Top 7 Drilling Equipment Manufacturers Manufacturers & Suppliers List

1. Epiroc – Drill Rigs

Domain: epiroc.com

Registered: 2017 (8 years)

Introduction: Drill rigs include various types such as Dimension stone equipment, Exploration drill rigs, Face drill rigs (Jumbos), Production drill rigs, Rotary blasthole drill rigs, and Surface drill rigs. Epiroc has been a leading manufacturer for 140 years, offering solutions for mining, construction, and demolition. The product range also encompasses electrification solutions, including battery solutions a…

2. SIMCO – SIMCO 7000 Water Well Drilling Rig

Domain: simcodrill.com

Registered: 1999 (26 years)

Introduction: SIMCO Drilling Equipment specializes in water well drilling rigs and equipment, geothermal drilling rigs, and parts and service. Key products include the SIMCO 7000 water well drilling rig, known for its auto indexing drill rod carousel (10 or 16 drill rod) and drilling depth of up to 1,100 feet using air or wet rotary methods. The company has over 50 years of experience in the drilling industry, …

3. CZM USA Corp – Foundation Drilling Rigs and Equipment

Domain: czm-us.com

Registered: 2012 (13 years)

Introduction: CZM USA Corp offers a comprehensive line of foundation drilling rigs and equipment, including:

1. **Cylinder Crowd Series**: EK300, EK250, EK240, EK200, EK160, EK125, EK65HP.

2. **Long Reach Series**: LR160, LR125, LR95, LR75, LR65, LR50, LR40.

3. **Cable Crowd Series**: EK300LS, EK270LS, EK260LS, EK240LS, EK160LS.

4. **Ultra Short Mast Series**: EK200USM, EK160USM.

5. **Micropile Series**: CR25,…

4. Watson – Customizable Drill Rigs

Domain: watsonusa.com

Registered: 1998 (27 years)

Introduction: Watson offers a range of customizable hydraulic and mechanical drill rigs designed for drilled shaft (bored pile) construction. The drill rigs are available on three standard mounts: Crawler Mount (CM), Truck Mount (TM), and Excadrill (EX). The specifications for various models include: 1030 TM/CM (30,000 ft-lb | 41 kNm), 1100 TM/CM (45,000 ft-lb | 61 kNm), 2200 TM (63,000 ft-lb | 85 kNm), 2500 TM…

5. RTDrill – Drilling Equipment Solutions

Domain: rtdrill.com

Registered: 2018 (7 years)

Introduction: RTDrill by Reichdrill offers a complete line of drilling equipment including DTH drill rigs, rotary drill rigs, and truck-mounted drill rigs. The company specializes in manufacturing equipment for various industries such as water well, oil and gas exploration, quarrying, construction, and mining. They focus on innovation and design improvements to enhance productivity and cost-efficiency. RTDrill …

6. TMG Manufacturing – Geotechnical Drill Rigs

Domain: tmgmfg.com

Registered: 2007 (18 years)

Introduction: TMG Manufacturing offers a range of geotechnical products and drilling rigs, including: 1. Multi-Purpose Drill Rigs 2. Geotechnical Drill Rigs 3. SPT and Coring Drill Rigs 4. CPT and DMT Test Rigs 5. Mini Geotechnical Drill Rigs 6. Micropile & Rotary Drill Rigs 7. CPT & SCPT Equipment 8. Compaction Grouting Products 9. Foundation Repair Products 10. Pre-Construction Products. TMG is located in Tam…

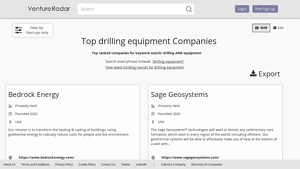

7. Ventureradar – Top Drilling Equipment Companies

Domain: ventureradar.com

Registered: 2011 (14 years)

Introduction: This company, Ventureradar – Top Drilling Equipment Companies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Introduction: Navigating the Global Market for drilling equipment manufacturers

In the competitive landscape of drilling equipment manufacturing, international B2B buyers face the pressing challenge of sourcing reliable and efficient drilling solutions tailored to their specific needs. Whether your focus is on mining, construction, or environmental drilling, understanding the nuances of the global market for drilling equipment manufacturers is crucial. This guide serves as a comprehensive resource, detailing various types of drilling rigs, their applications across different sectors, and essential supplier vetting criteria.

Navigating this complex terrain involves evaluating cost factors, assessing technological advancements, and understanding regional market dynamics, particularly for buyers from Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany. By leveraging the insights provided in this guide, B2B buyers will be empowered to make informed purchasing decisions that align with their operational requirements and strategic goals.

From the latest innovations in automated drilling technology to sustainable practices in equipment manufacturing, this guide will illuminate the path forward. Equip yourself with the knowledge to not only select the right drilling equipment but also to foster strong partnerships with manufacturers who can support your long-term objectives. Embrace the opportunity to enhance your drilling operations with confidence and precision.

