Top 7 China Cnc Machining Service Manufacturers & Suppliers List

1. PCBWay – CNC Machining & 3D Printing Services

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: CNC Machining Service: Offers CNC Milling, CNC Turning, and supports materials like Aluminum, Stainless Steel, Brass, Copper, Titanium, Mild Steel, and various plastics. 3D Printing Service: Includes Stereolithography (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), Selective Laser Melting (SLM), Selective Laser Sintering (SLS), PolyJet (PJ), and Vacuum Casting (VC) with mat…

2. At Machining – CNC Machining Services

Domain: at-machining.com

Registered: 2014 (11 years)

Introduction: Top China CNC Machining Service, Quick, Accurate, Flexible, No MOQ. Services include CNC Machining, CNC Milling, CNC Turning, Precision 5-Axis CNC Machining, Swiss CNC Machining, Small Batch CNC Machining, Precision Micro Machining, Sheet Metal Fabrication, Surface Finishing Services (Anodizing, Electroplating, Powder Coating), Carburizing Heat Treatment, Wire EDM Machining. Materials include Meta…

3. Hongsinn – Custom CNC Machining Services

Domain: m.hongsinn.com

Registered: 2013 (12 years)

Introduction: Custom CNC Machining Service, Bespoke CNC Machining, 5 Axis CNC Machining, CNC Turning Parts, CNC Milling Parts, CNC Cutting Service, CNC Lathe Parts, CNC Machining Large Parts, CNC Aluminium Parts, CNC Steel Parts, Plastic CNC Machining Parts, Carbide Machining, CNC Machining Automation Parts, CNC Machining Aerospace Parts, CNC Machining Medical Parts, Precision Mold Parts, CNC Prototype Service,…

4. China Machining – Precision CNC Services

Domain: china-machining.com

Registered: 2008 (17 years)

Introduction: CNC Machining Services in China, High-Quality CNC Machined Parts, ISO 9001:2015 certified facility, rapid prototyping and low-volume production, precision machined parts in various materials and surface finishes, CNC milling and turning capabilities, tolerances as tight as ±0.001mm, broad range of materials including metals (aluminum, steel, stainless steel, brass, copper), plastics (POM, PTFE, PC…

5. Yijin Solution – CNC Machining Services

Domain: yijinsolution.com

Registered: 2019 (6 years)

Introduction: CNC Machining Services from China, including CNC Turning, CNC Milling, 5 Axis CNC Machining, Rapid CNC Machining, Small Batch CNC Machining, High-Volume CNC Machining, Swiss Machining, CNC Wood Routing, and Sheet Metal Fabrication. Materials include plastics (ABS, Acetal, HDPE, Nylon, PA, PEEK, Phenolic, Polycarbonate, PVC, UHMW PE) and metals (Aluminum, Brass, Copper, Magnesium, Steel, Stainless …

6. HLH Prototypes – CNC Machining Services

Domain: hlhprototypes.com

Registered: 2012 (13 years)

Introduction: CNC Machining Services specializing in rapid prototyping using high-speed, high-precision CNC manufacturing. Services include: 3, 4, and 5 axis machining; a wide range of materials including plastics and metals; compliance with ISO 2678-1 International Tolerance legislation; capabilities for low to mid-volume production runs; and applications in various industries such as aerospace, automotive, te…

7. Top Level Intl. – CNC Machining Services

Domain: toplevelcnc.com

Registered: 2013 (12 years)

Introduction: This company, Top Level Intl. – CNC Machining Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Introduction: Navigating the Global Market for china cnc machining service

Navigating the complexities of sourcing China CNC machining services can be daunting for international B2B buyers. With a myriad of options available, finding reliable suppliers that offer high-quality, cost-effective solutions can pose a significant challenge. This guide aims to demystify the landscape of CNC machining services in China, covering essential aspects such as types of machining processes, applications across various industries, and effective strategies for supplier vetting.

From understanding the nuances of CNC milling and turning to exploring rapid prototyping techniques, this comprehensive resource is designed to empower decision-makers in Africa, South America, the Middle East, and Europe—regions where the demand for precision-engineered components is rapidly growing. By providing insights into pricing structures, lead times, and quality assurance practices, we equip buyers with the knowledge needed to make informed purchasing decisions that align with their specific project requirements.

As you delve into this guide, you will discover actionable tips and expert advice that will enable you to confidently select the right China CNC machining service provider, ensuring that your production goals are met with efficiency and excellence.

Understanding china cnc machining service Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Milling | Utilizes rotating tools to remove material; available in 3, 4, and 5-axis configurations. | Aerospace, automotive, electronics, and industrial machinery. | Pros: High precision, versatile for complex shapes. Cons: Setup time can be lengthy for complex designs. |

| CNC Turning | Rotates the workpiece against a stationary cutting tool; ideal for cylindrical parts. | Manufacturing shafts, bushings, and other round components. | Pros: Excellent for high-volume production; good surface finish. Cons: Limited to rotationally symmetric parts. |

| CNC Prototyping | Rapid production of prototypes using various materials; quick turnaround times. | Product development, testing, and validation across industries. | Pros: Fast lead times, cost-effective for small batches. Cons: May not be suitable for large-scale production. |

| Wire EDM Machining | Uses electrical discharges to cut hard materials with high precision; suitable for intricate shapes. | Aerospace, medical devices, and specialized tooling. | Pros: Exceptional precision and fine detail; ideal for hard materials. Cons: Slower than traditional machining methods. |

| 3D Printing | Layer-by-layer additive manufacturing; can utilize various materials including metals and plastics. | Prototyping, custom parts, and small production runs. | Pros: Highly flexible design options; rapid iteration. Cons: May have limitations in material strength compared to traditional methods. |

What are the Key Characteristics of CNC Milling Services?

