Top 7 Cnc Machining In China Manufacturers & Suppliers List

1. PCBWay – CNC Machining & 3D Printing Services

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: CNC Machining Service: Offers CNC milling (3-, 4-, & full 5-axis) and turning. 3D Printing Service: Includes technologies such as SLA, DLP, FDM, SLM, SLS, PolyJet, and Vacuum Casting. Sheet Metal Fabrication: Provides laser cutting, bending, and post-processing services. Injection Molding Service: Rapid molds and custom molded prototypes with fast lead times. Materials: Wide range including metals…

2. CNC Milling Services – Instant Quotes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Online Chinese CNC milling services like PCBWay, Rapid Direct, and Unionfab offer instant quotes for CNC machining. They provide significantly lower pricing for prototypes, with quotes ranging from $50-$100 for a small mechanical part made from mild steel, compared to $250-$400 from US-based services like Xometry and 3D Hubs. The turnaround time is not a priority for users, making these services a…

3. At Machining – CNC Machining Services

Domain: at-machining.com

Registered: 2014 (11 years)

Introduction: Top China CNC Machining Service, Quick, Accurate, Flexible, No MOQ. Services include CNC Machining, CNC Milling, CNC Turning, Precision 5-Axis CNC Machining, Swiss CNC Machining, Small Batch CNC Machining, Precision Micro Machining, Sheet Metal Fabrication, Surface Finishing Services (Anodizing, Electroplating, Powder Coating), Carburizing Heat Treatment, Wire EDM Machining. Materials include Meta…

4. China Machining – CNC Machining Services

Domain: china-machining.com

Registered: 2008 (17 years)

Introduction: CNC Machining Services in China, High-Quality CNC Machined Parts, ISO 9001:2015 certified facility, rapid prototyping and low-volume production, simple and complex precision machined parts, broad range of materials and surface finishes, CNC milling, CNC turning, high precision parts with tolerances as tight as ±0.001mm, materials include aluminum, steel, stainless steel, brass, copper, POM, PTFE, …

5. Hongsinn – Custom CNC Machining Solutions

Domain: m.hongsinn.com

Registered: 2013 (12 years)

Introduction: Custom CNC Machining Service, Bespoke CNC Machining, 5 Axis CNC Machining, CNC Turning Parts, CNC Milling Parts, CNC Cutting Service, CNC Lathe Parts, CNC Machining Large Parts, CNC Aluminium Parts, CNC Steel Parts, Plastic CNC Machining Parts, Carbide Machining, CNC Machining Automation Parts, CNC Machining Aerospace Parts, CNC Machining Medical Parts, Precision Mold Parts, CNC Prototype Service,…

6. 3Q Machining – CNC Machining Services

Domain: 3qmachining.com

Registered: 2020 (5 years)

Introduction: 3Q Machining offers a wide range of CNC machining services including Rapid Prototyping, Swiss Machining, CNC Precision Machining, 5 Axis Machining, CNC Mill & Turn, CNC Milling, CNC Turning, CNC Cutting, CNC Drilling, and Sub-contract Services. They provide custom CNC machining parts with capabilities for both metal and plastic materials, including Aluminum, Brass, Copper, Steel, Stainless Steel, …

7. Yijin Hardware – CNC Machining & Fabrication Services

Domain: yijinsolution.com

Registered: 2019 (6 years)

Introduction: 1. Yijin Hardware: Founded in 2003, located in Shenzhen, employs 51-200 people. Offers CNC Turning, CNC Milling, Sheet Metal Fabrication, Metal Laser Cutting, and Plasma Cutting services. Equipped with 887 advanced machines and 281 testing equipment. Focus on precision parts with a commitment to quality control. 2. Rapid Direct: Founded in 2009, located in Shenzhen, employs 100+. Specializes in CN…

Introduction: Navigating the Global Market for cnc machining in china

In an era where precision engineering is paramount, sourcing CNC machining services in China presents both opportunities and challenges for international B2B buyers. With China’s manufacturing prowess driving over $2 trillion in production annually, navigating this complex landscape requires a strategic approach. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must grapple with ensuring quality, managing costs, and selecting reliable suppliers amidst a sea of options.

This comprehensive guide is designed to empower businesses by illuminating the key facets of CNC machining in China. From understanding the various types of machining services, such as milling, turning, and 3D printing, to exploring their diverse applications across industries like automotive, aerospace, and medical devices, we provide actionable insights that facilitate informed purchasing decisions. Additionally, the guide delves into essential supplier vetting processes, cost considerations, and quality assurance measures, enabling buyers to mitigate risks and enhance their sourcing strategies.

By equipping international B2B buyers with the knowledge and tools necessary to navigate the global CNC machining market, this guide serves as a vital resource for those looking to leverage China’s manufacturing capabilities while ensuring that their specific needs are met with precision and reliability.

Understanding cnc machining in china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Milling | Utilizes rotary cutters to remove material, offers 3, 4, and 5-axis options | Aerospace, automotive, medical devices | Pros: High precision, versatile; Cons: Longer lead times for complex parts. |

| CNC Turning | Rotates the workpiece against a cutting tool, suitable for cylindrical parts | Automotive, machinery components | Pros: High efficiency for round parts; Cons: Limited to rotational shapes. |

| CNC Laser Cutting | Uses focused laser beams for cutting materials, ideal for intricate designs | Signage, sheet metal fabrication, electronics | Pros: Excellent cut quality, minimal material waste; Cons: Higher setup costs. |

| CNC Wire EDM | Employs electrically charged wire to cut through materials, suitable for hard metals | Tooling, mold making, aerospace components | Pros: Exceptional precision and finish; Cons: Slower than traditional methods. |

| CNC Sheet Metal Fabrication | Combines various processes like bending and punching for sheet metal | Automotive, construction, HVAC systems | Pros: Cost-effective for large runs; Cons: Limited complexity compared to milling. |

What are the Characteristics and Suitability of CNC Milling?

