Top 7 3D Printing Service Cost Manufacturers & Suppliers List

1. Reddit – 3D Printing Pricing Models

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Minimum charge of £10 tooling fee, plus £5 per hour of printing. Some users charge $10 minimum plus material costs and $2/hour of print time. Others weigh the finished print, calculate filament costs, and multiply by 3.

2. JCAD USA – 3D Printing Services

Domain: jcadusa.com

Registered: 2014 (11 years)

Introduction: 3D Printing Services Cost: Ranges from $1 (home printer) to thousands (commercial prints). Affordable for prototypes and small batches. Factors influencing cost: equipment, material, operational, maintenance, CAD design, labor. Example costs: Bottle lid – $100, Guitar tuning pegs – $250, Prototype brackets – $300, Belt buckle – $400, Garlic press – $500, 3D printed shoe – $750, Microphone holder -…

3. JLC 3DP – Custom 3D Printing Services

Domain: jlc3dp.com

Registered: 2021 (4 years)

Introduction: Online 3D Printing Service offering custom 3D printed parts using technologies such as Stereolithography (SLA), Multi Jet Fusion (MJF), Selective Laser Melting (SLM), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and White Jet Process (WJP). Materials available include Resin, Nylon (MJF), Metal (SLM), Plastic, and Nylon (SLS). Tolerances down to 0.2mm for 3D printing and 0.05mm…

4. Craftcloud® – 3D Printing Services

Domain: craftcloud3d.com

Registered: 2018 (7 years)

Introduction: Craftcloud® offers a streamlined 3D printing service with various manufacturing services including 3D Printing, CNC Machining, Sheet Metal Fabrication, and Casting & Molding. They provide over 170 unique materials such as SLS Nylon PA12, 316L Stainless Steel, HP® MJF Nylon PA12, PLA, and Standard Resin. The platform supports over 35 file formats for model uploads and features more than 20 differen…

5. PRTWD – 3D Printing Cost Insights

Domain: prtwd.com

Registered: 2015 (10 years)

Introduction: 3D printing costs range from $3 to thousands of dollars. Factors affecting the price include material type, model complexity, and labor. 3D printers can cost between $200 to $150,000. Common materials include thermoplastics (ABS, PLA) costing $20 to $70 per kg and resin costing $50 to $300 per litre. Post-processing is necessary for quality, involving curing, cleaning, and polishing. Profit margin…

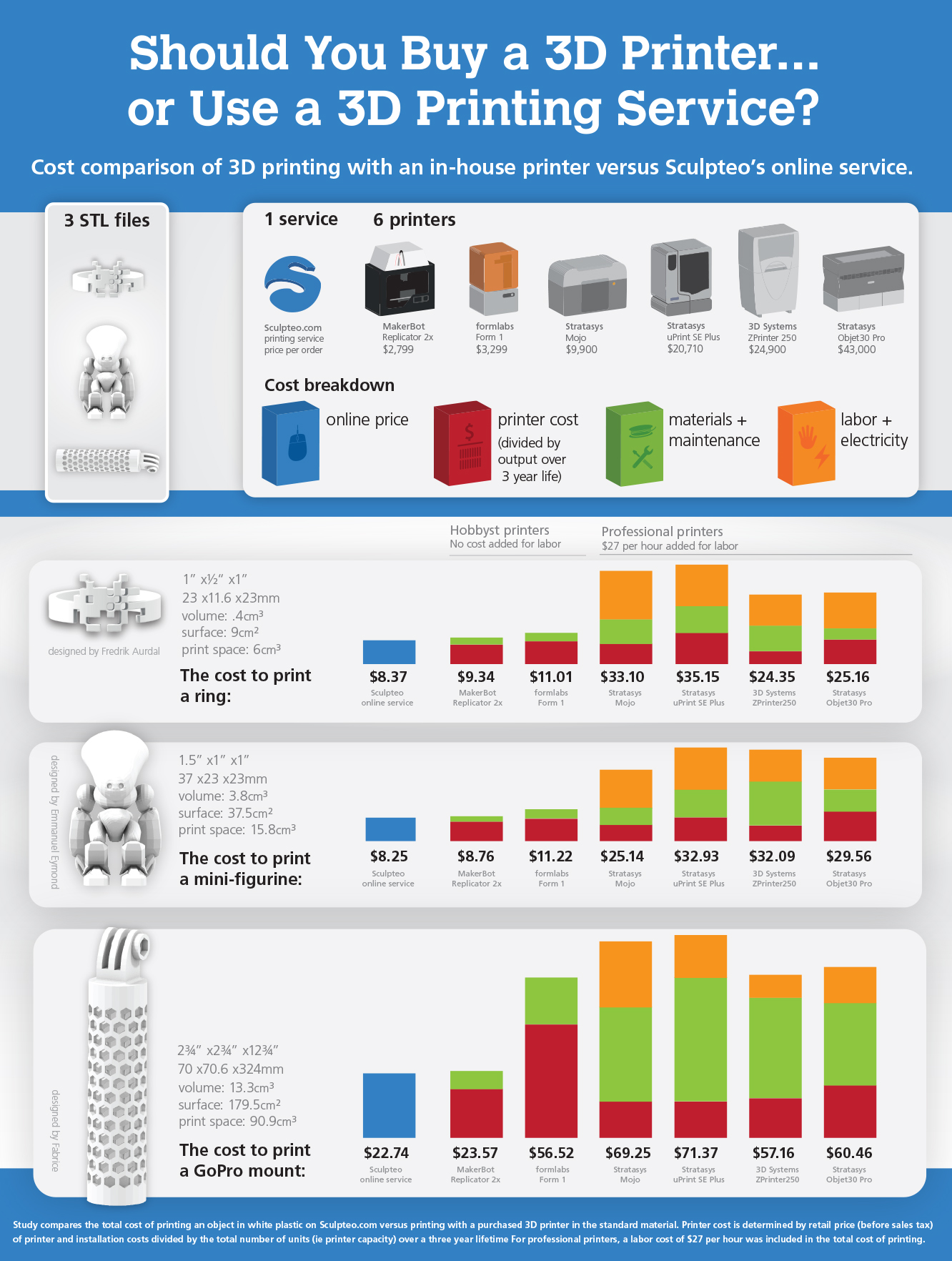

6. Sculpteo – 3D Printing Solutions

Domain: sculpteo.com

Registered: 2009 (16 years)

