Top 7 San Antonio Engine Machine Shop Manufacturers & Suppliers List

1. E&E – Engine Machining Services

Domain: eeengine.com

Registered: 2005 (20 years)

Introduction: E&E offers a range of engine machining and parts supply services, including:

1. **Machine Shop Services:**

– Cylinder Heads: valve jobs, resurfacing, pressure testing, welding, and more.

– Connecting Rods: checking, polishing, resizing, and installing piston pins.

– Cranks: cleaning, grinding, balancing, and straightening.

– Blocks: boring, honing, resurfacing, and assembling sho…

2. Bad Boyz Machine Shop – Engine Rebuilds & Precision Repair

Domain: badboyzmachineshop.com

Registered: 2023 (2 years)

Introduction: Engine Rebuilds: Expert restoration and precision repair for peak performance and durability. Block & Head Resurfacing: Machining to ensure flatness and smoothness for optimal engine performance. Block Honing: Refining cylinder walls for smooth surface and optimized piston movement. Crankshaft Grinding: Precision machining to restore crankshaft surface for longevity. Valve Jobs: Restoring valves a…

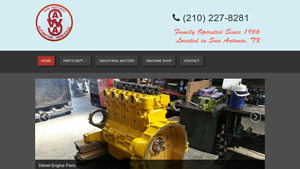

3. Engine Parts Now – Engine Rebuilding Services

Domain: enginepartsnow.com

Registered: 2011 (14 years)

Introduction: San Antonio Automotive Warehouse Company Inc. offers a wide range of motor parts, diesel engine parts, tractor and industrial parts, and auto parts. They provide complete engine rebuilding services, remanufacturing engines and components according to factory specifications. Their machine shop has been operational since 1966, providing high-quality industrial and auto motor rebuilding services. The…

4. San Antonio Machine Shops – Head Gasket Milling Recommendations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Recommendations for engine machine shops in San Antonio, specifically for milling a head gasket. User mentions Duffins by the airport charged $250 for a jeep 4.0 head surfaced about 2 years ago. Another user mentions Millers machine for small blocks.

5. Yelp – Auto Repair & Custom Fabrication

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: Driveshaft Repair, Carburetor Rebuild, Rotor Resurface, Rack Pinion, Alternators and Starters, Stainless Steel Fabrication, Auto Welding, Custom Metal Fabrication, Metal Fabricators, Aluminum Welding, Brakes and Rotors, Sewing Machine Repair, Precision Machining, Speed Shop, Suspension Install, 4×4 Shop, Industrial Supply, Tune Up, Plexiglass, Steel Fabrication, Catalytic Converter Repair, Metal B…

6. RMS Machine Shop – Auto Repair Services

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: RMS Machine Shop, LLC & RMS Auto Repair Shop located in San Antonio, TX.

7. V8 Buick – Engine Machine Shops in San Antonio

Domain: v8buick.com

Registered: 2002 (23 years)

Introduction: Engine machine shops in San Antonio, Texas, specifically for 455 Buicks. Key services mentioned include: decking a 455 block, checking and performing valve work on Edlebrock heads, and possibly facing the heads. Specific shops mentioned include Duffin Machine and Long’s Machine Shop. A shop in Houston, G&G Performance Engines, is also referenced for Buick work.

Introduction: Navigating the Global Market for san antonio engine machine shop

In the competitive landscape of global sourcing, finding a reliable San Antonio engine machine shop that meets diverse needs can be a daunting task for international B2B buyers. Challenges such as quality assurance, timely delivery, and cost-effectiveness often complicate the procurement process. This guide aims to demystify the complexities associated with sourcing engine machining services and parts from San Antonio, offering valuable insights tailored specifically for businesses in Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria.

Throughout this comprehensive resource, we will explore various types of services offered by San Antonio engine machine shops, including engine rebuilding, precision machining, and custom parts fabrication. We will also discuss the applications of these services across different industries, from automotive repair to heavy machinery. Additionally, the guide will provide actionable advice on supplier vetting, cost considerations, and best practices for establishing long-term partnerships with reliable service providers.

By equipping international buyers with critical information and practical strategies, this guide empowers them to make informed purchasing decisions that align with their operational needs and budgetary constraints. Whether you are seeking high-quality remanufactured engines or specialized machining services, understanding the San Antonio market landscape will enhance your procurement strategy and drive business success.

Understanding san antonio engine machine shop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| General Engine Machine Shops | Offer a wide range of services including machining, rebuilding, and parts supply for various engine types. | Auto repair shops, fleet maintenance, industrial machinery. | Pros: Comprehensive services; Cons: May lack specialization in high-performance engines. |

| Performance Engine Shops | Focus on high-performance engine builds and modifications, often for racing or specialized applications. | Racing teams, performance automotive shops, custom vehicle builders. | Pros: Expertise in performance enhancements; Cons: Higher costs and longer lead times. |

| Marine Engine Specialists | Specialize in engines used in marine applications, including boats and ships. | Marine repair facilities, commercial fishing fleets, yacht manufacturers. | Pros: In-depth knowledge of marine engines; Cons: Limited to marine applications. |

| Diesel Engine Repair Shops | Focus on diesel engine rebuilds and repairs, catering to heavy-duty vehicles and machinery. | Trucking companies, construction firms, agricultural businesses. | Pros: Expertise in diesel technology; Cons: May not service gasoline engines. |

| Remanufactured Engine Suppliers | Provide remanufactured engines with warranties, often at lower costs than new engines. | Auto dealers, fleet operators, independent mechanics. | Pros: Cost-effective solutions; Cons: Variability in quality depending on the supplier. |

What Are the Characteristics of General Engine Machine Shops?

