Top 6 Cnc China Manufacturers & Suppliers List

1. PCBWay – CNC Machining & 3D Printing Solutions

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: CNC Machining: Full 3-, 4-, & 5-axis milling and turning services. 3D Printing: Technologies include SLA, DLP, FDM, SLM, SLS, PolyJet, and Vacuum Casting. Sheet Metal Fabrication: Laser cutting and bending services available. Injection Molding: Rapid molds and custom molded prototypes with fast lead times. Materials: CNC machining materials include aluminum, stainless steel, brass, copper, titaniu…

2. STYLECNC – CNC Machines

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: STYLECNC is a leading CNC machine manufacturer from China, offering a wide range of products including: CNC Machines (CNC Router, CNC Wood Router, ATC CNC Router, Hobby CNC Router, Metal CNC Machine, Stone CNC Machine, Cabinet CNC Machine, CNC Machining Center, 3D CNC Router Machine, 4 Axis CNC Router Machine, 5 Axis CNC Router Machine, CNC Plasma Cutter, CNC Milling Machine, Edge Banding Machine)…

3. Elephant CNC – Professional CNC Machines

Domain: elephant-cnc.com

Registered: 2013 (12 years)

Introduction: Top #1 Professional CNC Machine Manufacturer in China. Product range includes: Furniture CNC Machine, Panel Furniture Production Line, CNC Nesting Machine, Wood Door Making Machine, Door Lock Drilling Machine, 4 Sides Wood Door Cutting Machine, Door, Wall and Cabinet Integrated Machine, Edge Banding Machines (Automatic, Manual, Semi-Automatic), Profiling Corner Trimming Machine, Panel Saw, Sliding…

4. China CNC Router – Mini CNC Routers & Laser Engraving Machines

Domain: china-cncrouter.com

Registered: 2015 (10 years)

Introduction: China CNC Router Manufacturer offering a range of products including: Mini CNC Routers (CNC 6040, CNC 3040, CNC 6090), DIY 5 Axis CNC Router (HY-…), CO2 Laser Engraving Machines (100W, 80W), and various CNC machines for metal and aluminum milling. Key features include high quality, competitive pricing, and a variety of models suitable for different applications such as engraving, cutting, and mi…

5. WMTCNC – CNC Lathe Machines

Domain: cncwmt.com

Registered: 2018 (7 years)

Introduction: WMTCNC Industrial Co., Ltd. offers a wide range of CNC and conventional machines, including:

1. **CNC Lathe Machines**:

– Flat Bed CNC Lathe (CK6150, CK6140, CK210)

– Slant Bed CNC Lathe (CK60L, SWL550/400)

– Swiss Type CNC Lathe

– CNC Pipe Threading Lathe Machine

– Vertical Lathe

– Facing Lathe

2. **CNC Milling Machines**:

– Vertical Machining Centres (VMC850L, VMC…

6. TAICNC – CNC Machine Tools

Domain: lvcnc.com

Registered: 2013 (12 years)

Introduction: TAICNC offers a range of CNC machine tools including: 1. Vertical Machining Center Series – Most popular CNC milling machines with wide applications. 2. Horizontal Machining Center Series – Essential for processing box products. 3. Double Column Machining Center Series – Designed for large workpiece-level mold processing. 4. CNC Tapping Center Series – Ideal for processing 3C digital products and …

Introduction: Navigating the Global Market for cnc china

Navigating the complexities of sourcing CNC machines from China can be a daunting task for international B2B buyers, especially when seeking reliable suppliers that meet specific operational needs. Whether your focus is on precision CNC milling, laser cutting, or custom fabrication, understanding the diverse landscape of CNC manufacturing is crucial for making informed decisions. This comprehensive guide aims to demystify the global market for CNC machines from China, addressing key considerations such as types of machines available, their applications across various industries, and essential supplier vetting processes.