Understanding drilling equipment manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Drilling Rigs | Utilizes a rotating drill bit to bore holes, ideal for deep drilling. | Oil & gas extraction, mineral exploration | Pros: High efficiency, suitable for deep wells. Cons: High initial investment and operational costs. |

| Water Well Drilling Rigs | Designed specifically for drilling water wells, often portable. | Agricultural irrigation, municipal water supply | Pros: Cost-effective for water sourcing. Cons: Limited to specific applications. |

| Geotechnical Drilling Rigs | Focused on soil and rock sampling, often equipped with specialized tools. | Construction, environmental assessments | Pros: Accurate data for site analysis. Cons: Slower drilling speeds compared to rotary rigs. |

| Blast Hole Drilling Rigs | Heavy-duty rigs designed for drilling large diameter holes for blasting. | Mining, construction, quarrying | Pros: High productivity in tough terrains. Cons: Requires skilled operators, higher maintenance. |

| Core Drilling Rigs | Extracts cylindrical samples of rock for analysis, often used in exploration. | Mineral exploration, geological surveys | Pros: Provides high-quality samples for analysis. Cons: More expensive and time-consuming than other methods. |

What Are Rotary Drilling Rigs and When Should You Use Them?

Rotary drilling rigs are the backbone of the oil and gas industry, designed to penetrate deep underground. Their ability to efficiently bore through various geological formations makes them suitable for extensive mineral exploration and oil extraction. B2B buyers should consider factors such as the depth of the required drilling and the specific geological conditions when selecting this type of equipment, as the initial investment can be significant.

How Do Water Well Drilling Rigs Meet Agricultural and Municipal Needs?

Water well drilling rigs are tailored to create access to groundwater sources, making them invaluable for agricultural irrigation and municipal water supply projects. These rigs are typically portable, allowing for flexibility in various terrains. Buyers should evaluate the rig’s capacity for depth and flow rate to ensure it meets their specific water sourcing needs, balancing cost with functionality.

Why Choose Geotechnical Drilling Rigs for Construction Projects?

Geotechnical drilling rigs are essential for obtaining soil and rock samples, providing critical data for construction and environmental assessments. These rigs are equipped with specialized tools to analyze subsurface conditions accurately. When purchasing, B2B buyers should focus on the rig’s sampling capabilities and the speed of operation, as these factors can significantly impact project timelines.

What Makes Blast Hole Drilling Rigs Ideal for Mining and Construction?

Blast hole drilling rigs are heavy-duty machines designed for creating large diameter holes needed for blasting in mining and construction. Their robust design allows for high productivity in challenging environments. However, B2B buyers must consider the skill level required for operation and the ongoing maintenance costs, as these factors can affect the overall efficiency of their operations.

How Are Core Drilling Rigs Used in Mineral Exploration?

Core drilling rigs are specialized equipment used to extract cylindrical samples of rock, which are essential for geological analysis and mineral exploration. These rigs provide high-quality samples that are critical for assessing the viability of mining projects. Buyers should weigh the cost against the rig’s sampling accuracy and the time required for drilling, as these elements play a crucial role in exploration success.

Key Industrial Applications of drilling equipment manufacturers

| Industry/Sector | Specific Application of drilling equipment manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Exploration and extraction drilling | Enhanced resource recovery and operational efficiency | Quality of equipment, technology integration, supplier reliability |

| Construction | Foundation drilling and site preparation | Improved project timelines and structural integrity | Compliance with local regulations, equipment versatility, and support services |

| Water Management | Water well and geothermal drilling | Sustainable water sourcing and energy efficiency | Environmental impact assessments, availability of parts, and service support |

| Mining | Mineral exploration and production drilling | Increased yield and reduced operational costs | Equipment durability, adaptability to terrain, and supplier reputation |

| Environmental Services | Geotechnical and environmental drilling | Accurate data collection for site assessments | Technology for real-time data analysis, compliance with environmental standards, and training for operators |

How Are Drilling Equipment Manufacturers Used in the Oil & Gas Sector?

Drilling equipment manufacturers play a crucial role in the oil and gas industry by supplying advanced drilling rigs and tools that facilitate exploration and extraction. These manufacturers provide specialized equipment designed for various geological conditions, enhancing resource recovery rates and optimizing operational efficiency. For international buyers, especially from regions like Africa and the Middle East, understanding local geological challenges and ensuring the availability of spare parts and technical support are vital for successful sourcing.

What Are the Applications of Drilling Equipment in Construction?

In the construction sector, drilling equipment is essential for foundation drilling and site preparation. Manufacturers offer a range of rigs capable of handling diverse soil conditions, ensuring structural integrity and timely project completion. Buyers must consider compliance with local regulations and the versatility of equipment when sourcing, as these factors can significantly impact project outcomes and safety standards.

How Does Drilling Equipment Support Water Management Initiatives?

Drilling equipment manufacturers provide rigs specifically designed for water well and geothermal drilling, which are critical for sustainable water sourcing and energy efficiency. These rigs help in accessing groundwater and geothermal resources, reducing reliance on non-renewable energy sources. For international buyers, especially in arid regions of Africa and South America, sourcing equipment that meets environmental impact standards and offers robust service support is crucial for long-term operational success.

What Role Does Drilling Equipment Play in Mining Operations?