General engine machine shops are versatile facilities that provide a broad spectrum of services, including machining, rebuilding, and parts supply for both domestic and foreign engines. They cater to various sectors, such as auto repair shops and industrial machinery maintenance. Buyers should consider the shop’s experience and equipment quality, as well as their ability to meet specific engine needs. While these shops offer comprehensive services, they may lack specialized expertise in high-performance modifications.

How Do Performance Engine Shops Differ?

Performance engine shops are tailored for customers seeking high-performance builds and modifications, often for racing or custom vehicles. These shops possess specialized knowledge in tuning and enhancing engine capabilities. They are ideal for racing teams and enthusiasts looking to maximize their vehicle’s performance. However, buyers should be prepared for potentially higher costs and longer lead times due to the custom nature of the work involved.

What Services Do Marine Engine Specialists Offer?

Marine engine specialists focus on engines designed for marine applications, such as boats and commercial vessels. They understand the unique challenges posed by marine environments and are equipped to handle repairs and rebuilds specific to these engines. This specialization makes them invaluable to marine repair facilities and commercial fishing fleets. Buyers should consider the shop’s reputation and experience in marine engines, as quality and reliability are paramount in this sector.

What Should Buyers Know About Diesel Engine Repair Shops?

Diesel engine repair shops are dedicated to servicing diesel engines, which are common in heavy-duty vehicles and machinery. These shops have extensive knowledge of diesel technology and cater to industries such as trucking, construction, and agriculture. When selecting a diesel engine repair shop, buyers should assess the shop’s certifications and experience with specific diesel models. While these shops excel in diesel repairs, they typically do not service gasoline engines.

Why Choose Remanufactured Engine Suppliers?

Remanufactured engine suppliers offer a cost-effective alternative to new engines by providing remanufactured units that meet or exceed OEM specifications. This option is attractive to auto dealers and fleet operators seeking reliable performance without the high costs associated with new engines. Buyers should evaluate the warranty offered and the supplier’s reputation for quality, as the variability in remanufactured engine quality can significantly impact performance and longevity.

Key Industrial Applications of san antonio engine machine shop

| Industry/Sector | Specific Application of san antonio engine machine shop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Precision engine rebuilding and remanufacturing | Reduces downtime and costs associated with new engine purchases | Quality of parts, turnaround time, warranty options |

| Marine Industry | Custom performance engine builds for marine vessels | Enhances vessel performance and fuel efficiency | Compliance with maritime regulations, availability of marine parts |

| Industrial Machinery | Engine machining for heavy-duty machinery | Increases machinery lifespan and operational efficiency | Technical expertise, ability to handle large components |

| Agriculture | Remanufactured engines for tractors and farm equipment | Cost-effective solutions for maintaining agricultural productivity | Availability of specific agricultural parts, lead times |

| Performance Racing | High-performance engine modifications | Provides competitive edge through enhanced power and reliability | Customization options, experience with racing specifications |

How Can the Automotive Repair Sector Benefit from San Antonio Engine Machine Shop Services?

In the automotive repair industry, San Antonio engine machine shops are crucial for precision engine rebuilding and remanufacturing. This service allows repair centers to offer high-quality solutions to their customers, reducing the downtime and costs associated with purchasing new engines. For international buyers, particularly from regions like Africa and South America, sourcing quality parts and ensuring a quick turnaround time are vital considerations. A strong warranty on remanufactured engines further enhances value, providing peace of mind for businesses and their clients.

What Role Does the Marine Industry Play in Custom Engine Solutions?

The marine industry relies on specialized engine builds to enhance the performance of vessels. San Antonio engine machine shops provide custom performance engine builds tailored for marine applications, ensuring that boats operate efficiently and reliably in demanding conditions. For businesses in the Middle East and Europe, compliance with maritime regulations is essential, making it crucial to partner with shops that understand these requirements. The availability of marine-specific parts is another critical factor for buyers in this sector.

How Does Engine Machining Support Industrial Machinery Operations?

In the industrial machinery sector, engine machining services are essential for maintaining heavy-duty equipment. San Antonio engine machine shops offer precise machining that extends the lifespan of engines, ultimately improving operational efficiency. International buyers, particularly from Africa and South America, must consider the technical expertise of the machine shop and its ability to handle large components. This ensures that businesses can rely on their machinery without frequent breakdowns, leading to increased productivity.

Why Are Remanufactured Engines Important for Agriculture?

The agricultural sector benefits significantly from remanufactured engines for tractors and other farm equipment. San Antonio engine machine shops provide cost-effective solutions that help farmers maintain productivity while managing budgets. For buyers in regions like Nigeria, the availability of specific agricultural parts and reasonable lead times are critical considerations. These remanufactured engines not only save costs but also support sustainable farming practices by reducing waste.