Introduction: 3D Printing Price and Delivery Options: Sculpteo offers various 3D printing technologies including Selective Laser Sintering (SLS), HP Jet Fusion, Stereolithography (SLA), Polyjet, Direct Metal Laser Sintering (DMLS), and more. Available materials include Nylon PA12, Ultrasint® PA11, TPU, Photopolymer Resins, and various metals like Stainless Steel and Aluminium. Pricing is calculated based on mat…

7. Prusa – 3D Printing Price Calculator

Domain: blog.prusa3d.com

Registered: 2013 (12 years)

Introduction: 3D Printing Price Calculator – Original Prusa 3D Printers. Allows users to calculate costs associated with 3D printing on demand. Users can load a gcode file or manually input print time and filament weight. Pre-filled with common values but editable. Features include options for currency selection, filament type (PLA, PETG, ASA, PC Blend, Other), spool price, power consumption, energy cost, labor…

Introduction: Navigating the Global Market for 3d printing service cost

In today’s competitive landscape, understanding 3D printing service costs is critical for B2B buyers aiming to innovate and optimize their manufacturing processes. Sourcing reliable 3D printing services can be particularly challenging for businesses in regions like Africa, South America, the Middle East, and Europe, where access to information and quality suppliers may vary. This guide serves as a comprehensive resource, addressing the complexities of 3D printing costs, including the factors that influence pricing, such as material selection, printing technology, and turnaround time.

As you navigate this global market, you’ll uncover various applications of 3D printing—from prototyping to low-volume production—allowing you to identify the best solutions for your specific needs. The guide also delves into effective supplier vetting strategies, ensuring you choose partners that align with your quality and budget requirements. By equipping you with actionable insights and practical knowledge, this guide empowers international B2B buyers to make informed purchasing decisions that enhance their operational efficiency and drive innovation. Whether you’re a startup in Vietnam or an established firm in Nigeria, understanding these nuances can significantly impact your bottom line and competitive edge in the marketplace.

Understanding 3d printing service cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Deposition Modeling (FDM) | Utilizes thermoplastic filaments; cost-effective for prototyping; lower resolution than others. | Prototyping, small batch production, educational tools. | Pros: Affordable, accessible; Cons: Limited material strength and detail. |

| Stereolithography (SLA) | Uses UV light to cure liquid resin; offers high detail and smooth finishes; slower than FDM. | High-detail prototypes, dental models, jewelry. | Pros: Excellent precision and surface finish; Cons: Higher material costs and post-processing required. |

| Selective Laser Sintering (SLS) | Uses a laser to fuse powdered materials; creates complex geometries; no support structures needed. | Aerospace, automotive, functional prototypes. | Pros: Strong, durable parts; Cons: Higher initial investment and longer lead times. |

| Metal 3D Printing (SLM/DMLS) | Melts metal powder using lasers; suitable for functional parts; requires specialized equipment. | Aerospace, medical devices, tooling. | Pros: High strength and durability; Cons: Expensive materials and machinery. |

| Multi Jet Fusion (MJF) | Fuses nylon powder using inkjet technology; faster than SLS; excellent mechanical properties. | Rapid prototyping, end-use parts in various industries. | Pros: High speed, good detail; Cons: Limited material options compared to others. |

What are the Characteristics of Fused Deposition Modeling (FDM) in 3D Printing Services?

Fused Deposition Modeling (FDM) is one of the most commonly used 3D printing technologies, especially for prototyping and educational purposes. FDM printers work by extruding thermoplastic filaments layer by layer to create objects. This method is particularly suitable for businesses looking for affordable and quick solutions for small batch production. However, FDM prints generally have lower resolution and material strength compared to other methods, making it less ideal for final products that require intricate details or high durability.

How Does Stereolithography (SLA) Stand Out in 3D Printing?

Stereolithography (SLA) employs a laser to cure liquid resin into solid parts, offering exceptional detail and smooth finishes. This technology is particularly advantageous for industries such as dental, jewelry, and high-detail prototyping. Although SLA provides superior precision, it comes with higher material costs and requires post-processing to achieve the desired finish. B2B buyers should consider their need for detail versus budget constraints when opting for SLA services.

Why Choose Selective Laser Sintering (SLS) for Complex Geometries?

Selective Laser Sintering (SLS) is renowned for its ability to create intricate geometries without the need for support structures, making it ideal for aerospace and automotive applications. By fusing powdered materials with a laser, SLS produces strong and durable parts that can withstand functional testing. While it offers significant advantages in terms of part performance, the initial investment and longer lead times can be a consideration for businesses with tight schedules.

What Advantages Does Metal 3D Printing (SLM/DMLS) Offer for B2B Applications?

Metal 3D printing technologies like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) are highly specialized processes that create parts from metal powders. These methods are particularly suited for industries requiring high-strength components, such as aerospace and medical devices. However, the costs associated with materials and machinery can be substantial. B2B buyers must weigh the benefits of durability and performance against the financial implications.