In the mining industry, drilling equipment is indispensable for mineral exploration and production. Manufacturers supply high-performance rigs that increase yield while reducing operational costs through efficient drilling practices. Buyers from Europe and South America should prioritize equipment durability and the adaptability of technology to varying terrain, ensuring that they can maintain productivity and safety in challenging conditions.

How Are Drilling Equipment Manufacturers Beneficial for Environmental Services?

Drilling equipment is also employed in geotechnical and environmental drilling, providing essential data for site assessments and environmental studies. This equipment helps in collecting soil and rock samples, which are critical for understanding site conditions and planning remediation efforts. Buyers must focus on technology that allows for real-time data analysis and compliance with environmental standards to ensure responsible drilling practices and accurate reporting.

3 Common User Pain Points for ‘drilling equipment manufacturers’ & Their Solutions

Scenario 1: Delays in Equipment Delivery Impacting Project Timelines

The Problem: B2B buyers often face significant delays in the delivery of drilling equipment, which can disrupt project timelines and lead to increased costs. In regions like Africa and South America, logistical challenges, customs clearance issues, and supply chain disruptions can exacerbate these delays. This situation not only affects operational efficiency but can also damage client relationships and impact future contracts.

The Solution: To mitigate delivery delays, buyers should establish clear communication channels with manufacturers. It is crucial to discuss and agree on realistic timelines during the procurement process. Additionally, buyers can leverage technology by using tracking systems that provide real-time updates on shipping status. Engaging with suppliers who have a robust logistics network and local distribution centers can also minimize delays. Building a strong relationship with the supplier and understanding their capabilities can help buyers anticipate potential issues and plan accordingly, ensuring that projects stay on track.

Scenario 2: Difficulty in Selecting the Right Equipment for Diverse Applications

The Problem: Many B2B buyers struggle with selecting the appropriate drilling equipment for specific applications, such as geothermal drilling, environmental projects, or mineral exploration. This challenge can arise from a lack of technical knowledge or insufficient information about available equipment features, leading to improper equipment choices that can hinder project success.

The Solution: Buyers should invest time in conducting thorough research before making a purchase. This involves not only reviewing product specifications but also consulting with application specialists from manufacturers. Engaging with experts who understand the nuances of various drilling applications can provide insights into the best equipment choices. Additionally, buyers can request demonstrations or trial periods for drilling rigs to evaluate their performance in real-world conditions. Utilizing a structured decision-making framework that includes factors like project scope, soil conditions, and budget can also streamline the selection process.

Scenario 3: Ensuring Equipment Reliability and Maintenance Support

The Problem: Another common pain point for B2B buyers is the concern over equipment reliability and the availability of maintenance support. When drilling equipment fails during operations, it can lead to costly downtime, safety hazards, and project delays. This is particularly critical in regions where access to repair services and spare parts may be limited.

The Solution: To ensure ongoing reliability, buyers should prioritize manufacturers that offer comprehensive maintenance plans and have a solid reputation for after-sales support. Before finalizing a purchase, it is advisable to inquire about the availability of spare parts and the average response time for service requests. Establishing a preventive maintenance schedule can help identify potential issues before they lead to equipment failure. Moreover, investing in training for operators on proper equipment handling and maintenance can significantly enhance performance and longevity, reducing the risk of unexpected breakdowns.

Strategic Material Selection Guide for drilling equipment manufacturers

What Are the Key Materials Used in Drilling Equipment Manufacturing?

When selecting materials for drilling equipment, manufacturers must consider various factors that impact performance, durability, and cost. Here, we analyze four common materials used in the industry: steel, aluminum, composite materials, and high-performance alloys. Each material has unique properties and implications for international buyers, especially those from regions like Africa, South America, the Middle East, and Europe.

How Does Steel Perform in Drilling Equipment Applications?

Steel is the most widely used material in drilling equipment due to its excellent strength and durability. It offers high-temperature and pressure ratings, making it suitable for various applications, including oil and gas drilling. Steel’s corrosion resistance can be enhanced through coatings or alloying with other elements.

Pros: Steel is highly durable and cost-effective, making it a preferred choice for many manufacturers. Its availability and ease of fabrication also contribute to its popularity.

Cons: While steel is robust, it can be heavy, which may affect the mobility of drilling rigs. Additionally, untreated steel is susceptible to corrosion, particularly in harsh environments, necessitating protective measures.

Impact on Application: Steel is compatible with various drilling media, including water, oil, and gas. However, in corrosive environments, additional considerations for protective coatings are essential.

Considerations for International Buyers: Compliance with international standards like ASTM for steel grades is crucial. Buyers should ensure that the steel used meets the specific requirements for their region, particularly in terms of corrosion resistance and mechanical properties.

What Advantages Do Aluminum Alloys Offer in Drilling Equipment?

Aluminum alloys are increasingly popular in drilling equipment due to their lightweight nature and good corrosion resistance. They are particularly beneficial in applications where weight reduction is critical, such as portable drilling rigs.

Pros: The primary advantage of aluminum is its lightweight, which enhances mobility and reduces operational costs. It also offers excellent resistance to corrosion, making it suitable for use in marine environments.

Cons: Aluminum has lower tensile strength compared to steel, which may limit its use in high-stress applications. Additionally, it can be more expensive than standard steel, impacting overall project budgets.

