Top 7 Custom Machine Manufacturer Manufacturers & Suppliers List

1. Ame – Custom Machine Solutions

Domain: ame.com

Registered: 1994 (31 years)

Introduction: Custom Machine Design and Build services, Rebuilds and Retrofits, CNC Workholding Systems, Rod Locks & Press Safety Solutions, Tool Clamping Systems, Machining Automation, Custom-Designed Machine Tool Systems, Contract Manufacturing, Engineering for Repeatability, Integrated Project Management, Quality and Reliability, Flexible Configurations, Carbide Saw Systems, Automated Pallet Delivery, Roboti…

2. Machine Concepts – Custom Machinery Solutions

Domain: machineconcepts.com

Registered: 1999 (26 years)

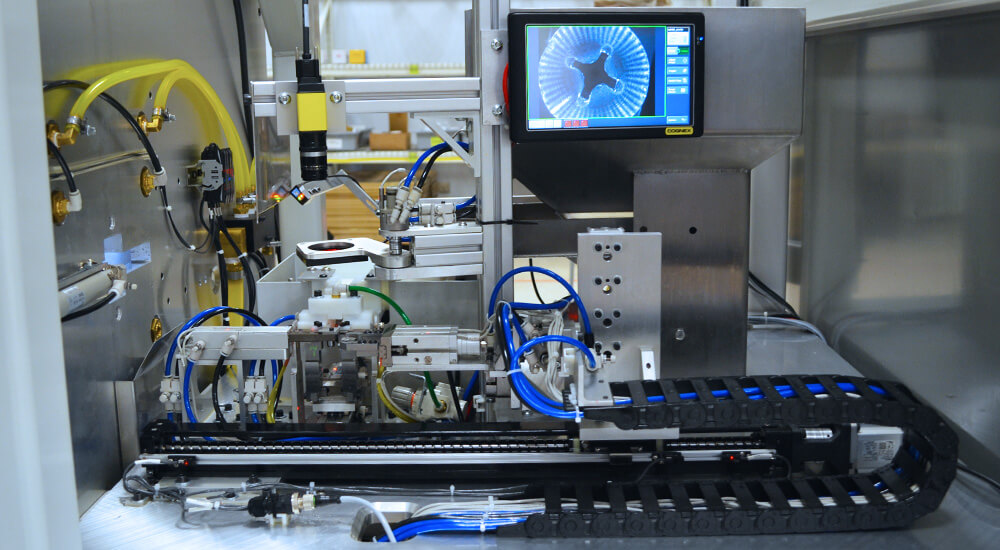

Introduction: Machine Concepts specializes in custom machinery design and building, offering a range of innovative processing equipment. Key product categories include: 1. Custom Automation Equipment: – Turnkey Automation Systems – Robotic Integration – Handling Systems – 2D & 3D Vision Systems 2. Custom Equipment Design and Build: – Laser Cells – Metal Forming – Custom Process Tooling – Assembly & Weld Fixture…

3. ONExia – Custom Automation Solutions

Domain: onexia.com

Registered: 2001 (24 years)

Introduction: Custom Machine Builder | ONExia specializes in custom automation solutions, offering turn-key robotic automation systems tailored to various industries. Key features include:

– Expertise in motion control, precision positioning, and machine vision.

– Comprehensive engineering support for specialized machinery and assemblies.

– Services include controls assembly, motion control programming, precis…

4. KSN Industry – Custom-Built Machines

Domain: ksnindustry.com

Registered: 2019 (6 years)

Introduction: Custom-built machines designed and manufactured for specific jobs to streamline production processes, insource machining, and maximize efficiency. Features include specially engineered solutions for parts handling, automation, and machining. Custom machines are adaptable, combining new and existing technologies for reliable operation. Benefits include long-term cost efficiency, low operational cos…

5. Peiffer Machine – Custom Machine Building Services

Domain: peiffer-machine.com

Registered: 1997 (28 years)

Introduction: Custom Machine Building Services for over 40 years, specializing in one-off specialized machines and small lots of sub-assemblies. Capabilities include CNC Machining, Welding, Painting, Grinding, Milling/Drilling, Mechanical Assembly, Electrical Assembly, Panel Building, Quality Control/Testing, Managed Inventory, and Integrated Shipping and Warehousing Support. Delivery and installation services …

6. RedViking – Specialty Automation Machines

Domain: redviking.com

Registered: 2008 (17 years)

Introduction: RedViking offers specialty machines designed for automation in various industries. These machines are tailored to meet specific customer needs, enhancing efficiency and productivity. Key features include custom engineering, integration with existing systems, and support for complex manufacturing processes. The solutions aim to improve operational performance and reduce costs.

7. Custom Machine, LLC – Precision Manufacturing Solutions

Domain: custommachineinc.com

Registered: 1996 (29 years)

Introduction: Custom Machine, LLC specializes in precision manufacturing of Aerospace, Medical, Semi-Conductor, and Commercial components and assemblies. They utilize advanced CNC Milling, Turning, Grinding, and EDM machines for complex geometry requiring multi-axis 3D machining techniques. Their services include onsite secondary processes such as FPI, MPI, Pressure testing, and Leak testing, allowing them to c…

Introduction: Navigating the Global Market for custom machine manufacturer

In the rapidly evolving global market, sourcing custom machinery that aligns with specific production needs can pose significant challenges for international B2B buyers. From complex automation systems to precision electromechanical equipment, the diversity of available options can be overwhelming. This guide serves as a comprehensive resource, addressing key aspects such as types of custom machines, their applications across various industries, effective supplier vetting processes, and cost considerations.

