

Considerations for International Buyers: Buyers should be mindful of the need for surface treatments and the importance of adhering to aerospace standards prevalent in Europe and the Middle East.

Summary Table of Common Aluminum Alloys for Machining Services

| Material | Typical Use Case for aluminum machining services | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum 6061 | Structural components, automotive parts | Excellent machinability and weldability | Moderate corrosion resistance | Medium |

| Aluminum 5052 | Marine applications, fuel tanks | Superior corrosion resistance | Cannot be heat-treated | Medium |

| Aluminum 7075 | Aerospace structures, military applications | Exceptional strength | Poor corrosion resistance | High |

| Aluminum 2024-T3 | Aircraft fittings, structural components | Excellent fatigue resistance | Poor weldability and corrosion resistance | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum machining services

What Are the Key Stages in the Manufacturing Process for Aluminum Machining Services?

Manufacturing aluminum parts involves several critical stages, each designed to ensure precision and quality. Understanding these stages is essential for B2B buyers looking to partner with suppliers who can meet stringent specifications.

Material Preparation: How Is Aluminum Primed for Machining?

The first step in the manufacturing process is the preparation of aluminum materials. This includes selecting the appropriate aluminum alloy based on the desired properties such as strength, weight, and corrosion resistance. Commonly used alloys include 6061, 6063, 7075, and 5052, each chosen for specific applications ranging from automotive components to aerospace fittings.

Once the alloy is selected, the material undergoes processes such as cutting and sawing to create manageable pieces. These initial cuts must be precise, as they will influence the machining process later on. It is crucial for suppliers to maintain strict tolerances during this stage to ensure optimal performance in subsequent machining operations.

Forming: What Techniques Are Employed in Aluminum Machining?

The forming stage typically employs CNC (Computer Numerical Control) machining, which is pivotal for achieving high precision in complex shapes. CNC machines can execute various operations, including milling, turning, and drilling, to produce intricate designs with exceptional accuracy.

Aluminum’s properties allow for relatively easy machining, requiring less power compared to harder metals. Techniques such as high-speed machining are often utilized to enhance efficiency while maintaining quality. Machinists must carefully monitor cutting speeds and feed rates to prevent overheating, which can affect the integrity of the material.

Assembly: How Are Machined Parts Joined Together?

In many cases, machined aluminum components require assembly to create a final product. This can involve welding, riveting, or the use of adhesives. The choice of assembly method depends on the application and the specific properties required for the final product.

Quality control during assembly is crucial, as improper joining can lead to product failure. Suppliers should employ skilled technicians who are adept in the chosen assembly methods and ensure that all joints meet industry specifications.

Finishing: What Processes Enhance the Final Product?

Finishing processes are essential for enhancing the appearance and durability of aluminum components. Common finishing techniques include anodizing, powder coating, and surface treatment. Anodizing, for example, not only improves corrosion resistance but also allows for aesthetic customization through color options.

Quality assurance in this stage focuses on ensuring that the finish meets both functional and aesthetic criteria. Rigorous testing is often conducted to assess the durability of finishes, especially for parts used in harsh environments.

What Quality Control Measures Are Essential in Aluminum Machining Services?

Quality control (QC) is a critical aspect of the aluminum machining process, ensuring that the final products meet the required specifications and standards. B2B buyers should be familiar with various international standards and industry-specific requirements that suppliers must adhere to.

Which International Standards Should B2B Buyers Look for?

The ISO 9001 standard is widely recognized for quality management systems and is crucial for suppliers in the aluminum machining industry. This standard ensures that companies consistently meet customer and regulatory requirements, thereby enhancing customer satisfaction.

Other industry-specific standards may include CE marking for products sold in Europe, which indicates compliance with health and safety regulations, and API standards for components used in the oil and gas sector. B2B buyers should verify that their suppliers possess the relevant certifications, as this can significantly impact product reliability and marketability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in aluminum machining services typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial inspection stage verifies the quality of raw materials before they are used in production. It includes assessing material certifications and conducting preliminary tests for composition and mechanical properties.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to ensure that machining processes adhere to specified tolerances. This may involve using precision measuring tools and techniques such as CMM (Coordinate Measuring Machine) inspections.

-

Final Quality Control (FQC): Once the machining process is complete, final inspections are performed to confirm that the finished products meet all specifications. This includes dimensional checks, surface finish evaluations, and functional testing, depending on the application.