Buyers from Africa, South America, the Middle East, and Europe—particularly in countries like Germany and Nigeria—will find valuable insights tailored to their unique requirements. We delve into cost analysis, quality assurance, and logistical considerations, empowering you to navigate challenges such as fluctuating prices and varying standards of manufacturing. By equipping you with the knowledge to assess suppliers effectively, this guide serves as a crucial resource to enhance your procurement strategy. Ultimately, our goal is to facilitate successful partnerships and foster growth in your business endeavors, ensuring that your investment in CNC technology yields optimal returns.

Understanding cnc china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Routers | Versatile for cutting various materials; user-friendly | Woodworking, foam molding, stone carving | Pros: Affordable, easy to operate; Cons: Limited precision for metals |

| CNC Milling Machines | High precision; capable of multi-axis operations | Aerospace, automotive, medical part manufacturing | Pros: Excellent accuracy; Cons: Higher initial investment |

| CNC Laser Machines | Uses laser technology for cutting and engraving | Sign making, custom jewelry, metal fabrication | Pros: Clean cuts, minimal waste; Cons: Material limitations |

| CNC Plasma Cutters | Cuts through thick metals using plasma technology | Heavy-duty metal fabrication, industrial applications | Pros: Fast cutting speeds; Cons: Less precision than laser cutters |

| CNC Wood Lathes | Designed specifically for wood turning | Furniture making, decorative arts | Pros: Specialized for wood; Cons: Limited to wood and similar materials |

What are CNC Routers and Their B2B Suitability?

CNC routers are versatile machines ideal for various materials, including wood, plastics, and foam. They excel in applications such as woodworking, where they can create intricate designs or shapes. For B2B buyers, the affordability and user-friendly operation make CNC routers an attractive option, especially for small businesses or startups. However, they may not provide the precision required for metalwork, which limits their application in industries demanding high accuracy.

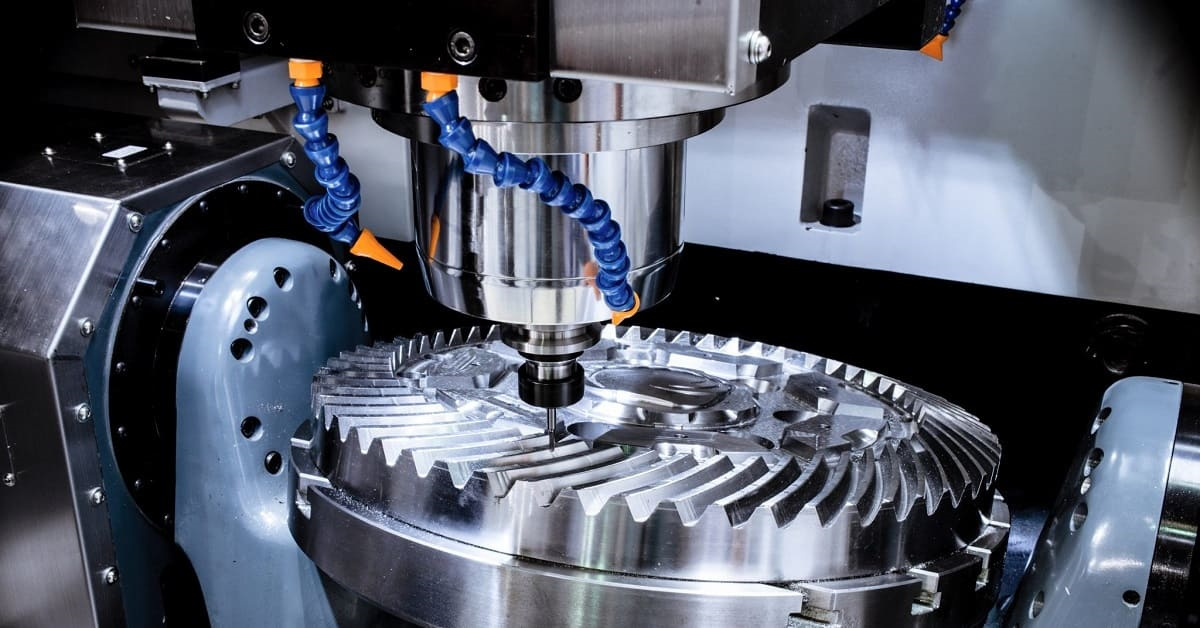

How Do CNC Milling Machines Benefit Businesses?