Designed with the needs of B2B buyers in Africa, South America, the Middle East, and Europe in mind—such as those in Nigeria and Saudi Arabia—this guide empowers decision-makers to navigate the intricacies of purchasing custom machinery. By providing actionable insights and strategic approaches, it equips buyers with the knowledge to make informed decisions that enhance productivity and operational efficiency. Understanding the landscape of custom machine manufacturing not only helps in selecting the right equipment but also fosters partnerships with reliable suppliers, ensuring seamless integration into existing production processes.

As you delve into this guide, expect to uncover valuable strategies and expert advice tailored to your unique business needs, enabling you to thrive in a competitive global marketplace.

Understanding custom machine manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Build-to-Print Manufacturers | Focus on producing machinery based on client designs; emphasize manufacturability and cost-effectiveness. | Aerospace, automotive, and industrial manufacturing. | Pros: Tailored solutions; Cons: Limited design flexibility once specifications are set. |

| Turnkey System Providers | Offer complete solutions from design to installation; integrate various systems for seamless operation. | Pharmaceuticals, food and beverage processing. | Pros: Comprehensive service; Cons: Potentially higher upfront costs. |

| Automated Equipment Builders | Specialize in high-precision automation systems; often involve complex electromechanical integration. | Electronics, automotive assembly, and life sciences. | Pros: Increased efficiency; Cons: High complexity may require extensive training. |

| Retrofit and Rebuild Specialists | Focus on upgrading existing machinery to enhance performance or extend lifespan; often more cost-effective. | Manufacturing facilities with aging equipment. | Pros: Cost savings; Cons: May not provide the latest technology. |

| Custom Robotic Systems Designers | Develop specialized robotic solutions for specific tasks, enhancing precision and productivity. | Medical device manufacturing, packaging, and logistics. | Pros: Tailored automation; Cons: High initial investment and integration challenges. |

What Are Build-to-Print Manufacturers and Their B2B Relevance?

Build-to-print manufacturers focus on delivering custom machinery based on client specifications. They assess designs for manufacturability and cost-effectiveness, ensuring that the final product aligns with the client’s operational needs. This type of manufacturer is particularly suitable for industries like aerospace and automotive, where precise adherence to designs is critical. B2B buyers should consider the trade-off between tailored solutions and the limited flexibility in making changes post-specification.

How Do Turnkey System Providers Enhance B2B Operations?

Turnkey system providers deliver comprehensive solutions that encompass everything from design to installation. They are particularly valuable in sectors like pharmaceuticals and food processing, where regulatory compliance and system integration are paramount. The primary advantage is the simplicity of dealing with a single supplier for the entire project, although this can lead to higher initial costs. Buyers must evaluate their budget against the benefits of streamlined operations.

What Advantages Do Automated Equipment Builders Offer?

Automated equipment builders specialize in creating high-precision machinery that integrates complex electromechanical systems. This type of manufacturer is ideal for industries such as electronics and automotive assembly, where efficiency and precision are crucial. While they enhance productivity, buyers should be aware that the complexity of these systems may necessitate significant training and support to maximize their benefits.

Why Consider Retrofit and Rebuild Specialists?

Retrofit and rebuild specialists focus on upgrading existing machinery to improve performance or extend its lifespan. This approach can be especially appealing to manufacturers with aging equipment, as it often represents a more cost-effective solution than investing in new machinery. Buyers should weigh the potential cost savings against the possibility that older systems may lack the latest technological advancements.

What Role Do Custom Robotic Systems Designers Play in B2B Manufacturing?

Custom robotic systems designers create specialized robotic solutions tailored for specific tasks, significantly enhancing productivity and precision. This is particularly relevant in sectors like medical device manufacturing and logistics, where automation can lead to substantial efficiency gains. However, the initial investment can be high, and integration challenges may arise, making it essential for buyers to assess their operational readiness for such advanced solutions.

Key Industrial Applications of custom machine manufacturer

| Industry/Sector | Specific Application of custom machine manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Automated Medical Equipment | Enhanced efficiency in patient care and reduced labor costs | Regulatory compliance, precision engineering, and reliability |

| Automotive | High-Precision Assembly Lines | Improved production speed and consistency | Scalability, adaptability, and integration with existing systems |

| Aerospace | Precision Fixturing and Automation Cells | Increased accuracy and reduced waste in manufacturing | Expertise in aerospace standards and materials |

| Food and Beverage | Custom Packaging Solutions | Extended shelf life and improved product presentation | Compliance with food safety regulations and cost-effectiveness |

| Pharmaceuticals | Aseptic Processing Systems for Drug Manufacturing | Ensured product integrity and compliance with regulations | Customization for specific drug types and regulatory standards |

How is Custom Machinery Used in Healthcare Applications?

In the healthcare sector, custom machine manufacturers develop automated medical equipment that streamlines the production of medical devices and pharmaceuticals. These machines help address challenges such as labor shortages and the need for higher efficiency in patient care. Buyers must prioritize regulatory compliance, precision engineering, and reliability, especially in regions with stringent healthcare standards, such as Europe and the Middle East. Custom solutions can lead to significant cost savings while maintaining high standards of quality and safety.

What Role Does Custom Machinery Play in Automotive Manufacturing?