How Can Performance Racing Thrive with High-Performance Engine Modifications?

In the performance racing industry, high-performance engine modifications are vital for gaining a competitive edge. San Antonio engine machine shops excel in offering tailored modifications that enhance power and reliability, crucial for racing success. Buyers from Europe, especially Germany, are particularly focused on customization options and the shop’s experience with racing specifications. Ensuring that the machine shop can meet these high standards is essential for businesses looking to excel in competitive racing environments.

3 Common User Pain Points for ‘san antonio engine machine shop’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Engine Parts

The Problem: B2B buyers often struggle with sourcing high-quality engine parts that meet specific requirements for various engine types, including domestic and foreign models. This challenge is exacerbated when they need parts that are not commonly stocked, leading to delays in repair and maintenance services. Furthermore, buyers may face issues with subpar quality or compatibility, which can result in costly repairs and extended downtime.

The Solution: To effectively source high-quality engine parts from a San Antonio engine machine shop, buyers should first establish clear specifications for the required parts, including brand, model, and any performance enhancements needed. Engaging with a reputable machine shop like E&E Engine or City Motor Supply can streamline this process, as these businesses often have established relationships with top-tier parts manufacturers. Buyers should also leverage the expertise of the shop’s team, who can provide insights into the best parts for performance and longevity. To ensure quality, request detailed product descriptions and certifications for parts, and consider visiting the shop to inspect the inventory. This proactive approach will minimize delays and ensure that the parts sourced meet the necessary standards.

Scenario 2: Uncertainty About Engine Rebuilding vs. Replacement

The Problem: Many B2B buyers, especially those managing repair centers or automotive businesses, often face the dilemma of whether to rebuild an existing engine or replace it with a new one. This decision can significantly impact their operational costs and service quality. Factors such as budget constraints, customer expectations, and the specific condition of the engine can complicate the decision-making process, leading to confusion and potential misallocation of resources.

The Solution: To navigate this challenge, buyers should conduct a thorough assessment of the engine’s condition and performance requirements. Working closely with a San Antonio engine machine shop, buyers can obtain professional evaluations of the engine’s components. Shops like E&E Engine provide comprehensive diagnostic services and can offer insights into the feasibility of rebuilding versus replacing. Buyers should consider factors such as the age of the engine, availability of parts, and the anticipated lifespan of a rebuilt engine compared to a new one. Additionally, discussing performance goals with the shop can help determine the best course of action. By relying on expert advice and detailed assessments, buyers can make informed decisions that align with their operational needs and customer expectations.

Scenario 3: Challenges in Engine Performance Enhancement

The Problem: B2B buyers often encounter difficulties in enhancing engine performance for their clients’ vehicles. This challenge is particularly pronounced in competitive markets where customers demand high performance, efficiency, and reliability. Buyers may lack the technical knowledge to implement the necessary modifications or may struggle to find a machine shop that can deliver the specialized services required for performance upgrades.

The Solution: To address this issue, buyers should partner with San Antonio engine machine shops that specialize in performance enhancements. Shops like City Motor Supply and E&E Engine offer tailored services for performance engines, including custom builds and specific modifications like camshaft selection and compression upgrades. Buyers should clearly communicate their performance objectives and vehicle specifications to the shop, allowing the machinists to recommend the best solutions. Additionally, staying informed about the latest trends in performance enhancements can empower buyers to make better decisions. By leveraging the expertise of specialized machine shops and maintaining open communication, buyers can successfully enhance engine performance, meet customer demands, and stay ahead in a competitive market.

Strategic Material Selection Guide for san antonio engine machine shop

What Are the Key Materials Used in San Antonio Engine Machine Shops?

In the context of engine machining and rebuilding, selecting the right materials is crucial for ensuring performance, durability, and compliance with international standards. Here, we analyze four common materials used in San Antonio engine machine shops: aluminum, cast iron, steel, and composite materials.

How Does Aluminum Benefit Engine Components?

Aluminum is widely used in engine components due to its lightweight and excellent thermal conductivity. It typically has a temperature rating up to 400°F (204°C) and exhibits good corrosion resistance, particularly when anodized.

Pros:

– Lightweight, which contributes to overall vehicle efficiency.

– Excellent heat dissipation, aiding in engine cooling.

– Good machinability allows for complex shapes and designs.

Cons:

– Less durable than steel or cast iron under high stress.

– More expensive than some alternatives, which can impact project budgets.

– Requires specific machining techniques to avoid deformation.

Impact on Application: Aluminum is ideal for components like cylinder heads and engine blocks, where weight reduction is crucial. However, it may not be suitable for high-performance applications without proper treatment.

Considerations for International Buyers: Compliance with standards such as ASTM B211 for aluminum alloys is essential. Buyers from regions like Europe (DIN standards) and Africa should verify material specifications to ensure compatibility with local practices.

What Role Does Cast Iron Play in Engine Manufacturing?

Cast iron is a traditional material for engine blocks and cylinder heads due to its excellent wear resistance and ability to withstand high temperatures and pressures. It typically has a temperature rating of around 1,200°F (649°C) and offers good corrosion resistance.