CNC milling is a widely used machining service that employs rotating cutting tools to remove material from a workpiece. This method is available in various configurations, including 3, 4, and 5-axis milling, allowing for the production of complex geometries. It is particularly suitable for industries such as aerospace and automotive, where precision and complexity are paramount. B2B buyers should consider the specific tolerances required for their projects, as well as the setup time involved, which can be significant for intricate designs.

How Does CNC Turning Differ from Other Machining Services?

CNC turning involves rotating the workpiece against a stationary cutting tool, making it ideal for producing cylindrical components such as shafts and bushings. This service is particularly advantageous for high-volume production due to its efficiency and ability to achieve excellent surface finishes. When purchasing turning services, buyers should evaluate the supplier’s capabilities regarding material types and the maximum diameter they can accommodate, ensuring compatibility with their project requirements.

Why Choose CNC Prototyping for Product Development?

CNC prototyping is designed for rapid production of prototypes, allowing businesses to test and validate their designs quickly. This service is particularly beneficial in the product development phase, where speed and cost-effectiveness are crucial. Buyers should assess the lead times offered by suppliers and whether they can accommodate iterative changes during the prototyping phase, which is common in early-stage product development.

What Makes Wire EDM Machining a Unique Option?

Wire EDM (Electrical Discharge Machining) utilizes electrical discharges to precisely cut hard materials into intricate shapes. This method is ideal for industries requiring high precision, such as aerospace and medical device manufacturing. B2B buyers should consider the material hardness and complexity of the designs they need, as Wire EDM is particularly effective for detailed work but may have longer lead times compared to traditional machining methods.

When Should Businesses Opt for 3D Printing Services?

3D printing, or additive manufacturing, builds parts layer by layer and can use a wide range of materials, including plastics and metals. This service is especially valuable for prototyping and producing custom parts in small quantities. Buyers should evaluate the material properties required for their applications, as 3D-printed parts may not always match the strength of traditionally machined components. Flexibility in design and rapid iteration are key advantages that make 3D printing a compelling choice for innovative projects.

Key Industrial Applications of china cnc machining service

| Industry/Sector | Specific Application of china cnc machining service | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of precision engine components | Ensures high performance and reliability | Certification standards, material specifications |

| Aerospace | Manufacturing of lightweight structural parts | Reduces weight and enhances fuel efficiency | Compliance with aviation regulations, quality control |

| Medical Devices | Creation of custom surgical instruments | Guarantees precision and safety in procedures | Biocompatibility, regulatory compliance |

| Consumer Electronics | Prototyping and production of casings and enclosures | Accelerates time-to-market for new products | Design flexibility, rapid turnaround |

| Industrial Machinery | Custom parts for machinery and equipment | Improves operational efficiency and durability | Tolerance levels, material availability |

How is China CNC Machining Service Applied in the Automotive Industry?

In the automotive sector, CNC machining services are integral for producing precision engine components, such as pistons, cylinder heads, and gear housings. This technology enables manufacturers to meet stringent tolerances and ensure high performance and reliability in vehicles. For international buyers, it is crucial to consider certification standards specific to the automotive industry and the material specifications required for various parts. Sourcing from China can offer competitive pricing and rapid production times, essential for staying ahead in a fast-paced market.

What Role Does CNC Machining Play in Aerospace Manufacturing?

CNC machining is vital in aerospace for manufacturing lightweight structural components, such as wing frames and fuselage parts. The precision of CNC machining allows for the production of complex geometries while maintaining the necessary strength-to-weight ratio, which is critical for enhancing fuel efficiency. Buyers from regions like the Middle East and Europe must ensure that suppliers comply with aviation regulations and quality control measures to mitigate risks associated with safety and performance.

How is CNC Machining Used in Medical Device Production?

In the medical sector, CNC machining is employed to create custom surgical instruments and implants that require high precision and biocompatibility. The ability to produce intricate designs while adhering to strict safety standards makes CNC machining a preferred choice for medical device manufacturers. International buyers should prioritize suppliers that demonstrate compliance with regulatory requirements and possess certifications for biocompatibility to ensure the safety and efficacy of medical devices.

Why is CNC Machining Important for Consumer Electronics?

CNC machining services are essential in the consumer electronics industry for prototyping and producing enclosures, casings, and internal components. The rapid turnaround and design flexibility offered by CNC machining enable companies to bring new products to market quickly and efficiently. For businesses in South America and Africa, sourcing from China can provide cost-effective solutions, but it is vital to consider factors such as material availability and the ability to meet specific design requirements.

How Does CNC Machining Enhance Industrial Machinery Production?