In the automotive industry, custom machine manufacturers create high-precision assembly lines tailored to specific vehicle components. These machines enhance production speed and consistency, addressing the industry’s demand for rapid and efficient manufacturing processes. International buyers, particularly in Africa and South America, should consider scalability and adaptability to integrate new technologies or adapt to changing market demands. The ability to customize machinery for diverse automotive applications can significantly reduce production downtime and improve overall profitability.

How is Custom Machinery Essential for Aerospace Production?

Custom machine manufacturers provide precision fixturing and automation cells that are critical in aerospace production. These specialized machines improve accuracy and reduce waste, ensuring that components meet the industry’s rigorous safety standards. Buyers must seek manufacturers with deep expertise in aerospace materials and compliance with international regulations. The ability to deliver tailored solutions that enhance production efficiency while adhering to strict quality standards is essential for maintaining competitive advantage in this high-stakes industry.

How Does Custom Machinery Benefit the Food and Beverage Sector?

In the food and beverage sector, custom machine manufacturers design packaging solutions that extend shelf life and improve product presentation. This is particularly valuable in international markets where product differentiation is key to capturing consumer interest. Buyers should focus on suppliers who understand food safety regulations and can provide cost-effective solutions that do not compromise quality. Custom machinery can also streamline the packaging process, reducing labor costs and increasing throughput.

Why are Custom Machines Critical for Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, aseptic processing systems are vital for ensuring product integrity and compliance with health regulations. Custom machine manufacturers develop these systems to meet specific requirements for various drug types, addressing challenges such as contamination and variability in production. International buyers must prioritize customization options that align with regulatory standards in their regions. The investment in specialized machinery not only enhances production reliability but also supports faster time-to-market for critical medications.

3 Common User Pain Points for ‘custom machine manufacturer’ & Their Solutions

Scenario 1: Delays in Production Due to Custom Machinery Development

The Problem: In a competitive global marketplace, B2B buyers often face significant challenges with lead times when commissioning custom machinery. These delays can stem from various factors, including inefficient communication with manufacturers, complex design specifications, and unforeseen technical issues. For companies in sectors like automotive or pharmaceuticals, where timing is critical for market entry, such delays can lead to lost revenue and diminished competitive advantage.

The Solution: To mitigate delays, buyers should adopt a proactive approach when sourcing custom machine manufacturers. Begin by clearly defining project requirements and expectations upfront. Engage in detailed discussions with potential manufacturers to understand their processes, timelines, and any potential bottlenecks. Utilize tools such as project management platforms to maintain transparency and keep all stakeholders informed throughout the development process. Additionally, consider manufacturers with proven track records in your industry, as they are more likely to understand your needs and adhere to timelines. Regular status updates and milestone reviews can also help ensure that projects stay on track, reducing the risk of costly delays.

Scenario 2: Inadequate Customization Leading to Operational Inefficiencies

The Problem: Many B2B buyers encounter operational inefficiencies when custom machinery does not fully align with their specific production processes. This misalignment can occur if manufacturers do not thoroughly understand the buyer’s operational needs or if they provide a one-size-fits-all solution rather than a tailored approach. As a result, businesses may struggle with increased downtime, higher maintenance costs, and ultimately, lower productivity.

The Solution: To ensure the machinery aligns perfectly with operational needs, buyers should engage in a collaborative design process with their custom machine manufacturer. This involves not only sharing detailed specifications but also providing insights into existing workflows and challenges. It is crucial to select a manufacturer that offers comprehensive engineering support and is willing to iterate on designs based on feedback. Additionally, consider conducting a pilot run or using prototypes to test machinery before full-scale production. This step allows for adjustments to be made based on real-world performance and ensures that the final product meets all operational requirements.

Scenario 3: Difficulty in Integrating New Machinery into Existing Systems

The Problem: Integrating new custom machinery into an existing production environment can be a daunting task for many B2B buyers. The challenges often arise from compatibility issues with current systems, unexpected downtime during transitions, and the need for employee retraining. These complications can disrupt operations, leading to lost productivity and increased costs.

The Solution: To streamline the integration process, buyers should prioritize working with manufacturers that specialize in modular designs and flexible configurations. These features facilitate easier integration with existing systems. Before purchasing, conduct a thorough assessment of your current machinery and production processes, and communicate these findings to the manufacturer. Request detailed integration plans and timelines from the manufacturer, which should include installation support and employee training sessions. It’s also beneficial to schedule the installation during off-peak hours to minimize disruptions. Lastly, maintaining an open line of communication with the manufacturer post-installation can help address any issues that arise quickly and efficiently, ensuring a smoother transition into the new operational setup.

Strategic Material Selection Guide for custom machine manufacturer

When selecting materials for custom machinery, understanding the properties, advantages, and limitations of each option is crucial for ensuring optimal performance and longevity. This guide analyzes four common materials used in custom machine manufacturing, providing B2B buyers with actionable insights tailored to their specific regional needs.

What are the Key Properties of Steel in Custom Machinery?

Steel is a widely utilized material in custom machinery due to its excellent mechanical properties. It boasts high tensile strength, durability, and resistance to deformation under stress. Steel can also withstand high temperatures and pressures, making it suitable for various applications.

Pros: Steel’s durability and strength make it ideal for heavy-duty machinery. It is relatively cost-effective compared to other materials and can be easily machined and welded, allowing for complex designs.

Cons: However, steel is prone to corrosion if not properly treated or coated, which can lead to maintenance issues. Additionally, its weight may be a disadvantage in applications requiring lightweight components.

Impact on Application: Steel is compatible with a wide range of media, including oils and gases, but may require protective coatings for corrosive environments.