Pros:

– Highly durable and can withstand significant stress.

– Cost-effective compared to other metals.

– Excellent vibration damping properties, enhancing engine performance.

Cons:

– Heavier than aluminum, which can affect vehicle performance.

– More challenging to machine, requiring specialized tools.

– Prone to rust if not properly maintained.

Impact on Application: Cast iron is suitable for heavy-duty applications, particularly in diesel engines where durability is paramount. However, its weight can be a disadvantage in performance-focused vehicles.

Considerations for International Buyers: Buyers should be aware of compliance with ASTM A48 for gray cast iron. In regions like South America, where heavy-duty vehicles are prevalent, cast iron remains a popular choice.

Why Is Steel a Preferred Material for Engine Components?

Steel, particularly high-carbon and alloy steels, is frequently used for crankshafts, connecting rods, and other high-stress components due to its strength and toughness. Steel components can handle extreme temperatures and pressures, often exceeding 1,500°F (815°C).

Pros:

– Exceptional strength-to-weight ratio.

– Good machinability and weldability.

– Resistant to deformation under load.

Cons:

– Heavier than aluminum, which can impact efficiency.

– More expensive than cast iron.

– Corrosion resistance is lower unless treated.

Impact on Application: Steel is ideal for components that require high strength and durability, such as crankshafts and camshafts. Its versatility makes it suitable for both performance and standard applications.

Considerations for International Buyers: Compliance with standards like ASTM A36 or A992 is crucial for ensuring quality. Buyers from Europe may prefer materials that meet EN standards for structural steel.

How Do Composite Materials Enhance Engine Performance?

Composite materials, such as carbon fiber and fiberglass, are increasingly used in engine components to reduce weight while maintaining strength. They can withstand temperatures up to 500°F (260°C) depending on the resin used.

Pros:

– Lightweight, significantly improving fuel efficiency.

– High resistance to corrosion and thermal expansion.

– Can be molded into complex shapes.

Cons:

– Generally more expensive than traditional materials.

– Requires specialized manufacturing processes.

– Not as widely accepted in heavy-duty applications.

Impact on Application: Composites are often used in performance engines and racing applications where weight savings are critical. Their unique properties allow for innovative designs.

Considerations for International Buyers: Compliance with ASTM D3039 for composite materials is essential. Buyers from regions like the Middle East may need to consider the availability of composite materials in their local markets.

Summary of Material Selection

| Material | Typical Use Case for San Antonio Engine Machine Shop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Cylinder heads, engine blocks | Lightweight, excellent heat dissipation | Less durable under high stress | Medium |

| Cast Iron | Engine blocks, cylinder heads | Highly durable, cost-effective | Heavier, challenging to machine | Low |

| Steel | Crankshafts, connecting rods | Exceptional strength-to-weight ratio | Heavier than aluminum, lower corrosion resistance | Medium |

| Composite | Performance engine components | Lightweight, high corrosion resistance | More expensive, requires specialized manufacturing | High |

This guide provides insights into material selection that can significantly impact the performance and longevity of engine components, catering to the needs of international B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for san antonio engine machine shop

What Are the Main Stages of Manufacturing in a San Antonio Engine Machine Shop?

In a San Antonio engine machine shop, the manufacturing process is a well-structured sequence designed to ensure precision and quality. This process typically comprises four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality raw materials, such as aluminum and steel, which are essential for engine components. These materials undergo rigorous inspection to verify their specifications and quality. Advanced techniques like CNC machining may be employed to cut and shape materials into initial forms suitable for further processing.

-

Forming: In this stage, specialized machinery is utilized to form the engine components. Techniques such as casting and forging are commonly used to create complex shapes. For example, cylinder heads and engine blocks are often cast using molds that ensure dimensional accuracy and structural integrity. Precision machining processes, including grinding and honing, refine these components to meet exact specifications.

-

Assembly: Once the individual components are formed, they are meticulously assembled. This stage includes the installation of critical parts like camshafts, crankshafts, and valves. Experienced technicians ensure that each part is aligned correctly and meets the required tolerances. Advanced tools such as torque wrenches are used to apply the correct torque settings, ensuring the reliability of the assembled engine.

-

Finishing: The final stage involves surface treatments and inspections to enhance the durability and performance of the engine parts. Techniques such as polishing, coating, and heat treatment may be applied to improve wear resistance and reduce friction. This stage is crucial for achieving the desired performance characteristics and longevity of the engine components.

How Is Quality Assurance Implemented in San Antonio Engine Machine Shops?

Quality assurance (QA) is a critical component of the manufacturing process in San Antonio engine machine shops. It ensures that all products meet international standards and customer expectations.

-

International Standards: Many engine machine shops in San Antonio adhere to ISO 9001 standards, which focus on maintaining a quality management system. This includes continuous improvement processes and customer satisfaction measures. Additionally, industry-specific certifications such as CE and API (American Petroleum Institute) may be relevant for certain products, ensuring compliance with international safety and quality regulations.

-

Quality Control Checkpoints: To maintain high standards, machine shops implement several quality control checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This step involves inspecting raw materials as they arrive at the facility to verify that they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing stages, periodic checks are conducted to ensure that the processes are producing parts within the required tolerances.