In the industrial machinery sector, CNC machining is utilized to manufacture custom parts that enhance the efficiency and durability of equipment. Components such as gears, shafts, and housings are often produced with high precision, which minimizes downtime and maintenance costs. For international buyers, it is essential to communicate specific tolerance levels and material requirements to ensure that the produced parts meet operational needs and industry standards.

3 Common User Pain Points for ‘china cnc machining service’ & Their Solutions

Scenario 1: Ensuring Quality Control in CNC Machining Parts

The Problem: One of the most pressing challenges for B2B buyers sourcing CNC machining services from China is maintaining consistent quality control. Many international buyers have experienced issues with parts that don’t meet specifications or have defects, leading to costly delays and rework. The vast geographical distance can complicate direct oversight, making it difficult to ensure that quality standards are upheld. This concern is particularly acute for industries such as aerospace and medical, where precision is non-negotiable.

The Solution: To address quality concerns, buyers should implement a robust quality assurance process when selecting a CNC machining service. Begin by thoroughly vetting potential suppliers: request certifications such as ISO 9001 and reviews from previous clients. Establish clear specifications and tolerances for your parts and ensure these are documented in your purchase order. Utilize technology to your advantage; many CNC machining companies now offer real-time tracking and updates on production status. Regularly scheduled video calls or on-site visits can also foster better communication and understanding of quality expectations. Lastly, consider employing third-party inspection services to verify quality before shipment, ensuring that the parts meet your standards before they reach your facility.

Scenario 2: Navigating Communication Barriers with Chinese Suppliers

The Problem: Communication can often be a significant barrier when dealing with CNC machining suppliers in China, especially for international buyers. Misunderstandings can arise due to language differences, cultural nuances, or varying interpretations of technical specifications. This can lead to errors in production, delays in delivery, and ultimately, dissatisfaction with the final product.

The Solution: To overcome communication barriers, buyers should prioritize clarity and consistency in their interactions with suppliers. Start by ensuring that all specifications are provided in a detailed, written format, including drawings and materials lists. Utilize tools such as CAD files to provide a visual reference. It’s also beneficial to work with suppliers that have English-speaking staff or offer bilingual services. Establish a single point of contact within the supplier’s organization to streamline communication and reduce the risk of miscommunication. Additionally, leveraging collaborative platforms can facilitate better real-time communication and project management, allowing for quicker adjustments and feedback loops throughout the machining process.

Scenario 3: Managing Lead Times and Delivery Expectations

The Problem: International buyers often face unpredictability regarding lead times and delivery schedules when sourcing CNC machining services from China. Due to factors such as local holidays, production capacity fluctuations, and shipping delays, parts may not arrive when expected, disrupting production schedules and leading to missed deadlines.

The Solution: To effectively manage lead times, buyers should engage in proactive planning and clear communication with their CNC machining suppliers. Request a detailed timeline that outlines each phase of the machining process, from design to shipping. Consider using suppliers that offer expedited services or have the capability for rapid prototyping to meet urgent needs. It’s also wise to account for potential delays by ordering critical parts well in advance. Establishing a buffer stock for essential components can provide a safety net against unforeseen delays. Regularly check in with your supplier for updates on production status and shipping timelines. Building a strong relationship with your supplier can lead to improved flexibility and responsiveness, helping to ensure that your projects stay on schedule.

Strategic Material Selection Guide for china cnc machining service

What Are the Key Properties of Common Materials Used in CNC Machining?

When selecting materials for CNC machining services in China, international B2B buyers must consider the properties and performance of various materials. Here, we analyze four common materials: Aluminum, Stainless Steel, ABS Plastic, and Titanium. Each material has unique characteristics that influence its suitability for specific applications.

How Does Aluminum Perform in CNC Machining Applications?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. It typically has a temperature rating of around 150°C and can withstand moderate pressure, making it suitable for various applications, including automotive and aerospace components.

Pros: Aluminum is durable yet lightweight, which reduces shipping costs and enhances performance in applications where weight is critical. It is also relatively inexpensive compared to other metals, making it a cost-effective choice for mass production.

Cons: While aluminum is resistant to corrosion, it can be less durable than some steel alloys under high-stress conditions. Additionally, its thermal expansion properties may require careful consideration in precision applications.

Impact on Application: Aluminum is compatible with various media, including water and oils, making it ideal for automotive parts and fluid systems.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and JIS, especially for aerospace applications where material certification is crucial.

What Are the Advantages and Disadvantages of Stainless Steel?

Stainless steel is renowned for its superior strength and corrosion resistance, with a temperature rating that can exceed 800°C. This material is often used in applications requiring durability and hygiene, such as medical devices and food processing equipment.

Pros: Stainless steel’s high strength-to-weight ratio and resistance to rust make it ideal for harsh environments. It is durable and can endure high temperatures, making it suitable for applications in various industries.

Cons: The primary drawback is its higher cost compared to aluminum and plastics. Additionally, stainless steel machining can be more complex, requiring specialized tools and techniques, which may increase production time.

Impact on Application: Its compatibility with a wide range of chemicals makes stainless steel a preferred choice for industries dealing with corrosive substances.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific grades of stainless steel (e.g., 304, 316) that comply with local regulations and industry standards.

How Does ABS Plastic Compare for CNC Machining?

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic known for its excellent impact resistance and ease of machining. It has a temperature rating of around 80°C and is often used in consumer products and prototypes.