How Does Multi Jet Fusion (MJF) Enhance Production Efficiency?

Multi Jet Fusion (MJF) is a cutting-edge technology that utilizes inkjet technology to fuse nylon powder, offering rapid production speeds and excellent mechanical properties. This method is becoming increasingly popular for producing end-use parts across various industries. While MJF boasts high speed and good detail, its material options may be more limited compared to other technologies. B2B buyers should evaluate their specific needs for speed and material variety when considering MJF for their projects.

Key Industrial Applications of 3d printing service cost

| Industry/Sector | Specific Application of 3D Printing Service Cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of lightweight components | Reduces weight and fuel consumption, enhancing efficiency | Material certifications, lead times, and precision requirements |

| Automotive | Rapid prototyping of parts | Speeds up the design process, reducing time-to-market | Quality assurance, scalability, and material options |

| Healthcare | Custom prosthetics and implants | Tailors solutions to individual patient needs | Regulatory compliance, biocompatibility of materials |

| Consumer Electronics | Functional prototypes for new devices | Facilitates innovation and user testing | Design flexibility, turnaround time, and cost efficiency |

| Architecture | Scale models and architectural prototypes | Enhances client presentations and project approvals | Detail accuracy, material choices, and shipping logistics |

How is 3D Printing Service Cost Applied in Aerospace?

In the aerospace sector, 3D printing service cost is leveraged for producing lightweight components that contribute to overall fuel efficiency. By utilizing advanced materials and printing techniques, manufacturers can create intricate designs that traditional manufacturing methods cannot achieve. For international buyers, especially in regions like Africa and South America, sourcing partners must ensure that materials meet industry-specific certifications to maintain safety and compliance. Additionally, understanding lead times and precision requirements is crucial, as delays can significantly impact production schedules.

What Role Does 3D Printing Play in Automotive Rapid Prototyping?

Automotive companies use 3D printing service cost for rapid prototyping of parts, which accelerates the design and testing phases. This approach allows manufacturers to quickly iterate on designs and bring products to market faster, offering a competitive edge. For B2B buyers in Europe and the Middle East, key considerations include quality assurance processes to ensure prototypes meet functional specifications and scalability for larger production runs. Material options should also be evaluated to balance cost and performance, particularly for high-stress components.

How Are Custom Prosthetics Revolutionized by 3D Printing in Healthcare?

In healthcare, 3D printing service cost is applied to create custom prosthetics and implants tailored to individual patient needs. This technology allows for enhanced patient outcomes and satisfaction, as devices can be designed to fit precisely. B2B buyers from regions like Nigeria and Vietnam must focus on regulatory compliance and the biocompatibility of materials used in medical applications. Engaging with suppliers who understand local regulations and can provide necessary certifications is critical to ensuring successful implementation.

How Do Consumer Electronics Benefit from 3D Printing for Prototyping?

The consumer electronics industry leverages 3D printing service cost to develop functional prototypes for new devices, facilitating innovation and user testing. This allows companies to gather feedback and make necessary adjustments before full-scale production. For international buyers, particularly in South America, sourcing partners should prioritize design flexibility and turnaround times to keep pace with rapidly changing market demands. Cost efficiency is also vital, as companies seek to minimize expenses without sacrificing quality.

What Advantages Does 3D Printing Offer in Architectural Model Creation?

In architecture, 3D printing service cost is utilized for creating scale models and architectural prototypes that enhance client presentations and project approvals. These detailed models can convey design intent more effectively than traditional drawings. For B2B buyers in Europe and the Middle East, considerations include detail accuracy and material choices that reflect the final building materials. Additionally, understanding shipping logistics is essential to ensure timely delivery for project milestones.

3 Common User Pain Points for ‘3d printing service cost’ & Their Solutions

Scenario 1: Understanding Variable Pricing Structures in 3D Printing Services

The Problem:

B2B buyers often encounter confusion when evaluating the costs associated with 3D printing services. This confusion arises from the wide range of pricing structures offered by different providers. Factors such as material type, print technology, and complexity of the design can lead to vastly different quotes, making it difficult for buyers to compare costs effectively. For instance, a company in Nigeria may receive a quote of $500 for a simple prototype from one service provider, while another provider in Europe may quote $1,000 for a similar project, leading to frustration and uncertainty regarding which option offers the best value.

The Solution:

To navigate the complexities of pricing, B2B buyers should adopt a structured approach to sourcing and evaluating 3D printing services. Start by defining specific project requirements, including material specifications, tolerances, and desired turnaround times. Utilize online platforms that aggregate quotes from multiple service providers, allowing you to compare prices transparently. When requesting quotes, be clear about your expectations and ask for itemized breakdowns of costs to understand how much each component contributes to the total price. This not only helps in making informed decisions but also facilitates negotiations based on clear data. Furthermore, consider reaching out to providers for bulk pricing options or long-term contracts, as many companies offer discounts for larger orders or repeat business.

Scenario 2: Managing Hidden Costs in 3D Printing Projects

The Problem:

Many B2B buyers are caught off guard by hidden costs associated with 3D printing services. While the initial quote may seem reasonable, additional charges such as setup fees, post-processing, and shipping can significantly inflate the total project cost. For instance, a company in South America may find that a seemingly affordable service quickly becomes prohibitively expensive once additional fees are factored in, leading to budget overruns and project delays.