– Final Quality Control (FQC): Before products are shipped, a final inspection is performed to ensure that all components meet quality specifications and performance standards. -

Common Testing Methods: Various testing methods are employed to assess the quality of engine components. These include:

– Dimensional Inspection: Utilizing tools like calipers and micrometers to measure dimensions accurately.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are used to detect internal flaws without damaging the components.

– Performance Testing: Engines may undergo testing on dynamometers to evaluate their performance under simulated operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control measures of a San Antonio engine machine shop is essential. Here are actionable steps to ensure supplier reliability:

-

Conducting Audits: Buyers can request to conduct audits of the machine shop’s facilities. An on-site audit allows buyers to assess manufacturing processes, quality control systems, and compliance with industry standards.

-

Reviewing Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection reports, certifications, and results from any third-party audits. Reviewing these documents can give buyers insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality systems and product reliability. This is particularly important for international buyers who may not be able to visit the facility in person.

-

Understanding Certification Nuances: Buyers should familiarize themselves with the specific certifications relevant to their region and industry. For example, European buyers may prioritize CE certifications, while buyers from the Middle East might look for compliance with local standards. Understanding these nuances can help in evaluating whether the supplier meets the necessary quality benchmarks.

What Are the Challenges and Considerations for International B2B Buyers?

When engaging with San Antonio engine machine shops, international B2B buyers must navigate several challenges:

-

Logistics and Shipping: Coordinating the shipment of heavy engine components internationally can be complex and costly. Buyers should work closely with suppliers to understand shipping options and associated costs.

-

Cultural Differences: Language barriers and differing business practices may pose challenges in communication. Establishing clear lines of communication and setting expectations early in the relationship can mitigate misunderstandings.

-

Compliance with Local Regulations: Buyers must ensure that the engine components they purchase comply with local regulations and standards in their home countries. This may involve additional testing or certifications upon arrival.

By understanding the manufacturing processes and quality assurance measures in place at San Antonio engine machine shops, international B2B buyers can make informed decisions that align with their quality expectations and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘san antonio engine machine shop’

Introduction

Navigating the procurement process for engine machining services in San Antonio can be daunting, especially for international B2B buyers. This guide serves as a comprehensive checklist to streamline your sourcing efforts, ensuring you select a machine shop that meets your technical needs, budget, and quality expectations.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the specifications of the engine components you require. This includes the type of engine (domestic, foreign, performance), the specific machining services needed (e.g., cylinder head resurfacing, crankshaft grinding), and any performance upgrades you’re considering. Having a detailed specification helps in communicating effectively with potential suppliers and ensures that you receive accurate quotes.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify engine machine shops in San Antonio that align with your specifications. Utilize online directories, industry forums, and trade shows to compile a list of potential suppliers. Focus on their areas of expertise, customer reviews, and case studies to gauge their reputation in the market.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each shortlisted supplier. Inquire about their machinery, technology, and processes to ensure they can handle your specific requirements. Look for shops that offer a range of services, such as precision machining, parts supply, and engine rebuilding, as this indicates a comprehensive approach to engine performance.

Step 4: Verify Certifications and Compliance

Ensure that the machine shops you consider have the necessary certifications and comply with industry standards. Certifications such as ISO 9001 indicate a commitment to quality management. Compliance with environmental regulations is also crucial, especially for international buyers concerned about sustainability practices.

Step 5: Request Quotes and Compare Pricing

Once you have a shortlist of qualified suppliers, request detailed quotes that outline pricing, timelines, and terms of service. Pay attention to what is included in the price, such as warranties, support services, and delivery options. Comparing these factors will help you identify the best value proposition.

Step 6: Check References and Past Work

Before finalizing your decision, ask for references from previous clients, especially those in similar industries or geographical locations. This will provide insights into the supplier’s reliability, quality of work, and customer service. Additionally, reviewing past projects can give you a clearer picture of their capabilities.

Step 7: Establish Communication and Service Agreements

Once you select a supplier, establish clear lines of communication and service agreements. Ensure that both parties understand the project scope, timelines, and expectations. A well-defined agreement will help mitigate misunderstandings and foster a productive working relationship.

By following this checklist, B2B buyers can effectively navigate the sourcing process for engine machine shops in San Antonio, ensuring they select a partner that meets their technical and business needs.

Comprehensive Cost and Pricing Analysis for san antonio engine machine shop Sourcing

What Are the Key Cost Components for Sourcing from San Antonio Engine Machine Shops?

When evaluating the cost structure of sourcing from engine machine shops in San Antonio, several key components need to be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the profit margin.

-

Materials: The cost of raw materials significantly impacts the total pricing. Engine parts such as pistons, bearings, and gaskets can vary widely based on quality and supplier. High-grade materials typically command higher prices but offer better durability and performance, which can be a crucial factor for international buyers.

-

Labor: Skilled labor is essential in engine machining and rebuilding. The labor costs in San Antonio reflect the expertise and experience of machinists, which can vary based on the complexity of the work required. Custom jobs may require more skilled labor, thereby increasing costs.