International Considerations: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN for steel quality and treatment processes.

How Does Aluminum Compare as a Material Choice?

Aluminum is another popular choice in custom machinery, especially where lightweight and corrosion resistance are priorities. Its low density and good strength-to-weight ratio make it suitable for applications requiring mobility and efficiency.

Pros: Aluminum is highly resistant to corrosion and does not rust, making it ideal for environments where moisture is present. It is also easier to machine than steel, allowing for intricate designs.

Cons: On the downside, aluminum has lower tensile strength compared to steel, which may limit its use in high-stress applications. Additionally, it can be more expensive than steel, impacting budget considerations.

Impact on Application: Aluminum is suitable for applications involving food processing or pharmaceuticals due to its non-reactive nature. However, it may not be suitable for high-temperature environments.

International Considerations: Buyers in Europe and South America should be aware of specific aluminum grades and their compliance with regional standards, ensuring they meet industry-specific requirements.

What Role Does Stainless Steel Play in Custom Machinery?

Stainless steel is favored for its exceptional corrosion resistance and aesthetic appeal. It is commonly used in industries where hygiene and cleanliness are paramount, such as food processing and pharmaceuticals.

Pros: The primary advantage of stainless steel is its ability to resist rust and corrosion, which extends the lifespan of machinery. It also maintains structural integrity at high temperatures.

Cons: The downside is that stainless steel can be more expensive than regular steel and may require specialized machining techniques, increasing manufacturing complexity.

Impact on Application: Stainless steel is compatible with various media, including aggressive chemicals, making it suitable for diverse applications.

International Considerations: B2B buyers should consider compliance with standards like ASTM A240 for stainless steel grades, particularly in regions with strict regulatory environments like Europe.

How Does Plastic Serve in Custom Machinery Applications?

Plastics, particularly engineering-grade plastics, are increasingly used in custom machinery for their versatility and lightweight properties. They can be engineered for specific applications, offering a range of mechanical and thermal properties.

Pros: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes, which makes them ideal for custom applications. They are also non-conductive, which can be advantageous in certain environments.

Cons: However, plastics generally have lower strength and durability compared to metals, which may limit their use in high-stress applications. They can also be sensitive to temperature extremes.

Impact on Application: Plastics are suitable for applications where chemical resistance is needed, such as in the food and beverage industry. However, they may not be suitable for high-temperature or high-pressure environments.

International Considerations: Buyers should ensure that the selected plastics meet relevant standards, such as FDA compliance for food-related applications, especially in regions with stringent health regulations.

Summary Table of Material Selection

| Material | Typical Use Case for custom machine manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machinery, structural components | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight machinery, automotive applications | Corrosion resistant and lightweight | Lower tensile strength | Medium to High |

| Stainless Steel | Food processing, medical equipment | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Plastic | Custom parts, food and beverage industry | Lightweight and versatile | Lower strength and thermal limits | Low to Medium |

This guide serves as a foundational resource for international B2B buyers, helping them navigate the complexities of material selection in custom machinery manufacturing. By understanding the properties and implications of each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom machine manufacturer

What Are the Key Stages in the Manufacturing Process for Custom Machinery?

The manufacturing process for custom machinery involves several critical stages that ensure the final product meets specific operational requirements and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Raw Material Processed?

The initial step in custom machinery manufacturing is material preparation. This involves selecting the right raw materials based on the machine’s design and intended application. Common materials include metals, plastics, and composites. The chosen materials undergo processes such as cutting, machining, or treatment to achieve the desired specifications. Techniques like laser cutting, CNC machining, and water jet cutting are often employed to ensure precision and reduce waste.

Forming: What Techniques Are Used to Shape Components?

Following material preparation, the forming stage shapes the raw materials into components that will be assembled into the final machinery. Techniques such as forging, stamping, and injection molding are commonly used, depending on the material and the complexity of the part. Advanced manufacturing methods, including additive manufacturing (3D printing), are increasingly used to produce intricate components that traditional methods may not efficiently create.

Assembly: How Are Components Integrated into the Final Product?

The assembly stage is where all the prepared and formed components come together. This process may involve manual labor or automated systems, depending on the complexity and volume of the machinery being produced. Custom machine builders often use modular designs, allowing for flexibility in production and easier integration of future upgrades. Quality assurance is crucial at this stage, as proper assembly directly impacts the functionality and reliability of the machinery.

Finishing: What Steps Ensure the Machinery Meets Final Specifications?

Finishing processes are applied to enhance the machine’s performance and aesthetics. Techniques such as painting, coating, or surface treatment are used to protect components from wear and corrosion while improving their appearance. Additionally, precision testing is conducted to ensure that all parts meet specified tolerances and functional criteria before the machinery is shipped to the client.

What Quality Assurance Practices Are Essential for Custom Machinery Manufacturers?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for custom machinery, ensuring that products meet both international standards and client specifications.

Which International Standards Should B2B Buyers Look For?

For B2B buyers, understanding the relevant international quality standards is critical. The ISO 9001 standard is widely recognized and outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Depending on the industry, additional certifications like CE marking for European markets or API standards for the oil and gas sector may also be pertinent.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints throughout the manufacturing process are vital for maintaining product integrity. These checkpoints typically include:

- Incoming Quality Control (IQC): This initial inspection ensures that all raw materials meet specified standards before they enter the production process.

- In-Process Quality Control (IPQC): During manufacturing, IPQC checks are performed at various stages to catch defects early and prevent costly rework.