The Solution:

To mitigate the risk of hidden costs, it is crucial for buyers to conduct thorough due diligence before committing to a service provider. Begin by asking potential suppliers to provide a comprehensive list of all potential fees associated with the project. This should include costs related to setup, finishing processes, and logistics. Additionally, consider leveraging digital tools that provide instant quotes with transparent pricing models, ensuring that all potential costs are accounted for upfront. Building strong relationships with your chosen service provider can also facilitate better communication regarding costs; frequent discussions can lead to discounts or the waiving of certain fees. Lastly, always have a contingency budget set aside to accommodate unexpected expenses, ensuring that your project remains on track financially.

Scenario 3: Balancing Quality and Cost in 3D Printing Services

The Problem:

B2B buyers often face the dilemma of balancing quality and cost when selecting a 3D printing service. While lower-cost options may be appealing, they can lead to subpar results, resulting in wasted resources and time. For example, a firm in Europe may choose a cheaper service provider to produce prototypes, only to receive poorly printed parts that require rework, ultimately costing more in the long run.

The Solution:

To strike the right balance between quality and cost, buyers should prioritize understanding their project requirements and desired outcomes. Start by identifying the critical attributes of the final product, such as strength, finish, and precision. Once these parameters are established, conduct research to find service providers that specialize in the required printing technology and materials. Request samples of previous work to evaluate quality firsthand before making a decision. Furthermore, consider using a phased approach to printing; start with lower-cost prototypes to validate designs before committing to higher-quality final prints. This strategy allows for adjustments without incurring significant costs. Engage in detailed discussions with potential providers about their quality assurance processes and certifications, ensuring that the chosen service not only meets budgetary constraints but also aligns with quality expectations.

Strategic Material Selection Guide for 3d printing service cost

What are the Key Properties of Common 3D Printing Materials?

When selecting materials for 3D printing services, B2B buyers must consider various factors that influence the performance, cost, and suitability of the end product. Below, we analyze four common materials used in 3D printing, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

1. PLA (Polylactic Acid)

Key Properties: PLA is a biodegradable thermoplastic derived from renewable resources like corn starch. It has a melting temperature around 180-220°C and offers good rigidity and dimensional stability.

Pros & Cons: PLA is easy to print, making it ideal for prototypes and low-volume production. It exhibits low warping and is available in various colors. However, it has lower heat resistance compared to other materials, making it unsuitable for high-temperature applications. Its biodegradability can be a double-edged sword; while environmentally friendly, it may not be suitable for long-term outdoor use.

Impact on Application: PLA is compatible with various media, but its lower durability and heat resistance limit its use in functional parts that experience stress or high temperatures.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding biodegradable materials. In regions like Europe, where sustainability is prioritized, PLA may be favored. However, in areas with less stringent environmental standards, its use might be less common.

2. ABS (Acrylonitrile Butadiene Styrene)

Key Properties: ABS is a durable thermoplastic known for its impact resistance and toughness. It has a higher melting temperature (around 220-250°C) compared to PLA, making it suitable for functional parts.

Pros & Cons: ABS is strong and can withstand higher temperatures, making it ideal for automotive and consumer products. However, it is more challenging to print due to warping and requires a heated bed. Additionally, it emits fumes during printing, necessitating good ventilation.

Impact on Application: ABS is widely used in applications requiring durability and impact resistance, such as housings and prototypes. Its strength makes it suitable for functional testing.

Considerations for International Buyers: Buyers must be aware of compliance with safety and environmental regulations, particularly in regions like Europe and North America, where there are strict standards for emissions. Understanding local preferences for material properties can also guide material selection.

3. Nylon (Polyamide)

Key Properties: Nylon is a versatile material known for its strength, flexibility, and resistance to abrasion. It has a melting temperature of around 220-260°C and excellent chemical resistance.

Pros & Cons: Nylon’s flexibility and durability make it suitable for functional parts and end-use products. However, it can be difficult to print due to its tendency to absorb moisture, which can affect print quality. The cost of nylon filaments is typically higher than that of PLA or ABS.

Impact on Application: Nylon is ideal for applications requiring wear resistance and flexibility, such as gears and functional prototypes. Its chemical resistance allows for use in various environments.

Considerations for International Buyers: Buyers should consider the availability of nylon filaments in their region and any specific compliance standards for chemical resistance. In sectors like automotive and aerospace, adherence to ASTM or DIN standards may be critical.

4. TPU (Thermoplastic Polyurethane)

Key Properties: TPU is a flexible material known for its elasticity and durability. It has a lower melting point (around 210-230°C) and offers excellent abrasion resistance and flexibility.

Pros & Cons: TPU is ideal for applications requiring flexibility, such as seals and gaskets. However, its printing process can be complex, requiring specific printer settings and conditions to avoid issues like stringing and poor layer adhesion.

Impact on Application: TPU’s flexibility makes it suitable for applications in consumer products and medical devices. Its resistance to wear and tear enhances the longevity of end products.

Considerations for International Buyers: Buyers must ensure that TPU products meet local regulatory standards, especially in the medical field. Understanding the market demand for flexible materials in regions like Africa and South America can also inform material selection.

Summary Table of Material Selection for 3D Printing Services

| Material | Typical Use Case for 3D Printing Service Cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototypes, low-volume production | Easy to print, biodegradable | Low heat resistance, less durable | Low |

| ABS | Automotive parts, consumer products | High durability, impact resistance | Warping issues, fumes during printing | Medium |

| Nylon | Functional parts, gears | Strong, flexible, chemical resistant | Moisture absorption, higher cost | High |

| TPU | Flexible products, seals, gaskets | Elasticity, abrasion resistance | Complex printing process | Medium |

This analysis provides B2B buyers with actionable insights into material selection for 3D printing services, considering performance, cost, and regional compliance factors.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d printing service cost

What Are the Main Stages of the 3D Printing Manufacturing Process?