What Common Testing Methods Are Used in Aluminum Machining?

B2B buyers should be aware of the various testing methods employed in the quality assurance process. Common techniques include:

-

Mechanical Testing: This includes tensile tests to evaluate strength, elongation, and hardness. Such tests are crucial for ensuring that the aluminum components can withstand the stresses they will encounter in their intended applications.

-

Non-Destructive Testing (NDT): Methods like ultrasonic testing and X-ray inspections help detect internal flaws without damaging the components. These tests are especially important for applications in aerospace and automotive industries where safety is paramount.

-

Surface Testing: Techniques such as visual inspections and surface roughness measurements ensure that the finishing processes have been effectively applied and that the components meet aesthetic and functional requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of a supplier’s quality control practices is essential for B2B buyers, especially when sourcing from international markets. Here are some strategies to consider:

What Steps Can Buyers Take to Audit Suppliers?

Conducting audits of potential suppliers can provide insight into their quality management systems. Buyers should request to review documentation such as quality manuals, inspection reports, and previous audit results.

Additionally, on-site audits can be beneficial. These visits allow buyers to assess the manufacturing environment, review equipment and processes, and engage with the production team.

How Can Buyers Utilize Third-Party Inspections?

Employing third-party inspection services can further enhance confidence in supplier quality. Third-party inspectors can perform independent evaluations of materials, processes, and finished products, providing unbiased reports that can inform purchasing decisions.

What Are the QC Considerations for International Buyers?

When sourcing aluminum machining services internationally, buyers must consider potential nuances in quality control practices. Different countries may have varying regulations and standards, which can affect product quality.

Buyers should familiarize themselves with local standards and practices to ensure compliance and assess whether suppliers can meet international quality benchmarks. This knowledge can help mitigate risks associated with cross-border sourcing and ensure that products meet the necessary requirements for their specific markets.

Conclusion: Ensuring Quality in Aluminum Machining Services

For B2B buyers, understanding the manufacturing processes and quality assurance measures in aluminum machining services is crucial for making informed decisions. By familiarizing themselves with the stages of production, relevant quality standards, and verification methods, buyers can confidently select suppliers that align with their business needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum machining services’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking aluminum machining services. It outlines crucial steps to ensure you select a supplier that meets your project requirements, delivers high-quality products, and adheres to industry standards. By following these steps, you can streamline your sourcing process and make informed decisions that enhance your operational efficiency.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications of the aluminum components you need. This includes dimensions, tolerances, alloy types, and surface finishes. Providing detailed specifications helps suppliers understand your requirements and ensures that the final products meet your expectations.

- Key Considerations:

- Identify the specific aluminum alloy needed (e.g., 6061, 7075).

- Determine the necessary tolerances and surface treatments.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of aluminum machining services. Look for companies with a strong reputation in your industry and positive customer feedback. This initial research will help you build a list of qualified candidates.

- Key Actions:

- Utilize online directories and industry forums to find suppliers.

- Check reviews and testimonials from other businesses.

Step 3: Evaluate Supplier Capabilities

Before making a commitment, assess the capabilities of each supplier. This includes their machining technology, production capacity, and quality control processes. Understanding these aspects will help you gauge whether they can meet your project demands.

- Key Questions:

- What type of CNC machines do they utilize?

- Can they handle your required production volume?

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you are considering hold relevant industry certifications and comply with international standards. Certifications such as ISO 9001 demonstrate a commitment to quality management and can be a critical factor in supplier selection.

- Important Certifications:

- ISO 9001 for quality management.

- ISO 14001 for environmental management.

Step 5: Request Quotes and Compare Pricing

Obtain detailed quotes from multiple suppliers to compare pricing structures. Look for transparency in their pricing, including any additional costs for tooling, setup, or shipping. This will help you identify the best value for your investment.

- What to Analyze:

- Breakdown of costs for each component.

- Lead times and payment terms.

Step 6: Assess Communication and Support

Evaluate the level of communication and support offered by each supplier. Responsive communication is vital for addressing concerns and ensuring smooth project execution. Test their responsiveness by reaching out with questions during your evaluation process.

- Key Indicators:

- Speed of response to inquiries.

- Willingness to provide additional information or clarification.