Pros: ABS is lightweight, cost-effective, and can be easily molded into complex shapes. It is also resistant to impact and can be finished in various colors, making it ideal for consumer-facing products.

Cons: However, ABS has lower heat resistance compared to metals and may not be suitable for high-temperature applications. Its chemical resistance is also limited, which can restrict its use in certain environments.

Impact on Application: ABS is compatible with various media, but caution should be exercised in applications involving high heat or aggressive chemicals.

Considerations for International Buyers: Buyers should ensure that ABS used in products meets relevant safety standards, particularly in consumer electronics and toys.

Why Choose Titanium for CNC Machining?

Titanium is a high-strength, lightweight metal with exceptional corrosion resistance and a temperature rating exceeding 600°C. It is commonly used in aerospace, medical implants, and high-performance automotive applications.

Pros: Titanium’s strength and resistance to extreme environments make it an excellent choice for applications that demand durability. Its biocompatibility is crucial for medical applications.

Cons: The primary limitation of titanium is its high cost and complex machining requirements, which can lead to longer lead times and increased production costs.

Impact on Application: Titanium is compatible with various media, including seawater, making it ideal for marine applications.

Considerations for International Buyers: Buyers from regions like Saudi Arabia should consider the specific grades of titanium that comply with industry standards for aerospace and medical applications.

Summary Table of Material Selection for CNC Machining

| Material | Typical Use Case for china cnc machining service | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, aerospace components | Lightweight and cost-effective | Less durable under high stress | Low |

| Stainless Steel | Medical devices, food processing equipment | High strength and corrosion resistance | Higher cost and complex machining | High |

| ABS Plastic | Consumer products, prototypes | Easy to machine and impact resistant | Limited heat and chemical resistance | Low |

| Titanium | Aerospace, medical implants | Exceptional strength and corrosion resistance | High cost and complex machining | High |

This detailed analysis provides B2B buyers with essential insights into material selection for CNC machining services in China, ensuring informed decisions that align with their project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for china cnc machining service

What Are the Main Stages of Manufacturing in China CNC Machining Services?

Manufacturing CNC machined parts in China involves several critical stages that ensure precision, quality, and efficiency. Understanding these stages is vital for international B2B buyers looking to source reliable and cost-effective machining services.

Material Preparation: What Should Buyers Know?

The initial stage of CNC machining begins with material selection and preparation. Common materials used include aluminum, stainless steel, brass, and various plastics. Buyers should specify the material type based on the intended application, as different materials have unique properties affecting performance and cost.

Once selected, materials are often cut into manageable sizes and shapes, followed by processes such as deburring and surface cleaning to remove any contaminants. This preparation is crucial as it lays the groundwork for accurate machining.

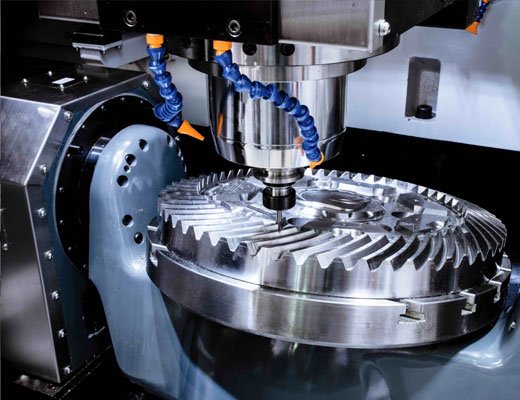

How Does the Forming Process Work?

The forming process is where the raw materials are transformed into specific shapes using CNC machines. The primary techniques involved include CNC milling and turning.

-

CNC Milling: This technique uses rotating cutting tools to remove material from a workpiece. It’s suitable for creating complex geometries and can be performed on 3-axis, 4-axis, or 5-axis CNC machines, allowing for intricate designs and high precision.

-

CNC Turning: This process involves rotating the workpiece while a stationary cutting tool removes material. It’s ideal for producing cylindrical parts, ensuring high accuracy and consistency.

Both techniques require skilled operators and advanced machinery to achieve the desired tolerances, which can be as tight as ±0.005mm, depending on the complexity of the part.

What Are the Finishing Techniques Used in CNC Machining?

After the forming process, finishing techniques enhance the surface quality and functional characteristics of the machined parts. Common finishing methods include:

- Anodizing: Often used for aluminum parts to increase corrosion resistance and surface hardness.

- Bead Blasting: Improves surface texture and prepares parts for further treatments like painting or coating.

- Polishing: Provides a smooth, shiny finish, which is often required for aesthetic components in consumer products.

These finishing techniques not only improve the durability and appearance of the parts but also ensure compliance with industry standards.

How Is Quality Assurance Integrated into CNC Machining Services?

Quality assurance (QA) is a fundamental aspect of CNC machining, ensuring that the final products meet both international standards and customer specifications. For B2B buyers, understanding the QA processes is essential for mitigating risks associated with sourcing parts from overseas suppliers.

Which International Standards Are Relevant to CNC Machining?

Many Chinese CNC machining companies adhere to international quality standards, with ISO 9001 being the most common. This certification ensures that the manufacturer has established a quality management system that is regularly audited for compliance. Additionally, industry-specific certifications such as CE for European markets and API for the oil and gas sector may also be relevant depending on the application.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards. This step is crucial to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, parts are monitored to ensure they adhere to design specifications. This may involve real-time measurements and adjustments to machining processes.