Impact on Application: Aluminum is ideal for applications requiring lightweight components, such as drill rigs used in remote or difficult-to-access locations. However, its lower strength may necessitate design modifications to ensure safety and performance.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades and standards (like DIN or JIS) relevant to their region. Understanding the cost implications of using aluminum versus steel is also essential for budget planning.

How Do Composite Materials Enhance Drilling Equipment Performance?

Composite materials, often made from a combination of fibers and resins, are gaining traction in drilling equipment due to their high strength-to-weight ratio and corrosion resistance. These materials are particularly useful in applications where traditional metals may fail.

Pros: Composites are lightweight, resistant to corrosion, and can be tailored for specific applications, providing versatility in design. They also have excellent fatigue resistance, which is beneficial for repetitive drilling operations.

Cons: The manufacturing process for composites can be complex and costly, which may deter some manufacturers. Additionally, they may not be suitable for all applications, particularly where high temperatures are involved.

Impact on Application: Composites are ideal for components that require a balance of strength and weight, such as drill bits and casing. However, their performance can be limited in extreme conditions.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards and certifications. Understanding the long-term performance and maintenance requirements of composites is also crucial.

What Role Do High-Performance Alloys Play in Drilling Equipment?

High-performance alloys, including nickel and titanium alloys, are essential for drilling in extreme conditions, such as deep-sea or high-temperature environments. These materials provide exceptional strength and corrosion resistance.

Pros: High-performance alloys offer superior durability and can withstand extreme temperatures and pressures, making them ideal for challenging drilling applications. Their longevity can lead to reduced maintenance costs over time.

Cons: The primary drawback is the high cost of these alloys, which can significantly impact project budgets. Manufacturing processes for these materials can also be complex, requiring specialized techniques.

Impact on Application: These alloys are critical in applications where failure is not an option, such as in deep-water drilling or high-pressure gas extraction. Their use can enhance safety and operational efficiency.

Considerations for International Buyers: Buyers must consider the availability of high-performance alloys in their regions and ensure compliance with relevant standards. Understanding the return on investment in terms of durability versus initial costs is vital for decision-making.

Summary Table of Strategic Material Selection

| Material | Typical Use Case for drilling equipment manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Oil and gas drilling rigs | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum Alloys | Portable drilling rigs | Lightweight and corrosion-resistant | Lower tensile strength | High |

| Composite Materials | Drill bits and casing | High strength-to-weight ratio | Complex manufacturing process | High |

| High-Performance Alloys | Deep-sea and high-temperature drilling | Exceptional durability and performance | High cost and complex manufacturing | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in drilling equipment manufacturing, enabling informed decisions that align with operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for drilling equipment manufacturers

What Are the Main Stages of Manufacturing Drilling Equipment?

The manufacturing process for drilling equipment typically encompasses several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring the durability, efficiency, and safety of the final product.

-

Material Preparation: The process begins with the selection of high-quality raw materials, such as steel and alloys, which are essential for the performance of drilling rigs and related equipment. These materials are then cut and shaped to specifications, ensuring they meet the required standards for strength and durability.

-

Forming: In this stage, various techniques such as forging, casting, and machining are employed to shape the components of the drilling equipment. For example, precision machining is crucial for parts like drill bits and rig frames to achieve the necessary tolerances and performance specifications.

-

Assembly: Once individual components are formed, they are assembled into complete units. This stage often involves the integration of various systems, including hydraulic, electrical, and mechanical components. The assembly process is typically performed in a clean environment to minimize contamination and ensure quality.

-

Finishing: The final stage involves surface treatment and coating to enhance corrosion resistance and durability. Techniques such as galvanizing, painting, or applying specialized coatings are common. This not only improves the aesthetic quality of the equipment but also extends its lifespan in challenging operational environments.

How Is Quality Assurance Ensured in Drilling Equipment Manufacturing?

Quality assurance (QA) is a vital component of the manufacturing process for drilling equipment, encompassing international standards and industry-specific regulations. These frameworks guide manufacturers in maintaining high-quality outputs.

-

International Standards: Many manufacturers adhere to ISO 9001, an internationally recognized standard for quality management systems. Compliance with ISO 9001 ensures that the manufacturer has established processes for consistent quality control, enhancing customer satisfaction and trust.

-

Industry-Specific Certifications: In addition to ISO standards, drilling equipment manufacturers often pursue industry-specific certifications such as CE marking for compliance with European safety standards and API (American Petroleum Institute) certifications for oil and gas equipment. These certifications validate the equipment’s reliability and safety for use in demanding environments.

What Are the Key Quality Control Checkpoints in Drilling Equipment Manufacturing?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process to ensure that each component meets the required specifications. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must provide certificates of conformity to verify that materials meet the specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and testing are conducted to monitor the quality of components. Techniques such as dimensional checks, non-destructive testing (NDT), and functional testing are employed to detect any defects early on.

-

Final Quality Control (FQC): Once the assembly is complete, the entire unit undergoes thorough testing and inspection to ensure it meets all operational and safety requirements. This may include performance testing under simulated operational conditions.

