Top 7 Cnc Machine Router Supplier Manufacturers & Suppliers List

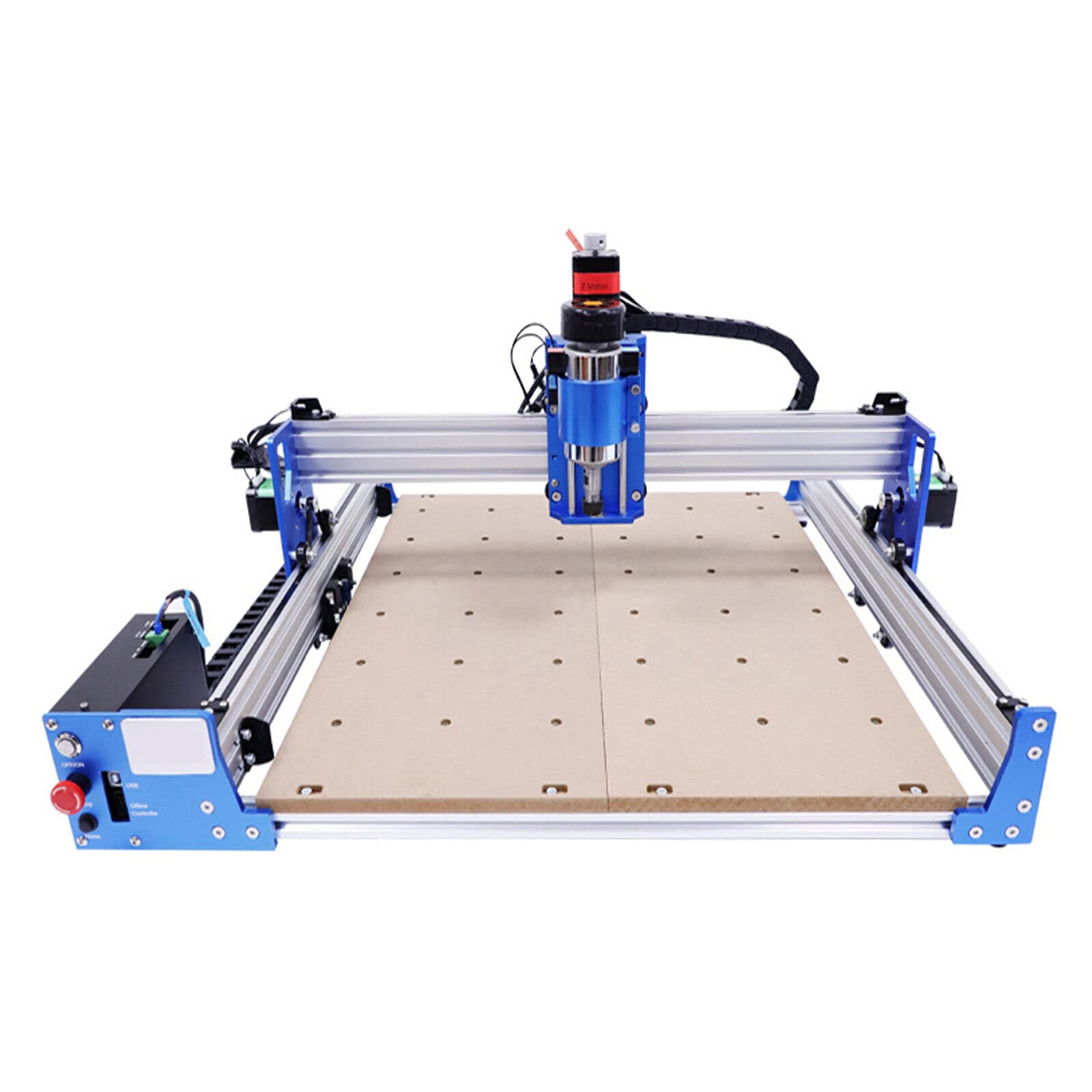

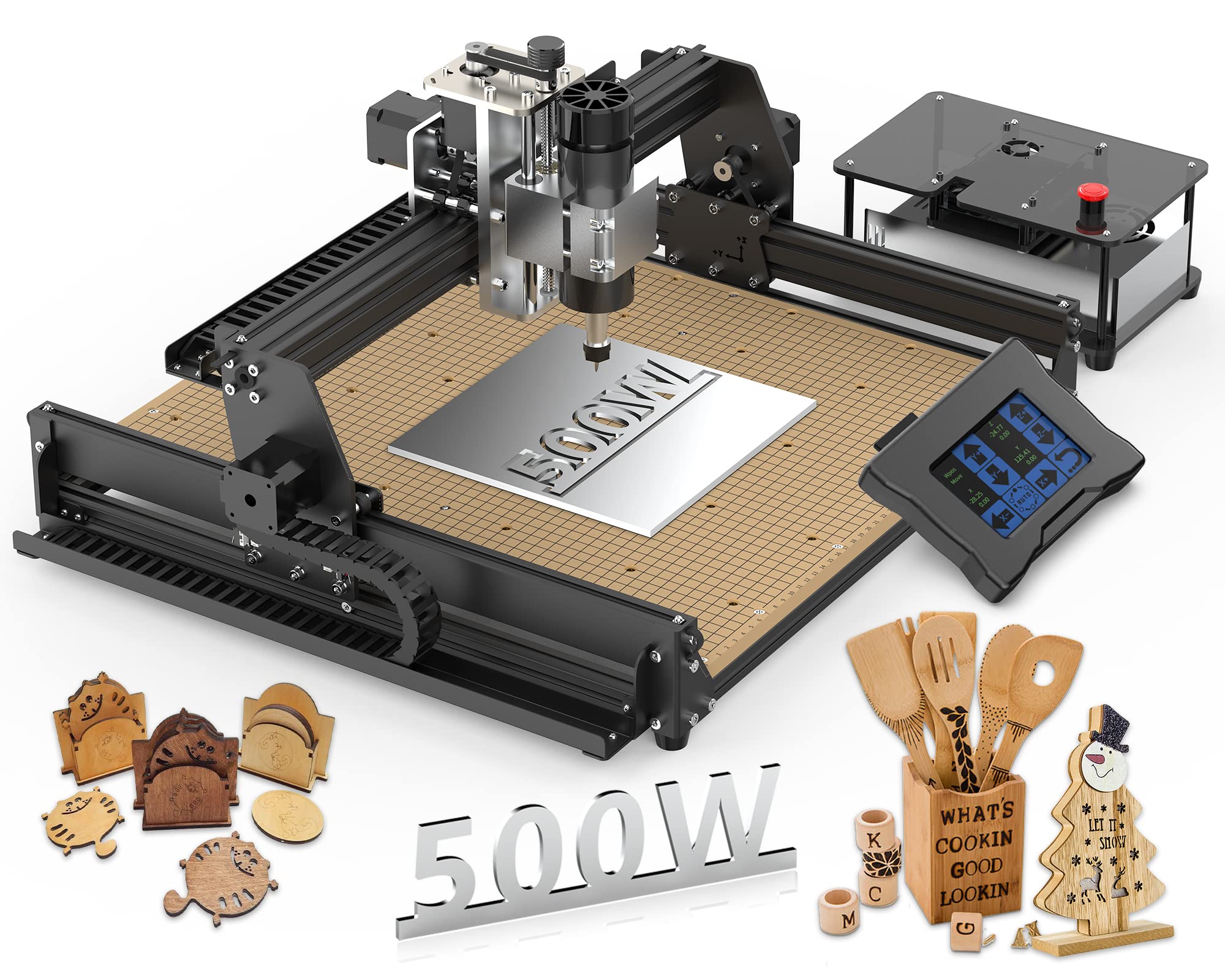

1. SainSmart – Genmitsu CNC Router

Domain: sainsmart.com

Registered: 2011 (14 years)

Introduction: Genmitsu CNC Router, Affordable Beginner-Friendly | SainSmart

2. Hendrick – CNC Routers

Domain: hendrickmanufacturing.com

Registered: 2007 (18 years)

Introduction: Hendrick CNC Routers include a range of industrial machines designed for precise cutting of various materials such as corrugated materials, aluminum, plastic, and wood. The product line features: 3 Axis CNC Routers: 1. HHD Series – Powerful router with 24/7 uptime, up to 16 tools, high-speed cutting with accuracy. 2. HSR Series – High-speed router built for durability, capable of routing wood, pla…

3. ShopBot Tools – Desktop MAX ATC

Domain: shopbottools.com

Registered: 1996 (29 years)

Introduction: Top CNC Router Manufacturer: ShopBot Tools, Made in USA. Product Categories: CNC Products, Desktop Tools, Gantry Tools, Accessories, Design Software, Financing. Key Products: Desktop (24″ x 18″), Desktop MAX (36″ x 24″), Desktop MAX ATC (36″ x 24″), PRS5 Standard (96″ x 48″), PRS5 Alpha (96″ x 48″), PRS5 Alpha ATC (96″ x 48″). Features: Versatile deck options (MDF spoil board, aluminum deck), Univ…

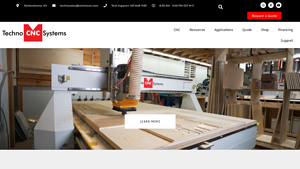

4. Techno CNC – CNC Routers & Plasma Cutters

Domain: technocnc.com

Registered: 2002 (23 years)

Introduction: CNC Routers: 4×4, 4×8, 5×10 sizes; Series include LC Series, Titan Series, Atlas Series, Venture Cabinet Nesting Series, HD II Tabletop, Venus Series, CNC Plasma Cutter, CO2 CNC Laser Cutter, Atlas Digital Registration Series, Venture Series, HDS Series, HDS Dual Bed Series, Goliath Series, Phoenix Series, BT1212 Tabletop Router, Venture Plus Series, Venture Nesting Production Work Center. Feature…

5. MillRight CNC – Alpha Arc Plasma Table

Domain: millrightcnc.com

Registered: 2016 (9 years)