Step 7: Conduct a Final Supplier Audit

Before finalizing your decision, consider conducting an on-site audit or requesting a virtual tour of the supplier’s facilities. This will give you insight into their operational practices, quality control measures, and overall manufacturing environment.

- What to Look For:

- Cleanliness and organization of the production area.

- Evidence of quality control practices in place.

By following this checklist, B2B buyers can ensure they select a reliable aluminum machining service provider that aligns with their technical needs and business objectives.

Comprehensive Cost and Pricing Analysis for aluminum machining services Sourcing

What Are the Key Cost Components of Aluminum Machining Services?

When sourcing aluminum machining services, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of aluminum alloy significantly influences cost. Common alloys like 6061, 6063, and 7075 vary in price due to their unique properties and applications. For instance, high-strength alloys like 7050 tend to be more expensive than general-purpose alloys due to their specialized characteristics.

-

Labor: Skilled labor is essential in CNC machining. Labor costs can fluctuate based on the complexity of the project, the level of expertise required, and regional wage differences. For international buyers, labor costs may also be affected by local economic conditions.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient operations can help mitigate these costs, so inquire about a supplier’s operational efficiency during negotiations.

-

Tooling: Tooling costs can vary depending on the complexity and volume of the parts being produced. Custom tooling can be expensive but may be necessary for high-precision components. Consider whether the supplier includes tooling costs in their pricing or if they are billed separately.

-

Quality Control (QC): Implementing a robust QC process ensures that the machined parts meet specified tolerances and standards. This adds an additional layer of cost but is crucial for industries such as aerospace and automotive where precision is paramount.

-

Logistics: Shipping costs can greatly impact the total cost of ownership. Factors such as distance, shipping method, and Incoterms can influence logistics expenses. For international buyers, understanding these terms is critical to avoid unexpected costs.

-

Margin: Suppliers will typically add a profit margin to cover their operational risks and ensure sustainability. This margin can vary based on market conditions, supplier reputation, and the complexity of the project.

How Do Price Influencers Affect Aluminum Machining Costs?

Several factors can influence the pricing of aluminum machining services:

-

Volume/MOQ: Larger orders often benefit from economies of scale, leading to lower per-unit costs. Discuss minimum order quantities (MOQs) with suppliers to maximize cost efficiency.

-

Specifications and Customization: Highly specialized parts requiring intricate designs or custom features may incur additional costs. Clearly defining specifications upfront can help avoid unexpected price increases later in the process.

-

Material Selection: The type of aluminum alloy selected can affect pricing. Alloys with superior properties or those that are less common may come at a premium.

-

Quality Certifications: Suppliers with certifications such as ISO or AS9100 may charge higher prices, but the assurance of quality and compliance can justify the cost, especially in regulated industries.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can significantly impact pricing. For international buyers, sourcing from regions with lower labor costs may provide savings, but consider potential trade-offs in quality and service.

-

Incoterms: Understanding the agreed-upon Incoterms (e.g., FOB, CIF) is vital for accurately assessing total costs, including shipping, insurance, and duties.

What Are Effective Buyer Tips for Cost-Efficiency in Aluminum Machining?

To maximize value and minimize costs in aluminum machining services, consider these actionable strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage quotes from multiple suppliers to strengthen your position.

-

Evaluate Total Cost of Ownership (TCO): Focus on the long-term implications of your purchase, including maintenance, potential rework, and logistics. A lower initial price may lead to higher costs down the line if quality is compromised.

-

Understand Pricing Nuances for International Sourcing: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and trade regulations that could affect pricing. Collaborating with local suppliers may mitigate some of these risks.

-

Request Detailed Quotes: Ask suppliers for itemized quotes that break down costs. This transparency helps in comparing offers and understanding where savings can be achieved.

Disclaimer on Indicative Prices

Pricing for aluminum machining services can fluctuate based on market conditions, material availability, and supplier capabilities. Always request updated quotes to ensure accuracy in your budgeting process.

Alternatives Analysis: Comparing aluminum machining services With Other Solutions

Introduction to Alternatives in Machining Services

When considering aluminum machining services, it’s essential for B2B buyers to evaluate alternative solutions that may better suit their specific manufacturing needs. Different machining techniques and materials can offer unique advantages in terms of performance, cost-efficiency, and application suitability. This analysis will compare aluminum machining services with two viable alternatives: plastic machining services and 3D printing technologies.