CNC milling machines are known for their high precision and ability to perform complex multi-axis operations. These machines are commonly used in industries such as aerospace and automotive for producing precise metal parts. B2B buyers should consider CNC milling machines for their accuracy, which can significantly enhance product quality. However, the initial investment is often higher than other CNC types, which could be a barrier for smaller companies or those with limited budgets.

What Advantages Do CNC Laser Machines Offer?

CNC laser machines utilize laser technology to cut and engrave materials with exceptional precision. They are widely used in applications like signage, jewelry, and metal fabrication. For businesses, the main advantages include clean cuts and minimal material waste, making them cost-effective in the long run. However, buyers should be aware of the limitations regarding material compatibility, as certain thick metals may not be suitable for laser cutting.

Why Choose CNC Plasma Cutters for Heavy-Duty Applications?

CNC plasma cutters are designed to cut through thick metals using a high-velocity plasma arc, making them ideal for heavy-duty metal fabrication. Industries such as construction and manufacturing benefit from the fast cutting speeds and ability to handle large sheets of metal. While plasma cutters are efficient, buyers should consider that they may lack the precision of laser cutters, which can be a drawback for applications requiring fine detail.

What Makes CNC Wood Lathes Essential for Woodworking?

CNC wood lathes are specialized machines focused on wood turning, allowing users to create items like furniture and decorative pieces. These lathes are essential for businesses in the woodworking industry, as they provide the necessary tools for crafting intricate designs. While they excel in wood applications, their limitation to wood and similar materials could restrict their use in businesses looking to diversify into other material types.

Key Industrial Applications of cnc china

| Industry/Sector | Specific Application of cnc china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision Machining of Aircraft Components | High accuracy and reliability in critical components | Certifications, quality control standards, lead time |

| Automotive | CNC Manufacturing of Engine Parts | Improved efficiency and reduced waste in production | Material specifications, tooling compatibility, cost |

| Electronics | Custom PCB Prototyping and CNC Machining | Rapid prototyping and reduced time-to-market | Design requirements, tolerances, assembly services |

| Medical Devices | CNC Fabrication of Surgical Instruments | Enhanced precision and compliance with safety standards | Regulatory compliance, material biocompatibility, traceability |

| Furniture and Woodworking | CNC Routing for Custom Furniture Design | Increased design flexibility and faster production cycles | Material types, software compatibility, after-sales support |

How is CNC China Used in the Aerospace Sector?

In the aerospace industry, CNC China is pivotal for the precision machining of aircraft components, such as fuselage sections and wing structures. These components require high accuracy due to safety regulations and performance standards. CNC machines ensure tight tolerances, thereby enhancing the reliability of the aircraft. International buyers should consider sourcing from manufacturers that possess relevant certifications like AS9100 and demonstrate robust quality control processes to mitigate risks associated with component failure.

What Role Does CNC China Play in Automotive Manufacturing?

CNC technology is extensively used in the automotive sector for manufacturing engine parts and transmission components. The precision offered by CNC machines leads to improved efficiency, reduced waste, and lower production costs. For international B2B buyers, it is essential to ensure that the CNC manufacturer can meet specific material specifications and tooling compatibility for automotive applications. Moreover, understanding the supplier’s production lead times can help in planning and inventory management.

How Does CNC China Facilitate Electronics Manufacturing?