Introduction: {“products”:[{“name”:”Alpha Arc Plasma Table”,”price”:”$8,000.00″,”cutting_area”:”50×50″”,”capabilities”:”Cuts 26 gauge to 1/2″ steel plate, edge start for up to 5/8″ steel plate, sever 1″ steel plate”,”lead_time”:”Approximately 5 weeks”},{“name”:”Mega V 2″,”price”:”$2,299.00″,”capabilities”:”Performance CNC router for hobbyists and businesses”},{“name”:”MillRight CNC Power Route Plus”,”price”:”$3…

6. Industrial CNC – Pro Series CNC Routers

Domain: industrialcnc.com

Registered: 2011 (14 years)

Introduction: Industrial CNC offers a range of CNC routers designed for various applications, including sign making, cabinetry, exhibits, schools, furniture, luthiers, and woodworking. The Pro Series line includes several models: 1. SHORT CUT 203 – Small Format CNC router with a 2’X3′ work area. 2. APPRENTICE 404 – 4’X4′ table suitable for weekend projects. 3. ARTISAN 408 – 4’X8′ CNC router for demanding produc…

7. ProBotix – CNC Routers

Domain: probotix.com

Registered: 2006 (19 years)

Introduction: CNC Routers from ProBotix are designed for precision and versatility in various applications. They offer features such as high-speed cutting, customizable configurations, and compatibility with various materials including wood, plastics, and metals. The routers are suitable for both hobbyists and professionals, providing reliable performance and ease of use. ProBotix also emphasizes customer suppo…

Introduction: Navigating the Global Market for cnc machine router supplier

In today’s competitive landscape, sourcing a reliable CNC machine router supplier poses significant challenges for international B2B buyers, especially those in emerging markets like Africa, South America, the Middle East, and Europe. With a myriad of options available, businesses must navigate varying quality standards, technological advancements, and pricing structures to find the right fit for their manufacturing needs. This guide serves as a comprehensive resource, illuminating the diverse types of CNC routers, their applications across different industries, and essential criteria for vetting suppliers effectively.