The manufacturing process for 3D printing involves several key stages that collectively contribute to the final product’s quality and cost. Understanding these stages can help B2B buyers appreciate the complexities involved in 3D printing services.

How Is Material Prepared for 3D Printing?

Material preparation is the first step in the 3D printing process. This involves selecting the appropriate material based on the desired properties of the final product, such as strength, flexibility, and thermal resistance. Common materials include thermoplastics like PLA and ABS, resins for SLA printing, and metals for SLM processes. The choice of material directly affects the cost, as more specialized materials tend to be more expensive.

Once selected, materials may need to be pre-processed. For instance, filament for FDM printers must be dried to eliminate moisture, which can lead to defects in the final print. For resin printing, the resin must be mixed and prepared in accordance with specific formulations. Proper material preparation is crucial to ensure the quality and integrity of the printed parts.

What Techniques Are Used in the Forming Stage of 3D Printing?

The forming stage is where the actual printing occurs. Various techniques are employed in this phase, each with its own advantages and applications:

- Fused Deposition Modeling (FDM): This widely-used technique extrudes thermoplastic filament layer by layer to create parts. It is cost-effective and suitable for prototyping.

- Stereolithography (SLA): This method utilizes a UV laser to cure liquid resin into solid parts. SLA is known for its high precision and smooth surface finish, making it ideal for intricate designs.

- Selective Laser Sintering (SLS): SLS uses a laser to sinter powdered material, creating strong and durable parts without the need for support structures. It is particularly effective for functional prototypes.

- Metal 3D Printing (SLM/DMLS): These methods use lasers to melt metal powder, producing high-strength components suitable for critical applications in aerospace and automotive industries.

Each of these techniques has unique implications for cost, lead time, and suitability for specific applications. B2B buyers should consider their project requirements and budget when selecting a technique.

How Is Assembly and Finishing Conducted After Printing?

After the printing is complete, parts often require assembly and finishing to meet specifications. Assembly may involve joining multiple printed components or adding non-printed elements, such as electronic components in a prototype.

Finishing processes can include sanding, painting, or applying protective coatings to enhance aesthetics and durability. The choice of finishing techniques can significantly impact the overall cost and turnaround time. For instance, a simple sandblasting may be less expensive than a detailed painting process.

What Quality Control Measures Are Essential in 3D Printing Services?

Quality assurance is paramount in the 3D printing industry, particularly for B2B buyers who depend on consistent quality for their products. Various international and industry-specific standards guide these quality control processes.

Which International Standards Should B2B Buyers Be Aware Of?

Many 3D printing services adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with such standards ensures that the service provider maintains high-quality processes and continuous improvement.

Additionally, industry-specific certifications may apply, such as CE marking for products sold in Europe or API standards for components used in the oil and gas industry. B2B buyers should inquire about these certifications to ensure that the products meet necessary regulatory requirements.

What Are the Key Quality Control Checkpoints?

Quality control in 3D printing typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step verifies the quality of raw materials and components before they enter the production process. It ensures that all materials meet specified standards.

- In-Process Quality Control (IPQC): Monitoring occurs during the printing process to catch any defects early. This may involve visual inspections or automated systems that measure dimensional accuracy.

- Final Quality Control (FQC): After printing and finishing, a final inspection checks the completed parts against specifications. This may involve dimensional checks, surface quality assessments, and functional testing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify a supplier’s quality control practices. Here are some effective methods:

- Audits: Conducting audits of the manufacturing facility can provide insights into their processes and adherence to quality standards. Buyers should look for evidence of ISO certification and other relevant compliance documentation.

- Quality Reports: Requesting detailed quality reports can help buyers understand the consistency of the supplier’s output. These reports may include metrics on defect rates and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality processes and product quality. This is particularly important for international transactions where buyers may not be able to visit the facility.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, face unique challenges in verifying quality control standards. Language barriers, different regulatory requirements, and varying levels of supplier capability can complicate the purchasing process.

To navigate these challenges, buyers should:

- Research Local Regulations: Understanding local regulations and standards can help buyers identify potential compliance issues with suppliers.

- Build Relationships: Establishing strong relationships with suppliers can foster open communication about quality control measures and expectations.

- Leverage Technology: Utilizing digital tools for tracking quality metrics and managing supplier relationships can enhance oversight and accountability.

By understanding the manufacturing processes and quality assurance measures in 3D printing, B2B buyers can make informed decisions, ensuring they select the right suppliers to meet their production needs effectively.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d printing service cost’

Introduction

This practical sourcing guide is designed to assist B2B buyers in understanding and procuring 3D printing services effectively. By following this step-by-step checklist, you can ensure that you make informed decisions regarding costs, supplier selection, and technical requirements, ultimately leading to successful project outcomes.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your project requirements. This includes the type of 3D printing technology needed (e.g., SLA, SLS, FDM) and the materials you intend to use. Defining specifications upfront helps suppliers provide accurate quotes and ensures that your expectations align with their capabilities.

Step 2: Research Potential Suppliers

Conduct thorough research on various 3D printing service providers. Look for companies that have a strong reputation in your industry and can meet your geographical needs. Review their portfolios and customer testimonials to gauge their experience and expertise in delivering similar projects.

Step 3: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that break down costs. Ensure that quotes include:

– Material costs: Understand the pricing for different materials, as this can significantly affect your overall budget.

– Operational fees: Inquire about any additional costs related to setup, finishing, and shipping to avoid unexpected expenses later.

Step 4: Evaluate Production Capabilities

Assess the production capabilities of each supplier to ensure they can meet your volume and quality requirements. Key aspects to consider include:

– Lead times: Confirm how quickly they can deliver your parts, especially if you have tight deadlines.