-

Final Quality Control (FQC): Once production is complete, finished parts undergo thorough inspections, including dimensional checks, surface quality assessments, and functional testing.

What Common Testing Methods Are Employed?

Testing methods vary but commonly include:

- Dimensional Inspection: Using tools like calipers and micrometers to ensure parts meet specified dimensions.

- Material Testing: Methods such as tensile testing and hardness testing to verify material properties.

- Functional Testing: Evaluating the performance of parts under operational conditions.

These tests help ensure that the products are not only manufactured to specifications but also perform reliably in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s QC processes is crucial to mitigate risks associated with quality and delivery. Here are effective strategies:

What Role Do Audits Play in Supplier Evaluation?

Conducting regular audits is one of the most effective ways to assess a supplier’s quality management system. Buyers can request documentation of past audits, certifications, and any corrective actions taken to address non-conformities. On-site audits can provide deeper insights into the manufacturing processes and QC protocols.

How Can Buyers Use Reports and Third-Party Inspections?

Suppliers should provide detailed QC reports for each order, including inspection results and any deviations from specifications. Additionally, engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality, offering peace of mind to buyers.

What Nuances Should International Buyers Consider Regarding QC?

When sourcing from China, international buyers must be aware of specific nuances:

-

Language Barriers: Ensure clear communication regarding specifications and quality expectations. Using detailed drawings and specifications in English can help minimize misunderstandings.

-

Cultural Differences: Building strong relationships with suppliers can enhance communication and foster a collaborative approach to quality assurance.

-

Shipping and Customs: Understand the implications of international shipping and customs regulations, which can affect delivery timelines and product integrity.

By focusing on these aspects, B2B buyers can navigate the complexities of sourcing CNC machined parts from China while ensuring high-quality outcomes for their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘china cnc machining service’

In today’s global marketplace, sourcing CNC machining services from China can provide businesses with high-quality manufacturing at competitive prices. This guide offers a step-by-step checklist for international B2B buyers looking to navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your project requirements, including dimensions, tolerances, materials, and surface finishes. This clarity will help potential suppliers assess their capability to meet your needs and provide accurate quotes. Be specific about any industry standards or certifications required for your parts.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable CNC machining service providers in China. Utilize online platforms, industry directories, and trade shows to gather a list of potential suppliers. Pay close attention to their experience, customer reviews, and product portfolio to gauge their reliability and expertise.

Step 3: Evaluate Supplier Certifications and Quality Assurance

Verify that the suppliers you are considering possess relevant certifications such as ISO 9001 for quality management systems. This ensures that they adhere to industry standards and maintain high-quality production processes. Additionally, inquire about their quality control measures, such as inspection protocols and testing methods.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of potential suppliers, request detailed quotes that include pricing, lead times, and terms of service. Compare these quotes not only on price but also on the value they provide, including shipping costs, payment terms, and any additional services like prototyping or post-processing. Remember, the lowest price may not always guarantee the best quality.

Step 5: Assess Communication and Responsiveness

Effective communication is critical when working with overseas suppliers. Pay attention to how quickly and clearly potential suppliers respond to your inquiries. A supplier who is responsive and provides detailed answers demonstrates their commitment to customer service and can help prevent misunderstandings later in the process.

Step 6: Request Samples or Prototypes

If possible, ask for samples or prototypes of your desired parts before making a bulk order. This step allows you to evaluate the quality of the machining, materials, and finishes firsthand. It also provides an opportunity to identify any necessary adjustments before full-scale production begins.

Step 7: Establish Clear Terms and Conditions

Once you select a supplier, ensure that all terms and conditions are clearly defined in a contract. This should include pricing, payment terms, delivery schedules, and penalties for late delivery or quality issues. Having a well-documented agreement helps protect your interests and provides a reference point in case of disputes.

By following this checklist, international B2B buyers can streamline the sourcing process and enhance their chances of establishing successful partnerships with CNC machining service providers in China.

Comprehensive Cost and Pricing Analysis for china cnc machining service Sourcing

What Are the Key Cost Components in China CNC Machining Services?

When sourcing CNC machining services from China, understanding the cost structure is crucial for international buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials like aluminum and plastic tend to be more affordable, while premium materials such as titanium or specialty alloys can considerably increase expenses. Prices fluctuate based on global supply and demand, so it’s essential to stay informed about market trends.

-

Labor: Labor costs in China are generally lower than in many Western countries, which contributes to competitive pricing. However, the skill level of the workforce can vary, influencing the quality of the finished product. Skilled labor may command higher wages but often results in better precision and fewer errors.

-

Manufacturing Overhead: This includes costs associated with running the factory, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, but buyers should evaluate how these costs are factored into the pricing.

-

Tooling: Custom tooling can be a significant upfront investment, especially for complex designs. Tooling costs vary based on the intricacy of the part being produced and the materials used. It’s often a one-time cost that can be amortized over larger production runs.

-

Quality Control (QC): Ensuring high-quality standards involves additional costs related to inspections, testing, and certifications. Buyers should verify that suppliers have robust QC processes in place, as this can prevent costly rework or returns.