Which Testing Methods Are Commonly Used in Drilling Equipment Manufacturing?

Manufacturers employ various testing methods to assess the performance and reliability of drilling equipment. Common methods include:

- Hydraulic Testing: This method tests the integrity of hydraulic systems under pressure, ensuring there are no leaks and that components can withstand operational stresses.

- Load Testing: Equipment is subjected to maximum operational loads to verify that it can handle the expected stresses without failure.

- Functional Testing: This ensures that all systems, such as electrical and hydraulic systems, operate as intended under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence to ensure that their suppliers adhere to stringent quality control practices. Here are several actionable steps:

-

Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should request access to audit reports or consider hiring third-party auditors to evaluate supplier facilities.

-

Quality Assurance Reports: Suppliers should provide comprehensive QA reports detailing their quality management practices, inspection results, and certifications. These documents should outline their adherence to international and industry-specific standards.

-

Third-Party Inspections: Engaging independent inspection services can offer an unbiased evaluation of the supplier’s quality control measures. This is particularly important for buyers in regions with stringent import regulations.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential:

-

Regulatory Compliance: Different regions have varying regulations regarding drilling equipment. Buyers must be aware of local compliance requirements, such as CE marking in Europe or API standards in the U.S.

-

Cultural Considerations: Building relationships with suppliers often involves understanding cultural differences in business practices. This can affect negotiations, contract terms, and quality expectations.

-

Supply Chain Reliability: International buyers should assess the reliability of a supplier’s logistics and supply chain. Delays in the supply chain can impact project timelines, making it crucial to choose suppliers with robust logistics capabilities.

In conclusion, understanding the manufacturing processes and quality assurance practices is critical for B2B buyers in the drilling equipment sector. By focusing on the manufacturing stages, quality control checkpoints, testing methods, and verification strategies, buyers can make informed decisions and ensure the reliability and performance of the equipment they procure.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drilling equipment manufacturers’

Introduction

This sourcing guide is designed to assist international B2B buyers in effectively procuring drilling equipment from reputable manufacturers. By following this step-by-step checklist, you can ensure that you make informed decisions that align with your operational needs and business objectives.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before engaging with suppliers. This includes determining the type of drilling equipment needed (e.g., rotary drills, core drills) and its intended application, such as oil and gas exploration or construction. Consider factors like drilling depth, diameter, and environmental conditions to ensure compatibility with your project requirements.

Step 2: Conduct Market Research

Thorough market research helps you identify potential suppliers and understand current market trends. Analyze the competitive landscape, focusing on manufacturers known for quality and reliability. Utilize industry reports and online resources to gather insights into leading brands and emerging technologies that may benefit your operations.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers that demonstrate a solid track record of delivering high-quality equipment and have positive feedback from existing clients. This step minimizes risks associated with supplier selection.

Step 4: Verify Supplier Certifications and Standards

Ensure that your chosen manufacturers comply with relevant industry certifications and standards. This may include ISO certifications, safety standards, and environmental regulations. Suppliers that adhere to these standards are more likely to provide reliable and safe equipment, which is critical for maintaining operational integrity and compliance.

Step 5: Assess After-Sales Support and Service

After-sales support is a key factor that can significantly impact your operations. Inquire about the availability of spare parts, warranty conditions, and technical support. A supplier that offers comprehensive after-sales service can help reduce downtime and ensure your equipment remains operational, which is vital for project success.

Step 6: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that outline pricing, terms, and conditions. Compare these quotations not only on price but also on the value offered, including delivery timelines, payment terms, and additional services. This will help you make a balanced decision that considers both cost and quality.

Step 7: Negotiate Terms and Finalize Contracts

After reviewing quotations, engage in negotiations to secure the best possible terms. Discuss payment schedules, delivery timelines, and service agreements to ensure clarity on both sides. Finalizing a well-structured contract protects your interests and establishes a clear framework for the supplier relationship moving forward.

By adhering to these steps, you can streamline your procurement process and enhance your ability to select the right drilling equipment manufacturer that meets your specific needs.

Comprehensive Cost and Pricing Analysis for drilling equipment manufacturers Sourcing

What Are the Key Cost Components for Drilling Equipment Manufacturers?

When sourcing drilling equipment, understanding the cost structure is vital. The primary cost components include:

-

Materials: The raw materials used in manufacturing drilling rigs significantly impact the overall cost. High-grade steel, specialized alloys, and advanced composite materials are commonly employed, each contributing differently to the price.

-

Labor: Labor costs encompass skilled workers who assemble and test the equipment. Regions with lower labor costs may offer competitive pricing, but it’s essential to ensure that quality is not compromised.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and indirect labor. Manufacturers with optimized operations can pass savings onto buyers.

-

Tooling: Custom tooling is often required for specialized rigs. The cost of designing and manufacturing these tools can be substantial, particularly if the specifications are unique or complex.

-

Quality Control (QC): Rigorous QC processes ensure that equipment meets industry standards. While this adds to the initial cost, it is crucial for ensuring long-term reliability and safety.

-

Logistics: Shipping costs vary based on the size and weight of the equipment, as well as the distance to the destination. Understanding Incoterms can help buyers anticipate additional charges.