Comparison Table

| Comparison Aspect | Aluminum Machining Services | Plastic Machining Services | 3D Printing Technologies |

|---|---|---|---|

| Performance | High precision and strength; excellent for structural components | Moderate precision; suitable for non-structural applications | Variable precision; ideal for complex geometries but may require post-processing |

| Cost | Moderate to high; depends on complexity and volume | Generally lower; cost-effective for high volumes | Variable; initial setup can be high, but low-cost for small batches |

| Ease of Implementation | Requires skilled labor and specialized machinery | Easier to implement; many standard processes available | Requires expertise in software and design; can be complex |

| Maintenance | High maintenance due to machinery wear | Lower maintenance; simpler equipment | Moderate; printers require regular calibration and maintenance |

| Best Use Case | Aerospace, automotive, and heavy-duty applications | Consumer products, prototypes, and low-stress applications | Rapid prototyping, custom designs, and low-volume production |

Detailed Breakdown of Alternatives

Plastic Machining Services

Plastic machining services involve shaping plastic materials into desired forms through processes like CNC machining or injection molding. While these services generally offer lower costs and easier implementation than aluminum machining, they are best suited for non-structural applications where high strength is not critical. The precision of plastic machining can be moderate, which might not meet the stringent requirements of industries like aerospace or automotive. However, for consumer products and prototypes, plastic machining can be an effective and economical choice.

3D Printing Technologies

3D printing, or additive manufacturing, is a rapidly evolving technology that allows for the creation of complex geometries directly from digital models. This method excels in rapid prototyping and is particularly advantageous for custom designs and low-volume production runs. However, the performance can vary significantly depending on the material used and the printing technology applied. While 3D printing can reduce material waste and lead times, it may require post-processing to achieve the desired finish and strength, which can add to the overall cost and complexity of implementation.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right machining service requires careful consideration of your specific application, budget, and production needs. Aluminum machining services are ideal for high-strength, high-precision requirements, making them suitable for demanding industries. Conversely, if cost-effectiveness and ease of implementation are priorities, plastic machining might be a better option for less critical applications. For projects needing rapid prototyping or intricate designs, 3D printing could be the most advantageous choice. Ultimately, assessing the performance, cost, and best use cases of each alternative will empower B2B buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for aluminum machining services

What Are the Key Technical Properties in Aluminum Machining Services?

When considering aluminum machining services, understanding critical specifications is essential for making informed decisions. Here are some of the most important properties to keep in mind:

1. Material Grade

Aluminum comes in various grades, each with unique characteristics suitable for different applications. Common grades include 6061, 6063, and 7075. For example, 6061 is widely regarded for its versatility and good machinability, while 7075 is known for its high strength, making it ideal for aerospace applications. Selecting the appropriate grade is crucial for ensuring that the final product meets specific performance requirements.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. In machining, tight tolerances (often in the range of ±0.005 inches or less) are vital for ensuring parts fit correctly in assemblies. Precision in tolerance can significantly affect the functionality and reliability of the final product, especially in industries like aerospace and automotive, where safety is paramount.

3. Surface Finish

The surface finish of machined aluminum parts can affect their performance and aesthetic appeal. Common finishes include anodizing, which enhances corrosion resistance, and bead blasting, which improves surface texture. For B2B buyers, specifying the required surface finish is important to ensure that the parts meet both functional and aesthetic standards.

4. Hardness

Hardness measures a material’s resistance to deformation or scratching, which is vital in applications where wear and tear are expected. Aluminum alloys can vary significantly in hardness, with some, like 7075, being much harder than others. Understanding hardness is essential for selecting materials that can withstand operational stresses without compromising integrity.

5. Weight-to-Strength Ratio

Aluminum is prized for its excellent weight-to-strength ratio, making it ideal for applications where reducing weight without sacrificing strength is critical. This property is particularly important in industries such as aerospace and automotive, where every gram counts toward efficiency and performance.

6. Electrical Conductivity

Aluminum’s natural conductivity makes it a preferred choice for electrical applications, such as wiring and connectors. When sourcing aluminum machining services, considering the conductivity of the alloy is essential for ensuring it meets the electrical performance requirements of your project.

What Are Common Trade Terminology Used in Aluminum Machining Services?