CNC milling is a versatile machining process that utilizes rotating cutters to remove material from a workpiece. It can operate in multiple axes (3, 4, and 5-axis), allowing for the creation of complex geometries and high-precision parts. This method is particularly suitable for industries like aerospace and automotive, where precision is paramount. When considering CNC milling, buyers should evaluate the complexity of the part, lead times, and the material’s machinability to ensure optimal results.

How Does CNC Turning Work and What are its Key Applications?

CNC turning involves rotating the workpiece while a stationary cutting tool removes material. This method is predominantly used for producing cylindrical parts and is highly efficient for high-volume production. Industries such as automotive and machinery frequently employ CNC turning for components like shafts and bushings. Buyers should focus on the required tolerances, material types, and production volumes, as these factors significantly influence the overall cost and lead time.

What Makes CNC Laser Cutting a Preferred Choice for Intricate Designs?

CNC laser cutting utilizes high-powered lasers to cut through various materials with exceptional precision. This method is particularly effective for intricate designs and thin materials, making it a popular choice in signage, electronics, and sheet metal fabrication. Buyers should consider the thickness of the material, design complexity, and potential setup costs. The advantages of minimal waste and high-quality cuts often outweigh the initial investment, particularly for detailed projects.

Why Choose CNC Wire EDM for Precision Cutting?

CNC wire EDM (Electrical Discharge Machining) is a specialized process that uses electrically charged wire to cut through conductive materials. This method is ideal for hard metals and is commonly used in tooling and mold-making applications. The precision and surface finish achievable with wire EDM are unmatched, making it suitable for high-stakes industries like aerospace. Buyers should assess the material hardness, part complexity, and lead time requirements, as wire EDM can be slower than other machining methods but offers superior accuracy.

What are the Benefits of CNC Sheet Metal Fabrication?

CNC sheet metal fabrication encompasses several processes, including cutting, bending, and punching, tailored for flat sheet materials. This method is widely utilized in industries such as automotive, construction, and HVAC systems due to its cost-effectiveness for large production runs. Buyers should evaluate the required tolerances, material types, and design complexity when considering sheet metal fabrication. While it offers efficient production, the complexity of shapes achievable is somewhat limited compared to CNC milling and turning.

Key Industrial Applications of cnc machining in china

| Industry/Sector | Specific Application of CNC Machining in China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of precision engine components | Enhanced performance and reliability of vehicles | Certifications, quality control processes, and delivery timelines |

| Aerospace & Aviation | Manufacturing of lightweight structural parts | Improved fuel efficiency and safety standards | Material certifications, adherence to stringent regulations, and traceability |

| Medical Devices | Creation of custom surgical instruments | High precision and compliance with health standards | ISO certifications, biocompatibility of materials, and rapid prototyping capabilities |

| Consumer Electronics | Fabrication of intricate housing and components | Faster time-to-market for new products | Design flexibility, surface finish options, and scalability of production |

| Industrial Machinery | Custom parts for machinery and equipment | Increased operational efficiency and reduced downtime | Material selection, lead times, and the ability to handle complex designs |

How Is CNC Machining Used in the Automotive Industry in China?

In the automotive sector, CNC machining is utilized to produce precision engine components, such as crankshafts and camshafts, which demand high accuracy and durability. This technology addresses challenges like maintaining tight tolerances and ensuring consistent quality. International B2B buyers must consider the manufacturer’s certifications, quality control processes, and delivery timelines to guarantee reliable production that meets automotive standards.

What Role Does CNC Machining Play in Aerospace and Aviation?

CNC machining plays a critical role in the aerospace industry by manufacturing lightweight structural parts, such as fuselage components and wing structures. These parts must meet stringent safety and performance standards, which CNC machining can ensure through precise manufacturing processes. Buyers should focus on sourcing suppliers with the necessary material certifications and compliance with regulatory standards, as well as robust traceability systems.

How Is CNC Machining Applied in the Medical Devices Sector?

In the medical devices industry, CNC machining is essential for creating custom surgical instruments that require high precision and adherence to health standards. This application ensures that instruments are not only accurate but also safe for patient use. Buyers from international markets should prioritize suppliers with ISO certifications, knowledge of biocompatible materials, and rapid prototyping capabilities to expedite product development.

What Are the Benefits of CNC Machining for Consumer Electronics?

CNC machining is crucial in the consumer electronics sector for fabricating intricate housing and components that require detailed designs and precise finishes. This technology helps companies bring products to market more quickly while ensuring high-quality standards. B2B buyers should seek manufacturers that offer design flexibility, a variety of surface finish options, and scalable production capabilities to meet fluctuating demands.

How Does CNC Machining Enhance Industrial Machinery Production?

In the realm of industrial machinery, CNC machining is used to create custom parts that enhance machinery performance and reduce operational downtime. This capability is vital for businesses that rely on efficient and reliable equipment. When sourcing these components, buyers should consider the material selection, lead times for production, and the manufacturer’s ability to handle complex designs to ensure optimal performance.