Buyers can expect to delve into crucial topics, including the latest technological trends in CNC routing, cost considerations, and how to assess supplier reliability and customer service. Additionally, the guide will offer insights into the unique challenges faced by businesses in regions like Brazil and Saudi Arabia, providing tailored strategies to overcome potential obstacles.

By equipping B2B buyers with the knowledge and tools necessary for informed purchasing decisions, this guide empowers businesses to enhance their operational efficiency and product quality. Whether you’re a small workshop or a large-scale manufacturing facility, understanding the CNC machine router market will be instrumental in driving growth and innovation within your organization.

Understanding cnc machine router supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Entry-Level CNC Routers | Affordable, user-friendly, suitable for beginners | Small workshops, hobbyists, prototyping | Pros: Cost-effective, easy to use. Cons: Limited capabilities for heavy-duty tasks. |

| Industrial CNC Routers | High precision, robust construction, advanced automation features | Manufacturing, aerospace, large-scale production | Pros: High durability, excellent precision. Cons: Higher initial investment, complex operation. |

| Desktop CNC Routers | Compact size, versatile for various materials | Small-scale production, educational purposes | Pros: Space-efficient, affordable. Cons: Limited work area, less powerful. |

| Specialty CNC Routers | Tailored for specific materials (e.g., foam, metal) | Niche markets like signage, aerospace components | Pros: Optimized performance for specific tasks. Cons: Limited versatility across different materials. |

| Custom CNC Routers | Built to unique specifications, extensive customization options | Large enterprises with specific needs | Pros: Tailored solutions, enhanced productivity. Cons: Longer lead times, higher costs. |

What are Entry-Level CNC Routers and Their B2B Suitability?

Entry-level CNC routers are designed for beginners and small businesses looking to explore CNC machining without significant financial risk. These machines are typically affordable and user-friendly, making them suitable for hobbyists, prototyping, and small workshops. When considering an entry-level CNC router, buyers should evaluate the machine’s ease of use, support resources, and the range of materials it can handle. While they may lack the capabilities for heavy-duty tasks, their cost-effectiveness makes them an attractive option for new entrants into the CNC market.

How Do Industrial CNC Routers Stand Out in the Market?

Industrial CNC routers are built for high precision and robust performance, making them ideal for demanding manufacturing environments. With advanced automation features and the ability to handle larger workpieces, these routers are commonly used in industries such as aerospace and large-scale production. Buyers interested in industrial CNC routers should consider factors like machine durability, precision specifications, and the availability of technical support. Although they require a higher initial investment, their long-term reliability and efficiency often justify the cost for serious manufacturers.

What Advantages Do Desktop CNC Routers Offer for Small Businesses?

Desktop CNC routers provide a compact and versatile solution for small-scale production and educational purposes. These machines can handle various materials, including wood, plastics, and soft metals, and are perfect for businesses with limited space. Buyers should assess the machine’s footprint, capabilities, and ease of operation. While desktop CNC routers are generally more affordable, their limited work area and power may restrict larger projects, making them best suited for smaller, detailed work.

Why Consider Specialty CNC Routers for Niche Applications?

Specialty CNC routers are tailored for specific materials, such as foam or metal, and are designed to excel in niche markets like signage or aerospace components. These machines are optimized for particular tasks, providing enhanced performance and efficiency. When purchasing a specialty CNC router, buyers should focus on the machine’s capabilities regarding the intended material and application. While these routers offer excellent performance for specific tasks, their limited versatility might not meet broader production needs.

What are the Benefits and Considerations for Custom CNC Routers?

Custom CNC routers are built to meet unique specifications and provide extensive customization options for large enterprises with specific needs. These machines are designed to optimize productivity and efficiency in specialized operations. Buyers should consider the customization capabilities, lead times, and costs associated with custom solutions. While they can offer significant advantages in productivity, the longer lead times and higher costs can be a drawback for businesses looking for immediate solutions.

Key Industrial Applications of cnc machine router supplier

| Industry/Sector | Specific Application of CNC Machine Router Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture design and prototyping | Enhanced design flexibility, reduced lead times | Machine size, precision, and material compatibility |

| Signage and Advertising | Production of intricate signs and displays | High-quality finishes, scalability for large orders | Software compatibility, customization options |

| Aerospace and Automotive | Precision components fabrication | Improved accuracy and reduced waste | Compliance with industry standards, durability |

| Construction and Architecture | Architectural modeling and custom fixtures | Streamlined project timelines and enhanced aesthetics | Material handling capabilities, size of work area |

| Art and Craft | Artistic carvings and personalized gifts | Unique product offerings and market differentiation | Versatility in material types, ease of use for artisans |

How Is CNC Machine Router Used in Furniture Manufacturing?

In the furniture manufacturing sector, CNC routers are pivotal for creating custom designs and prototypes. These machines allow manufacturers to cut and shape wood with precision, facilitating intricate designs that traditional methods cannot achieve. By streamlining the production process, businesses can significantly reduce lead times and increase output. International buyers, particularly from regions like Africa and South America, should consider the machine’s size and precision to accommodate diverse wood types and design specifications.

What Are the Applications of CNC Routers in Signage and Advertising?

CNC routers are extensively used in the signage and advertising industry to produce intricate signs and displays. These machines enable the creation of high-quality finishes and detailed designs that attract customers and enhance brand visibility. The scalability of CNC routers allows businesses to fulfill large orders efficiently. For international B2B buyers, ensuring compatibility with graphic design software and customization options is crucial for meeting diverse market demands.

Why Is CNC Routing Important in Aerospace and Automotive Industries?

In the aerospace and automotive sectors, CNC routers play a critical role in fabricating precision components. These machines are designed to achieve high accuracy, which is essential for parts that must meet strict safety and performance standards. By minimizing waste and maximizing efficiency, CNC routers contribute to cost savings in production. Buyers in these industries should prioritize sourcing machines that comply with industry regulations and are built for durability to withstand rigorous operational demands.

How Do CNC Routers Benefit Construction and Architecture?