– Technology: Ensure that the supplier uses advanced technologies that align with your quality standards.

Step 5: Verify Supplier Certifications

It’s essential to confirm that your selected suppliers have the necessary certifications and compliance with industry standards. Look for:

– ISO certifications: These indicate adherence to quality management systems.

– Material safety data sheets (MSDS): Ensure that materials used comply with safety regulations relevant to your industry.

Step 6: Discuss Post-Processing Options

Inquire about post-processing services offered by the supplier. Effective post-processing can enhance the final product’s quality, durability, and aesthetics. Ask about:

– Finishing techniques: Options like sanding, painting, or coating can improve the final appearance.

– Quality assurance measures: Understand how they ensure that each part meets your specifications before delivery.

Step 7: Establish Clear Communication Channels

Finally, ensure that there are clear communication channels established with your chosen supplier. Regular updates and feedback loops can help address any potential issues early in the process. This includes:

– Point of contact: Designate a specific person for communication on both sides.

– Progress updates: Agree on regular intervals for updates throughout the production process.

By following this checklist, B2B buyers can navigate the complexities of sourcing 3D printing services, ensuring that they receive quality products at competitive prices while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for 3d printing service cost Sourcing

What Are the Key Cost Components Influencing 3D Printing Service Pricing?

When evaluating the cost of 3D printing services, several key components contribute to the overall pricing structure. These include:

-

Materials: The choice of materials significantly impacts costs. Common materials like PLA or ABS can be more affordable, while specialized resins or metal powders may lead to higher expenses. For instance, nylon and advanced composites can cost substantially more, which can be a deciding factor based on the project’s requirements.

-

Labor: Labor costs encompass the time spent on operating printers, post-processing tasks such as cleaning and finishing, and the management of quality control. Automation in the printing process can reduce these costs, but human oversight remains crucial, especially for complex projects.

-

Manufacturing Overhead: This includes the depreciation of printing equipment, maintenance, utilities, and facility costs. Understanding the operational efficiency of a service provider can provide insights into how these costs are integrated into pricing.

-

Tooling: Although 3D printing generally requires less upfront tooling compared to traditional manufacturing, specific projects may necessitate unique setups that could add to costs. This is particularly relevant for custom designs or large-scale production runs.

-

Quality Control (QC): Ensuring the quality of printed parts is vital, especially in regulated industries. Providers may implement various QC measures, which can add to the pricing but are essential for maintaining standards.

-

Logistics: Shipping and handling charges can vary widely based on the destination and delivery speed. International buyers should factor in these costs, especially if they are using services from different regions.

-

Margin: Finally, the profit margin set by the service provider will affect the final price. Different companies have varying pricing strategies, which can reflect their market positioning and service offerings.

How Do Price Influencers Affect 3D Printing Costs?

Several factors influence the pricing of 3D printing services, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically result in lower per-unit costs. Understanding a supplier’s MOQ can be crucial for optimizing budget allocations.

-

Specifications and Customization: Custom projects often incur additional costs. Buyers should clearly define their specifications to receive accurate quotes, as intricate designs may require more time and resources.

-

Materials Selection: The choice of material not only affects the cost but also the performance and durability of the final product. Buyers should balance their budget with the required material properties.

-

Quality and Certifications: For industries such as aerospace or medical, certified materials and processes are non-negotiable. This can increase costs but is essential for compliance and safety.

-

Supplier Factors: The reputation, experience, and capabilities of a supplier can influence pricing. Established providers may charge more for their expertise but can offer reliability and quality assurance.

-

Incoterms: Understanding Incoterms is essential for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and risk management, which can significantly impact overall costs.

What Are the Best Practices for B2B Buyers to Optimize 3D Printing Costs?

International B2B buyers can adopt several strategies to optimize their 3D printing costs effectively:

-

Negotiate Pricing: Establishing a rapport with suppliers can open doors for negotiation, especially for larger orders or long-term contracts. Don’t hesitate to ask for bulk discounts or flexible payment terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial quotes, consider the long-term costs associated with the use of printed parts, including maintenance, durability, and the potential for rework.

-

Understand Pricing Nuances: Pricing structures can vary widely among suppliers. It’s beneficial to obtain quotes from multiple providers and compare not only costs but also service levels and delivery times.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can reduce shipping costs and lead times, providing a more cost-effective solution.

-

Stay Informed on Market Trends: The 3D printing landscape is rapidly evolving. Keeping abreast of new materials, technologies, and best practices can help buyers make informed decisions that align with their budget and project goals.

Disclaimer on Indicative Prices

The prices provided in various sources are indicative and can vary widely based on numerous factors, including project specifications, market conditions, and supplier capabilities. Buyers are encouraged to seek personalized quotes and conduct thorough due diligence when selecting a 3D printing service provider.

Alternatives Analysis: Comparing 3d printing service cost With Other Solutions

Exploring Alternatives to 3D Printing Service Costs for B2B Buyers

When considering manufacturing solutions, 3D printing offers unique advantages, particularly for rapid prototyping and low-volume production. However, various alternatives exist that may suit different business needs, especially when evaluating costs and operational efficiency. Below, we compare 3D printing services with two viable alternatives: traditional CNC machining and injection molding.

| Comparison Aspect | 3D Printing Service Cost | CNC Machining | Injection Molding |

|---|---|---|---|

| Performance | High precision and flexibility for complex designs | Excellent for detailed specifications; limited by material type | High-speed production; less flexible for design changes |

| Cost | Variable; low for small batches, high for large volumes | Higher initial costs; cost-effective for larger production runs | High upfront costs due to mold creation; economical for mass production |

| Ease of Implementation | Simple file upload and quick turnaround | Requires skilled operators and setup time | Complex setup; requires design and production planning |

| Maintenance | Minimal ongoing costs; depends on service provider | Moderate; machinery requires regular maintenance | High; molds need maintenance and replacement over time |

| Best Use Case | Prototyping, custom parts, low-volume production | Precision parts, one-off custom components | Mass production of standardized parts |

What Are the Pros and Cons of CNC Machining?