3 Common User Pain Points for ‘cnc machining in china’ & Their Solutions

Scenario 1: Quality Assurance in CNC Machining Parts

The Problem: One of the most significant challenges faced by international B2B buyers when sourcing CNC machining services in China is ensuring consistent quality. Buyers often worry about the reliability of machining processes, especially when dealing with complex parts that require tight tolerances. This concern is amplified by the geographical distance, language barriers, and differing quality standards between countries. Poor quality can lead to costly delays, rework, and ultimately, a damaged reputation in the market.

The Solution: To mitigate quality concerns, buyers should prioritize partnering with CNC machining companies that have established quality assurance protocols. Request detailed documentation of the supplier’s quality control processes, such as ISO certifications and inspection reports. It’s also beneficial to ask for samples or prototypes before placing bulk orders to evaluate the machining precision firsthand. Utilizing third-party inspection services in China can provide an added layer of assurance, allowing buyers to verify that the parts meet specified standards before shipment. Establishing clear communication channels and setting up regular progress updates can further ensure that quality remains a priority throughout the production process.

Scenario 2: Communication Barriers and Misunderstandings

The Problem: Effective communication is crucial in the CNC machining industry, yet many international buyers encounter challenges due to language differences and cultural misunderstandings. Misinterpretations can lead to incorrect specifications, delays in production, and increased costs. This issue is particularly prevalent when technical details are involved, as the nuances of engineering terms may not translate well across languages.

The Solution: To overcome communication barriers, buyers should consider employing a bilingual project manager or liaison who understands both the technical aspects of CNC machining and the cultural context. This person can facilitate clearer communication between the buyer and the machining company. Additionally, using visual aids such as diagrams, CAD drawings, and detailed specifications can help bridge gaps in understanding. Establishing a shared online platform for project updates and documentation can also streamline communication and ensure that all parties are aligned on project goals and timelines.

Scenario 3: Supply Chain Delays and Logistics Issues

The Problem: International buyers often face unpredictable supply chain delays when sourcing CNC machined parts from China. Factors such as customs regulations, shipping logistics, and local holidays can lead to unexpected disruptions. These delays can have a cascading effect on production schedules, affecting the overall project timeline and financial forecasts.

The Solution: To minimize the risk of delays, buyers should build a robust supply chain strategy that includes contingency planning. This involves selecting suppliers with a proven track record of on-time delivery and understanding the specific logistics challenges associated with shipping from China. Utilizing local logistics experts can provide insight into potential bottlenecks and help navigate customs processes more efficiently. Establishing a buffer stock or safety inventory of critical components can also provide a cushion against unforeseen disruptions, ensuring that production can continue smoothly even in the event of delays. Regularly reviewing and adjusting the supply chain strategy based on market conditions and supplier performance will further enhance resilience.

Strategic Material Selection Guide for cnc machining in china

When selecting materials for CNC machining in China, international B2B buyers must consider various factors that influence product performance, cost, and suitability for specific applications. Below are analyses of four common materials used in CNC machining, focusing on their key properties, advantages and disadvantages, application impacts, and considerations for buyers from diverse regions.

What are the Key Properties of Aluminum in CNC Machining?

Aluminum is one of the most widely used materials in CNC machining due to its favorable properties. It is lightweight, has excellent corrosion resistance, and offers good thermal and electrical conductivity. Aluminum can withstand moderate temperatures and pressures, making it suitable for various applications, including automotive and aerospace components.

Pros & Cons:

Aluminum is durable and easy to machine, which reduces manufacturing complexity. However, its cost can be higher than some other materials, and it may not be suitable for high-stress applications without proper alloying.

Impact on Application:

Aluminum’s compatibility with various media, including air and water, makes it ideal for components in HVAC systems and marine environments.

Considerations for Buyers:

International buyers should ensure compliance with standards such as ASTM and ISO for aluminum grades. Additionally, understanding local preferences for specific alloys can enhance product acceptance in regions like Africa and South America.

How Does Stainless Steel Perform in CNC Machining Applications?

Stainless steel is renowned for its strength, corrosion resistance, and ability to withstand extreme temperatures. It is commonly used in industries such as medical devices, food processing, and aerospace.

Pros & Cons:

The durability of stainless steel makes it ideal for high-stress applications. However, it can be more challenging to machine than aluminum, leading to higher manufacturing costs.

Impact on Application:

Stainless steel’s resistance to corrosion and heat makes it suitable for applications involving harsh chemicals or high temperatures, such as in oil and gas industries.

Considerations for Buyers:

Buyers should be aware of the specific grades of stainless steel required for their applications, as compliance with standards like ASTM A240 is crucial. Additionally, buyers from the Middle East should consider the material’s performance in high-temperature environments.

What are the Advantages of Using Plastics in CNC Machining?

Plastics such as ABS, Nylon, and POM are increasingly popular in CNC machining due to their versatility, lightweight nature, and resistance to corrosion. They are commonly used in consumer products, automotive parts, and electronic housings.

Pros & Cons:

Plastics are generally less expensive than metals and are easier to machine, allowing for complex designs. However, they may not offer the same level of strength or heat resistance as metals, which can limit their use in high-stress applications.

Impact on Application:

Plastics are compatible with various media, making them suitable for applications in electronics and consumer goods where weight reduction is essential.