CNC routers are invaluable in construction and architecture for creating detailed architectural models and custom fixtures. These machines help streamline project timelines by allowing for rapid prototyping and adjustments in design. Additionally, they enhance the aesthetic appeal of projects through precise cuts and finishes. Buyers from regions like the Middle East and Europe should consider the material handling capabilities and the size of the work area to ensure that their projects can be executed effectively.

What Role Do CNC Routers Play in Art and Craft?

In the art and craft sector, CNC routers enable artisans to create unique carvings and personalized gifts. The versatility of these machines allows for a wide range of materials, including wood, plastic, and metal, to be used, which opens up various creative possibilities. This capability not only helps artisans differentiate their products in a competitive market but also enhances their production efficiency. When sourcing CNC routers, ease of use and adaptability for different material types are essential considerations for international buyers.

3 Common User Pain Points for ‘cnc machine router supplier’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right CNC Router for Specific Needs

The Problem: B2B buyers often face a daunting challenge when selecting a CNC router that aligns with their specific operational requirements. With a vast array of machines available, ranging from entry-level models to high-end industrial routers, buyers can struggle to discern which features are truly necessary for their applications. This can lead to over-investment in capabilities that exceed their needs or under-investment, resulting in inadequate performance. For international buyers, additional complications arise from varying standards and specifications across regions, making it even harder to make an informed decision.

The Solution: To navigate this challenge, buyers should start by conducting a comprehensive needs assessment. This involves evaluating the types of materials they will be working with (wood, metal, plastic), the complexity of the projects, and the desired precision levels. Creating a detailed specification sheet can help identify essential features such as spindle power, work area size, and compatibility with various software. Next, engaging with reputable CNC machine suppliers for personalized consultations can provide insights into which models best fit the defined criteria. Buyers should also consider suppliers that offer trial periods or demonstrations, enabling them to see the machines in action before making a commitment. Furthermore, reviewing customer testimonials and case studies can provide real-world insights into the performance of different models, aiding in the decision-making process.

Scenario 2: Concerns About Technical Support and Maintenance

The Problem: After investing in a CNC router, many B2B buyers worry about the availability and quality of technical support and maintenance services. Issues such as machine breakdowns or software malfunctions can significantly disrupt production schedules, leading to lost revenue. International buyers may face additional hurdles, including time zone differences and language barriers, which can make it difficult to get timely assistance from suppliers based in different regions.

The Solution: To mitigate these concerns, buyers should prioritize suppliers that offer robust post-purchase support, including lifetime technical assistance and comprehensive training programs. Before making a purchase, inquire about the supplier’s support structure, response times, and available resources. Opting for suppliers that provide localized support or have regional representatives can enhance communication and facilitate quicker resolutions to technical issues. Additionally, buyers should consider investing in training for their staff to ensure they are well-equipped to handle minor issues independently, thus minimizing reliance on external support. Establishing a clear service agreement that outlines maintenance schedules and support availability can further ensure that buyers have a reliable backup when issues arise.

Scenario 3: High Costs of Ownership and Operation

The Problem: Another common pain point for B2B buyers is the total cost of ownership associated with CNC routers, which includes not only the initial purchase price but also ongoing operational costs such as maintenance, tooling, and energy consumption. Many buyers underestimate these costs, which can lead to budget overruns and financial strain, particularly for small to medium-sized enterprises. Additionally, the return on investment may not meet expectations if the machines are not utilized to their full potential.

The Solution: To effectively manage costs, buyers should adopt a holistic approach when evaluating CNC routers. Begin by calculating the total cost of ownership over the machine’s expected lifespan, factoring in maintenance, consumables, and energy usage. Engaging with suppliers that provide transparent pricing models and detailed operational cost breakdowns can aid in this analysis. Furthermore, buyers should explore financing options or leasing arrangements that can alleviate upfront costs and spread expenses over time. Investing in high-quality tools and accessories from the outset can also reduce long-term maintenance costs and enhance machine performance. Finally, ensuring that operators are well-trained can maximize productivity and minimize waste, ultimately leading to a better return on investment.

Strategic Material Selection Guide for cnc machine router supplier

What Materials Should International B2B Buyers Consider for CNC Machine Routers?

When selecting materials for CNC machine routers, it is crucial to understand the properties, advantages, and limitations of each material type. This knowledge can significantly impact the performance and suitability of the machine for specific applications, especially for international buyers from diverse regions like Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in CNC machine routers.

1. Aluminum

Key Properties:

Aluminum is lightweight yet strong, with excellent corrosion resistance and thermal conductivity. It can withstand moderate temperatures and pressures, making it suitable for various machining applications.

Pros & Cons:

Aluminum offers high durability and is relatively easy to machine, which reduces manufacturing complexity. However, it can be more expensive than other materials like wood or plastic, and its softness may lead to wear over time in high-friction applications.

Impact on Application:

Aluminum is commonly used in the aerospace and automotive industries for components that require precision and lightweight properties. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers:

Buyers should be aware of compliance with international standards such as ASTM and ISO. In regions like Brazil and Saudi Arabia, understanding local regulations regarding aluminum sourcing and recycling can also be beneficial.

2. Steel

Key Properties:

Steel is known for its high strength and durability, with excellent temperature and pressure ratings. It is resistant to deformation and can handle heavy workloads.

Pros & Cons:

The primary advantage of steel is its robustness, making it ideal for heavy-duty applications. However, it is heavier than aluminum and can be more challenging to machine, increasing manufacturing complexity and costs.

Impact on Application:

Steel is widely used in construction and manufacturing industries, especially for components that require high strength and wear resistance. It is compatible with a variety of cutting and shaping processes.

Considerations for International Buyers:

Steel sourcing can vary by region, and buyers should consider local availability and pricing. Compliance with standards like DIN (Germany) or JIS (Japan) is crucial, especially for buyers in Europe and the Middle East.

3. Wood

Key Properties:

Wood is a natural material that offers good machinability and is relatively lightweight. It has varying resistance to temperature and humidity, depending on the type of wood.

Pros & Cons:

Wood is cost-effective and widely available, making it an attractive option for many businesses. However, it may not be as durable as metals and can be susceptible to warping or degradation over time.