- Final Quality Control (FQC): Before shipment, FQC verifies that the completed machinery adheres to all specifications and quality standards.

What Testing Methods Are Commonly Used?

Various testing methods are employed to validate the quality and functionality of custom machinery. Common methods include:

- Functional Testing: Ensures that the machinery operates according to design specifications.

- Performance Testing: Assesses the machine’s efficiency, speed, and output capacity.

- Durability Testing: Evaluates the machinery’s performance under simulated operational conditions to predict its lifespan.

How Can B2B Buyers Verify the Quality Assurance of Custom Machinery Manufacturers?

B2B buyers must conduct thorough due diligence to ensure that potential suppliers maintain robust quality assurance practices.

What Steps Should Buyers Take to Audit Suppliers?

Conducting audits is one of the most effective ways to verify a supplier’s quality assurance processes. Buyers can request access to the manufacturer’s quality management documentation, including their QMS certifications and internal audit reports. It is also advisable to perform on-site visits to assess the manufacturing environment and quality control measures firsthand.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an unbiased evaluation of a manufacturer’s capabilities and adherence to quality standards. These inspections can be particularly beneficial for international buyers who may not have the resources for in-house audits.

What Are the Unique QC Challenges for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance. Variability in regulatory standards, potential language barriers, and cultural differences can complicate supplier relationships. Buyers should ensure that manufacturers understand the specific regulatory requirements of their home markets, including any necessary certifications.

Conclusion: How Can B2B Buyers Ensure Quality in Custom Machinery Manufacturing?

For B2B buyers looking to procure custom machinery, understanding the manufacturing processes and quality assurance practices is essential. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control measures, buyers can make informed decisions when selecting suppliers. Moreover, conducting audits and engaging third-party inspections can further enhance confidence in the quality of the machinery being procured. This diligence will ultimately lead to successful partnerships and operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom machine manufacturer’

Introduction

Navigating the procurement of custom machinery can be complex, especially for international B2B buyers. This step-by-step checklist is designed to streamline your sourcing process, ensuring you find a manufacturer that meets your specific needs and complies with industry standards. By following these actionable steps, you can mitigate risks and enhance the efficiency of your operations.

Step 1: Define Your Technical Specifications

Clearly articulate what you need from the custom machinery. This includes understanding the technical requirements, production capacities, and any specific industry standards or regulations that must be met.

- Detailing specifications: Outline the dimensions, materials, and performance criteria necessary for your project.

- Compliance considerations: Identify any regulatory compliance needed, especially in sectors like healthcare or aerospace, where precision and safety are paramount.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify manufacturers with a proven track record in custom machinery relevant to your industry.

- Industry experience: Look for companies that have experience in your specific sector, as they will be more familiar with the unique challenges and requirements.

- Portfolio review: Examine their past projects to gauge their capabilities and the complexity of machinery they can produce.

Step 3: Evaluate Supplier Certifications

Before engaging with a manufacturer, verify their certifications and quality management systems.

- Quality assurance: Ensure they comply with international standards (e.g., ISO 9001) that guarantee a commitment to quality.

- Safety certifications: Check for any additional certifications relevant to your industry, such as cGMP for pharmaceutical applications.

Step 4: Request Proposals and Quotes

Once you have narrowed down your options, request detailed proposals and quotes from shortlisted manufacturers.

- Cost breakdown: Look for transparency in pricing, including costs for materials, labor, and any additional services like installation and support.

- Delivery timelines: Pay attention to the proposed timelines to ensure they align with your production schedule.

Step 5: Assess Communication and Support

Effective communication is vital throughout the manufacturing process. Evaluate how potential suppliers handle inquiries and provide support.

- Response time: Assess how quickly they respond to your questions and concerns; a prompt response often indicates a commitment to customer service.

- Ongoing support: Inquire about post-installation support and maintenance services, which are crucial for minimizing downtime.

Step 6: Conduct Site Visits or Virtual Tours

If possible, visit the manufacturing facility or take a virtual tour to better understand their capabilities and work environment.

- Facility standards: Look for cleanliness, organization, and adherence to safety protocols, which reflect their operational standards.

- Technology and equipment: Observe the technology and machinery in use, ensuring they are up-to-date and capable of producing high-quality custom solutions.

Step 7: Check References and Reviews

Finally, ask for references and read reviews from past clients to validate the manufacturer’s reliability and quality of service.

- Client feedback: Contact previous clients to gather insights on their experiences regarding delivery timelines, quality, and customer service.

- Case studies: Review case studies that demonstrate the manufacturer’s ability to handle projects similar to yours, providing further assurance of their expertise.

By following these steps, you can effectively source a custom machine manufacturer that aligns with your business needs, ensuring a successful partnership and optimal production outcomes.

Comprehensive Cost and Pricing Analysis for custom machine manufacturer Sourcing

What Are the Key Cost Components in Custom Machine Manufacturing?

When sourcing custom machinery, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

- Materials: The choice of materials significantly affects costs. High-quality or specialized materials can increase initial expenses but may offer greater durability and performance, reducing long-term costs.

- Labor: Skilled labor is essential for the design, assembly, and quality control of custom machinery. Labor costs can vary based on location and the complexity of the machinery being produced.

- Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and equipment depreciation. A manufacturer’s overhead can differ widely based on operational efficiency and location.

- Tooling: Custom machinery often requires specialized tooling, which can be a significant upfront investment. Understanding the tooling requirements early can help in budget planning.