-

Manufacturing Overhead: This includes costs associated with running the machine shop, such as utilities, rent, and equipment maintenance. Shops with advanced technology may have higher overhead but can offer faster turnaround times and improved precision.

-

Tooling: Tooling costs are significant in the engine machining process. Specialized tools for tasks such as crankshaft grinding or cylinder head resurfacing are necessary, and their costs can be factored into the overall pricing structure.

-

Quality Control: Implementing strict QC measures ensures that parts meet performance standards. However, rigorous quality testing can add to the overall cost. Buyers should seek shops that balance quality assurance with cost-efficiency.

-

Logistics: Shipping costs are particularly relevant for international buyers. Factors such as distance, weight, and delivery timelines can influence logistics expenses. Understanding Incoterms is crucial for managing these costs effectively.

-

Margin: Finally, the profit margin set by the machine shop influences pricing. This can vary based on competition, demand, and the shop’s reputation for quality.

How Do Price Influencers Affect Sourcing Decisions for Engine Machine Shops?

Several price influencers can impact the cost of sourcing from San Antonio engine machine shops:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Buyers should consider negotiating minimum order quantities (MOQ) to benefit from lower pricing.

-

Specifications and Customization: Custom-engineered parts may incur additional costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials affects both cost and quality. Parts that meet international quality standards may be priced higher but can reduce long-term operational costs.

-

Supplier Factors: The relationship with the supplier can influence pricing. Long-standing partnerships may result in better pricing and terms due to trust and established communication.

-

Incoterms: Understanding the terms of shipping and delivery is essential. Different Incoterms can affect who bears the cost of shipping, insurance, and customs duties, impacting the total cost.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing from San Antonio?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several tips can enhance cost-efficiency:

-

Negotiate Terms: Always negotiate pricing and terms. Establishing a good rapport with suppliers can lead to better deals and more flexible payment options.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial price. Evaluate the TCO, which includes maintenance, operational efficiency, and potential downtime costs associated with lower-quality parts.

-

Understand Pricing Nuances: Be aware that pricing may vary based on market demand and material costs. Keep abreast of market trends to better negotiate prices.

-

Research and Compare Suppliers: Utilize online platforms to compare different engine machine shops in San Antonio. Gather quotes and assess service offerings to ensure the best value.

-

Plan for Logistics: Factor in shipping times and costs when placing orders. Efficient logistics planning can prevent delays and additional costs.

Disclaimer for Indicative Prices

The prices discussed are indicative and can fluctuate based on market conditions, supplier pricing strategies, and changes in material costs. Buyers should conduct thorough market research and engage in direct discussions with suppliers to obtain accurate and current pricing information.

Alternatives Analysis: Comparing san antonio engine machine shop With Other Solutions

Understanding Alternatives in Engine Machine Shop Solutions

In the realm of engine repairs and rebuilds, businesses often seek reliable machine shop services that can meet their specific needs. While the San Antonio Engine Machine Shop offers a robust range of services, it’s crucial for B2B buyers to explore alternative options to determine the most suitable solution for their operational requirements. This analysis will compare the San Antonio Engine Machine Shop with other viable alternatives to provide insights into the best choice for different business contexts.

Comparison Table

| Comparison Aspect | San Antonio Engine Machine Shop | City Motor Supply | Bad Boyz Machine Shop |

|---|---|---|---|

| Performance | High-quality precision machining for all engine types | Specialized in performance and marine engines | Expert restoration with a focus on precision repair |

| Cost | Competitive pricing with a focus on value | Affordable with a wide range of parts | Mid-range pricing; offers custom solutions |

| Ease of Implementation | Established processes and experienced staff | Streamlined services with quick turnaround | Detailed consultations for tailored services |

| Maintenance | Regular support and parts availability | Comprehensive inventory for easy access | Focus on routine maintenance and repair |

| Best Use Case | General engine rebuilds and repairs | Performance and custom builds | Restoration and precision repairs |

Analyzing Alternative Solutions: City Motor Supply

City Motor Supply stands out as a strong alternative, particularly for businesses focused on performance engines. They offer a broad selection of domestic and foreign engines, including specialized performance builds. One of the significant advantages of City Motor Supply is their competitive pricing and extensive inventory, which ensures quick access to parts. However, their focus on performance may not cater to all standard engine rebuild needs, potentially limiting options for businesses seeking general services.

Evaluating Alternative Solutions: Bad Boyz Machine Shop

Bad Boyz Machine Shop is another noteworthy competitor, particularly in the precision repair space. They emphasize expert restoration and offer a variety of services, including crankshaft grinding and valve jobs. Their approach is tailored, which allows for a high degree of customization to meet specific client needs. However, this customization can sometimes lead to longer turnaround times compared to more streamlined operations like the San Antonio Engine Machine Shop or City Motor Supply.

Conclusion: How to Choose the Right Engine Machine Shop Solution

When selecting the right engine machine shop solution, B2B buyers should carefully consider their specific needs, including the type of engines they work with, budget constraints, and the level of customization required. The San Antonio Engine Machine Shop excels in providing comprehensive services for various engine types, making it ideal for general repairs and rebuilds. In contrast, City Motor Supply may be preferable for performance-focused projects, while Bad Boyz Machine Shop is suited for detailed restorations. By evaluating these alternatives against their operational demands, buyers can make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for san antonio engine machine shop

What Are the Critical Technical Properties in Engine Machine Shops?