-

Margin: Manufacturers typically apply a margin to cover their operational costs and profit. This margin can vary widely depending on the manufacturer’s market position and the competitive landscape.

How Do Price Influencers Affect Drilling Equipment Costs?

Several factors influence the pricing of drilling equipment, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can often lead to reduced unit prices. Buyers should negotiate MOQs that align with their operational needs.

-

Specifications and Customization: Custom-built rigs tailored to specific applications will typically incur higher costs. Clear communication of requirements is essential to avoid unexpected expenses.

-

Materials: The choice of materials can dramatically affect pricing. Buyers should balance cost with the desired durability and performance.

-

Quality and Certifications: Equipment that meets international standards (e.g., ISO certifications) may come at a premium but ensures reliability and safety, making it a worthwhile investment.

-

Supplier Factors: The reputation and financial stability of a supplier can influence pricing. Established manufacturers with proven track records may charge more but often provide better warranties and support.

-

Incoterms: Understanding shipping terms can prevent unexpected costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks.

What Tips Can Help Buyers Negotiate Better Prices?

International B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, can benefit from the following strategies:

-

Negotiate Terms: Always negotiate pricing, delivery terms, and payment options. Suppliers may have flexibility, especially for bulk orders.

-

Focus on Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, operating costs, maintenance, and eventual disposal. Sometimes a higher initial cost can lead to lower long-term expenses.

-

Understand Pricing Nuances: Be aware of regional pricing differences due to local demand, tariffs, and currency fluctuations. This knowledge can empower buyers during negotiations.

-

Seek Multiple Quotes: Obtain quotes from several suppliers to gauge the market rate. This approach can provide leverage in negotiations.

Disclaimer on Pricing Information

The pricing discussed here is indicative and can vary based on numerous factors, including market conditions, supplier negotiations, and specific project requirements. It is advisable for buyers to conduct thorough market research and engage in direct discussions with manufacturers to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing drilling equipment manufacturers With Other Solutions

Exploring Alternatives to Drilling Equipment Manufacturers

In the ever-evolving landscape of drilling solutions, it is essential for B2B buyers to consider various alternatives to traditional drilling equipment manufacturers. This analysis aims to compare drilling equipment manufacturers with two viable alternatives: contract drilling services and advanced drilling technology solutions. Each option presents unique advantages and drawbacks that can significantly influence operational efficiency and cost-effectiveness.

| Comparison Aspect | Drilling Equipment Manufacturers | Contract Drilling Services | Advanced Drilling Technology Solutions |

|---|---|---|---|

| Performance | High-quality, reliable rigs for diverse applications | Variable performance based on service provider | Enhanced precision and efficiency with automation |

| Cost | High initial investment; long-term savings possible | Lower upfront costs, ongoing operational costs | Moderate to high investment, potential for significant cost savings |

| Ease of Implementation | Requires significant setup and training | Quick deployment; reliance on provider’s expertise | Requires training and integration with existing systems |

| Maintenance | Regular maintenance needed; support services available | Maintenance handled by the contractor | Advanced technology may require specialized support |

| Best Use Case | Ideal for large-scale, long-term projects | Suitable for short-term or specialized projects | Best for high-precision, data-driven drilling operations |

What Are the Pros and Cons of Contract Drilling Services?

Contract drilling services allow companies to outsource their drilling operations to specialized firms. This option is particularly beneficial for organizations that may not have the capital for significant upfront investments in drilling rigs. The primary advantage is the lower initial cost, as companies only pay for the services rendered without the burden of equipment ownership. However, the performance can vary significantly depending on the contractor’s expertise and reliability. Additionally, companies may face challenges related to scheduling and availability, which can impact project timelines.

How Do Advanced Drilling Technology Solutions Compare?

Advanced drilling technology solutions encompass innovations such as automated drilling rigs and data analytics software that optimize drilling performance. These technologies can significantly improve precision and efficiency, leading to reduced operational costs in the long run. The initial investment can be moderate to high, but the potential for enhanced productivity often justifies the expense. A downside is that these solutions may require specialized training for personnel and could necessitate integration with existing systems, which can complicate implementation.

Conclusion: How Should B2B Buyers Choose the Right Drilling Solution?

When selecting a drilling solution, B2B buyers must assess their specific needs, project scope, and available resources. For those requiring immediate access to drilling capabilities without the commitment of equipment purchase, contract drilling services may be the best fit. Conversely, organizations focused on long-term efficiency and technological advancement should consider investing in advanced drilling technologies. Ultimately, the choice hinges on balancing initial investment against operational efficiency, ensuring that the selected solution aligns with the company’s overall strategy and objectives.

Essential Technical Properties and Trade Terminology for drilling equipment manufacturers

What Are the Essential Technical Properties of Drilling Equipment?

When evaluating drilling equipment, understanding key technical properties is crucial for making informed purchasing decisions. Here are some of the most important specifications to consider:

1. Material Grade

Material grade refers to the type of metal or composite used in the manufacturing of drilling equipment. Common materials include high-strength steel and aluminum alloys, which are selected based on their durability and resistance to wear and corrosion. For B2B buyers, choosing the right material grade ensures that the equipment can withstand harsh operating conditions, thereby enhancing longevity and reducing maintenance costs.