In the electronics industry, CNC China is instrumental in the rapid prototyping of printed circuit boards (PCBs) and other components. This capability allows businesses to reduce their time-to-market significantly while ensuring that prototypes meet precise design requirements. Buyers should focus on manufacturers that provide comprehensive design support and adhere to strict tolerances. Additionally, sourcing suppliers with advanced assembly capabilities can streamline the production process and enhance overall project efficiency.

Why is CNC China Important for Medical Device Production?

CNC machining is critical in the medical device industry for fabricating surgical instruments and implants that require exceptional precision. The use of CNC technology ensures compliance with stringent safety standards and enhances the reliability of medical devices. Buyers from international markets must prioritize manufacturers that demonstrate regulatory compliance and can provide materials that are biocompatible. Traceability in the production process is also crucial for maintaining quality assurance.

How Can CNC China Transform Furniture and Woodworking Industries?

CNC routing technology is revolutionizing the furniture and woodworking industries by enabling the creation of custom furniture designs with high precision. This technology allows manufacturers to produce intricate designs quickly, leading to faster production cycles and greater design flexibility. When sourcing CNC machinery, buyers should consider the types of materials used, software compatibility for design applications, and the availability of after-sales support to ensure smooth operations.

3 Common User Pain Points for ‘cnc china’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in CNC Machining

The Problem: A common issue faced by B2B buyers when sourcing CNC machinery from China is the variability in quality assurance standards. Buyers often find themselves receiving products that do not meet their specifications, leading to costly delays and potential reputational damage. This is particularly concerning for businesses in industries like aerospace or medical devices, where precision and compliance with regulatory standards are critical. Many buyers feel overwhelmed by the multitude of manufacturers and struggle to determine which ones can provide consistent quality.

The Solution: To tackle this challenge, buyers should implement a structured supplier evaluation process. Begin by creating a detailed checklist of quality standards specific to your industry, including certifications such as ISO 9001 or AS9100. Before placing large orders, request sample parts and conduct thorough inspections using tools like CMM (Coordinate Measuring Machines) to verify dimensions and tolerances. Additionally, establishing a clear communication channel with the manufacturer can help clarify expectations and resolve issues quickly. Regular audits of the manufacturing facility—either in-person or via video conferencing—can also ensure adherence to quality standards throughout the production process.

Scenario 2: Overcoming Language and Cultural Barriers in Communication

The Problem: International buyers often face significant language and cultural barriers when dealing with suppliers in China. Miscommunication can lead to misunderstandings regarding project specifications, timelines, and pricing. This issue is particularly acute for buyers from regions like Africa and South America, where different business practices and negotiation styles may not align with those in China. As a result, projects can fall behind schedule, and costs can escalate, impacting the overall business relationship.

The Solution: To mitigate these risks, invest in hiring a local intermediary or consultant who understands both the Chinese market and your specific industry. This individual can facilitate communication and help bridge cultural gaps, ensuring that your needs are accurately represented. Additionally, utilize technology such as translation apps or services to enhance direct communication with suppliers. Setting up regular video conferences can also foster better relationships and provide opportunities for real-time clarification. It is vital to establish clear, written documentation of agreements in both languages to avoid future disputes.

Scenario 3: Managing Delivery Times and Supply Chain Disruptions

The Problem: Buyers often grapple with unpredictable delivery times when sourcing CNC products from China. Factors such as port congestion, customs delays, and unforeseen events like global pandemics can disrupt the supply chain, leading to missed deadlines and lost business opportunities. This unpredictability can be particularly detrimental for manufacturers who rely on timely deliveries to maintain production schedules.

The Solution: To enhance supply chain reliability, B2B buyers should diversify their sourcing strategies. Instead of relying on a single supplier, consider establishing relationships with multiple manufacturers across different regions in China. This can create a buffer against localized disruptions. Implementing a just-in-time inventory system can also help minimize the impact of delays by reducing the amount of stock on hand and allowing for quick adjustments based on supplier performance. Additionally, using freight forwarders with strong networks can provide better visibility and tracking of shipments, enabling proactive management of any potential delays. Regularly reviewing and adjusting your logistics strategy based on performance metrics will further enhance your ability to navigate delivery challenges effectively.

