Top 8 3D Printing Service Prototyping Manufacturers & Suppliers List

1. Protolabs – On-Demand 3D Printing Services

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Online 3D Printing Service offering on-demand 3D printing for rapid prototyping and production in as fast as 1 day. Six 3D printing technologies available: Metal 3D Printing (Direct Metal Laser Sintering), Multi Jet Fusion, Stereolithography, PolyJet, Selective Laser Sintering, and Advanced Photopolymers. Over 120 additive manufacturing machines with capacity to print 250,000+ parts monthly. Certi…

2. Formlabs – Rapid Prototyping Solutions

Domain: formlabs.com

Registered: 2009 (16 years)

Introduction: 3D Printing Applications: Rapid Prototyping with Formlabs 3D printers enables in-house production of prototypes within a day, allowing for multiple design iterations based on real-life testing. Key features include:

– Concept Exploration: Create low-risk concept models and proof-of-concept prototypes quickly from CAD designs.

– Functional Prototyping: Produce prototypes with material properties si…

3. Craftcloud – 3D Printing & Manufacturing Services

Domain: craftcloud3d.com

Registered: 2018 (7 years)

Introduction: Craftcloud offers a streamlined 3D printing service with various manufacturing services including 3D Printing, CNC Machining, Sheet Metal Fabrication, and Casting & Molding. They provide over 170 unique materials such as SLS Nylon PA12, 316L Stainless Steel, HP® MJF Nylon PA12, PLA, and Standard Resin. The platform supports over 35 file formats for model uploads and features more than 20 different…

4. Hubs – Instant 3D Printing Quotes

Domain: hubs.com

Registered: 1998 (27 years)

Introduction: Online 3D printing service offering instant quotes for custom manufacturing. Capabilities include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Multi Jet Fusion (MJF). Services include CNC machining, sheet metal fabrication, and injection molding. Quality certifications include ISO 9001, ISO 13485, and AS9100. Lead times range from 1 to 3 business d…

5. PCBWay – 3D Printing Services

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: 3D Printing Service offering FDM, SLA, MJF, SLS, and DMLS technologies for producing plastic and metal parts. Key features include high-quality prototypes and production parts, high precision, and superb service. Materials available include various plastics (ABS, Nylon, PLA, PETG, etc.) and metals (Aluminum, Stainless steel, Titanium, etc.). Industries served include Automotive, Industrial machine…

6. Shapeways – 3D Printing Services

Domain: shapeways.com

Registered: 2008 (17 years)

Introduction: 3D Printing Service Online; Manufacturing Technologies: Additive Manufacturing, Selective Laser Sintering (SLS), Binder Jetting, Multi Jet Fusion (MJF), Stereolithography (SLA), Selective Laser Melting (SLM), Material Jetting, Fused Deposition Modeling (FDM), Wax Casting; Materials: Nylon 12 (PA12), Nylon 11 (PA11), Thermoplastic Elastomer (TPE), Stainless Steel 17-4 PH, Stainless Steel 316L, Full…

7. Sculpteo – Online 3D Printing Service

Domain: sculpteo.com

Registered: 2009 (16 years)

Introduction: Online 3D Printing Service, Instant Quotes, Free shipping and 10% off first order, 30+ materials for any application, ISO 9001 & ISO 13485 certified, Secure File Upload, Fast Turnaround, Shipping worldwide, 3D printing technologies include SLS, SLA, FDM, MJF, DMLS, SLM, Advanced finishing services like polishing, chemical smoothing, dyeing, 1000+ parts printed per day, 10,000+ happy customers each…

8. Stratasys – Advanced 3D Printing Solutions

Domain: stratasys.com

Registered: 1993 (32 years)

Introduction: Advanced Rapid Prototyping with 3D Printing enables faster and more accurate product development compared to traditional methods. Key products include: J35™ Pro Desktop 3D printer (small footprint, low-maintenance, silent operation), J55™ Prime (640,000 color options, five resins simultaneously), J850™ Prime (large-capacity, multi-material, full-color models), Neo® Series (high surface quality, re…