Navigating the world of aluminum machining involves familiarity with specific industry jargon. Here are several key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of aluminum machining, an OEM may require custom machined parts that meet specific design and quality standards for their finished products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs effectively and avoid excess stock. In aluminum machining, MOQs can vary based on the complexity and cost of the machining process.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers requesting pricing and terms for specific products or services. This process helps buyers compare costs and services across different suppliers, ensuring that they receive competitive quotes for their aluminum machining needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. For B2B buyers in aluminum machining, understanding Incoterms is essential for clarifying shipping costs, risks, and delivery responsibilities, which can significantly impact the overall cost and timing of a project.

5. CNC (Computer Numerical Control)

CNC refers to the automation of machine tools using computer programming. CNC machining allows for high precision and repeatability in the production of aluminum parts, making it a preferred method in modern manufacturing. Familiarity with CNC capabilities can help buyers assess potential suppliers’ technological competencies.

6. Tolerance Levels

Tolerance levels indicate the precision with which parts are manufactured. Different industries have varying requirements for tolerance, making it essential for buyers to communicate their needs clearly to ensure the final product meets operational specifications.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing aluminum machining services, ultimately leading to successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the aluminum machining services Sector

What Are the Key Market Dynamics and Trends Impacting Aluminum Machining Services?

The aluminum machining services sector is undergoing significant transformation driven by various global trends. One of the primary factors is the increasing demand for lightweight materials across industries such as aerospace, automotive, and medical. As manufacturers seek to enhance fuel efficiency and reduce emissions, aluminum’s impressive strength-to-weight ratio makes it a preferred choice. Additionally, advancements in CNC machining technology are enabling the production of complex, high-precision components faster and more cost-effectively.

Emerging technologies such as automation and artificial intelligence are reshaping sourcing dynamics. Companies are investing in smart manufacturing systems that optimize production processes, reduce waste, and enhance quality control. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these trends is critical. They must evaluate suppliers not just on price, but also on their technological capabilities and commitment to innovation.

Furthermore, the growth of e-commerce platforms has facilitated easier access to global suppliers. Buyers can now leverage online quoting tools to compare prices and lead times, streamlining their sourcing processes. As competition intensifies, firms that can offer tailored solutions and quick turnaround times will have a competitive edge.

How Can Sustainability and Ethical Sourcing Impact My B2B Aluminum Machining Decisions?

Sustainability has become a central theme in sourcing decisions, particularly in the aluminum machining services industry. The environmental impact of aluminum production, primarily due to its energy-intensive extraction and processing stages, necessitates a focus on recycling and sustainable practices. Approximately 75% of all aluminum produced is still in use today, highlighting the importance of recycling in reducing the carbon footprint associated with new production.

B2B buyers should prioritize suppliers that demonstrate a commitment to ethical sourcing and sustainability. This includes seeking partners with certifications such as ISO 14001 for environmental management or those that utilize green materials in their machining processes. By choosing suppliers that adhere to sustainable practices, businesses can enhance their brand reputation and meet the growing demand from consumers for environmentally responsible products.

Moreover, companies that incorporate recycled aluminum into their production can achieve significant cost savings and contribute to a circular economy. This approach not only minimizes waste but also aligns with the increasing regulatory pressure on manufacturers to adopt greener practices. As a result, sustainability is not just a trend; it has become a crucial factor influencing sourcing decisions in the aluminum machining services market.

How Has the Aluminum Machining Services Sector Evolved Over Time?

The evolution of aluminum machining services can be traced back to the early days of industrial manufacturing when aluminum was first introduced as a viable material. Initially used in lightweight applications, its popularity surged during the mid-20th century, particularly in the aerospace and automotive sectors. Technological advancements in machining processes, particularly the advent of CNC technology in the late 20th century, revolutionized how aluminum components were produced, enabling greater precision and efficiency.

Over the years, the introduction of various aluminum alloys has further expanded the applications of aluminum machining services. Each alloy offers unique properties suited to specific industries, from corrosion resistance in marine applications to high-strength options for aerospace components. Today, as industries increasingly prioritize customization and rapid prototyping, aluminum machining services continue to adapt, driven by technological innovation and the need for sustainable practices. This ongoing evolution is essential for B2B buyers looking for cutting-edge solutions to meet their complex manufacturing needs.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum machining services

-

How do I choose the right aluminum machining supplier?