Considerations for Buyers:

International buyers should verify that the plastics used meet relevant standards, such as UL certifications for electrical components. Understanding local market preferences for specific plastic types can also be beneficial.

Why Choose Titanium for CNC Machining?

Titanium is known for its exceptional strength-to-weight ratio and corrosion resistance, making it a preferred choice in aerospace, medical, and high-performance applications.

Pros & Cons:

While titanium offers outstanding durability and performance, it is one of the more expensive materials to machine due to its hardness and the complexity involved in processing it.

Impact on Application:

Titanium’s biocompatibility makes it ideal for medical implants, while its strength makes it suitable for aerospace components that must endure extreme conditions.

Considerations for Buyers:

B2B buyers should ensure that titanium components comply with international standards such as ASTM F136 for medical applications. Additionally, understanding the cost implications of titanium machining is crucial for budgeting.

Summary Table of Material Selection for CNC Machining in China

| Material | Typical Use Case for CNC Machining in China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive and aerospace components | Lightweight and corrosion-resistant | Higher cost compared to some metals | Medium |

| Stainless Steel | Medical devices and food processing | Excellent strength and durability | More challenging to machine | High |

| Plastics | Consumer products and electronic housings | Cost-effective and easy to machine | Limited strength compared to metals | Low |

| Titanium | Aerospace and medical implants | High strength-to-weight ratio | Expensive and complex to machine | High |

This strategic material selection guide aims to equip international B2B buyers with actionable insights to make informed decisions when sourcing CNC machined components in China. Understanding the properties, advantages, and regional considerations for each material will facilitate better product outcomes and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc machining in china

What Are the Main Stages of CNC Machining Manufacturing Processes in China?

CNC (Computer Numerical Control) machining in China is characterized by a series of well-defined stages that ensure the efficient production of high-quality components. Understanding these stages is crucial for international B2B buyers looking to source precision parts.

1. Material Preparation

The manufacturing process begins with material selection, where suppliers often provide various options, including metals like aluminum, stainless steel, and plastics such as ABS and Nylon. The selected material is then cut into manageable sizes, typically using saws or shears, to prepare it for machining. This initial step is crucial as it sets the foundation for the subsequent machining processes.

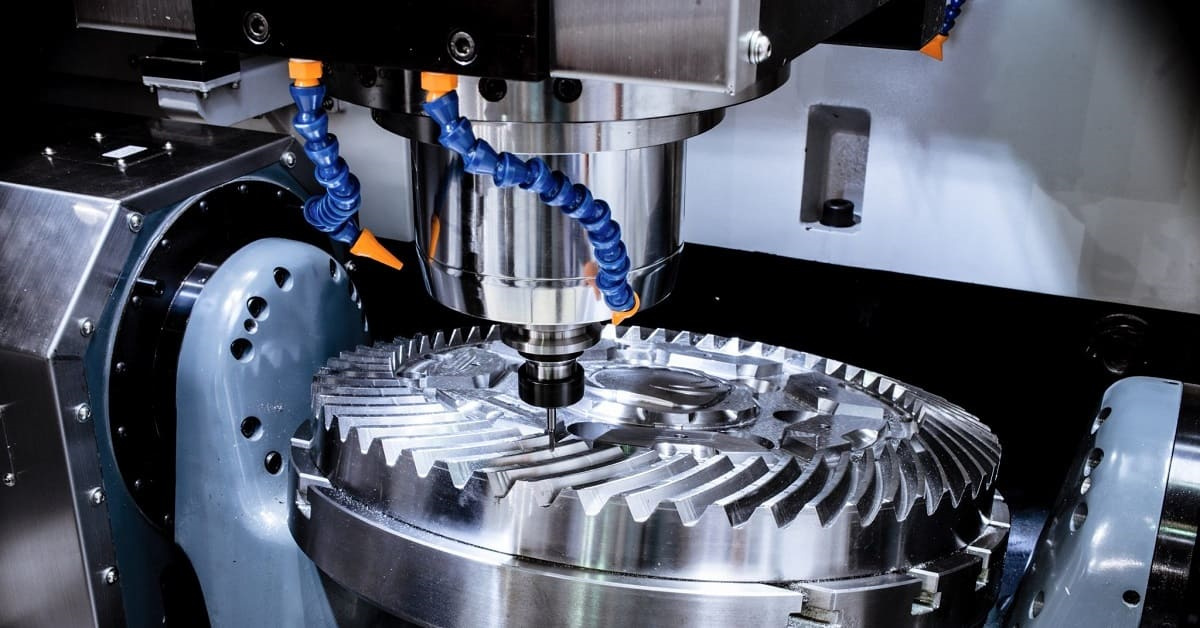

2. Forming: How Are Components Shaped Through CNC Machining?

Once the material is prepared, the next step is forming. This involves several machining techniques, including:

- CNC Milling: Utilizes rotating cutting tools to remove material from a workpiece, producing complex shapes and features.

- CNC Turning: Involves rotating the workpiece against a stationary cutting tool to create cylindrical parts.

- 5-Axis Machining: Allows for the manipulation of the workpiece in multiple directions, enabling the production of intricate geometries in a single setup.

These techniques are critical for achieving high precision and meeting the specifications required by various industries, including automotive, aerospace, and medical devices.