Impact on Application:

Wood is commonly used in furniture production, cabinetry, and decorative items. Its compatibility with various finishes allows for aesthetic versatility.

Considerations for International Buyers:

Buyers should be aware of local wood sourcing regulations and sustainability practices, especially in regions like Africa and South America, where deforestation concerns may arise. Compliance with environmental standards is also essential.

4. Composite Materials

Key Properties:

Composite materials, such as fiberglass or carbon fiber, are engineered for high strength-to-weight ratios and excellent corrosion resistance. They can withstand high temperatures and pressures.

Pros & Cons:

The main advantage of composites is their lightweight nature combined with high durability, making them suitable for specialized applications. However, they can be more expensive and complex to manufacture compared to traditional materials.

Impact on Application:

Composites are increasingly used in aerospace, automotive, and marine applications where weight savings are critical. Their compatibility with advanced machining processes makes them a modern choice.

Considerations for International Buyers:

Understanding the local market for composite materials is vital, as availability can vary. Buyers should also consider compliance with international standards and certifications, especially in high-tech industries.

Summary Table of Material Selection for CNC Machine Routers

| Material | Typical Use Case for cnc machine router supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | More expensive than wood/plastics | Medium |

| Steel | Heavy-duty machinery, construction components | High strength and durability | Heavier and harder to machine | High |

| Wood | Furniture, cabinetry, decorative items | Cost-effective and widely available | Less durable, susceptible to warping | Low |

| Composite Materials | Aerospace, automotive, marine applications | High strength-to-weight ratio | Expensive and complex to manufacture | High |

This guide provides a comprehensive overview of material selection for CNC machine routers, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc machine router supplier

What Are the Key Stages in the Manufacturing Process of CNC Machine Routers?

The manufacturing process of CNC machine routers involves several key stages, each critical to ensuring the quality and performance of the final product. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

Material Preparation

The first stage in the manufacturing process is material preparation. High-quality materials, such as structural steel for frames and aluminum for parts, are sourced from reputable suppliers. These materials undergo rigorous inspections to ensure they meet the necessary specifications. Common practices include checking for material consistency, strength, and surface finish. Only materials that pass these inspections proceed to the next stage, ensuring that the foundation of the CNC router is built on reliable components.

Forming Techniques

Once the materials are prepared, they are subjected to forming processes. Techniques such as laser cutting, CNC machining, and bending are employed to create the various components of the router. Laser cutting offers precision in shaping complex parts, while CNC machining provides the accuracy needed for tight tolerances. Additionally, forming processes are often optimized through computer simulations, allowing for adjustments before the physical manufacturing begins. This stage is crucial for ensuring that each part fits together seamlessly in the assembly phase.

Assembly Process

After forming, the next step is assembly. This phase involves integrating all the individual components, including the frame, motors, spindles, and electronic systems. Advanced robotics and skilled technicians work together to ensure that each router is assembled with precision. During assembly, quality checks are performed at various points to detect any misalignments or defects early in the process. This proactive approach minimizes the risk of issues arising later in the production cycle.

Finishing Touches

The final stage in the manufacturing process is finishing. This includes surface treatments such as painting, anodizing, or powder coating to enhance durability and aesthetics. Additionally, quality assurance tests are conducted to ensure that the machine functions correctly and meets performance specifications. Finishing also involves thorough cleaning and packaging to prepare the CNC routers for shipment.

What Quality Control Measures Are Essential for CNC Machine Router Suppliers?

Quality assurance is a critical aspect of the CNC router manufacturing process. For B2B buyers, understanding the quality control measures in place can provide confidence in their supplier’s reliability.

What International Standards Should CNC Machine Router Suppliers Adhere To?

Many CNC machine router suppliers adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that the manufacturer consistently meets customer requirements and enhances satisfaction through effective system implementation. Additionally, certifications like CE mark and API may be relevant for suppliers targeting specific markets, ensuring that the products meet European and American safety and quality standards.

What Are the Key Quality Control Checkpoints?

Quality control is typically segmented into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers should verify that materials meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are conducted to monitor the quality of the production. This may include dimensional checks, visual inspections, and functional tests to ensure that components are being manufactured correctly.

-

Final Quality Control (FQC): Once the CNC router is fully assembled, a comprehensive evaluation is performed. This includes functional testing, performance validation, and final inspections to confirm that the machine meets all specifications and standards.

What Testing Methods Are Commonly Used?

Testing methods for CNC routers include:

-

Functional Testing: Ensures that all components operate correctly under simulated working conditions.

-

Durability Testing: Assesses the longevity of the machine through stress tests that mimic prolonged usage.

-

Precision Testing: Involves measuring the accuracy of cuts and operations to ensure they meet industry standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for reducing risks associated with sourcing CNC routers.

What Steps Can Buyers Take to Ensure Supplier Quality?

-

Conduct Supplier Audits: Buyers should consider conducting on-site audits of potential suppliers. This allows them to assess the manufacturing environment, quality control measures, and compliance with international standards directly.

-

Request Quality Assurance Reports: Suppliers should be willing to provide documentation that details their quality control processes, including test results and compliance certifications. Reviewing these documents can help buyers gauge the reliability of the supplier.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing and quality assurance practices. These inspectors can conduct assessments at various stages of production, ensuring adherence to agreed-upon specifications.

What Are the Unique Quality Control Nuances for International Buyers?

International buyers may face unique challenges related to quality control, including language barriers, differing regulations, and varying market expectations. It is essential for buyers to:

-

Understand Local Standards: Familiarize themselves with the local quality standards and regulations relevant to their market. This knowledge will help in assessing whether the supplier’s certifications are applicable and recognized.

-

Establish Clear Communication: Maintaining open lines of communication with suppliers can help clarify expectations and resolve any issues promptly. Regular updates during the manufacturing process can also enhance transparency.

-

Build Long-term Relationships: Establishing a solid relationship with suppliers can facilitate better quality control and responsiveness to concerns. Long-term partnerships often lead to improved trust and a greater willingness from suppliers to meet buyer needs.