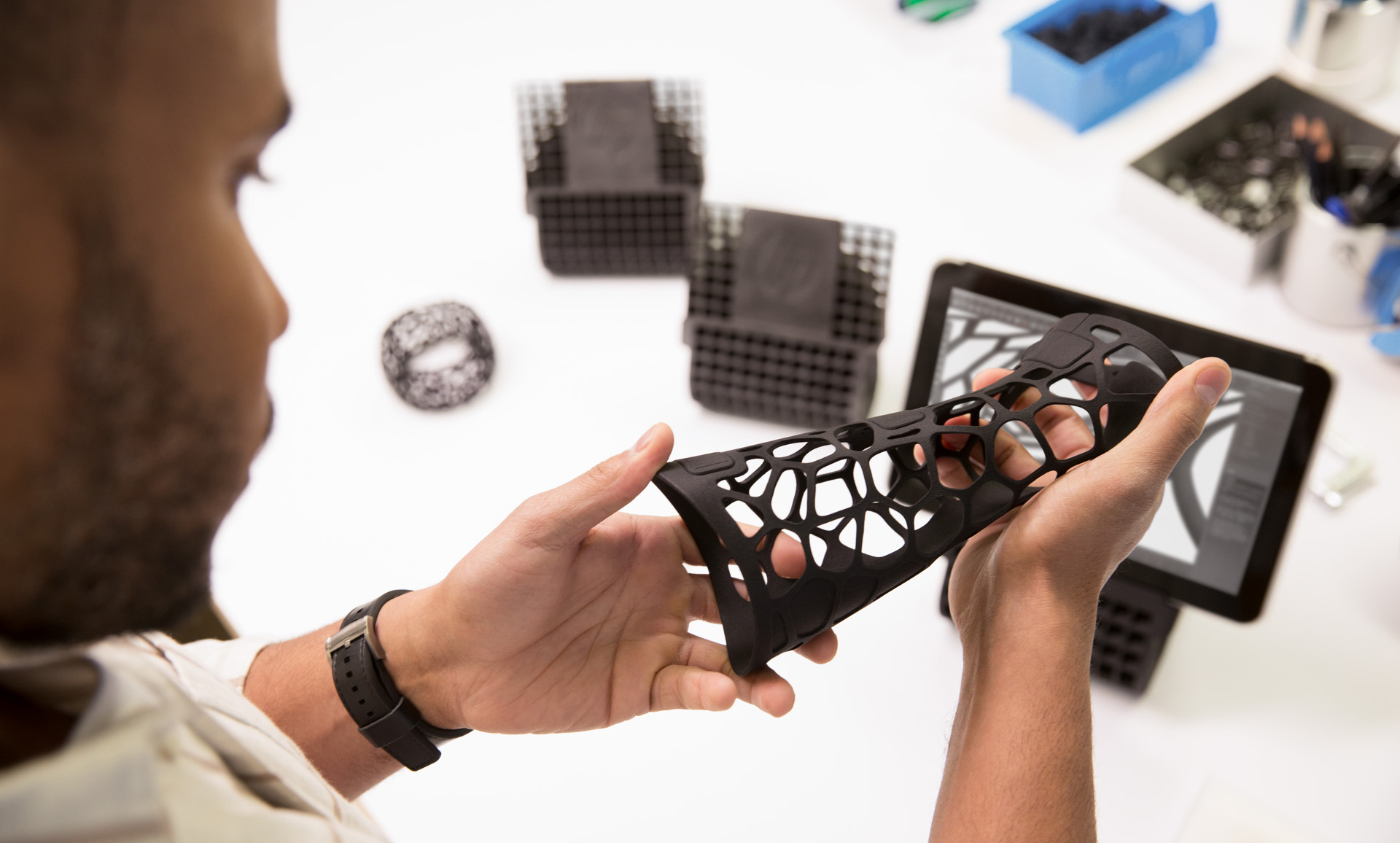

Introduction: Navigating the Global Market for 3d printing service prototyping

In the dynamic landscape of manufacturing, sourcing reliable 3D printing service prototyping solutions poses a significant challenge for international B2B buyers. As companies strive to accelerate product development and reduce time-to-market, the need for efficient prototyping methods becomes paramount. This guide offers a comprehensive exploration of the global market for 3D printing services, detailing various technologies, materials, and applications available to businesses today. From understanding the nuances of Selective Laser Sintering (SLS) and Stereolithography (SLA) to evaluating the strengths of different materials such as nylon and ABS, this resource serves as a vital tool for informed decision-making.

By delving into key aspects such as supplier vetting processes, cost considerations, and quality certifications, this guide empowers buyers from diverse regions—including Africa, South America, the Middle East, and Europe—to navigate the complexities of sourcing 3D printing services effectively. With an emphasis on practical insights and strategic recommendations, it equips businesses to select partners that align with their specific needs, ensuring they can leverage 3D printing technologies to enhance innovation and competitiveness in their respective markets. Ultimately, this guide is designed to transform the way international B2B buyers approach prototyping, fostering confidence and clarity in their purchasing decisions.

Understanding 3d printing service prototyping Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stereolithography (SLA) | Utilizes UV lasers to cure resin layer by layer for high precision. | Prototyping intricate designs, dental models. | Pros: High detail, smooth finish. Cons: Limited material strength. |

| Selective Laser Sintering (SLS) | Fuses powdered materials using a laser, suitable for complex geometries. | Functional prototypes, end-use parts. | Pros: Strong, durable parts. Cons: Surface finish may require post-processing. |

| Fused Deposition Modeling (FDM) | Extrudes thermoplastic filament layer by layer, widely accessible. | Low-cost prototyping, educational applications. | Pros: Cost-effective, versatile materials. Cons: Lower resolution compared to SLA/SLS. |

| Multi Jet Fusion (MJF) | Applies agents to nylon powder, enhancing strength and detail. | Production parts, complex assemblies. | Pros: Fast production, excellent mechanical properties. Cons: Higher setup costs. |

| Direct Metal Laser Sintering (DMLS) | Uses lasers to fuse metal powder into fully dense parts. | Aerospace, medical implants, tooling. | Pros: High strength, complex metal geometries. Cons: Expensive materials and processes. |

What Are the Characteristics of Stereolithography (SLA) in 3D Printing Service Prototyping?

Stereolithography (SLA) is known for its exceptional precision and smooth surface finishes, making it ideal for applications requiring intricate details, such as dental models and prototypes of consumer products. SLA printers use UV lasers to cure liquid resin layer by layer, resulting in highly accurate parts. B2B buyers should consider SLA when aesthetics and detail are paramount, although they should be aware that the material strength may not be as high as other methods.

How Does Selective Laser Sintering (SLS) Benefit B2B Buyers?

Selective Laser Sintering (SLS) is a robust 3D printing technique that uses a laser to fuse powdered materials, allowing for the production of complex geometries and functional prototypes. It is particularly beneficial for industries requiring durable parts, such as automotive and aerospace. B2B buyers should consider SLS for applications where strength and functional performance are essential, but they may need to factor in potential post-processing for surface finish improvements.

Why Choose Fused Deposition Modeling (FDM) for Prototyping?

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing methods due to its cost-effectiveness and ease of use. It works by extruding thermoplastic filament, making it suitable for low-cost prototypes and educational purposes. While FDM is versatile and offers a range of materials, B2B buyers should note that it typically offers lower resolution compared to SLA and SLS, making it less suitable for highly detailed applications.

What Are the Advantages of Multi Jet Fusion (MJF) for Production Parts?

Multi Jet Fusion (MJF) is a cutting-edge technology that applies fusing and detailing agents to nylon powder, leading to parts with excellent mechanical properties and details. This method is ideal for producing complex assemblies and functional parts rapidly. B2B buyers should consider MJF for high-volume production, but they should also be aware of potentially higher setup costs compared to other methods.