3. Assembly: What Role Does Assembly Play in CNC Machining?

For projects that require multiple components, assembly is a vital stage. This process may involve joining machined parts using methods such as welding, fastening, or adhesive bonding. Effective assembly ensures that the final product meets the required functional and aesthetic standards.

4. Finishing: How Is Surface Quality Achieved?

The finishing stage focuses on enhancing the surface quality of machined parts. Techniques such as anodizing, plating, and polishing are employed to improve appearance and corrosion resistance. A high-quality finish is essential for components used in consumer electronics and medical devices, where aesthetics and hygiene are paramount.

What Quality Assurance Measures Are Implemented in CNC Machining?

Quality assurance (QA) is critical in CNC machining to ensure that products meet international standards and client specifications. Buyers should be aware of the QA measures that reputable Chinese manufacturers employ.

International Standards: What Certifications Should Buyers Look For?

Manufacturers in China often comply with international quality standards such as ISO 9001, which sets the framework for quality management systems. Additionally, industry-specific certifications like CE (for electrical equipment), API (for oil and gas), and others may be applicable depending on the product’s end-use. Buyers should verify these certifications to ensure that suppliers adhere to recognized quality benchmarks.

Key Quality Control Checkpoints: What Are the Stages of Quality Control?

Quality control in CNC machining typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to monitor dimensions and tolerances.

- Final Quality Control (FQC): A thorough inspection of finished products before shipping, ensuring they meet the agreed specifications.

These checkpoints help to catch defects early and minimize waste, providing buyers with confidence in the quality of their products.

Common Testing Methods: How Is Quality Verified?

Manufacturers utilize various testing methods to ensure quality, including:

- Dimensional Inspection: Using tools like calipers and CMM (Coordinate Measuring Machines) to verify the dimensions of machined parts.

- Material Testing: Conducting tensile and hardness tests to ensure materials meet specified mechanical properties.

- Functional Testing: Testing components in real-world conditions to ensure they perform as intended.

By employing these methods, manufacturers can provide documentation that demonstrates compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control in China?

For international buyers, verifying the quality control processes of suppliers in China is essential to mitigate risks. Here are actionable steps to ensure quality:

1. Conduct Supplier Audits

Before entering into a business relationship, buyers should perform audits of potential suppliers. This can include on-site visits to assess the manufacturing facilities, equipment, and quality control practices. Audits can also reveal the supplier’s commitment to maintaining quality standards.

2. Request Quality Reports

Buyers should ask suppliers for quality reports that detail inspection results, testing methods, and compliance with international standards. These reports provide transparency and help buyers understand the supplier’s quality assurance processes.

3. Utilize Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and final products. These services can conduct inspections at various stages of production, ensuring that products meet the required specifications before shipping.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances when dealing with Chinese manufacturers:

- Understanding Local Regulations: Different regions may have varying regulations regarding product safety and quality. Buyers should be aware of these regulations to ensure compliance.

- Cultural Considerations: Communication barriers and cultural differences can affect quality control processes. Establishing clear communication channels and expectations is vital for successful collaboration.

- Logistical Challenges: Shipping and customs can introduce additional risks. Buyers should work with suppliers to ensure that quality is maintained throughout the logistics process.

By understanding these nuances, buyers can better navigate the complexities of sourcing CNC machined parts from China, ensuring they receive high-quality products that meet their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc machining in china’

Introduction

This sourcing guide provides a structured checklist for international B2B buyers looking to procure CNC machining services in China. With its advanced manufacturing capabilities and competitive pricing, China has become a top destination for sourcing precision machined components. Following these steps will ensure a successful procurement process and help you find reliable suppliers who meet your specific needs.

Step 1: Define Your Technical Specifications

Clearly outline the dimensions, tolerances, materials, and finishes required for your CNC machined parts. Precise specifications will not only guide suppliers in producing your components but also help prevent misunderstandings that could lead to costly errors. Consider creating detailed technical drawings or CAD files to communicate your requirements effectively.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable CNC machining suppliers in China. Utilize platforms like Alibaba, Made-in-China, or industry-specific directories to compile a list of potential candidates. Pay attention to supplier ratings, reviews, and their specialization in your required materials or processes.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to assess the technical capabilities of potential suppliers. Request information about their machinery, technology, and production processes. Ensure they can handle the complexity and volume of your project, and ask for examples of similar work they have completed.

Step 4: Verify Supplier Certifications

Check for relevant certifications such as ISO 9001, which indicates adherence to quality management standards. Certifications can provide assurance of a supplier’s commitment to quality and reliability. Additionally, inquire about their quality control measures and processes to ensure they meet your expectations.

Step 5: Request Quotes and Compare Pricing

Once you have narrowed down your list of suppliers, request detailed quotes that outline pricing, lead times, and payment terms. Comparing quotes will help you understand the market rates and determine which supplier offers the best value for your specific needs. Be cautious of prices that seem too low, as they may indicate compromised quality.

Step 6: Initiate Sample Production

Before placing a bulk order, ask for prototypes or samples of your parts. This step allows you to evaluate the supplier’s craftsmanship, material quality, and overall capability. Use this opportunity to test the parts against your specifications and confirm they meet your requirements.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish a primary point of contact within the supplier’s organization and ensure they are fluent in your preferred language. Regular updates on production progress, quality checks, and any potential issues will foster a productive relationship and minimize misunderstandings.

By following this checklist, you can streamline your sourcing process for CNC machining in China, ensuring that you find a qualified supplier that meets your business needs while maintaining quality and efficiency.