When engaging with an engine machine shop, understanding key technical properties is essential for ensuring quality and compatibility with your requirements. Here are several critical specifications:

-

Material Grade

– The material grade refers to the quality and type of materials used in engine components, such as steel or aluminum alloys. Higher-grade materials typically offer better durability and performance. For B2B buyers, selecting a supplier who uses high-grade materials ensures longer-lasting products and reduces the frequency of replacements. -

Tolerance

– Tolerance defines the allowable variation in dimensions of engine parts. Precision machining often requires tight tolerances (e.g., ±0.001 inches) to ensure proper fit and function. In a B2B context, understanding tolerances helps buyers select parts that meet specific operational standards, reducing the risk of assembly issues or engine failure. -

Surface Finish

– This specification describes the texture of the surface of machined parts. A finer surface finish can enhance the performance of components, especially in critical areas like cylinder walls or mating surfaces. B2B buyers should prioritize suppliers who can meet specific surface finish requirements to ensure optimal engine performance. -

Heat Treatment

– Heat treatment processes, such as tempering or hardening, affect the strength and durability of engine components. For B2B transactions, it’s crucial to verify that the machine shop employs appropriate heat treatment methods to enhance the longevity and reliability of their products, particularly in high-performance applications. -

Balancing

– Balancing refers to the process of equalizing the weight distribution of moving parts, such as crankshafts and flywheels. Proper balancing is vital for smooth engine operation and reducing vibrations. Buyers should inquire about balancing services offered by machine shops to avoid performance issues and ensure engine longevity.

What Are Common Trade Terms Used in Engine Machine Shops?

Understanding industry terminology can streamline communications and improve negotiations with engine machine shops. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to parts made by the original manufacturer of the vehicle or engine. B2B buyers often seek OEM parts for their high quality and compatibility with existing systems, ensuring reliability and performance. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. For international buyers, understanding MOQs is vital for budgeting and inventory management, as it may influence purchasing decisions and supply chain logistics. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should utilize RFQs to compare pricing and terms among different machine shops, ensuring they receive competitive offers. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping, insurance, and delivery obligations, reducing the risk of disputes and misunderstandings. -

Re-manufactured vs. Rebuilt

– Re-manufactured engines are restored to original specifications, often including new parts and extensive testing, while rebuilt engines may simply be repaired with existing components. Understanding these distinctions aids buyers in selecting the right option based on quality and cost considerations. -

Performance Specifications

– These are criteria that define how engine components should perform under specific conditions, such as horsepower or torque. B2B buyers should ensure that machine shops can meet their performance specifications to achieve desired outcomes in their applications.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when selecting engine machine shops in San Antonio, ultimately leading to more successful business partnerships and projects.

Navigating Market Dynamics and Sourcing Trends in the san antonio engine machine shop Sector

What Are the Key Market Dynamics and Trends in the San Antonio Engine Machine Shop Sector?

The engine machine shop sector in San Antonio is experiencing robust growth driven by several global factors. Increased demand for high-performance and remanufactured engines is a notable trend, fueled by both cost considerations and environmental awareness. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking reliable suppliers that can provide both quality and competitive pricing. Enhanced connectivity and logistics capabilities are facilitating easier access to these markets, allowing for a more dynamic sourcing environment.

Emerging technologies, such as advanced machining processes and real-time inventory management systems, are transforming operations within the sector. These innovations enable engine shops to optimize their workflows, reduce lead times, and improve product quality. As a result, buyers can expect faster turnaround times and enhanced customization options for their engine needs. The rise of e-commerce platforms is also changing the way buyers source parts, providing greater transparency and a wider selection of suppliers.

Moreover, the growing focus on performance upgrades and custom builds is reshaping buyer expectations. Many buyers are looking for specialized services, including performance tuning and restoration of classic engines, which require shops to have a diverse range of capabilities and expertise. This trend presents an opportunity for San Antonio engine machine shops to position themselves as leaders in niche markets, catering specifically to the needs of international clients.

How Is Sustainability Influencing Sourcing Decisions in the San Antonio Engine Machine Shop Sector?

Sustainability and ethical sourcing are becoming increasingly important in the engine machine shop sector. As environmental regulations tighten globally, businesses are actively seeking suppliers who prioritize eco-friendly practices. This includes using recycled materials, minimizing waste, and employing energy-efficient processes. For B2B buyers from regions like Africa and Europe, where sustainability standards may be more stringent, partnering with responsible suppliers is essential for compliance and brand reputation.

In the San Antonio engine machine shop sector, the adoption of ‘green’ certifications and materials is on the rise. Buyers are encouraged to inquire about suppliers’ sustainability practices, such as the use of remanufactured components that reduce resource consumption and waste. Many engine shops now offer products designed to improve fuel efficiency and lower emissions, aligning with global sustainability goals.

Furthermore, suppliers that demonstrate transparency in their supply chains are likely to gain a competitive edge. This involves providing information about the sourcing of materials, production processes, and waste management practices. As international buyers increasingly prioritize ethical considerations, San Antonio engine machine shops that embrace sustainability can enhance their appeal in the global marketplace.