In summary, understanding the manufacturing processes and quality assurance protocols of CNC machine router suppliers is crucial for B2B buyers. By focusing on these elements, buyers can make informed decisions and choose reliable suppliers that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc machine router supplier’

This guide is designed to assist international B2B buyers in sourcing CNC machine routers effectively. By following this step-by-step checklist, businesses can ensure that they select the right suppliers to meet their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the supplier search, clearly outline the technical specifications of the CNC router you require. Consider factors such as spindle power, work area size, material compatibility, and any specific features like dual Z-axis or closed-loop systems. Having detailed specifications will help you communicate your needs effectively and narrow down your options.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential CNC router suppliers. Utilize online directories, industry forums, and trade shows to gather a list of candidates. Pay attention to suppliers that have a strong presence in your target regions, such as Africa, South America, the Middle East, and Europe, as they may better understand local market needs.

Step 3: Evaluate Supplier Experience and Reputation

Assess the experience and reputation of each supplier. Look for suppliers that have been in the industry for several years and have a proven track record. Check for online reviews, testimonials, and case studies that demonstrate their capabilities and reliability. Engaging with existing customers can provide insights into the supplier’s performance and customer service.

Step 4: Request Detailed Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, shipping options, and delivery timelines. Compare these quotes carefully, taking into account not just the base price but also the total cost of ownership, which includes maintenance, parts, and any additional software or training that may be required.

Step 5: Verify Supplier Certifications and Compliance

It is crucial to ensure that your chosen supplier complies with relevant industry standards and certifications. Verify their ISO certifications, CE markings, or any other certifications that apply to CNC machinery. This step helps mitigate risks associated with quality and safety, ensuring that the machines meet international standards.

Step 6: Assess After-Sales Support and Training

Evaluate the after-sales support offered by the supplier. A reliable supplier should provide technical support, warranty details, and training for your team. Inquire about the availability of spare parts and service options, as ongoing support can significantly impact the efficiency of your operations.

Step 7: Conduct a Final Review and Make Your Decision

After gathering all necessary information, conduct a final review of your options. Weigh the pros and cons of each supplier based on your specifications, pricing, support, and reputation. Making an informed decision will ultimately lead to a successful procurement process and a strong partnership with your CNC router supplier.

By following this checklist, B2B buyers can confidently navigate the sourcing process and select the right CNC machine router supplier to meet their business needs.

Comprehensive Cost and Pricing Analysis for cnc machine router supplier Sourcing

What Are the Key Cost Components in CNC Machine Router Sourcing?

When sourcing CNC machine routers, understanding the cost structure is paramount. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals, plastics, or composite materials will typically result in higher prices but can enhance the durability and precision of the machine.

-

Labor: Labor costs vary based on geographic location and the complexity of manufacturing. Regions with lower labor costs can offer competitive pricing, but it’s essential to ensure that quality is not compromised.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient production processes can help lower these costs, allowing suppliers to offer more competitive prices.

-

Tooling: The cost of tooling is often a hidden expense. Custom tooling for specific designs can drive up costs, while standardized tools may offer more economical options.

-

Quality Control (QC): Investing in rigorous QC processes ensures product reliability and compliance with international standards. This can add to the initial costs but may lead to long-term savings by reducing returns and enhancing customer satisfaction.

-

Logistics: Shipping and handling costs can vary significantly, especially for international shipments. Factors such as distance, shipping method, and customs duties can influence the final price.

-

Margin: Suppliers will factor in their profit margin, which can vary based on competition, market demand, and product differentiation.

How Do Price Influencers Affect CNC Router Costs?

Several factors influence the pricing of CNC routers, making it crucial for buyers to consider these elements:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often have tiered pricing based on order volumes, making it advantageous for larger projects.

-

Specifications and Customization: Customized CNC routers tailored to specific needs typically come at a premium. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: Routers made from high-grade materials or those that meet specific industry certifications may command higher prices. Buyers should ensure that the investment aligns with their operational requirements.

-

Supplier Factors: The reputation, reliability, and service offerings of suppliers can also impact pricing. Established suppliers may charge more due to their proven track record, but they may offer better after-sales support.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is essential. They dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and liability, which can affect total expenses.

What Are Effective Buyer Tips for Negotiating CNC Router Prices?

To secure the best deals on CNC routers, consider the following buyer tips:

-

Negotiate Terms: Always seek to negotiate pricing, payment terms, and delivery schedules. Suppliers may be willing to offer discounts for prompt payment or longer contract commitments.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, evaluate the TCO, which includes maintenance, operational costs, and potential downtime. A cheaper machine might incur higher long-term costs.

-

Understand Pricing Nuances in International Sourcing: Different regions have varying pricing structures influenced by local demand, competition, and economic conditions. For instance, buyers from Africa or South America might face different tariffs and shipping costs compared to those in Europe.

-

Conduct Market Research: Familiarize yourself with the market rates for CNC routers in your specific region. This knowledge can provide leverage during negotiations and help avoid overpaying.

-

Request Multiple Quotes: Engage with multiple suppliers to get a range of quotes. This not only helps in price comparison but also provides insights into the market landscape.

Conclusion: Why Are Indicative Prices Important for B2B Buyers?

While indicative prices can offer a starting point for budgeting, it’s crucial to remember that final costs may vary based on customization, shipping, and other factors. Conducting thorough research and understanding the full cost structure will empower buyers to make informed purchasing decisions.

Alternatives Analysis: Comparing cnc machine router supplier With Other Solutions

Understanding Alternatives to CNC Machine Router Suppliers

In the landscape of manufacturing and fabrication, CNC machine routers are a popular choice for precision cutting, shaping, and carving. However, various alternative solutions exist, each with distinct advantages and limitations. This analysis will compare CNC machine router suppliers with two viable alternatives: laser cutting machines and traditional manual routing. Understanding these options is crucial for B2B buyers looking to enhance their operational capabilities.