When Should B2B Buyers Consider Direct Metal Laser Sintering (DMLS)?

Direct Metal Laser Sintering (DMLS) is a specialized process that fuses metal powders using lasers, allowing for the creation of complex metal parts that are fully dense. This technology is particularly relevant for industries like aerospace and medical, where high strength and intricate designs are critical. While DMLS offers significant advantages in terms of material properties, B2B buyers must consider the higher costs associated with materials and the printing process itself.

Key Industrial Applications of 3d printing service prototyping

| Industry/Sector | Specific Application of 3D Printing Service Prototyping | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Rapid prototyping of complex components | Reduced lead times and costs for part development | Certifications (ISO, ITAR), material specifications, speed of delivery |

| Automotive | Production of functional prototypes for testing | Enhanced design validation and performance testing | Tolerance requirements, material compatibility, scalability |

| Healthcare | Custom medical devices and implants | Personalized solutions that improve patient outcomes | Biocompatibility, regulatory compliance, precision requirements |

| Consumer Electronics | Prototyping enclosures and components | Faster time-to-market for new products | Design flexibility, prototyping speed, material options |

| Industrial Equipment | Creating tooling and fixtures for production | Cost-effective manufacturing solutions and improved efficiency | Material durability, lead times, design complexity |

How is 3D Printing Service Prototyping Used in Aerospace?

In the aerospace sector, 3D printing service prototyping is employed for rapid prototyping of complex components, such as brackets and housings. This technology allows manufacturers to produce parts with intricate geometries that traditional methods struggle to achieve. By using additive manufacturing, companies can significantly reduce lead times and costs associated with part development. International buyers must ensure that suppliers hold relevant certifications (e.g., ISO, ITAR) and can provide materials that meet stringent performance requirements.

What are the Applications of 3D Printing in the Automotive Industry?

The automotive industry utilizes 3D printing for the production of functional prototypes used in testing and validation processes. This allows manufacturers to iterate designs quickly, ensuring that the final products meet performance and safety standards. The ability to create prototypes that mimic the mechanical properties of final parts helps in reducing time-to-market. Buyers in regions like Africa and South America should focus on sourcing partners that can meet specific tolerance requirements and offer materials compatible with automotive applications.

How is 3D Printing Transforming Healthcare Solutions?

In healthcare, 3D printing service prototyping is pivotal for creating custom medical devices and implants tailored to individual patient needs. This personalization enhances patient outcomes and improves surgical efficiency. The technology also facilitates the rapid development of prototypes for testing new medical solutions. International B2B buyers must prioritize suppliers who can demonstrate biocompatibility and compliance with regulatory standards to ensure safety and efficacy in medical applications.

What Role Does 3D Printing Play in Consumer Electronics?

3D printing is increasingly used in the consumer electronics sector for prototyping enclosures and components, enabling companies to bring new products to market more swiftly. This technology allows for greater design flexibility and rapid iterations, which are critical in a fast-paced industry. Buyers should consider suppliers that can provide a variety of material options and demonstrate quick turnaround times to keep up with consumer demand.

How is 3D Printing Beneficial for Industrial Equipment Manufacturing?

In industrial equipment manufacturing, 3D printing service prototyping is essential for creating tooling and fixtures that enhance production efficiency. This approach reduces costs and improves manufacturing workflows by allowing for the rapid production of custom tools. Buyers should assess the durability of materials used, as well as the lead times and complexity of designs to ensure that their sourcing aligns with production needs.

3 Common User Pain Points for ‘3d printing service prototyping’ & Their Solutions

Scenario 1: Unpredictable Lead Times for Prototypes

The Problem: B2B buyers often face the challenge of unpredictable lead times when ordering prototypes through 3D printing services. For instance, a product development team in Nigeria might require a prototype for an upcoming trade show but discover that the estimated delivery time fluctuates significantly. This uncertainty can jeopardize product launch timelines, lead to missed opportunities, and strain relationships with stakeholders who rely on timely updates.

The Solution: To mitigate the risk of unpredictable lead times, B2B buyers should prioritize working with 3D printing services that provide transparent and reliable timelines. It’s essential to request a detailed breakdown of the production process, including setup, material sourcing, and post-processing stages. Buyers should also explore services that offer expedited options, allowing for quicker turnaround times without sacrificing quality. Furthermore, establishing a buffer in project timelines can accommodate potential delays, ensuring that prototypes arrive in a timely manner even if unforeseen issues arise.

Scenario 2: Limited Material Options Leading to Compromised Quality

The Problem: A common issue faced by businesses, particularly in Africa and South America, is the limited range of materials available for 3D printing services. For example, a manufacturing company may require a prototype made from a specific type of nylon for a high-stress application, but the service provider only offers basic plastics. This limitation can lead to compromised functionality and performance of prototypes, ultimately affecting product quality and market readiness.

The Solution: To address this pain point, B2B buyers should conduct thorough research on the material capabilities of potential 3D printing partners before placing orders. It’s advisable to inquire about the full spectrum of materials, including advanced options like carbon-fiber reinforced plastics or specialty metals. Buyers should also engage in discussions about custom material solutions, as some providers may be open to sourcing or developing materials tailored to specific project requirements. Building a relationship with a versatile supplier who can accommodate diverse material needs will significantly enhance the quality and performance of prototypes.

Scenario 3: Difficulty in Achieving Desired Tolerances and Specifications

The Problem: Achieving precise tolerances and specifications is crucial for many B2B buyers, especially in industries like aerospace or medical devices. A common scenario occurs when a European engineering firm requests a prototype with specific dimensional tolerances, only to receive parts that fall short of the required standards. This misalignment can lead to increased costs due to reprints and delays in the overall project timeline.