2. Torque Capacity

Torque capacity indicates the maximum rotational force that a drill rig can apply during operation. This specification is vital for determining the rig’s efficiency and effectiveness in different drilling environments, such as oil and gas extraction or mineral exploration. Buyers must consider torque capacity to ensure the chosen equipment meets the demands of their specific projects, preventing downtime and costly operational failures.

3. Weight and Dimensions

Weight and dimensions are critical for logistical considerations, including transport and installation. A lighter rig may be easier to maneuver, especially in remote or challenging terrains, while compact dimensions can facilitate access to tight spaces. For international B2B buyers, understanding these specifications helps in planning for transportation costs and site setup, ensuring a smooth operation flow.

4. Drilling Depth and Diameter

Drilling depth and diameter define the range of operations for a drilling rig. Different applications require varying depths and diameters; for instance, geothermal wells typically require deeper drilling compared to water wells. Understanding these specifications ensures that the equipment selected is suitable for the intended application, thereby optimizing performance and productivity.

5. Hydraulic System Specifications

Hydraulic systems in drilling equipment play a crucial role in power transmission and operational efficiency. Key specifications include pressure ratings and flow rates. A robust hydraulic system enhances the rig’s performance, allowing for smoother operation and faster drilling times. B2B buyers should prioritize equipment with advanced hydraulic capabilities to increase productivity on site.

What Are Common Trade Terms in the Drilling Equipment Industry?

Familiarity with industry terminology can significantly streamline communication and negotiations. Here are some essential trade terms relevant to drilling equipment manufacturers:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers looking for quality and compatibility when sourcing replacement parts or new equipment.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers to understand budget constraints and inventory management. Knowing the MOQ can help in planning purchases more effectively, especially for smaller operations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and other terms for specific products or services. Crafting a well-defined RFQ can lead to more accurate quotes and better negotiation outcomes, ensuring that buyers receive competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is vital for international transactions, as they dictate risk and cost responsibilities, influencing overall procurement strategies.

5. Lead Time

Lead time is the time between placing an order and receiving the goods. This is a critical factor for B2B buyers, as longer lead times can affect project timelines. Being aware of lead times helps in planning procurement schedules and managing expectations with stakeholders.

Conclusion

Understanding the essential technical properties and trade terminology associated with drilling equipment is vital for B2B buyers. By familiarizing themselves with these specifications and terms, companies can make more informed purchasing decisions, optimize their procurement processes, and ultimately enhance operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the drilling equipment manufacturers Sector

What Are the Key Market Trends Impacting Drilling Equipment Manufacturers?

The global drilling equipment market is undergoing significant transformation, driven by several key factors. The demand for advanced drilling solutions is increasing across diverse sectors, including oil and gas, construction, and mining. This is fueled by the need for enhanced efficiency and safety in operations. Technological advancements, particularly in automation and IoT, are becoming essential for manufacturers aiming to improve operational performance. For instance, automated drilling rigs are increasingly preferred as they reduce labor costs and increase precision, which is critical in competitive markets like Africa and South America.

Moreover, the emphasis on sustainability is reshaping sourcing trends. Buyers are increasingly seeking suppliers who prioritize eco-friendly practices and materials. This shift is particularly pronounced in Europe, where stringent regulations around emissions and environmental impact are being implemented. Additionally, manufacturers are exploring digital solutions, such as predictive maintenance and real-time data analytics, to optimize performance and reduce downtime, thus appealing to international B2B buyers seeking reliability and cost-effectiveness.

How Is Sustainability Influencing Sourcing Decisions in the Drilling Equipment Sector?

Sustainability has emerged as a critical factor in the drilling equipment manufacturing sector, influencing sourcing and procurement strategies among international buyers. The environmental impact of drilling activities is under scrutiny, prompting manufacturers to adopt sustainable practices throughout their supply chains. This includes utilizing renewable materials, implementing energy-efficient processes, and reducing waste.

Ethical sourcing is also gaining traction, as buyers increasingly favor companies that demonstrate corporate social responsibility. Certifications such as ISO 14001 for environmental management systems and adherence to ethical labor practices are becoming essential criteria for procurement decisions. Buyers in regions like the Middle East and Europe are particularly keen on partnering with manufacturers that can provide transparency in their sourcing practices, thereby ensuring compliance with local regulations and enhancing their brand reputation.

Furthermore, the integration of “green” technologies, such as electric and hybrid drilling rigs, is reshaping the product offerings of manufacturers. This not only reduces the carbon footprint of drilling operations but also aligns with the growing demand for sustainability in sectors like construction and environmental remediation.

How Has the Drilling Equipment Manufacturing Sector Evolved Over Time?

The drilling equipment manufacturing sector has seen considerable evolution over the last century, driven by technological advancements and shifting market demands. Initially focused on basic mechanical solutions, the industry has transitioned to embrace sophisticated technologies, such as hydraulic and pneumatic systems. This evolution was largely fueled by the oil and gas boom in the mid-20th century, which created a surge in demand for efficient drilling solutions.