Comparison Table

| Comparison Aspect | CNC Machine Router Supplier | Laser Cutting Machine | Traditional Manual Routing |

|---|---|---|---|

| Performance | High precision and versatility for a range of materials | Exceptional precision, especially for thin materials | Variable precision; depends on operator skill |

| Cost | Moderate initial investment; lower long-term costs | Higher initial investment; operational costs can vary | Low initial costs; long-term costs depend on labor |

| Ease of Implementation | Requires technical expertise for setup and operation | Moderate complexity; often requires training | Simple setup; minimal training needed |

| Maintenance | Regular maintenance required; parts may need replacement | Generally low maintenance; optics require cleaning | High wear and tear; frequent tool replacement |

| Best Use Case | Ideal for woodworking, plastics, and metals | Best for intricate designs and thin materials like acrylic | Suitable for less complex shapes and small-scale projects |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Laser Cutting Machines?

Laser cutting machines utilize focused laser beams to cut through materials with high precision. They excel in applications where intricate designs are necessary, making them ideal for industries like signage and aerospace. However, the higher initial investment and operational costs associated with laser technology can be a barrier for some businesses. Additionally, they are more suited for thinner materials, which may limit their use in thicker substrates compared to CNC routers.

How Does Traditional Manual Routing Compare?

Traditional manual routing involves using handheld tools for cutting and shaping materials. This method offers a low initial investment and is straightforward to implement, making it accessible for small businesses and hobbyists. However, the performance is heavily dependent on the operator’s skill level, leading to inconsistencies in precision. Furthermore, manual routing may incur higher long-term costs due to labor and the frequent replacement of worn tools.

Making an Informed Decision on CNC Machine Router Suppliers

When selecting the right solution, B2B buyers should consider their specific operational needs, budget constraints, and the materials they commonly work with. CNC machine routers provide a balance of performance and cost-effectiveness for a variety of applications, while laser cutting machines offer unparalleled precision for intricate designs. Traditional manual routing can be beneficial for simpler tasks but may lack the efficiency and consistency required for larger-scale operations. Ultimately, evaluating these alternatives against your business objectives will lead to a more informed purchasing decision.

Essential Technical Properties and Trade Terminology for cnc machine router supplier

What Are the Key Technical Properties of CNC Machine Routers That B2B Buyers Should Consider?

When evaluating CNC machine routers, several technical properties are critical for ensuring the machines meet the specific needs of various industries. Here are some essential specifications to consider:

1. Spindle Power (Watts)

Spindle power is a crucial specification that indicates the machine’s cutting capacity. Higher spindle power (measured in watts) allows for faster cutting speeds and the ability to work with denser materials, such as metals. For businesses focused on high-volume production or cutting complex materials, investing in routers with higher spindle power can improve efficiency and reduce operational costs.

2. Work Area Dimensions

The size of the work area determines the maximum dimensions of the material that can be processed. Common sizes range from compact desktop models suitable for small projects to large industrial machines for extensive workpieces. Understanding the required work area is vital for businesses to ensure they can accommodate their project needs without limitations.

3. Material Compatibility

CNC routers can work with a variety of materials, including wood, plastic, metal, and composites. Each machine has specific capabilities regarding material thickness and density. B2B buyers must assess their materials to choose a router that can handle their unique requirements, ensuring quality output and operational efficiency.

4. Motion Control System

The type of motion control system affects precision and speed. Common systems include stepper motors and servo motors, with servo motors typically offering higher accuracy and faster speeds. For applications requiring intricate designs or high precision, investing in machines with advanced motion control systems can lead to improved product quality and reduced waste.

5. Tolerance Levels

Tolerance refers to the allowable deviation from a specified dimension, crucial for ensuring that parts fit together correctly. Machines with tighter tolerance levels (measured in millimeters or inches) are essential for high-precision applications, such as aerospace or automotive parts manufacturing. Buyers should prioritize routers that meet their tolerance requirements to avoid costly rework.

6. Build Quality and Materials

The construction of the CNC router affects its durability, stability, and overall performance. High-quality materials, such as stress-annealed steel frames, contribute to a machine’s longevity and ability to handle rigorous use. B2B buyers should evaluate the build quality to ensure their investment will withstand long-term operational demands.

What Trade Terminology Should B2B Buyers Know When Working with CNC Machine Router Suppliers?

Understanding common industry jargon can facilitate better communication and decision-making in B2B transactions. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the CNC router industry, buyers often work with OEMs to obtain custom components or machines tailored to their specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to plan their purchases effectively and manage inventory costs. This term is especially relevant for companies looking to optimize their supply chain.

3. RFQ (Request for Quotation)

An RFQ is a formal process where potential buyers request pricing and terms from suppliers for specific products or services. By issuing an RFQ, businesses can gather competitive quotes and make informed purchasing decisions based on cost and quality.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities associated with their purchases.

5. CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing)

CAD refers to the use of software to create precise drawings and technical illustrations, while CAM involves using software to control machine tools in manufacturing processes. Understanding these terms is essential for businesses looking to integrate design and manufacturing processes effectively.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing CNC machine routers, ensuring they choose the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the cnc machine router supplier Sector

What Are the Key Market Dynamics and Trends Affecting CNC Machine Router Suppliers?

The CNC machine router supplier sector is witnessing significant evolution driven by technological advancements and changing buyer preferences. Global demand for precision machining is on the rise, fueled by industries such as woodworking, aerospace, automotive, and prototyping. Emerging markets in Africa, South America, the Middle East, and Europe are particularly keen on adopting CNC technologies to enhance manufacturing capabilities and improve product quality. The shift towards automation and Industry 4.0 is prompting suppliers to integrate advanced features such as IoT connectivity and AI-driven analytics into their machinery, allowing for real-time monitoring and predictive maintenance.

Moreover, international B2B buyers are increasingly prioritizing suppliers that offer customization options, scalable solutions, and comprehensive support services. This trend is particularly prominent in regions like Brazil and Saudi Arabia, where local industries are evolving rapidly. Additionally, the demand for affordable entry-level CNC routers is growing, as small and medium-sized enterprises (SMEs) seek to enter the market without significant capital investment. As a result, suppliers are diversifying their product lines to include budget-friendly options alongside high-end machines, catering to a broader spectrum of customer needs.