The Solution: To ensure that prototypes meet the desired tolerances, B2B buyers should engage in a collaborative design and review process with their 3D printing service provider. This involves sharing detailed CAD files and specifications early in the project and requesting a Design for Additive Manufacturing (DFAM) analysis. Such an analysis helps identify potential issues before production begins. Buyers should also seek providers who offer advanced 3D printing technologies known for high precision, such as Stereolithography (SLA) or Direct Metal Laser Sintering (DMLS). Consistent communication throughout the project, including updates on any potential challenges in meeting specifications, will help maintain alignment and ensure successful outcomes.

Strategic Material Selection Guide for 3d printing service prototyping

What Are the Key Properties of Common 3D Printing Materials for Prototyping?

When selecting materials for 3D printing service prototyping, understanding the properties and performance characteristics of each material is essential. This analysis focuses on four commonly used materials: ABS, Nylon, Polycarbonate, and TPU. Each material has distinct advantages and limitations that can significantly impact the end product’s suitability for specific applications.

How Does ABS Perform in 3D Printing Prototyping?

Acrylonitrile Butadiene Styrene (ABS) is a widely used thermoplastic known for its strength and durability. It has a high impact resistance and can withstand temperatures up to 100°C. ABS is also relatively lightweight, making it suitable for various applications, including automotive and consumer goods.

Pros: ABS is cost-effective, easy to print, and provides a smooth finish. Its versatility allows for post-processing techniques like sanding and painting.

Cons: It has lower chemical resistance and can warp during cooling, which may complicate the manufacturing process. Additionally, it emits fumes during printing, necessitating proper ventilation.

Impact on Application: ABS is compatible with various media but may not be suitable for applications requiring high chemical resistance or prolonged exposure to UV light.

Considerations for International Buyers: Compliance with standards like ASTM D638 is crucial. Buyers from regions like Africa and South America should consider local availability and the need for proper ventilation equipment during printing.

What Makes Nylon a Preferred Choice for Prototyping?

Nylon, particularly in its powdered form, is favored for its excellent mechanical properties, including high tensile strength and flexibility. It can withstand temperatures up to 80°C and has good abrasion resistance.

Pros: Nylon is highly durable, making it ideal for functional prototypes and end-use parts. It also offers excellent layer adhesion, resulting in strong, cohesive parts.

Cons: Nylon can absorb moisture, which may affect its mechanical properties. It is also more expensive than some other materials, which can be a consideration for budget-conscious projects.

Impact on Application: Its durability makes Nylon suitable for applications in automotive, aerospace, and consumer products. However, moisture sensitivity requires careful storage and handling.

Considerations for International Buyers: Buyers should ensure compliance with standards like ISO 9001 and consider the availability of moisture-resistant storage solutions, particularly in humid regions.

Why Choose Polycarbonate for High-Performance Prototyping?

Polycarbonate (PC) is a high-performance thermoplastic known for its exceptional impact resistance and optical clarity. It can withstand temperatures up to 120°C, making it suitable for applications that require heat resistance.

Pros: Polycarbonate is highly durable and can be used for applications requiring transparency, such as lenses and protective covers. Its strength makes it ideal for functional prototypes.

Cons: It is more expensive than ABS and can be challenging to print due to its tendency to warp. Additionally, it requires precise temperature control during the printing process.

Impact on Application: Polycarbonate is suitable for applications in electronics and automotive industries, especially where transparency and impact resistance are critical.

Considerations for International Buyers: Compliance with standards like ASTM D648 is important. Buyers should consider the costs associated with temperature-controlled printing environments, especially in regions with fluctuating climates.

What Are the Benefits of Using TPU in 3D Printing?

Thermoplastic Polyurethane (TPU) is known for its rubber-like elasticity and flexibility. It can endure temperatures up to 80°C and offers excellent abrasion and impact resistance.

Pros: TPU is highly versatile, allowing for the production of flexible prototypes that can withstand repeated stress. It is also resistant to oils and chemicals.

Cons: Printing with TPU can be complex due to its flexibility, requiring specific printer settings and potentially leading to longer print times. It is also more expensive than standard thermoplastics.

Impact on Application: TPU is ideal for applications in automotive parts, medical devices, and consumer products requiring flexibility and durability.

Considerations for International Buyers: Compliance with medical-grade standards is essential for applications in healthcare. Buyers should also consider the availability of specialized printers capable of handling flexible materials.

Summary Table of Material Selection for 3D Printing Service Prototyping

| Material | Typical Use Case for 3D Printing Service Prototyping | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| ABS | Automotive components, consumer goods | Cost-effective and easy to print | Lower chemical resistance, warping | Low |

| Nylon | Functional prototypes, end-use parts | High durability and flexibility | Moisture absorption, higher cost | Medium |

| Polycarbonate | Electronics, automotive parts | Exceptional impact resistance | Expensive, printing complexity | High |

| TPU | Flexible prototypes, medical devices | Rubber-like elasticity | Complex printing process, higher cost | High |

This comprehensive analysis provides a strategic overview for international B2B buyers, helping them make informed decisions when selecting materials for 3D printing service prototyping.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d printing service prototyping

What Are the Main Stages of the Manufacturing Process for 3D Printing Service Prototyping?

The manufacturing process for 3D printing service prototyping involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the final product meets the desired specifications and quality standards.

How Does Material Preparation Influence the Quality of 3D Printed Parts?

Material preparation is the first and foundational step in the 3D printing process. This stage involves selecting and preparing the appropriate materials, which can include plastics, metals, or elastomers. Each material has unique properties and may require specific handling and storage conditions. For instance, metal powders must be kept dry and free from contamination, while thermoplastics may need to be dried to remove moisture before processing.

During this stage, suppliers often conduct pre-production checks to ensure material quality, which can include verifying material certifications and conducting visual inspections. B2B buyers should inquire about material sourcing and quality assurance measures taken by suppliers to ensure that the raw materials are of high quality and suitable for their specific applications.

What Techniques Are Used in the Forming Stage of 3D Printing?