- Quality Control (QC): Implementing robust QC measures ensures that the machinery meets specifications and regulatory requirements. This can add to costs but is essential for minimizing future liabilities.

- Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping mode, and Incoterms can influence logistics expenses.

- Margin: Suppliers typically include a profit margin in their pricing, which can vary based on competition, market conditions, and the perceived value of the machinery.

How Do Price Influencers Affect Custom Machine Costs?

Several factors can influence the pricing of custom machinery, including:

- Volume and Minimum Order Quantity (MOQ): Larger orders often come with discounts. However, if a buyer requires a low MOQ, they may face higher per-unit costs.

- Specifications and Customization: Highly specialized or unique designs can escalate costs. It’s essential to clearly communicate your needs to avoid unexpected expenses during production.

- Materials Quality and Certifications: The demand for certified materials (such as ISO compliance) can lead to higher prices. However, these certifications can enhance product reliability and marketability.

- Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

- Incoterms: The chosen Incoterms can impact the final price by determining responsibility for shipping, insurance, and tariffs. Understanding these terms is vital for accurate cost estimation.

What Tips Can Buyers Use to Negotiate Better Pricing?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several strategies can help in negotiating better pricing:

- Conduct Market Research: Understanding the market landscape and average pricing can empower buyers during negotiations. Knowing competitors’ offerings can provide leverage.

- Emphasize Long-Term Partnerships: Suppliers may be more willing to negotiate if they see potential for ongoing business. Highlighting your company’s growth plans can foster favorable terms.

- Focus on Total Cost of Ownership (TCO): Rather than only considering initial costs, buyers should evaluate the TCO, including maintenance, operation, and potential downtime. This perspective can justify a higher initial investment if long-term savings are evident.

- Be Flexible with Specifications: If possible, consider adjusting specifications to fit standard offerings, which can reduce costs. Customization often drives up prices.

- Leverage International Trade Agreements: Understanding and utilizing trade agreements can help mitigate tariffs and taxes, reducing overall costs.

What Should Buyers Keep in Mind Regarding Indicative Pricing?

Buyers should be aware that prices for custom machinery can vary significantly based on the aforementioned factors. Indicative prices provided by manufacturers are often estimates and can fluctuate based on changes in material costs, labor rates, and market demand. It is advisable to request detailed quotes that break down costs and understand the conditions that may lead to price adjustments. Engaging with multiple suppliers can also provide a broader perspective on pricing trends and options available in the market.

Alternatives Analysis: Comparing custom machine manufacturer With Other Solutions

Exploring Alternatives to Custom Machine Manufacturing

In the competitive landscape of industrial production, businesses often seek the most efficient and cost-effective solutions to meet their unique manufacturing needs. While custom machine manufacturing is a popular choice, several viable alternatives exist that may better suit specific operational requirements. This analysis will compare custom machine manufacturing with robotic automation and off-the-shelf machinery to help B2B buyers make informed decisions.

| Comparison Aspect | Custom Machine Manufacturer | Robotic Automation | Off-the-Shelf Machinery |

|---|---|---|---|

| Performance | High precision, tailored to specific needs | Versatile, high-speed operations | Standardized performance, may lack adaptability |

| Cost | Generally higher initial investment, but potential long-term savings | Mid-range cost with potential for ROI | Lower upfront cost, but may incur higher operational costs |

| Ease of Implementation | Requires detailed planning and design; longer lead times | Moderate complexity; integration with existing systems can be challenging | Quick to implement, minimal customization needed |

| Maintenance | May require specialized knowledge for upkeep | Regular maintenance needed; can be complex | Generally easier maintenance with readily available parts |

| Best Use Case | Complex, unique production processes requiring high customization | High-volume production with repetitive tasks | Standardized tasks with predictable processes |

Understanding Robotic Automation as an Alternative

Robotic automation offers a flexible solution for manufacturing processes that require speed and efficiency. These systems can be programmed to handle repetitive tasks, making them ideal for high-volume production lines. The initial investment is generally moderate, and companies often see a return on investment through increased productivity and reduced labor costs. However, integrating robotic systems into existing processes can be complex, requiring careful planning and potentially significant changes to workflows. While maintenance is necessary, it often demands specialized knowledge, which can be a drawback for companies without in-house expertise.

Evaluating Off-the-Shelf Machinery for Manufacturing Needs

Off-the-shelf machinery is a cost-effective option for businesses that require standardized equipment without the need for extensive customization. This solution often features lower initial costs and faster implementation times, making it appealing for companies looking to quickly ramp up production. However, the performance of off-the-shelf machinery may not meet the specific needs of all operations, particularly those that require unique processes or high levels of precision. Additionally, while maintenance tends to be simpler due to the availability of parts and support, these machines may incur higher operational costs over time due to inefficiencies in handling specialized tasks.

Making the Right Choice for Your Manufacturing Needs

When considering which solution is best for your business, it’s essential to weigh the specific requirements of your production process against the strengths and weaknesses of each alternative. Custom machine manufacturing shines in scenarios demanding high precision and tailored solutions, while robotic automation excels in environments prioritizing speed and efficiency. Off-the-shelf machinery serves well for operations where standardization is acceptable and quick implementation is critical.

Ultimately, the decision should align with your operational goals, budget constraints, and long-term vision for growth. By carefully analyzing these factors, B2B buyers can select the most suitable manufacturing solution to enhance productivity and drive business success.

Essential Technical Properties and Trade Terminology for custom machine manufacturer

What Are the Key Technical Properties for Custom Machinery?