-

Logistics: Shipping costs can vary widely depending on the destination, shipping method, and volume. Incoterms (International Commercial Terms) also play a role in determining who bears the shipping costs and risks during transit.

-

Margin: Suppliers typically add a margin to cover their profit, which can vary based on competition and perceived value. Understanding the supplier’s pricing strategy can provide insights into negotiation opportunities.

How Do Price Influencers Affect CNC Machining Costs?

Several factors influence the pricing of CNC machining services, including:

-

Volume/MOQ: Higher order volumes often lead to lower unit costs due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQs) to benefit from bulk pricing.

-

Specifications/Customization: Complex or highly customized parts typically incur higher costs due to increased labor and tooling requirements. Clear specifications can help suppliers provide more accurate quotes.

-

Materials: As mentioned earlier, the choice of material can dramatically affect pricing. Discussing alternative materials with suppliers might yield cost savings without compromising quality.

-

Quality/Certifications: Parts that require specific industry certifications (e.g., ISO, RoHS) may attract higher prices due to the additional processes involved. Buyers must weigh the need for these certifications against their budget.

-

Supplier Factors: Supplier reputation, experience, and geographical location can influence pricing. Established suppliers may charge more for their expertise and reliability.

-

Incoterms: Understanding Incoterms is vital for determining who is responsible for shipping costs and risks. This can significantly affect the total landed cost of the parts.

What Buyer Tips Can Help Maximize Cost-Efficiency in CNC Machining?

-

Negotiate Effectively: Use the insights from your analysis of cost components and price influencers to negotiate favorable terms. Highlight your potential for repeat business to encourage suppliers to offer better pricing.

-

Focus on Total Cost of Ownership (TCO): Rather than just evaluating the initial price, consider the TCO, which includes maintenance, logistics, and potential rework costs. A lower-priced part might lead to higher TCO if it requires extensive quality assurance or frequent replacements.

-

Understand Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences and currency fluctuations. These factors can impact the final cost and should be included in budget considerations.

-

Request Detailed Quotes: Always ask for itemized quotes that break down each cost component. This transparency allows for better comparison across suppliers and aids in identifying areas for negotiation.

-

Consider Long-Term Relationships: Establishing a long-term partnership with a supplier can lead to better pricing and service. Consistent orders may incentivize suppliers to offer discounts or improved terms.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of CNC machining services in China is essential for international B2B buyers. By considering the various cost components, price influencers, and strategic negotiation tips, buyers can make informed decisions that optimize their sourcing strategies.

Alternatives Analysis: Comparing china cnc machining service With Other Solutions

Understanding Alternative Solutions to China CNC Machining Services

In the landscape of precision manufacturing, businesses often face the decision of selecting the most suitable method for producing custom parts. While China CNC machining services are known for their cost-effectiveness and rapid turnaround, other alternatives may also provide valuable benefits depending on specific project requirements. This section compares China CNC machining services with two viable alternatives: 3D printing and traditional manufacturing methods, allowing B2B buyers to make informed decisions.

Comparison Table

| Comparison Aspect | China CNC Machining Service | 3D Printing | Traditional Manufacturing |

|---|---|---|---|

| Performance | High precision (±0.005mm) | Moderate precision (±0.1mm) | Varies by method; can be high |

| Cost | Competitive pricing (up to 30% savings) | Generally higher for low volumes | Lower for high-volume production |

| Ease of Implementation | Streamlined online quoting and ordering | Requires design adaptations for printing | Established processes; may require tooling |

| Maintenance | Low; factory-managed | Low; primarily software updates | Higher; machinery upkeep needed |

| Best Use Case | Complex, high-precision parts | Prototyping and low-volume runs | High-volume production with simple designs |

Analyzing 3D Printing as an Alternative

3D printing, or additive manufacturing, is a rapidly growing technology that offers unique advantages. It allows for the creation of complex geometries that would be challenging or impossible to achieve with traditional methods. This technology is particularly advantageous for rapid prototyping and producing low-volume custom parts. However, the trade-off often comes in the form of reduced precision compared to CNC machining, with tolerances typically around ±0.1mm. Additionally, while the upfront costs may be higher for small batches, the elimination of tooling costs can make it more economical for certain projects.

Evaluating Traditional Manufacturing Methods

Traditional manufacturing methods encompass a range of processes including stamping, casting, and injection molding. These methods are often more cost-effective for large-scale production due to lower per-unit costs at high volumes. However, they may involve significant upfront costs for tooling and setup. While traditional manufacturing can achieve high levels of precision, it is generally less flexible than CNC machining or 3D printing when it comes to design changes and rapid prototyping. This makes it less suitable for projects requiring quick iterations or complex designs.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate manufacturing method, B2B buyers should consider several factors, including project scale, complexity, and budget. If precision and complexity are paramount, China CNC machining services may offer the best balance of quality and cost. For projects emphasizing rapid iteration and design flexibility, 3D printing might be the preferred choice. Conversely, traditional manufacturing is ideal for high-volume, straightforward production runs. By carefully evaluating these aspects, businesses can align their manufacturing strategies with their specific needs, ensuring optimal outcomes for their projects.

Essential Technical Properties and Trade Terminology for china cnc machining service

What Are the Critical Technical Properties of CNC Machining Services in China?