The forming stage is where the actual 3D printing occurs. Various techniques are employed depending on the desired characteristics of the final product. Some of the most common methods include:

-

Fused Deposition Modeling (FDM): This technique extrudes thermoplastic filaments layer by layer. It is widely used for prototyping due to its affordability and ease of use.

-

Stereolithography (SLA): SLA uses a laser to cure liquid resin into solid parts. This method is known for producing high-resolution prototypes with smooth surface finishes.

-

Selective Laser Sintering (SLS): SLS involves fusing powdered materials using a laser, allowing for complex geometries and functional parts.

-

Direct Metal Laser Sintering (DMLS): DMLS is used for creating metal parts, where a laser sinters metal powder into a solid structure. This method is ideal for functional prototypes and end-use parts.

Each of these techniques has specific applications, and B2B buyers should work closely with suppliers to determine the most suitable method for their requirements.

How Does Assembly Fit into the 3D Printing Process?

In many cases, the assembly stage may not be necessary, as 3D printing can produce complex parts in a single process. However, for multi-part assemblies, this stage involves the integration of various components to create a finished product. This may require additional techniques such as welding, fastening, or adhesive bonding.

B2B buyers should clarify whether their prototypes will require assembly and ensure that suppliers have the necessary capabilities and experience to handle complex assemblies.

What Are the Key Finishing Techniques Used After 3D Printing?

Finishing techniques enhance the aesthetic and functional properties of 3D printed parts. Common finishing methods include:

-

Post-Processing: This can involve sanding, polishing, or painting to improve surface quality and appearance.

-

Heat Treatment: For metal parts, heat treatment can improve mechanical properties such as strength and durability.

-

Coating: Applying protective coatings can enhance corrosion resistance and other functional properties.

Buyers should discuss finishing options with suppliers to ensure the final parts meet their specific requirements, both functionally and aesthetically.

What Quality Control Measures Are Critical for 3D Printing Service Prototyping?

Quality assurance is paramount in the 3D printing industry to ensure that products meet international standards and client specifications. Adhering to recognized quality standards helps mitigate risks and enhances trust between suppliers and buyers.

Which International Standards Should B2B Buyers Be Aware Of?

Several international standards govern quality assurance in 3D printing, including:

-

ISO 9001:2015: This standard focuses on quality management systems and is widely recognized across various industries, ensuring consistent product quality.

-

ISO 13485: Specifically for medical devices, this standard ensures that manufacturers meet regulatory requirements.

-

AS9100D: Relevant for aerospace manufacturers, this standard ensures that companies meet strict quality requirements.

-

ITAR Compliance: For companies dealing with defense articles, ensuring compliance with the International Traffic in Arms Regulations is crucial.

B2B buyers should verify that their suppliers are certified to relevant standards, which can be a strong indicator of quality and reliability.

What Are the Key Quality Control Checkpoints in the 3D Printing Process?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified criteria.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed to monitor parameters such as temperature, pressure, and layer adhesion.

-

Final Quality Control (FQC): After production, parts are inspected for dimensional accuracy, surface finish, and overall quality. Common methods include visual inspections, dimensional measurements, and functional tests.

B2B buyers should inquire about the QC processes their suppliers employ, as this can significantly affect the reliability of the prototypes produced.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several actions:

-

Conduct Audits: Regular audits of suppliers’ facilities can help assess their adherence to quality standards and procedures.

-

Request Reports: Suppliers should provide documentation of their quality control processes, including inspection reports and compliance certificates.

-

Utilize Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased evaluation of a supplier’s quality practices.

What Unique QC Considerations Should International Buyers Keep in Mind?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and quality expectations is crucial. Factors to consider include:

-

Import Regulations: Ensure that parts meet the importing country’s regulations and standards, which may differ from those in the supplier’s country.

-

Cultural and Language Differences: Effective communication is essential. Buyers should ensure that all quality expectations are clearly articulated and understood.

-

Supply Chain Logistics: Consider how quality is maintained throughout the supply chain, from material sourcing to final delivery.

By taking these factors into account, B2B buyers can establish strong partnerships with their suppliers and ensure that the 3D printing service prototyping meets their high standards for quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d printing service prototyping’

This guide serves as a comprehensive checklist for B2B buyers seeking to procure 3D printing service prototyping. By following these steps, you can ensure a streamlined sourcing process, identify high-quality suppliers, and ultimately achieve successful prototyping outcomes.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for effective communication with potential suppliers. Detail the dimensions, tolerances, materials, and any specific design requirements your prototypes must meet. This clarity helps suppliers provide accurate quotes and ensures that the final product aligns with your expectations.

- Consider: The intended use of the prototype, whether for functional testing or visual presentation.

- Document: Any industry standards or regulations that must be adhered to, particularly for specialized applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in 3D printing services relevant to your needs. Look for companies with a strong reputation, proven track record, and positive customer reviews. This foundational step is essential to ensure that you partner with a reliable provider.

- Focus on: Companies that have experience in your industry, as they will better understand your unique requirements.

- Utilize: Online platforms, industry forums, and social media to gather insights and feedback from other users.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their technical capabilities and equipment. Review the variety of 3D printing technologies they offer, such as SLS, SLA, or DMLS, and ensure they can accommodate your material and size specifications. This evaluation is vital for guaranteeing that the supplier can deliver high-quality prototypes.

- Ask for: Examples of previous work, including case studies that showcase their expertise in similar projects.

- Inquire about: Their production capacity and turnaround times to ensure they can meet your deadlines.

Step 4: Verify Supplier Certifications

Certifications are indicators of a supplier’s commitment to quality and industry standards. Check for relevant certifications such as ISO 9001:2015, AS9100D, or ITAR registration, which demonstrate compliance with quality management systems and regulatory requirements. This step is essential to mitigate risks associated with quality and reliability.

- Request documentation: To confirm that the supplier maintains these certifications.