When engaging with a custom machine manufacturer, understanding specific technical properties is crucial for making informed decisions. Here are some of the most important specifications to consider:

-

Material Grade

The material grade defines the quality and type of materials used in manufacturing machinery. Common grades include stainless steel, aluminum, and various alloys, each selected based on the application’s requirements. For instance, stainless steel is favored in food and pharmaceutical industries due to its corrosion resistance. Choosing the right material grade directly impacts the machine’s durability, performance, and compliance with industry regulations. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. It is a critical specification, especially in precision engineering, where even a minor deviation can lead to malfunction or inefficiency. Understanding tolerance levels helps buyers ensure that components fit together correctly, which is vital for maintaining productivity and minimizing downtime. -

Cycle Time

Cycle time is the total time taken to complete one cycle of operation, from start to finish. In production environments, optimizing cycle time is essential for enhancing throughput and efficiency. Custom machine manufacturers often design systems to minimize cycle time while maintaining quality, which is a key consideration for B2B buyers looking to improve operational efficiency. -

Load Capacity

Load capacity indicates the maximum weight or force that a machine can handle safely. This specification is vital for buyers as it ensures that the machinery can meet the demands of the production process without risk of failure. Understanding load capacity helps in selecting the right machinery for specific applications, particularly in heavy industries. -

Energy Efficiency

Energy efficiency refers to the machine’s ability to perform its function using minimal energy. With rising energy costs and increasing environmental regulations, selecting energy-efficient machinery can lead to significant cost savings and a reduced carbon footprint. B2B buyers should prioritize this property to ensure long-term operational sustainability.

What Are Common Trade Terms Used in Custom Machinery Manufacturing?

Familiarity with industry jargon can streamline communication between buyers and manufacturers. Here are several essential terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM produces components or equipment that may be marketed by another manufacturer. In the context of custom machinery, an OEM may provide parts that are integral to the final machine, ensuring quality and compatibility. Understanding OEM relationships is crucial for buyers who want to ensure the reliability of their machinery. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In custom machinery, MOQs can affect pricing and inventory management. Buyers need to be aware of MOQs to avoid excess costs and ensure they meet production needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and details from suppliers for specific products or services. In the custom machinery sector, submitting an RFQ allows buyers to compare quotes and understand the costs associated with their project, enabling better budget management. -

Incoterms

International Commercial Terms (Incoterms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers, especially in regions like Africa and South America, where logistics and shipping terms can significantly impact project timelines and costs. -

Turnkey Solutions

A turnkey solution refers to a complete package that is ready for immediate use upon delivery. For custom machinery, this means the manufacturer handles everything from design to installation, simplifying the process for the buyer. This term is crucial for decision-makers looking for comprehensive solutions that minimize operational disruptions.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of custom machine manufacturing more effectively, ensuring they make informed purchasing decisions that align with their operational goals.

Navigating Market Dynamics and Sourcing Trends in the custom machine manufacturer Sector

What Are the Key Trends and Drivers Shaping the Custom Machine Manufacturing Market?

The custom machine manufacturing sector is experiencing robust growth driven by several global factors. One significant driver is the increasing demand for automation across various industries, including healthcare, automotive, and aerospace. As businesses aim to enhance efficiency and reduce operational costs, custom machinery that integrates advanced automation technologies is becoming indispensable. This trend is particularly prevalent in emerging markets like Nigeria and Saudi Arabia, where industrialization is accelerating.

Current B2B technology trends, such as the adoption of Industry 4.0 principles, are reshaping sourcing strategies. Companies are now prioritizing suppliers who can offer not only high-quality machinery but also seamless integration of IoT and data analytics capabilities. This shift is evident in the growing demand for machinery that supports real-time monitoring and predictive maintenance, enabling businesses to optimize their production processes.

Furthermore, the custom machine manufacturing landscape is increasingly characterized by a focus on flexibility and scalability. Manufacturers are responding to the need for adaptable solutions that can evolve with changing market demands. For international buyers, especially in regions like South America and Europe, sourcing from manufacturers that provide scalable solutions is becoming a priority to ensure long-term competitiveness.

How Is Sustainability Influencing Sourcing Decisions in Custom Machine Manufacturing?

Sustainability is emerging as a critical factor in the sourcing decisions of international B2B buyers in the custom machine manufacturing sector. As environmental concerns gain prominence, companies are recognizing the importance of ethical sourcing and minimizing their ecological footprint. This trend is particularly relevant in regions like Europe, where stringent regulations govern environmental impact.

Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using eco-friendly materials and reducing waste during the manufacturing process. Certifications related to sustainability, such as ISO 14001, are becoming essential for suppliers aiming to establish credibility in the marketplace. Furthermore, the use of green certifications and materials not only helps in compliance with regulations but also appeals to a growing base of environmentally conscious consumers.

In addition, the integration of energy-efficient technologies in custom machinery is gaining traction. Buyers are looking for solutions that not only enhance productivity but also contribute to lower energy consumption and reduced greenhouse gas emissions. By partnering with manufacturers that emphasize sustainability, businesses can enhance their brand reputation while also meeting their corporate social responsibility goals.

How Has the Custom Machine Manufacturing Sector Evolved Over Time?

The custom machine manufacturing sector has undergone significant evolution over the past few decades, driven by technological advancements and changing market needs. Initially focused on traditional manufacturing methods, the industry has transitioned towards automation and smart manufacturing technologies. This shift has enabled manufacturers to create highly specialized machinery tailored to the unique requirements of various sectors, including healthcare, automotive, and aerospace.