Comprehensive Cost and Pricing Analysis for cnc machining in china Sourcing

What are the Key Cost Components in CNC Machining Sourcing from China?

When considering CNC machining in China, international buyers must understand the various cost components involved in the sourcing process. The primary elements include:

-

Materials: The type of material selected significantly influences the overall cost. Common materials such as aluminum and stainless steel are generally more affordable compared to specialized materials like titanium or high-performance plastics. Buyers should evaluate their material requirements carefully to optimize costs.

-

Labor: Labor costs in China are typically lower than in many Western countries, which can lead to substantial savings. However, prices can vary by region and the complexity of the machining process. Skilled labor, particularly in precision machining, may command higher wages.

-

Manufacturing Overhead: This includes factory operational costs, utilities, and equipment depreciation. Efficient manufacturing facilities often have lower overhead costs, allowing them to offer competitive pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom parts. These costs depend on the complexity of the design and the type of machining required. Investing in high-quality tooling can enhance precision and reduce long-term costs.

-

Quality Control (QC): Ensuring quality through inspections and testing is crucial for maintaining product standards. The costs associated with QC processes should be factored into the overall budget, particularly for industries like aerospace or medical devices, where certifications are essential.

-

Logistics: Shipping costs can vary based on the Incoterms chosen, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight). Buyers should consider these terms to understand who bears the transportation costs and risks.

-

Margin: Suppliers typically add a profit margin to their costs. This can vary based on the supplier’s capabilities, market competition, and relationship with the buyer.

How Do Price Influencers Affect CNC Machining Costs?

Several factors influence the pricing of CNC machining services in China:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing discounts. Buyers should assess their needs to determine whether they can benefit from economies of scale.

-

Specifications and Customization: Highly customized parts or complex designs usually incur higher costs due to the additional time and resources required for production.

-

Material Selection: The choice of material not only affects the price but also impacts the machining process. Certain materials may require specific tooling or machining techniques, influencing overall costs.

-

Quality and Certifications: Parts requiring stringent quality standards or specific certifications (like ISO or AS9100) may lead to increased costs due to the additional processes involved in meeting these standards.

-

Supplier Factors: The reputation, experience, and location of the supplier can affect pricing. Established suppliers with advanced facilities may charge higher rates but can offer better quality and reliability.

-

Incoterms: Understanding the implications of different shipping terms can help buyers manage logistics costs effectively. Terms like EXW (Ex Works) may lead to lower upfront costs but could result in higher logistics expenses later.

What Tips Can Help International Buyers Optimize CNC Machining Costs?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost-efficiency:

-

Negotiate Terms: Building a strong relationship with suppliers can lead to better pricing and terms. Open communication about volume expectations and long-term partnerships can yield favorable results.

-

Evaluate Total Cost of Ownership: Beyond initial pricing, consider long-term factors such as maintenance, potential rework, and the cost of delays. This holistic view can lead to smarter sourcing decisions.

-

Leverage Technology: Utilize online platforms that provide instant quotes and comparisons across multiple suppliers. This can streamline the sourcing process and enhance transparency.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations and market trends that may affect pricing. For instance, demand spikes during specific times of the year can lead to increased costs.

Disclaimer on Indicative Prices

Prices for CNC machining in China can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough research and request quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing cnc machining in china With Other Solutions

Exploring Alternatives to CNC Machining in China

In the global manufacturing landscape, CNC machining in China has emerged as a popular solution for precision part production. However, various alternatives may suit different business needs, depending on factors such as budget, required precision, and production volume. Understanding these alternatives can empower international B2B buyers to make informed decisions that align with their operational goals.

| Comparison Aspect | CNC Machining in China | 3D Printing | Injection Molding |

|---|---|---|---|

| Performance | High precision; excellent for complex designs | Good for rapid prototyping; less precision for functional parts | Excellent for mass production; high precision |

| Cost | Moderate to high; costs vary with volume and complexity | Low for small batches; high setup costs for large volumes | High initial setup costs; cost-effective for large volumes |

| Ease of Implementation | Requires skilled operators and setup time | User-friendly; quick to prototype | Complex setup; requires molds |

| Maintenance | Regular maintenance needed for machinery | Low maintenance; mainly software updates | Maintenance tied to mold wear and tear |

| Best Use Case | Custom parts and prototypes across industries | Rapid prototyping and low-volume production | High-volume production of identical parts |

What Are the Advantages and Disadvantages of 3D Printing as an Alternative?

3D printing, also known as additive manufacturing, is a viable alternative, particularly for small-scale production and rapid prototyping. Its strengths lie in the ability to quickly produce complex geometries without the need for tooling. This method is cost-effective for low-volume runs but may struggle with the precision and surface finish required for high-performance applications. Additionally, the material options in 3D printing are expanding, but they may not match the mechanical properties of traditionally machined parts.

How Does Injection Molding Compare to CNC Machining?

Injection molding is another alternative worth considering, particularly for businesses focused on high-volume production. This method excels in creating large quantities of identical parts at a lower unit cost once the initial mold is produced. However, the setup costs for molds can be substantial, making it less ideal for short runs or prototypes. While injection molding offers excellent precision and surface finish, it is less flexible in design changes compared to CNC machining and 3D printing.

Making the Right Choice: Which Solution Suits Your Business Needs?