- Understand: The implications of non-compliance, especially for industries with stringent regulatory standards.

Step 5: Request Quotes and Compare Costs

Once you have narrowed down your list of potential suppliers, request detailed quotes for your project. Compare not just the prices, but also the terms of service, lead times, and post-processing options. This analysis will help you make an informed decision based on value rather than just cost.

- Consider: Any additional charges for shipping, tariffs, or expedited services.

- Look for: Transparency in pricing to avoid unexpected costs later in the process.

Step 6: Establish Communication Channels

Effective communication is key to a successful partnership. Establish clear communication channels with your chosen supplier to facilitate collaboration throughout the prototyping process. Regular updates and feedback loops will help ensure that the project stays on track and aligns with your specifications.

- Set expectations: For response times and project milestones.

- Utilize: Collaborative tools or platforms that can streamline communication and document sharing.

Step 7: Conduct a Trial Order

Before placing a large order, consider conducting a trial order for a small batch of prototypes. This step allows you to assess the supplier’s capabilities and the quality of their work firsthand. It is an effective way to validate your choice of supplier and make any necessary adjustments before scaling up production.

- Evaluate: The quality, accuracy, and adherence to your specifications.

- Provide feedback: To the supplier, which can help in refining the process for future orders.

Comprehensive Cost and Pricing Analysis for 3d printing service prototyping Sourcing

What Are the Key Cost Components in 3D Printing Service Prototyping?

When sourcing 3D printing services for prototyping, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of material significantly influences the cost. Common materials like ABS and nylon are generally more affordable, while specialized materials such as titanium or advanced photopolymers can be considerably more expensive. Additionally, the form of the material (e.g., filament vs. powder) can impact pricing.

-

Labor: Skilled labor is required for the setup, operation, and post-processing of 3D printing machines. Labor costs can vary based on the complexity of the project and the expertise required.

-

Manufacturing Overhead: This encompasses the costs associated with running the facility, including maintenance of machines, utilities, and administrative expenses. High-capacity facilities with advanced technology may have lower overhead per unit due to economies of scale.

-

Tooling: While 3D printing often requires less tooling compared to traditional manufacturing methods, certain processes may necessitate tooling for specific features or finishing processes, adding to the cost.

-

Quality Control (QC): Ensuring that parts meet specified tolerances and quality standards incurs costs related to inspections, testing, and certification. Compliance with international standards (e.g., ISO certifications) can further influence QC expenses.

-

Logistics: The cost of shipping parts, especially for international orders, can be significant. Factors such as distance, shipping method, and customs duties should be factored into total costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This can vary widely based on market competition and the unique value proposition of the service provider.

How Do Price Influencers Affect 3D Printing Costs?

Several factors can influence the pricing of 3D printing services:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes often lead to lower costs per unit due to economies of scale. Conversely, small orders may incur higher per-piece costs.

-

Specifications and Customization: Custom designs with intricate specifications may require more time and resources to produce, increasing costs. Standardized designs can help in negotiating better pricing.

-

Materials: As mentioned, the choice of material plays a crucial role. Premium materials come with higher costs but may be necessary for specific applications.

-

Quality and Certifications: Parts requiring stringent quality controls or certifications (e.g., for aerospace or medical applications) will generally have higher associated costs.

-

Supplier Factors: The reputation, experience, and technology of the supplier can impact pricing. Established suppliers with advanced capabilities may charge a premium for their services.

-

Incoterms: The terms of delivery can significantly affect the final cost. Understanding whether the price includes shipping, insurance, and customs duties can help in budgeting accurately.

What Are Effective Buyer Tips for Negotiating 3D Printing Prices?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, employing strategic approaches can enhance cost-efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing based on volume, repeat business, or long-term contracts. Suppliers may offer discounts for bulk orders or ongoing relationships.

-

Assess Total Cost of Ownership (TCO): Consider not just the upfront costs, but also the long-term implications of your choices. Factors like durability, maintenance, and logistics should influence your decision.

-

Understand Pricing Nuances for International Buyers: Be aware of potential price fluctuations due to currency exchange rates, international tariffs, and taxes. Including these in your overall budget can prevent unexpected expenses.

-

Request Detailed Quotes: Ensure quotes break down costs by component to better understand where your budget is being allocated. This transparency can also facilitate better negotiation.

-

Research Multiple Suppliers: Comparing quotes and services from different suppliers can help you identify the best value for your specific needs.

Disclaimer on Indicative Prices

Pricing in the 3D printing industry can fluctuate based on market conditions, material availability, and technological advancements. The figures and examples provided in this analysis are indicative and should not be considered fixed. Always consult with suppliers for the most accurate and current pricing tailored to your specific requirements.

Alternatives Analysis: Comparing 3d printing service prototyping With Other Solutions

Understanding Alternatives in Prototyping Solutions

In today’s fast-paced manufacturing landscape, businesses often seek the most efficient and cost-effective methods for prototyping. While 3D printing service prototyping has gained significant traction due to its flexibility and speed, it is essential to consider alternative solutions that may better suit specific project requirements. This analysis compares 3D printing service prototyping with traditional manufacturing methods such as CNC machining and injection molding, providing insights into their respective advantages and disadvantages.

Comparison Table

| Comparison Aspect | 3D Printing Service Prototyping | CNC Machining | Injection Molding |

|---|---|---|---|

| Performance | High precision, complex geometries | High precision, limited complexity | High volume consistency, limited complexity |

| Cost | Moderate for low volumes, high for large batches | High setup costs, economical for medium to large runs | High initial setup, economical for mass production |

| Ease of Implementation | Simple, requires CAD files | Requires skilled operators, setup time | Complex setup, requires molds |

| Maintenance | Low, mainly software updates | Moderate, depends on equipment | High, molds require maintenance |

| Best Use Case | Low to medium volume, complex designs | Medium volume, high precision parts | High volume production, simple geometries |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a solid block.