As globalization has expanded, so too has the market for custom machinery. International buyers now have access to a diverse range of suppliers who can provide innovative solutions that meet their specific needs. The integration of advanced technologies such as robotics, artificial intelligence, and IoT has further transformed the landscape, enabling manufacturers to offer more sophisticated and efficient machinery.

In summary, the evolution of the custom machine manufacturing sector reflects a broader trend towards automation, sustainability, and customization, making it an increasingly vital component of global supply chains. B2B buyers looking to navigate this dynamic market must consider these factors to make informed sourcing decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of custom machine manufacturer

-

How do I choose the right custom machine manufacturer for my business needs?

Choosing the right custom machine manufacturer involves evaluating several key factors. First, assess their industry experience and technical capabilities to ensure they align with your specific production requirements. Request case studies or references from similar projects to gauge their reliability. Additionally, consider their ability to provide support throughout the project lifecycle, from design to installation. Communication is crucial, so ensure they can effectively understand and implement your specifications. Finally, evaluate their quality assurance processes to ensure consistent product performance. -

What are the common customization options available when ordering custom machinery?

Customization options vary widely among manufacturers but typically include design modifications, size and capacity adjustments, and specific features tailored to unique production processes. Some manufacturers may also offer modular designs that allow for future expansions or adaptations. It’s important to communicate your specific requirements clearly and inquire about the manufacturer’s ability to integrate advanced technologies such as automation and robotics. Additionally, consider whether they can provide ongoing support for maintenance and upgrades after installation. -

What is the minimum order quantity (MOQ) for custom machinery, and how does it affect pricing?

Minimum order quantities (MOQ) for custom machinery can vary significantly depending on the manufacturer and the complexity of the equipment. Generally, higher MOQs can lead to lower per-unit costs due to economies of scale, but they may require a larger upfront investment. If you anticipate needing multiple machines over time, negotiating a favorable MOQ can be beneficial. Always discuss your production forecasts with the manufacturer to find a balance between your budget and production needs, ensuring you’re not overcommitting resources. -

What payment terms should I expect when working with a custom machine manufacturer?

Payment terms can differ widely among manufacturers and may be influenced by your location and the scale of the project. Common practices include a deposit upfront, followed by milestone payments tied to project phases, and a final payment upon delivery or installation. Some manufacturers may also offer financing options or extended payment plans for larger orders. It’s essential to clarify payment schedules early in negotiations and ensure that both parties agree to the terms to avoid any misunderstandings later in the project. -

How can I ensure quality assurance during the custom machine manufacturing process?

To ensure quality assurance, begin by selecting a manufacturer with a robust quality control system in place. Request documentation of their quality standards and procedures, including certifications such as ISO. Throughout the manufacturing process, maintain open lines of communication to address any concerns promptly. You may also want to schedule regular progress updates and inspections, either virtually or on-site, to monitor compliance with your specifications. Finally, discuss post-delivery support, including warranties and maintenance services, to safeguard your investment. -

What logistics considerations should I keep in mind when importing custom machinery?

Logistics is a critical aspect of importing custom machinery. Start by understanding the shipping options available, including freight terms and timelines, to ensure timely delivery. Be aware of customs regulations in your country, including import duties and compliance documentation. It’s also important to coordinate with your manufacturer on packaging and labeling requirements to prevent damage during transit. Collaborating with a logistics partner experienced in international shipping can help streamline the process and mitigate potential challenges. -

How can I effectively vet a potential custom machine manufacturer?

Vetting a custom machine manufacturer involves thorough research and due diligence. Start by reviewing their portfolio and case studies to assess their experience in your industry. Request references from previous clients to gain insight into their reliability and performance. Check for relevant certifications and quality standards, and consider visiting their facility if possible to observe their operations firsthand. Finally, evaluate their communication responsiveness and willingness to collaborate, as a strong partnership is crucial for successful project outcomes. -

What are the advantages of investing in custom machinery versus off-the-shelf solutions?

Investing in custom machinery offers several advantages, particularly for businesses with specific production needs. Custom solutions are tailored to optimize efficiency and productivity, potentially reducing waste and downtime. They can also be designed to integrate seamlessly into existing processes, accommodating unique workflows. While the initial investment may be higher than off-the-shelf options, the long-term benefits, such as improved quality and adaptability, often lead to a better return on investment. Additionally, custom machines can be upgraded or reconfigured to meet future demands, ensuring continued relevance in a changing market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for custom machine manufacturer

The importance of strategic sourcing in the custom machinery sector cannot be overstated. By partnering with experienced manufacturers, international B2B buyers can ensure they receive tailor-made solutions that meet specific operational needs, enhance productivity, and comply with regulatory standards. Engaging with suppliers who prioritize quality, flexibility, and scalability can significantly reduce costs and lead times while fostering innovation.

For businesses in Africa, South America, the Middle East, and Europe, the landscape of custom machinery manufacturing presents unique opportunities. As industries increasingly demand automation and specialized solutions, sourcing partners who can offer robust engineering support and integrated project management becomes crucial. This approach not only drives efficiency but also positions companies to adapt swiftly to market changes.

Looking ahead, the potential for growth in the custom machinery market is promising. Companies that embrace strategic sourcing will not only optimize their operations but also stay ahead of the competition. As you consider your next steps, engage with trusted custom machine manufacturers to explore how tailored solutions can propel your business forward. Your next partnership could be the key to unlocking new levels of efficiency and success.