CNC machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a solid block.

Pros:

– Precision: CNC machining provides excellent accuracy and is ideal for producing intricate components.

– Material Variety: It can work with a wide range of materials, including metals, plastics, and composites, making it versatile for different applications.

Cons:

– Higher Initial Costs: The setup costs for CNC machines can be significant, especially for small runs.

– Longer Lead Times: Compared to 3D printing, CNC machining typically requires more time for setup and production.

What Are the Advantages and Disadvantages of Injection Molding?

Injection molding involves creating parts by injecting molten material into a mold, making it suitable for high-volume production.

Pros:

– Cost Efficiency for Mass Production: Once the mold is created, the cost per unit drops significantly, making it economical for large quantities.

– Speed: Injection molding can produce thousands of parts quickly, reducing time to market.

Cons:

– High Initial Investment: The cost of designing and manufacturing molds can be prohibitive for smaller companies or low-volume projects.

– Limited Design Flexibility: Changing the design once the mold is created can be costly and time-consuming.

How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate manufacturing solution requires a thorough understanding of your specific needs, including production volume, budget constraints, and time sensitivity. For businesses focused on rapid prototyping or low-volume needs, 3D printing services provide unparalleled flexibility and speed. In contrast, CNC machining may be preferable for precision parts in smaller quantities, while injection molding shines in scenarios where high-volume production is required, despite its higher initial setup costs. Evaluating these aspects will empower B2B buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for 3d printing service cost

What Are the Key Technical Properties Influencing 3D Printing Service Costs?

Understanding the technical properties of 3D printing is crucial for B2B buyers looking to manage costs effectively. Here are some essential specifications that impact the pricing of 3D printing services:

1. Material Grade

Material grade refers to the quality and type of material used in 3D printing, such as plastics, metals, or resins. High-grade materials can enhance the durability and functionality of the final product but often come with increased costs. B2B buyers must assess the trade-off between material quality and budget, especially when producing parts that require specific mechanical properties or aesthetic finishes.

2. Tolerance

Tolerance indicates the allowable deviation from a specified dimension in the printed part. Precise tolerances (e.g., ±0.1 mm) are critical for applications in industries such as aerospace and automotive, where even minor discrepancies can lead to failures. Understanding tolerance requirements helps businesses select appropriate printing technologies and materials, ultimately influencing the overall service cost.

3. Layer Height

Layer height is the thickness of each layer of material deposited during the 3D printing process. A smaller layer height results in finer details and smoother surfaces but increases printing time and material usage, thus raising costs. For B2B buyers, balancing the need for detail with production speed and cost efficiency is essential when choosing layer height settings.

4. Infill Density

Infill density refers to the amount of material used to fill the interior of a printed object, typically expressed as a percentage. Higher infill densities enhance strength but also increase material costs and printing time. Businesses must evaluate their specific strength requirements against budget constraints to determine the optimal infill density for their applications.

5. Post-Processing Requirements

Post-processing involves additional steps taken after printing, such as cleaning, sanding, or painting. These processes can significantly impact the final cost of a 3D printed part. B2B buyers should consider the time and resources required for post-processing when calculating the total expense of a project.

What Are Common Trade Terms Related to 3D Printing Services?

Familiarity with industry terminology can aid B2B buyers in making informed decisions regarding 3D printing services. Here are some common terms to understand:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another company. In 3D printing, OEMs often provide specialized components tailored to specific applications. Understanding OEM relationships can help businesses negotiate better pricing and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For 3D printing services, this can affect the cost per unit, as lower quantities may lead to higher per-unit costs. B2B buyers should clarify MOQ policies with service providers to align their production needs with pricing structures.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing information for specific products or services. In the context of 3D printing, submitting an RFQ allows businesses to compare costs and capabilities of different service providers, facilitating better purchasing decisions.

4. Incoterms

Incoterms are international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers to avoid unexpected costs and delays in the delivery of 3D printed products.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the final product. In 3D printing, lead times can vary based on the complexity of the design, material availability, and production capacity. B2B buyers should factor lead times into their project timelines to ensure timely delivery and avoid disruptions in their supply chains.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting 3D printing services, ultimately optimizing their production processes and costs.

Navigating Market Dynamics and Sourcing Trends in the 3d printing service cost Sector

What Are the Current Market Dynamics and Key Trends in the 3D Printing Service Cost Sector?

The global 3D printing service market is experiencing significant growth, driven by advancements in technology, increasing demand for customized solutions, and the growing trend toward rapid prototyping. As industries such as automotive, aerospace, and healthcare embrace additive manufacturing, international B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking to integrate 3D printing into their operations. Cost efficiency is a primary driver; businesses can produce prototypes and small batches at a fraction of traditional manufacturing costs, making it an attractive option for startups and established companies alike.

Emerging technologies such as Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS) are expanding the material options available, from plastics to metals, thereby broadening the applications of 3D printing. Furthermore, the rise of online 3D printing services allows buyers to compare quotes from multiple manufacturers, enabling them to select the best price and quality without geographical constraints. This trend is particularly beneficial for B2B buyers in regions with limited local manufacturing capabilities.