In the realm of CNC machining, several technical specifications are vital for ensuring quality and precision in manufacturing processes. Understanding these properties is essential for B2B buyers looking to make informed decisions when selecting a CNC machining service provider in China.

1. Material Grade

Material grade refers to the specific classification of materials used in CNC machining, such as aluminum, stainless steel, or plastics. Different grades exhibit varying mechanical properties, such as strength, flexibility, and corrosion resistance. B2B buyers must consider material grade as it directly impacts the durability and performance of the final product. Selecting the appropriate material grade can also influence cost-effectiveness and suitability for specific applications.

2. Tolerance

Tolerance is a critical specification that indicates the allowable deviation from a desired dimension. For instance, CNC machining services may offer tolerances as tight as ±0.005mm. In B2B contexts, tighter tolerances are essential for applications requiring high precision, such as aerospace and medical devices. Understanding tolerance levels helps buyers determine if a machining service can meet their project specifications, ensuring that components fit together seamlessly.

3. Surface Finish

Surface finish refers to the texture and quality of the surface of machined parts. Common surface finishes include anodizing, bead blasting, and polishing. The choice of surface finish can affect both the aesthetic appeal and functional performance of the part, such as corrosion resistance and wear characteristics. Buyers should specify their surface finish requirements to ensure that the final product meets both aesthetic and functional needs.

4. Lead Time

Lead time is the duration from order placement to delivery of the finished product. In the competitive B2B landscape, fast lead times are crucial for maintaining production schedules and meeting market demands. Many CNC machining services in China offer lead times ranging from a few days to several weeks, depending on the complexity of the project. Understanding lead time helps buyers plan their production processes effectively.

5. Production Volume

Production volume refers to the quantity of parts that can be manufactured in a single run. CNC machining services can accommodate both low-volume prototypes and large-scale production. B2B buyers should assess their production needs to choose a service provider that aligns with their volume requirements, ensuring cost-efficiency and timely delivery.

What Are the Common Trade Terms Used in CNC Machining Services?

Familiarity with trade terminology is essential for effective communication and negotiation in B2B transactions involving CNC machining services. Here are several key terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In CNC machining, an OEM may outsource the production of specific components to a machining service provider. Understanding OEM relationships can help buyers establish partnerships that enhance their product offerings.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In CNC machining, MOQs can vary based on factors such as material type and complexity of the parts. B2B buyers should inquire about MOQs to ensure that their order quantities align with the supplier’s capabilities and policies.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. In CNC machining, an RFQ typically includes details such as part specifications, quantities, and required lead times. Providing a comprehensive RFQ allows suppliers to give accurate quotes, facilitating better decision-making for buyers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as delivery terms, risk transfer, and shipping costs. Familiarity with Incoterms helps B2B buyers negotiate better shipping terms and understand their liabilities in international CNC machining contracts.

5. CAD (Computer-Aided Design)

CAD refers to the software used to create precise drawings and models of parts before machining. A strong understanding of CAD is crucial for buyers as it directly influences the quality and accuracy of the final product. Buyers should ensure that their CNC machining service can work with their CAD files to streamline the production process.

By grasping these essential technical properties and industry terminology, B2B buyers can navigate the complexities of sourcing CNC machining services in China more effectively, ensuring they achieve their project goals while optimizing costs and timelines.

Navigating Market Dynamics and Sourcing Trends in the china cnc machining service Sector

What Are the Key Trends Shaping the China CNC Machining Service Market?

The China CNC machining service sector is witnessing significant transformations driven by global demand for precision engineering and cost-effective manufacturing solutions. Key market drivers include the increasing need for rapid prototyping and low-volume production, particularly in industries like automotive, aerospace, and consumer electronics. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, are increasingly leveraging China’s robust supply chain and competitive pricing structures to optimize their manufacturing processes.

Emerging trends include the integration of advanced technologies such as Industry 4.0, which emphasizes automation, data exchange, and smart manufacturing. This shift is enhancing operational efficiencies and enabling real-time monitoring of production processes. Additionally, there is a growing emphasis on customization and flexibility, as buyers seek suppliers who can adapt to their unique specifications quickly. The rise of online platforms offering instant quotes and order tracking is also making sourcing more accessible and transparent for international buyers, streamlining the procurement process.

Furthermore, sustainability is becoming a pivotal concern, with an increasing number of companies prioritizing suppliers who adhere to environmentally friendly practices. This shift is influencing the sourcing strategies of B2B buyers, who are now looking for partners that can provide sustainable solutions alongside competitive pricing and quality assurance.

How Is Sustainability and Ethical Sourcing Impacting the China CNC Machining Service Sector?

Sustainability and ethical sourcing are becoming critical components of the CNC machining service landscape in China. The environmental impact of manufacturing processes, particularly in terms of waste generation and energy consumption, is under scrutiny as global buyers increasingly demand responsible sourcing practices. This trend is particularly relevant for international B2B buyers from regions like Africa, South America, and Europe, where environmental regulations are becoming stricter.

Many Chinese CNC machining service providers are responding to this demand by adopting green manufacturing practices. This includes the use of eco-friendly materials, waste reduction strategies, and energy-efficient machinery. Certifications such as ISO 14001 (Environmental Management) are becoming increasingly important, as they signify a commitment to sustainability and ethical practices.