What Is the Historical Context of the San Antonio Engine Machine Shop Sector?

The engine machine shop sector in San Antonio has evolved significantly over the past few decades. Historically, the industry began as a small-scale operation catering primarily to local automotive needs. However, as vehicle technology advanced and the demand for high-performance engines grew, shops began to expand their services. The rise of remanufactured engines in the late 20th century marked a pivotal moment, as it allowed businesses to meet consumer demand for cost-effective and environmentally friendly solutions.

Today, San Antonio is recognized as a hub for engine machine shops, with a diverse range of services that cater to both domestic and international markets. This evolution reflects broader trends in the automotive industry, where innovation and sustainability are now at the forefront of business strategies. For international B2B buyers, understanding this historical context can provide valuable insights into the capabilities and growth potential of San Antonio’s engine machine shop sector.

Frequently Asked Questions (FAQs) for B2B Buyers of san antonio engine machine shop

-

How do I solve issues with engine performance in my fleet?

To address engine performance issues in your fleet, begin by conducting a thorough diagnostic assessment of each vehicle. Common problems include worn-out engine parts, inadequate fuel quality, or improper maintenance. Partnering with a reliable San Antonio engine machine shop can provide expert restoration services, including precision machining and remanufactured engine components tailored to your specifications. Regular maintenance schedules and utilizing quality parts can significantly enhance the longevity and efficiency of your fleet’s engines. -

What is the best machine shop service for remanufactured engines?

The best machine shop service for remanufactured engines should include comprehensive diagnostics, precision machining, and a robust warranty. In San Antonio, several machine shops offer specialized services like cylinder head repairs, crankshaft grinding, and complete engine rebuilds. Look for shops that utilize high-quality parts from reputable suppliers, provide customized solutions based on your operational needs, and have a strong track record of customer satisfaction. -

How can I ensure the quality of engine parts from a supplier?

To ensure the quality of engine parts from a supplier, request certifications and quality assurance documentation that verify adherence to industry standards. It’s also beneficial to ask for samples or conduct a small trial order to evaluate the parts’ performance. Engaging in regular communication with the supplier about their sourcing and manufacturing processes can provide additional assurance. Lastly, consider suppliers who offer warranties on their products, as this reflects confidence in their quality. -

What are typical payment terms for international orders with engine machine shops?

Typical payment terms for international orders with engine machine shops often include a deposit upfront (usually 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net 30 or net 60 terms based on creditworthiness and established relationships. It’s crucial to clarify these terms before finalizing any agreements and to consider using secure payment methods that protect your transaction. -

What customization options are available for engine rebuilds?

Many San Antonio engine machine shops offer extensive customization options for engine rebuilds, including performance upgrades, specific part selections, and tailored machining processes. Buyers can specify preferences for compression ratios, camshaft profiles, and even fuel types. Discussing your specific requirements with the machine shop will help them create a rebuild that meets your unique performance goals while adhering to industry standards. -

What logistics should I consider when sourcing from a San Antonio engine machine shop?

When sourcing from a San Antonio engine machine shop, consider logistics such as shipping costs, delivery timelines, and customs regulations in your country. It’s advisable to work with suppliers who have experience in international shipping and can provide detailed shipping options. Additionally, confirm that the shop can package the components securely to prevent damage during transit, and inquire about insurance options for high-value shipments. -

How can I vet an engine machine shop before making a purchase?

To vet an engine machine shop, conduct thorough research by reviewing customer testimonials, checking online ratings, and asking for references from previous clients. It’s also beneficial to visit the shop if possible to inspect their facilities and equipment. Engaging in discussions about their processes, quality control measures, and experience in handling international orders can provide insights into their reliability and expertise. -

What should I know about minimum order quantities (MOQs) when sourcing parts?

Minimum order quantities (MOQs) can vary significantly among engine machine shops. Some shops may have low MOQs for standard parts, while custom components may require higher MOQs due to manufacturing costs. Before placing an order, inquire about the MOQ for the specific parts you need and assess whether it aligns with your operational requirements. If your needs are smaller, consider negotiating terms or exploring alternative suppliers that can accommodate lower quantities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for san antonio engine machine shop

In conclusion, engaging with San Antonio’s engine machine shops offers international B2B buyers a competitive edge in sourcing high-quality engine components and services. The region is home to skilled machinists, advanced technology, and a wide array of remanufactured and performance engines tailored to meet specific needs. By strategically sourcing from these established suppliers, businesses can benefit from cost savings, improved engine performance, and enhanced reliability—all critical factors in maintaining operational excellence.

As buyers from Africa, South America, the Middle East, and Europe seek reliable partners in the automotive sector, the strategic sourcing of parts and services from San Antonio’s machine shops can significantly elevate their supply chain efficiency. The collaborative potential with local experts not only ensures superior quality but also fosters innovation through customized solutions.

Looking ahead, international buyers are encouraged to leverage the expertise and resources available in San Antonio. By establishing strong partnerships with local engine machine shops, businesses can navigate the complexities of engine repairs and rebuilds while positioning themselves for future growth. Reach out today to explore the myriad opportunities that await in this thriving market.