Choosing the right manufacturing solution depends on specific business needs. For B2B buyers, evaluating the volume of production, required precision, and budget constraints is essential. If rapid prototyping and flexibility are priorities, 3D printing may be the best fit. Conversely, for high-volume production with consistent quality, injection molding stands out. Meanwhile, CNC machining in China remains a strong choice for custom, high-precision parts, especially when complexity is involved.

In conclusion, understanding the strengths and limitations of each alternative allows international buyers to align their manufacturing strategies with their operational goals effectively. By considering factors such as performance, cost, ease of implementation, maintenance, and best use cases, businesses can make informed decisions that best suit their production requirements.

Essential Technical Properties and Trade Terminology for cnc machining in china

What Are the Essential Technical Properties for CNC Machining in China?

When engaging in CNC machining in China, understanding critical technical properties is vital for ensuring product quality and meeting project specifications. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the classification of materials based on their physical and chemical properties. In CNC machining, common materials include metals like aluminum, stainless steel, and titanium, as well as plastics such as ABS and nylon. Selecting the appropriate material grade is crucial as it affects the strength, weight, corrosion resistance, and overall performance of the machined part. B2B buyers must specify material grades to ensure compatibility with their application needs.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. In CNC machining, it defines how much a part can deviate from its specified dimensions. High precision tolerances (e.g., ±0.01 mm) are often required for industries like aerospace and medical devices, where even minor deviations can result in failure. Understanding tolerance requirements helps buyers communicate their quality standards effectively and minimizes costly rework.

3. Surface Finish

Surface finish describes the texture and smoothness of a machined part’s surface. Different processes yield various finishes, such as anodizing, bead blasting, or polishing. The chosen surface finish can impact not only aesthetics but also functionality, such as reducing friction or enhancing corrosion resistance. Buyers should clarify surface finish specifications to align with their product’s end-use.

4. CNC Machining Process Type

There are several CNC machining processes, including milling, turning, and electrical discharge machining (EDM). Each method has its own strengths and is suited for different applications. For instance, milling is ideal for creating complex shapes, while turning is better for cylindrical parts. Understanding which process to use can significantly affect production efficiency and cost.

5. Production Volume

Production volume refers to the quantity of parts required. This metric influences the choice of machining method and the cost per unit. For instance, low-volume orders may be more suited for rapid prototyping, while high-volume needs could benefit from more automated processes. Clearly defining production volume helps manufacturers optimize their processes and pricing.

What Trade Terminology Should B2B Buyers Know in CNC Machining?

Understanding industry terminology is crucial for effective communication and negotiation with manufacturers. Here are some common terms used in the CNC machining sector:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another company. In the context of CNC machining, buyers often engage with OEMs to source custom components tailored to their specifications. Knowing this term helps buyers navigate supplier relationships and expectations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. In CNC machining, MOQs can vary significantly based on the complexity of the part and production methods. Understanding MOQs is essential for buyers to manage inventory and budgeting effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific services or products. In CNC machining, an RFQ typically includes detailed specifications, material requirements, and quantities. Properly crafting an RFQ can lead to better pricing and service terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade rules that define the responsibilities of buyers and sellers. They clarify aspects such as shipping, insurance, and risk management. Familiarity with Incoterms is vital for buyers to understand their obligations and minimize potential disputes.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the finished product. In the context of CNC machining, lead times can vary based on factors such as complexity, material availability, and production capacity. Understanding lead times helps buyers plan their projects and manage expectations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the complexities of CNC machining in China more effectively, ensuring successful outcomes for their projects.

Navigating Market Dynamics and Sourcing Trends in the cnc machining in china Sector

What Are the Current Dynamics and Key Trends in the CNC Machining Market?

The CNC machining sector in China is witnessing robust growth, driven by the increasing demand for precision-engineered parts across various industries, including aerospace, automotive, and medical devices. As of 2023, the global CNC machining market is projected to exceed $23 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.1%. This surge is attributed to advancements in manufacturing technology, such as multi-tasking machines and sophisticated control systems, which enhance efficiency and precision.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, several trends are emerging. The rise of automation and robotics is transforming production capabilities, enabling faster turnaround times and reduced labor costs. Additionally, there is an increasing adoption of additive manufacturing techniques, which complement traditional CNC machining by allowing for rapid prototyping and complex geometries. Buyers should also be aware of the growing importance of digital platforms for sourcing and procurement, which streamline the process of finding suppliers and obtaining quotes.

Market dynamics are also shaped by geopolitical factors, trade regulations, and local sourcing strategies. Companies are urged to conduct thorough due diligence on potential suppliers to ensure compliance with international standards and to mitigate risks associated with supply chain disruptions.

How Are Sustainability and Ethical Sourcing Influencing CNC Machining in China?

Sustainability and ethical sourcing are gaining traction in the CNC machining industry, driven by increasing awareness of environmental impacts and corporate social responsibility. International buyers are increasingly prioritizing suppliers who adhere to environmentally friendly practices. The importance of ethical supply chains cannot be overstated; it influences brand reputation, customer loyalty, and compliance with regulations in various markets.

In China, several manufacturers are adopting green certifications and using sustainable materials in their CNC machining processes. Certifications such as ISO 14001 for environmental management systems and adherence to RoHS (Restriction of Hazardous Substances) standards are becoming crucial for suppliers aiming to cater to international markets. By sourcing from companies committed to sustainable practices, buyers not only minimize their environmental footprint but also enhance their own corporate sustainability narratives.