Additionally, buyers are encouraged to look for suppliers that offer sustainable materials, such as recycled metals and bioplastics, which not only reduce environmental footprints but also cater to the growing market for eco-conscious products. By prioritizing suppliers that align with sustainability goals, B2B buyers can enhance their brand reputation and meet the expectations of their customers, who are increasingly favoring environmentally responsible products.

How Has the China CNC Machining Service Market Evolved Over Time?

The evolution of the CNC machining service market in China can be traced back to the early 1980s when the country began to open up its economy. Initially focused on low-cost manufacturing, the sector has transformed dramatically over the decades. The introduction of advanced CNC technology and automation has allowed Chinese manufacturers to enhance precision and efficiency, making them competitive on a global scale.

Throughout the 1990s and early 2000s, China positioned itself as the “world’s factory,” attracting international businesses seeking cost-effective manufacturing solutions. As demand for high-quality, precision-engineered products grew, so did the capabilities of CNC machining services. Today, China is not only a leader in terms of volume but also in technological advancements, offering sophisticated machining services that meet the diverse needs of B2B buyers worldwide.

In summary, the China CNC machining service sector continues to adapt to changing market dynamics, driven by technological advancements and shifting buyer expectations towards sustainability and ethical sourcing. International B2B buyers can leverage these trends to enhance their manufacturing strategies and ensure long-term success in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of china cnc machining service

-

How do I choose the right CNC machining service provider in China?

When selecting a CNC machining service provider in China, consider their experience, manufacturing capabilities, and client testimonials. Look for companies with a robust portfolio that demonstrates versatility across materials and industries. Ensure they have modern equipment and quality control processes in place. Additionally, verify their responsiveness to inquiries and their ability to handle international logistics effectively, as these factors can significantly impact the success of your project. -

What are the typical lead times for CNC machining services in China?

Lead times can vary based on the complexity of your project and the service provider. Generally, for CNC machining services, expect lead times ranging from 3 to 14 business days. Prototyping may be quicker, while larger production runs can take longer. Always request a detailed timeline during the quoting process to align expectations and ensure timely delivery, particularly if you are working to a tight schedule. -

What is the minimum order quantity (MOQ) for CNC machining services?

Minimum order quantities (MOQs) for CNC machining services in China can vary widely depending on the supplier. Some providers may accept orders for single prototypes, while others might require a minimum of 50 or more units for production runs. Discuss your project needs upfront with potential suppliers to find a partner that aligns with your order volume and budget constraints. -

How can I ensure quality control for my CNC machined parts?

To ensure quality control for your CNC machined parts, choose a provider with established quality assurance processes, including in-house inspections and certifications (like ISO 9001). Request detailed reports on machining tolerances, material specifications, and surface finishes. Additionally, consider requesting samples or prototypes before committing to larger production runs, allowing you to verify quality firsthand. -

What payment terms should I expect when sourcing CNC machining services from China?

Payment terms can vary among suppliers, but common arrangements include a 30% deposit upfront with the balance due upon completion or shipment of the order. Some suppliers may offer flexible terms based on your relationship and order volume. Always clarify payment methods accepted, whether via bank transfer, PayPal, or letter of credit, and ensure that you have a clear invoice detailing all costs involved. -

How do logistics and shipping work for CNC machined parts from China?

Logistics for CNC machined parts typically involve the supplier handling the shipping process. Most providers will offer options for express, air, or sea freight based on your timeline and budget. Ensure that you discuss shipping costs, estimated delivery times, and customs documentation with your supplier. Additionally, consider engaging a freight forwarder to facilitate smooth customs clearance and delivery to your final destination. -

Can I customize my CNC machined parts according to specific designs?

Yes, most CNC machining service providers in China offer extensive customization options. You can submit your designs in various formats (like CAD files), and the supplier will work with you to ensure that your specifications are met. Discuss material choices, finishes, and any specific tolerances required to ensure that the final product aligns with your expectations and application needs. -

What industries can benefit from CNC machining services in China?

CNC machining services in China cater to a wide array of industries, including automotive, aerospace, medical, consumer electronics, and industrial machinery. Each industry may have unique requirements regarding precision, materials, and production volumes. If you are in a specialized sector, look for suppliers with relevant experience and certifications to ensure compliance with industry standards and regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for china cnc machining service

In the evolving landscape of global manufacturing, China’s CNC machining services stand out as a strategic advantage for international B2B buyers. The key takeaways emphasize the importance of quality, cost-effectiveness, and rapid turnaround times. Companies like PCBWay, JLCCNC, and AT Precision Machining Ltd showcase advanced capabilities, offering precision machining that meets stringent tolerances and diverse material requirements. This allows businesses to streamline their production processes while maintaining high standards of quality.

Strategic sourcing from China not only reduces operational costs but also enhances product innovation through access to cutting-edge technologies and expertise. By partnering with reputable suppliers, companies can ensure timely delivery and responsive customer service, which are critical in today’s fast-paced markets.

As we look to the future, international buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to leverage these opportunities. Investing in reliable CNC machining services can propel your business forward, enabling you to stay competitive and responsive to market demands. Explore potential partnerships today to harness the full benefits of China’s manufacturing prowess and drive your success in the global marketplace.