Pros:

– CNC machining offers high precision and surface finish, making it suitable for parts that require tight tolerances.

– It can work with a variety of materials, including metals and plastics, making it versatile.

Cons:

– The initial setup costs are significant due to the need for specialized equipment and skilled operators.

– It is less suitable for complex geometries compared to 3D printing, as certain designs may not be feasible to machine.

How Does Injection Molding Compare?

Injection molding is a manufacturing process where molten material is injected into a mold to create parts.

Pros:

– Once the initial mold is created, the cost per unit decreases significantly for high-volume production, making it cost-effective for mass manufacturing.

– It provides excellent repeatability and consistency across large batches.

Cons:

– The initial costs for mold creation can be prohibitively high for low-volume projects.

– The process is limited to simpler geometries and can take longer to set up compared to 3D printing.

Conclusion: Which Prototyping Solution is Right for You?

Choosing the right prototyping solution depends on several factors, including project volume, complexity, and budget constraints. 3D printing service prototyping excels in low to medium volume projects with intricate designs, allowing for rapid iterations and adjustments. CNC machining offers high precision and is best suited for medium volumes where tolerances are critical, while injection molding shines in mass production scenarios where cost efficiency is paramount. B2B buyers should evaluate their specific needs, including design intricacies and production timelines, to select the most appropriate method for their prototyping requirements.

Essential Technical Properties and Trade Terminology for 3d printing service prototyping

What Are the Key Technical Properties in 3D Printing Service Prototyping?

When selecting a 3D printing service for prototyping, understanding specific technical properties is crucial. These specifications not only influence the manufacturing process but also affect the performance, cost, and time to market of the final product. Here are some critical properties to consider:

-

Material Grade

Material grade refers to the specific classification of materials used in 3D printing, such as plastics (like ABS, Nylon, or Polycarbonate) or metals (like Stainless Steel or Titanium). Each material has unique mechanical properties, thermal resistance, and chemical compatibility. Selecting the right material grade ensures that the prototype meets the required performance standards and functional requirements. -

Tolerance

Tolerance specifies the allowable deviation in dimensions and geometry of the printed part. Tighter tolerances (e.g., ±0.002 inches) result in higher precision but may increase production costs. Understanding tolerances is vital for ensuring that the prototype fits seamlessly into existing systems and meets design specifications, especially in industries like aerospace or medical devices where precision is critical. -

Max Part Size

The maximum part size indicates the largest dimension that can be achieved with a particular 3D printing technology. Different processes have varying limits, which can affect design decisions. Knowing the max part size helps buyers plan their prototypes accordingly and ensures that they do not exceed the capabilities of the chosen service provider. -

Minimum Feature Size

This specification defines the smallest detail that can be accurately reproduced in the printed part. It is particularly important in applications requiring intricate designs or fine details, such as consumer products or complex mechanical components. Understanding minimum feature size helps in assessing the feasibility of designs before production. -

Post-Processing Options

Post-processing refers to any additional treatments applied to a printed part after it has been manufactured, such as sanding, painting, or coating. These options can enhance the aesthetics or mechanical properties of the prototype. Buyers should inquire about post-processing capabilities to ensure that the final product meets their quality and functional requirements. -

Lead Time

Lead time is the duration from order placement to delivery. In a competitive business environment, quick turnaround times can provide a significant advantage. Understanding lead times helps in project planning and ensures that prototypes are available when needed for testing or production.

What Are Common Trade Terms Used in 3D Printing Service Prototyping?

Familiarity with industry terminology is essential for effective communication and negotiation in the 3D printing space. Here are several key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of 3D printing, it refers to businesses that outsource the production of components to specialized 3D printing service providers. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units that a supplier is willing to produce. In 3D printing, this term is relevant for batch orders. Understanding MOQ helps buyers assess the feasibility of their project in terms of cost and production scale. -

RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price bids from suppliers for specific products or services. It is an essential step in the procurement process, allowing buyers to compare costs and services across different 3D printing providers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers for the delivery of goods. Understanding Incoterms is crucial for international transactions, as they clarify shipping responsibilities, risk transfer, and cost allocation. -

DMLS (Direct Metal Laser Sintering)

DMLS is an advanced 3D printing technology used for producing metal parts. This term is particularly relevant for industries requiring high-strength components, such as aerospace and automotive. Familiarity with DMLS can help buyers understand the capabilities and limitations of metal 3D printing. -

FDM (Fused Deposition Modeling)

FDM is one of the most common 3D printing technologies, which works by extruding thermoplastic filaments layer by layer. It is essential for buyers to know about FDM as it often represents a cost-effective option for producing durable prototypes.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when engaging with 3D printing service providers, ensuring that they choose solutions that align with their project needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the 3d printing service prototyping Sector

What Are the Current Market Dynamics and Key Trends in 3D Printing Service Prototyping?

The 3D printing service prototyping sector is experiencing transformative growth driven by several global factors. The increasing demand for rapid prototyping across industries such as aerospace, automotive, and healthcare is propelling the market. Companies are seeking faster turnaround times and more cost-effective solutions, which 3D printing readily provides. In regions like Africa and South America, where manufacturing capabilities are evolving, businesses are leveraging 3D printing to streamline product development and reduce lead times. This shift is further supported by advancements in additive manufacturing technologies, allowing for a diverse range of materials and intricate designs.

Emerging technologies, such as Multi Jet Fusion (MJF) and Direct Metal Laser Sintering (DMLS), are redefining production capabilities, enabling the creation of complex geometries that were previously unattainable. B2B buyers must stay informed about these technological advancements to make strategic sourcing decisions. Additionally, the rise of online platforms for instant quoting and ordering is simplifying the procurement process, enhancing accessibility for international buyers. This trend is particularly beneficial for companies in developing markets, as it facilitates entry into global supply chains.

How Does Sustainability Influence Sourcing Decisions in 3D Printing?