Moreover, the use of recycled materials and energy-efficient processes is on the rise, which can lead to cost savings and improved product quality. B2B buyers should look for suppliers that can demonstrate their commitment to sustainability through certifications, transparent practices, and a clear strategy for reducing environmental impacts.

What Is the Historical Context of CNC Machining in China?

CNC machining in China has evolved significantly over the past few decades, transitioning from basic manufacturing techniques to becoming a global leader in precision machining. The industry began gaining momentum in the late 20th century as China opened its doors to foreign investment and technology transfer. The introduction of advanced CNC technologies and a skilled workforce helped establish a robust manufacturing ecosystem.

By the early 2000s, China had emerged as a manufacturing powerhouse, with CNC machining playing a critical role in various sectors. The government’s focus on high-tech industries and innovation further accelerated growth, positioning China as a key player in global supply chains. Today, Chinese CNC machining companies are recognized for their capabilities in producing complex parts with high precision, catering to diverse industries worldwide. For international B2B buyers, understanding this evolution is essential for identifying reliable suppliers that can meet their specific manufacturing needs.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc machining in china

-

How do I find reliable CNC machining suppliers in China?

Finding reliable CNC machining suppliers in China involves thorough research and vetting. Start by exploring online directories and trade platforms such as Alibaba, Made-in-China, and Global Sources. Look for suppliers with verified credentials, positive reviews, and a strong track record in your industry. Request references and check their previous work. Additionally, consider visiting the facility if possible or utilizing third-party inspection services to assess their capabilities and quality standards. -

What are the typical minimum order quantities (MOQs) for CNC machining in China?

Minimum order quantities (MOQs) for CNC machining services in China can vary significantly based on the supplier, material, and complexity of the parts. Generally, MOQs can range from as low as 10 units for simple parts to several hundred for complex designs. Discuss your specific project requirements with potential suppliers to negotiate MOQs that align with your production needs, especially if you are looking for a prototype or small batch production. -

What payment terms should I expect when sourcing CNC machining services in China?

Payment terms can vary by supplier, but common practices include a 30% deposit upfront, with the remaining balance due before shipment. Some suppliers may also accept letters of credit or offer payment through secure platforms like PayPal or Alibaba’s Trade Assurance. Ensure you discuss and agree upon payment terms early in negotiations to avoid misunderstandings later. Always verify the supplier’s payment options and any associated fees. -

What factors should I consider when customizing CNC machined parts?

When customizing CNC machined parts, consider material selection, design specifications, tolerances, and surface finishes. Clearly communicate your requirements to the supplier, including any industry standards that must be met. It’s essential to provide detailed drawings and specifications. Additionally, discuss lead times for prototypes and production runs, as well as the supplier’s capabilities for handling complex geometries or multi-material components. -

How can I ensure quality assurance (QA) for my CNC machined parts?

To ensure quality assurance for CNC machined parts, request that the supplier provides detailed quality control processes, including inspection reports and certifications. Inquire about their compliance with international quality standards such as ISO 9001. Consider implementing a third-party inspection service to verify product quality before shipment. Establishing clear communication about quality expectations and tolerances from the outset is crucial for a successful partnership. -

What logistics considerations should I keep in mind when importing CNC machined parts from China?

Logistics considerations when importing CNC machined parts from China include shipping methods, customs clearance, and lead times. Determine whether air or sea freight is more suitable for your needs based on urgency and budget. Collaborate with a freight forwarder experienced in international shipping to navigate customs regulations and ensure timely delivery. Additionally, factor in potential delays due to inspections or documentation requirements when planning your timelines. -

What are the advantages of sourcing CNC machining from China?

Sourcing CNC machining from China offers several advantages, including competitive pricing due to lower labor costs, access to advanced manufacturing technologies, and a wide range of material options. China’s robust supply chain network allows for rapid prototyping and production, facilitating quicker turnaround times. Additionally, many Chinese manufacturers have established quality control processes that meet international standards, making them reliable partners for global buyers. -

How can I communicate effectively with my CNC machining supplier in China?

Effective communication with your CNC machining supplier in China is vital for project success. Use clear, concise language and avoid jargon that may lead to misunderstandings. Consider using visual aids, such as diagrams or CAD files, to illustrate your requirements. If there are language barriers, using a translator or bilingual team member can help. Regular updates and check-ins via email or video calls can foster a collaborative relationship and address any issues promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc machining in china

As international B2B buyers increasingly look to capitalize on the benefits of CNC machining in China, strategic sourcing emerges as a vital component of successful procurement. The competitive landscape offers unparalleled access to advanced manufacturing capabilities, diverse materials, and cost-effective solutions. By leveraging China’s robust CNC machining infrastructure, businesses can achieve precision and quality that meet global standards.

A key takeaway is the importance of forging strong partnerships with reputable manufacturers. Engaging with established CNC machining companies can enhance product quality and streamline supply chain processes, ensuring timely delivery and responsiveness to market demands. Additionally, staying informed about emerging trends—such as automation, additive manufacturing, and material innovations—will position buyers to make informed decisions that drive competitiveness.

Looking ahead, the CNC machining market is poised for significant growth, driven by technological advancements and increasing demand across various industries. For buyers from Africa, South America, the Middle East, and Europe, now is the opportune time to explore strategic sourcing options in China. Embrace this opportunity to elevate your production capabilities and drive your business forward in an evolving global market.