Selecting the right supplier involves evaluating their experience, capabilities, and reputation. Look for suppliers with proven expertise in aluminum machining and a portfolio that aligns with your industry needs. Assess their certifications, such as ISO 9001, to ensure quality management practices. Additionally, request references from other clients and inquire about their delivery times and flexibility in handling changes in order quantities. Conducting a site visit can also provide insights into their manufacturing processes and quality controls. -

What is the best aluminum alloy for my machining project?

The best aluminum alloy depends on your specific application requirements. For general purposes, Aluminum 6061 is a versatile choice known for its excellent machinability and weldability. If weight and strength are critical, consider Aluminum 7075, which offers high strength but lower corrosion resistance. For applications requiring good corrosion resistance, Aluminum 5052 is ideal. Always discuss your project needs with suppliers to ensure the selected alloy meets both performance and cost considerations. -

What are the typical minimum order quantities (MOQ) for aluminum machining services?

Minimum order quantities can vary significantly between suppliers and depend on factors like the complexity of the part and the machining processes required. Generally, MOQs for aluminum machining can range from a few pieces to hundreds, especially for high-volume production runs. It’s essential to communicate your specific needs upfront, as some suppliers may be willing to accommodate smaller orders or offer flexible solutions based on your project’s context. -

What payment terms should I expect when sourcing aluminum machining services internationally?

Payment terms for international transactions typically include options such as advance payment, net 30, or letter of credit. Suppliers may request partial payment upfront, especially for custom orders, with the balance due upon delivery or after inspection. It is crucial to clarify these terms before finalizing contracts to avoid misunderstandings. Additionally, consider using secure payment methods that protect both parties, such as escrow services for larger transactions. -

How can I ensure the quality of the aluminum parts produced?

Ensuring quality starts with selecting a reputable supplier that adheres to strict quality management standards. Request to review their quality assurance processes, including inspection protocols and certifications. Ask for first-article inspections and ongoing quality checks throughout the production process. Additionally, consider implementing a supplier audit process to verify their adherence to quality standards and to establish clear specifications and tolerances for your parts. -

What logistics considerations should I keep in mind when sourcing aluminum machining services from abroad?

Logistics play a crucial role in international sourcing. Consider shipping costs, lead times, and customs regulations that may affect delivery. Work with suppliers who have experience in international shipping to navigate these complexities smoothly. It’s also advisable to establish a clear timeline for production and delivery, including buffer times for unexpected delays. Collaborating with a logistics partner can help streamline the process and ensure timely delivery of your components. -

How do I handle communication and collaboration with an overseas aluminum machining supplier?

Effective communication is key to successful collaboration with overseas suppliers. Establish clear communication channels, such as regular video calls, emails, and project management tools, to keep everyone on the same page. Clearly outline project specifications, timelines, and expectations in written documents to minimize misunderstandings. Be mindful of time zone differences and cultural nuances that may impact interactions. Regular updates and feedback loops can also enhance collaboration and project outcomes. -

What are the environmental considerations when sourcing aluminum machining services?

Environmental sustainability is increasingly important in manufacturing. When sourcing aluminum machining services, inquire about the supplier’s practices regarding waste management, energy consumption, and the use of recyclable materials. Many aluminum suppliers now focus on sustainable practices, such as using recycled aluminum and minimizing emissions. Understanding these practices not only helps you comply with environmental regulations but can also enhance your brand’s reputation in the marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for aluminum machining services

In the dynamic landscape of aluminum machining services, strategic sourcing emerges as a critical driver for enhancing operational efficiency and product quality. By leveraging advanced CNC machining technologies, businesses can benefit from aluminum’s lightweight yet robust characteristics, making it an ideal choice across various industries, including aerospace, automotive, and medical. The emphasis on precision, repeatability, and sustainability not only meets the growing demand for high-quality components but also aligns with global trends toward eco-friendly manufacturing practices.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the selection of reliable aluminum machining partners is paramount. Engaging with suppliers that demonstrate expertise in diverse aluminum alloys, such as 6061 and 7075, can significantly impact your product development timelines and overall competitiveness in the market.

As we look to the future, the integration of automation, AI, and innovative materials will redefine the boundaries of aluminum machining capabilities. Now is the time to explore these opportunities—connect with experienced machining service providers to elevate your manufacturing processes and ensure your business remains at the forefront of industry advancements.