Sustainability is increasingly becoming a priority for international B2B buyers in the 3D printing sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. For instance, the use of recycled materials and bio-based polymers in 3D printing not only minimizes waste but also meets the growing demand for environmentally friendly products. Certifications like ISO 14001 and materials labeled as “green” are becoming essential criteria for sourcing decisions.

Furthermore, the importance of ethical supply chains cannot be understated. Companies are recognizing that transparency in sourcing and production processes fosters trust and can enhance brand reputation. B2B buyers are encouraged to partner with 3D printing service providers who prioritize ethical sourcing, ensuring that their materials are obtained responsibly and sustainably. This trend resonates particularly well with companies targeting environmentally conscious consumers, further driving the need for sustainable practices in prototyping.

How Has 3D Printing Evolved to Meet B2B Needs?

The evolution of 3D printing technology has significantly impacted B2B prototyping services. Initially limited to basic plastic models, the industry has expanded to include a wide variety of materials, including metals and advanced composites, enabling the production of high-performance prototypes. Over the years, the introduction of sophisticated printing techniques, such as Stereolithography (SLA) and Fused Deposition Modeling (FDM), has enhanced the quality and precision of printed parts.

As businesses increasingly recognize the potential of 3D printing for rapid prototyping, the focus has shifted towards creating production-ready components. This evolution not only reduces time-to-market but also allows for customization at scale, catering to the diverse needs of international buyers. With ongoing advancements, the 3D printing service prototyping sector is poised for continued growth, offering innovative solutions that meet the dynamic demands of the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d printing service prototyping

-

How do I choose the right 3D printing service for my prototyping needs?

Choosing the right 3D printing service involves assessing your specific project requirements, such as material type, part complexity, and desired turnaround time. Research potential suppliers’ capabilities in terms of the technologies they use (like SLA, SLS, or FDM) and ensure they offer the materials that suit your application. Additionally, consider their certifications, customer service reputation, and past project examples. Request samples to evaluate their print quality and ensure they can meet your quality assurance standards. -

What is the best material for 3D printing prototypes?

The best material for 3D printing prototypes depends on the functionality and application of the part. For functional prototypes, durable materials like Nylon or ABS are often recommended due to their strength and versatility. If aesthetics and detail are critical, consider using SLA with resin materials for smooth finishes. For parts requiring high thermal resistance, ULTEM or similar materials may be the best choice. Always consult with your supplier to find the optimal material for your specific use case. -

What are the typical minimum order quantities (MOQs) for 3D printing services?

Minimum order quantities can vary significantly between 3D printing service providers and depend on the technology used and the complexity of the parts. Some suppliers offer on-demand printing with no MOQ, allowing you to order single prototypes, while others may require a minimum order for production runs, typically ranging from 10 to 100 units. It’s essential to clarify these details with your supplier upfront to align your project needs with their capabilities. -

How can I vet a 3D printing supplier for international trade?

To vet a 3D printing supplier for international trade, start by checking their certifications, such as ISO standards, which indicate quality management practices. Look for customer reviews and case studies that demonstrate their experience and reliability in your industry. Request references from previous clients, especially those in your region, to assess their track record. Additionally, consider suppliers that offer robust communication channels and support for international shipping, including customs and tariffs. -

What payment terms should I expect when working with 3D printing services?

Payment terms for 3D printing services can vary widely depending on the supplier and your order size. Common practices include upfront payments for first-time orders, especially for custom work, while established relationships may allow for net 30 or net 60 terms. Ensure you discuss payment methods (credit card, bank transfer) and any additional fees for international transactions. It’s advisable to have a clear agreement to avoid misunderstandings later in the project. -

What quality assurance measures should I look for in a 3D printing service?

When evaluating a 3D printing service, inquire about their quality assurance (QA) processes. Look for services that conduct regular inspections, utilize advanced measurement tools, and adhere to recognized quality standards (like ISO 9001). Ask about their post-processing capabilities, as these can significantly impact the final product’s quality. A reliable supplier should also provide documentation of their QA processes and be willing to share test results for your specific prototypes. -

How does shipping logistics work for international 3D printing orders?

Shipping logistics for international 3D printing orders typically involves understanding customs regulations, tariffs, and shipping options. Choose a supplier experienced in international shipping to ensure compliance with all legal requirements. Discuss shipping methods (air freight, sea freight) based on urgency and budget. Many suppliers offer door-to-door shipping services, but it’s crucial to confirm who bears the costs and responsibilities for potential delays or damages during transit. -

What customization options are available with 3D printing services?

Most 3D printing services offer extensive customization options, allowing you to tailor parts to your specific design requirements. This includes selecting materials, colors, surface finishes, and even incorporating complex geometries that traditional manufacturing cannot achieve. Some services provide design support to optimize your CAD files for 3D printing. Always communicate your customization needs clearly and ensure the supplier has the capabilities to meet them, including any additional costs associated with bespoke features.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 3d printing service prototyping

In the evolving landscape of 3D printing service prototyping, strategic sourcing emerges as a critical factor for international B2B buyers seeking competitive advantage. By leveraging advanced technologies such as Stereolithography, Fused Deposition Modeling, and Direct Metal Laser Sintering, companies can achieve rapid prototyping, reduce time-to-market, and enhance product innovation. Sourcing from reputable providers not only ensures high-quality outputs but also offers access to a diverse range of materials tailored to specific applications.

As businesses from Africa, South America, the Middle East, and Europe explore the potential of 3D printing, understanding the nuances of material selection and production capabilities becomes essential. Buyers are encouraged to engage with service providers that offer transparent pricing, quick turnaround times, and a commitment to quality certifications.

Looking ahead, the integration of 3D printing into supply chains will continue to reshape manufacturing processes, fostering innovation and sustainability. International buyers are urged to seize this opportunity by forging strategic partnerships that enable them to remain agile and responsive to market demands. Embrace the future of prototyping—explore your options today and position your business for success in a dynamic global marketplace.