Strategic Material Selection Guide for cnc china

When selecting materials for CNC machining in China, international B2B buyers must consider various factors that can significantly impact the performance, durability, and cost-effectiveness of their final products. Here, we analyze four common materials used in CNC machining, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum for CNC Machining?

Aluminum is a lightweight, corrosion-resistant metal that is widely used in CNC machining. It has excellent thermal and electrical conductivity, making it suitable for various applications, including automotive and aerospace components. Its temperature rating typically ranges from -200°C to 600°C, depending on the alloy.

Pros: Aluminum is easy to machine, has a good strength-to-weight ratio, and is relatively inexpensive compared to other metals. It is also recyclable, which adds to its sustainability.

Cons: While durable, aluminum can be less resistant to wear compared to harder metals. It may also require surface treatments to enhance its corrosion resistance for specific applications.

Impact on Application: Aluminum is compatible with various media, including water and chemicals, making it ideal for components exposed to different environments.

Considerations for International Buyers: Compliance with standards such as ASTM and EN is crucial. Buyers should also consider the availability of specific aluminum alloys that meet their project requirements.

How Does Stainless Steel Perform in CNC Machining Applications?

Stainless steel is known for its exceptional corrosion resistance and strength, making it a popular choice for applications requiring durability. It can withstand temperatures up to 1,000°C, depending on the grade, and is often used in food processing, medical devices, and automotive parts.

Pros: Stainless steel is highly durable and resistant to rust and staining. It also has a long lifespan, which can reduce long-term costs.

Cons: The machining process can be more complex and costly due to its hardness. Additionally, stainless steel can be heavier than other materials, which may not be suitable for all applications.

Impact on Application: Its corrosion resistance makes it ideal for components exposed to harsh environments, including marine and industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ISO and JIS. The availability of specific stainless steel grades may vary by region, so understanding local suppliers is essential.

What Are the Benefits of Using Plastics in CNC Machining?

Plastics, such as acrylic, polycarbonate, and nylon, are increasingly popular in CNC machining due to their versatility and lightweight properties. They can withstand temperatures up to 80°C to 120°C, depending on the type.

Pros: Plastics are generally less expensive to machine than metals and can be produced in various colors and finishes. They are also resistant to corrosion and chemicals.

Cons: While lightweight, plastics can be less durable than metals and may not be suitable for high-stress applications. They can also be sensitive to UV light and may degrade over time.

Impact on Application: Plastics are suitable for applications requiring lightweight components, such as housings and enclosures.

Considerations for International Buyers: Compliance with safety and environmental regulations is essential, especially for applications in food and medical sectors. Understanding regional preferences for specific plastic types can also aid in material selection.

How Does Titanium Compare as a CNC Machining Material?

Titanium is renowned for its high strength-to-weight ratio and corrosion resistance, making it ideal for aerospace, medical, and high-performance applications. It can withstand temperatures up to 600°C.

Pros: Titanium is extremely durable and biocompatible, making it suitable for medical implants. It also has excellent resistance to corrosion in harsh environments.

Cons: The cost of titanium is significantly higher than other materials, and its machining can be complex, requiring specialized tools and techniques.

Impact on Application: Titanium is ideal for applications where strength and weight are critical, such as aerospace components and high-performance automotive parts.

Considerations for International Buyers: Buyers must consider the high cost and availability of titanium alloys. Compliance with aerospace and medical standards is crucial for applications in these industries.