How Are Sustainability and Ethical Sourcing Shaping the 3D Printing Service Cost Sector?

Sustainability has become a focal point for businesses globally, and the 3D printing sector is no exception. The environmental impact of traditional manufacturing processes has prompted companies to explore more sustainable alternatives, with 3D printing offering significant advantages. By minimizing waste through additive manufacturing—where material is only used where needed—companies can significantly reduce their carbon footprint.

Ethical sourcing is also gaining traction as consumers and businesses alike demand transparency in supply chains. This is particularly relevant for B2B buyers in emerging markets, who are increasingly looking for suppliers that prioritize sustainable practices and materials. Certifications such as ISO 14001 for environmental management and the use of biodegradable or recycled materials are becoming important criteria in supplier selection. By prioritizing sustainability and ethical sourcing, companies not only enhance their brand reputation but also align with global trends toward responsible business practices.

What Is the Evolution of 3D Printing and Its Impact on B2B Costs?

The evolution of 3D printing can be traced back to the 1980s, when the first rapid prototyping technologies emerged. Initially, 3D printing was limited to prototyping, but advancements in materials and technologies have transformed it into a viable manufacturing solution for low-volume production and customized parts. This shift has significantly impacted B2B costs, enabling companies to reduce lead times and minimize inventory expenses.

Today, 3D printing is integral to product development cycles across various industries, allowing businesses to iterate designs quickly and affordably. The continuous improvement of 3D printing technologies—such as increased printing speeds and enhanced material properties—further lowers the cost barriers for B2B buyers. As a result, the market is poised for continued growth, driven by the need for efficiency and innovation in manufacturing processes. By understanding the historical context and current landscape, international buyers can better navigate the complexities of sourcing 3D printing services tailored to their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d printing service cost

-

How do I determine the cost of 3D printing services for my project?

To accurately estimate the cost of 3D printing services, consider factors such as material type, print complexity, and size. Each service provider has different pricing structures based on these elements. It’s advisable to gather quotes from multiple suppliers, specifying your requirements, such as the desired material and finish, to obtain a comprehensive cost analysis. Additionally, inquire about any potential hidden fees or minimum order quantities that could impact your budget. -

What materials are commonly used in 3D printing, and how do they affect costs?

Common materials for 3D printing include PLA, ABS, nylon, and various resins. The choice of material significantly influences the cost; for instance, high-performance materials like nylon can be more expensive than standard PLA. Additionally, specialized materials may require specific printing technologies, which can further increase costs. Understanding the properties of each material will help you make informed decisions based on your project requirements and budget constraints. -

What is the minimum order quantity (MOQ) for 3D printing services?

Minimum order quantities can vary significantly among 3D printing service providers. While some may offer no minimum order, others might require a certain volume to ensure cost-effectiveness. It’s essential to clarify the MOQ with potential suppliers upfront, especially if you’re considering a small batch or prototype production. This information can influence your decision on which service to choose based on your project scope and financial viability. -

How can I ensure quality assurance (QA) in my 3D printed parts?

To ensure quality assurance in your 3D printed parts, select a service provider with a solid reputation for quality control. Ask about their QA processes, including how they inspect and test prints for accuracy and durability. Request samples of previous work to assess their craftsmanship. Additionally, consider suppliers who offer post-processing services, as these can enhance the final product’s quality and performance. -

What payment terms should I expect when sourcing 3D printing services internationally?

Payment terms for 3D printing services can vary based on the supplier and the scale of your order. Common options include upfront payments, partial payments upon order confirmation, or payment upon delivery. When dealing with international suppliers, consider factors such as currency exchange rates and transaction fees. It’s advisable to establish clear payment terms upfront to avoid misunderstandings and ensure a smooth transaction process. -

How do I vet potential suppliers for 3D printing services?

Vetting suppliers involves assessing their experience, capabilities, and customer reviews. Start by reviewing their portfolio to see examples of their work and check if they specialize in the materials and technologies you require. Look for online reviews and testimonials from other B2B clients. Additionally, consider requesting references and engaging in direct communication to gauge their responsiveness and professionalism. -

What logistics considerations should I be aware of when ordering 3D printed parts?

Logistics play a crucial role in the timely delivery of 3D printed parts. Consider factors such as shipping methods, delivery times, and costs associated with international shipping. It’s essential to discuss shipping options with your supplier to understand their capabilities and any potential delays. Additionally, ensure that the supplier has experience with customs regulations in your country to avoid unexpected issues upon arrival. -

Can I customize my 3D printed parts, and what impact does that have on cost?

Yes, customization is one of the key benefits of 3D printing. Most service providers allow for modifications in design, material, and finishing options. However, customization can impact costs, as complex designs may require additional time and resources to produce. It’s important to communicate your specific customization needs to the supplier to receive an accurate quote and understand how these changes may affect the overall project budget.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 3d printing service cost

In conclusion, understanding the costs associated with 3D printing services is crucial for international B2B buyers looking to optimize their sourcing strategies. The pricing landscape varies widely based on factors such as material choice, print technology, and operational expenses. By leveraging strategic sourcing, businesses can secure competitive pricing while ensuring high-quality outputs tailored to their specific needs.

Additionally, the ability to compare multiple providers and technologies allows buyers from regions such as Africa, South America, the Middle East, and Europe to make informed decisions that align with their budgetary constraints and project timelines. As the 3D printing industry continues to evolve, embracing these services will not only enhance product development but also foster innovation and reduce time-to-market.

For businesses ready to take the next step, it’s essential to actively seek out reliable 3D printing partners and explore the diverse range of materials and technologies available. Engaging with multiple service providers can yield better pricing and faster turnaround times, ultimately driving business success in a competitive global market.