How Can Sustainability and Ethical Sourcing Impact Your CNC Machine Router Procurement?

Sustainability is becoming a critical consideration in the CNC machine router supplier sector, as businesses recognize the environmental impact of their operations. Buyers are increasingly aware of the carbon footprint associated with manufacturing processes and are seeking suppliers that prioritize eco-friendly practices. This includes the use of sustainable materials, energy-efficient machinery, and waste reduction strategies.

Moreover, ethical sourcing is paramount, as international buyers demand transparency in the supply chain. Suppliers are encouraged to obtain certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) to demonstrate their commitment to sustainability. Utilizing ‘green’ materials, such as recycled metals and eco-friendly lubricants, can not only reduce environmental impact but also appeal to a growing segment of environmentally conscious consumers. By choosing suppliers with strong sustainability credentials, businesses can enhance their brand reputation and meet the increasing regulatory demands for environmental accountability.

What Is the Evolution of CNC Machine Routers and Its Significance for B2B Buyers?

The evolution of CNC machine routers dates back to the mid-20th century when numerical control (NC) technology was first introduced. Initially, these machines were limited to simple tasks and were primarily used in industrial settings. However, advancements in computer technology in the 1980s and 1990s transformed CNC routers into versatile tools capable of executing complex designs with high precision.

Today, CNC routers are integral to various sectors, enabling manufacturers to optimize production processes and reduce lead times. The ability to automate tasks has made CNC routers indispensable for businesses looking to enhance efficiency and reduce labor costs. For B2B buyers, understanding this evolution is crucial as it highlights the technological innovations that continue to shape the market. It also underscores the importance of investing in modern, reliable machines that can adapt to changing production demands and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc machine router supplier

-

How do I choose the right CNC router supplier for my business needs?

Choosing the right CNC router supplier involves assessing several key factors. Start by evaluating the supplier’s reputation in the industry, which can be done through online reviews, testimonials, and case studies. Next, consider their product range and whether they offer machines that fit your specific applications, such as wood, metal, or composite materials. Additionally, inquire about their customer service and support options, including technical assistance and warranty policies. Lastly, ensure they have experience shipping to your region, which can affect lead times and logistics. -

What is the best CNC router for small-scale production?

For small-scale production, look for a CNC router that balances affordability with reliability. Entry-level models, such as desktop CNC routers, are excellent for businesses starting out. Brands like Genmitsu offer budget-friendly options with decent spindle power and versatility for various materials. Ensure the machine supports your intended applications, whether it’s woodworking, engraving, or light metal work. Additionally, consider features like ease of use and available training resources to maximize productivity. -

What are the minimum order quantities (MOQ) for CNC routers?

Minimum order quantities can vary widely among CNC router suppliers, often depending on the type of machine and the supplier’s production capabilities. Some suppliers may allow single unit purchases, especially for entry-level models, while others may require bulk orders for industrial-grade machines. It’s essential to communicate directly with suppliers to clarify their MOQ policies and negotiate terms that suit your business needs, especially if you plan to scale your operations. -

How can I ensure the quality of CNC routers from international suppliers?

To ensure quality when sourcing CNC routers from international suppliers, request detailed product specifications and certifications. Look for suppliers who adhere to international quality standards, such as ISO certifications. Additionally, ask for samples or demonstration units to evaluate performance firsthand. Consider conducting factory visits or audits, if feasible, to assess manufacturing processes. Lastly, read reviews from other international buyers to gauge their experiences regarding product quality and supplier reliability. -

What payment terms should I expect when buying CNC routers?

Payment terms can vary significantly among CNC router suppliers and may include options like upfront payment, installment plans, or letters of credit. Many suppliers require a deposit upon order confirmation, with the balance due prior to shipping. It’s advisable to negotiate terms that align with your cash flow needs. Additionally, confirm the accepted payment methods, which may include bank transfers, credit cards, or escrow services for added security. -

What customization options are typically available for CNC routers?

Most CNC router suppliers offer a range of customization options to suit specific production needs. These may include different spindle powers, work area sizes, and additional features like automatic tool changers or advanced dust collection systems. You can also request software integrations that align with your existing production processes. Discuss your requirements with potential suppliers to explore available configurations and ensure that the machine meets your operational goals. -

What should I consider regarding logistics and shipping when importing CNC routers?

When importing CNC routers, logistics and shipping considerations are critical. First, confirm the supplier’s shipping capabilities and whether they can handle customs clearance for your destination country. Evaluate shipping options, including air versus sea freight, based on your urgency and budget. Additionally, consider delivery times and potential import tariffs or duties that may apply. It’s wise to work with a freight forwarder familiar with international machinery shipping to streamline the process. -

How do I access technical support and training for my CNC router?

Accessing technical support and training is crucial for maximizing the value of your CNC router investment. Many reputable suppliers offer lifetime technical support via phone, email, or online chat. Additionally, inquire about training resources, such as webinars, user manuals, and video tutorials, to help your team effectively operate the machine. Some suppliers may also provide on-site training as part of the purchase agreement, which can be beneficial for complex setups or advanced functionalities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc machine router supplier

In conclusion, the strategic sourcing of CNC machine routers is crucial for international buyers looking to enhance their manufacturing capabilities. Key takeaways include the importance of selecting suppliers that offer not only high-quality machines but also comprehensive support services, including training and technical assistance. As manufacturers increasingly seek to innovate and optimize their production processes, investing in reliable CNC routers can lead to significant competitive advantages.

Moreover, understanding the diverse offerings from suppliers across different regions—such as affordable models for entry-level users or high-performance machines for industrial applications—enables buyers to align their procurement with specific operational needs. Strategic sourcing empowers businesses to make informed decisions that enhance productivity while minimizing costs.

As we look ahead, the demand for CNC routers is expected to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. This presents a unique opportunity for B2B buyers to leverage the latest technology and expand their capabilities. We encourage you to engage with reputable suppliers, explore their product ranges, and take proactive steps to secure the best solutions for your machining needs. The future of your manufacturing success begins with informed sourcing decisions today.