In recent decades, the introduction of computer-aided design (CAD) and simulation technologies has further revolutionized the manufacturing process, allowing for more precise and innovative equipment designs. As global energy demands continue to rise, manufacturers are now focusing on sustainable practices and automated systems to meet the challenges of modern drilling operations. This historical context is crucial for B2B buyers, as it highlights the ongoing trend towards innovation and sustainability that is shaping the future of the drilling equipment industry.

Conclusion

Navigating the complexities of the drilling equipment market requires international B2B buyers to stay informed about current trends, sustainability practices, and the historical context of the sector. By understanding these dynamics, buyers can make informed sourcing decisions that align with their operational goals and ethical standards, ensuring a competitive edge in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of drilling equipment manufacturers

-

How do I select the right drilling equipment for my project?

Choosing the appropriate drilling equipment begins with a thorough assessment of your project’s specific needs, including the type of material you will be drilling, the depth required, and the environmental conditions. Consider factors such as the drilling method (e.g., rotary, percussion), power source (e.g., hydraulic, electric), and mobility (e.g., wheeled, tracked). Engaging with manufacturers for expert advice and possibly conducting a feasibility study can help ensure you select the most efficient and cost-effective solution for your operations. -

What is the best type of drill rig for geothermal and water well drilling?

For geothermal and water well drilling, a versatile and robust drill rig such as the SIMCO 7000 is often recommended. It features an auto-indexing drill rod carousel and can achieve significant drilling depths, making it suitable for various geological conditions. Additionally, consider rigs that offer hydraulic capabilities for better efficiency and adaptability in different terrains. Always consult with manufacturers to match your specific requirements with the capabilities of their equipment. -

What factors should I consider when vetting drilling equipment manufacturers?

When vetting drilling equipment manufacturers, prioritize their industry experience, reputation, and product range. Evaluate their certifications, compliance with international standards, and customer reviews. Assess their after-sales support, including maintenance services and availability of spare parts. Additionally, inquire about their capacity for customization and responsiveness to inquiries, as these factors can significantly impact your overall purchasing experience. -

What are the common payment terms for international drilling equipment purchases?

Payment terms can vary widely among manufacturers, but common practices include upfront payments, partial payments upon order confirmation, and balance payments prior to shipping. Letters of credit and escrow services are also frequently used in international transactions to ensure security for both parties. Always clarify payment terms in the purchase agreement to avoid misunderstandings and ensure smooth transactions. -

Are there minimum order quantities (MOQ) for drilling equipment?

Minimum order quantities can vary significantly between manufacturers and the type of equipment. Some manufacturers may have flexible MOQs, especially for custom or specialized equipment, while others may set strict limits based on production costs. It’s advisable to discuss your specific needs with manufacturers early in the negotiation process to determine if they can accommodate smaller orders or if they offer options for joint purchasing with other clients. -

How can I ensure quality assurance in my drilling equipment purchases?

To ensure quality assurance, request detailed product specifications, certifications, and test results from manufacturers. Conducting factory visits or audits can provide insights into their production processes and quality control measures. Additionally, consider requesting samples or pilot runs to evaluate performance before committing to larger orders. Establishing clear quality expectations in your contracts can also help safeguard against potential issues. -

What logistics considerations should I be aware of when importing drilling equipment?

Logistics play a crucial role in the successful importation of drilling equipment. Key considerations include shipping methods, customs regulations, and potential tariffs or duties. Engage with logistics providers who specialize in heavy equipment to ensure efficient transport and handling. Additionally, account for lead times in production and shipping to avoid project delays, and confirm that the manufacturer can provide necessary shipping documentation and support for customs clearance. -

How can I find reputable suppliers for drilling equipment in my region?

To find reputable suppliers for drilling equipment, start by conducting online research, attending industry trade shows, and leveraging professional networks. Industry-specific directories and associations can provide valuable contacts. Additionally, consider reaching out to local industry peers for recommendations based on their experiences. Verifying suppliers through references and checking their financial stability can further ensure that you are partnering with a reliable and capable manufacturer.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for drilling equipment manufacturers

What Are the Key Takeaways for Strategic Sourcing in Drilling Equipment?

In the rapidly evolving landscape of drilling equipment manufacturing, strategic sourcing has emerged as a crucial component for international B2B buyers. Understanding the diverse applications of drilling rigs—from oil and gas to geothermal and environmental drilling—enables buyers to make informed decisions tailored to their specific needs. The emphasis on sustainability and automation in modern equipment not only enhances operational efficiency but also aligns with global trends towards greener practices.

How Can Buyers Optimize Their Procurement Strategies?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should leverage relationships with manufacturers known for innovation and reliability. Engaging with suppliers that offer comprehensive support services, including rapid parts delivery and expert consultation, can significantly reduce downtime and enhance project outcomes.

What Does the Future Hold for Drilling Equipment Manufacturers?

Looking ahead, the drilling equipment sector is set to experience continued growth driven by technological advancements and rising global demand for energy. By prioritizing strategic sourcing, buyers can position themselves to capitalize on emerging opportunities, ensuring they are equipped with the best tools for success. Embrace this proactive approach and connect with leading manufacturers today to secure your competitive edge in the market.