Summary Table of Material Selection for CNC Machining

| Material | Typical Use Case for cnc china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive and aerospace parts | Lightweight and corrosion-resistant | Less wear-resistant than harder metals | Medium |

| Stainless Steel | Food processing and medical devices | High durability and corrosion resistance | More complex machining process | High |

| Plastics | Housings and enclosures | Cost-effective and versatile | Less durable than metals | Low |

| Titanium | Aerospace and high-performance components | High strength-to-weight ratio | Expensive and complex machining | High |

This analysis provides B2B buyers with a clear understanding of the materials available for CNC machining in China, enabling them to make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc china

What Are the Main Stages of Manufacturing Processes for CNC Machining in China?

The manufacturing process for CNC (Computer Numerical Control) machining in China is typically divided into several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring that the final product meets the required specifications and quality standards.

How Is Material Prepared in CNC Manufacturing?

Material preparation involves selecting the right raw materials based on the specifications of the project. This may include metals like aluminum, steel, or titanium, as well as non-metals like plastics or composites. Suppliers often source materials from local or international vendors, ensuring they meet industry standards for quality. The material is then cut to size, cleaned, and inspected for any defects before moving to the next stage.

What Techniques Are Used for Forming in CNC Machining?

Forming is the stage where the actual machining takes place. CNC machines utilize various methods such as milling, turning, and drilling to shape the material into the desired form. Advanced techniques like 5-axis machining allow for complex geometries and tighter tolerances, which are essential for high-precision components. The programming of the CNC machines is critical, as it dictates the machine’s movements and operations based on the design specifications.

How Is Assembly Conducted in CNC Manufacturing?

Once individual components are machined, they may require assembly, especially in the case of multi-part products. This stage can involve welding, fastening, or other joining methods. Quality control is essential during assembly to ensure that parts fit together correctly and function as intended. Automated assembly processes are often employed for higher efficiency and consistency.

What Finishing Techniques Are Commonly Used in CNC Machining?

Finishing processes are crucial for enhancing the aesthetic and functional qualities of the machined parts. Common techniques include anodizing, painting, polishing, and coating, which not only improve appearance but also increase corrosion resistance and wear properties. The choice of finishing technique often depends on the intended application of the product and customer specifications.

What Quality Assurance Standards Are Relevant for CNC Machining in China?

Quality assurance is a vital aspect of CNC machining, particularly for international B2B buyers who require reliable and consistent products. Several international standards, such as ISO 9001, provide frameworks for quality management systems, ensuring that manufacturers maintain high levels of quality throughout their processes.

How Do International Standards Impact Quality Control in CNC Manufacturing?

ISO 9001 focuses on various quality management principles, including customer focus, leadership, and continuous improvement. Compliance with these standards helps manufacturers in China demonstrate their commitment to quality and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) for oil and gas components can further assure buyers of product reliability.

What Are the Key Quality Control Checkpoints in CNC Manufacturing?

Quality control in CNC machining involves several checkpoints throughout the production process. These checkpoints typically include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): During the machining process, operators perform regular inspections to identify any deviations from the desired specifications.

- Final Quality Control (FQC): After assembly, a thorough inspection is conducted to ensure the final product meets all quality requirements before shipping.

What Common Testing Methods Are Used for Quality Assurance in CNC Machining?

Various testing methods are employed to validate the quality of CNC machined parts. These may include:

- Dimensional Inspection: Utilizing tools like calipers and micrometers to measure dimensions against specified tolerances.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection help identify internal flaws without damaging the part.

- Functional Testing: Ensuring that the product performs as expected in its intended application.

How Can B2B Buyers Verify Supplier Quality Control in CNC Manufacturing?

For international buyers, verifying a supplier’s quality control practices is essential to ensure they receive high-quality products. Here are some actionable steps:

- Conduct Supplier Audits: Regular audits allow buyers to evaluate the supplier’s quality management systems and production processes firsthand.

- Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including inspection results and compliance with relevant standards.

- Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

For buyers from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in Chinese CNC manufacturing is vital. Different regions may have specific regulatory requirements that suppliers must adhere to. Additionally, cultural differences in business practices can impact communication and expectations regarding quality. Therefore, establishing clear guidelines and expectations upfront can help mitigate misunderstandings and ensure a smooth procurement process.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices for CNC machining in China is crucial for international B2B buyers. By familiarizing themselves with the stages of production, relevant standards, and quality control measures, buyers can make informed decisions and establish successful partnerships with Chinese manufacturers. This proactive approach not only enhances product quality but also fosters trust and reliability in cross-border transactions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc china’

In the competitive landscape of international manufacturing, sourcing CNC machines from China presents significant opportunities for B2B buyers. This practical sourcing guide outlines essential steps to ensure you procure the right equipment tailored to your business needs, while minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify the exact specifications of the CNC machinery you require. Consider factors such as the type of materials you’ll be working with (metal, wood, plastic), desired precision levels, and specific functionalities (cutting, engraving, milling). A clear definition helps streamline your search and ensures that potential suppliers can meet your operational needs.

Step 2: Conduct Market Research

Thoroughly research the CNC machine market in China. Understand the various types of machines available, their price ranges, and the latest technological advancements. This knowledge will empower you to make informed decisions and identify suppliers who offer competitive pricing and innovative solutions tailored to your industry.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record and positive reviews, as this will help you assess their reliability and the quality of their products.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications, such as ISO 9001 for quality management systems or CE marking for compliance with European safety standards. These certifications indicate a commitment to quality and can significantly reduce the risk of purchasing subpar equipment. Don’t hesitate to ask for documentation to confirm their certifications.

Step 5: Request Samples or Prototypes

Whenever possible, request samples or prototypes of the CNC machines you are considering. This allows you to evaluate the quality, performance, and suitability of the equipment for your specific applications. Pay attention to the machine’s build quality, precision, and user-friendliness during this assessment.

Step 6: Discuss After-Sales Support and Warranty

Inquire about the after-sales support offered by the supplier, including installation assistance, training, and technical support. A solid warranty policy is also crucial; it should cover defects and provide options for maintenance and repairs. Understanding these aspects will help ensure that you are supported throughout the lifecycle of the machine.

Step 7: Negotiate Terms and Place Your Order

Once you’ve selected a supplier, negotiate the terms of your purchase, including pricing, payment methods, delivery timelines, and shipping arrangements. Ensure that all terms are documented to avoid misunderstandings later. A well-negotiated contract will protect your interests and lay the groundwork for a successful business relationship.

By following this checklist, B2B buyers can navigate the complexities of sourcing CNC machinery from China effectively, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for cnc china Sourcing

What Are the Key Cost Components in CNC Sourcing from China?

When sourcing CNC machinery from China, understanding the cost structure is essential for international buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. For example, sourcing high-grade steel or aluminum will increase costs compared to standard materials. Additionally, the fluctuating prices of raw materials can affect overall expenses.

-

Labor: Labor costs in China are generally lower than in Europe or North America, which can lead to significant savings. However, specialized skills, particularly in advanced CNC machining, may command higher wages, affecting pricing.

-

Manufacturing Overhead: This includes costs associated with the production process, such as utilities, factory maintenance, and equipment depreciation. Manufacturers often factor these costs into their pricing, so it’s crucial to assess the operational efficiency of potential suppliers.

-

Tooling: Custom tooling can be a significant upfront cost, especially for specialized parts. Understanding the tooling requirements for your specific needs can help you budget appropriately.

-

Quality Control (QC): Implementing quality assurance measures adds to the overall cost but is essential for ensuring product reliability. Buyers should inquire about the QC processes of suppliers to understand how these costs are integrated into pricing.

-

Logistics: Shipping costs can vary widely based on the mode of transport (air vs. sea), distance, and volume. Understanding the logistics involved can help buyers forecast total expenses more accurately.

-

Margin: Suppliers often include a profit margin that can vary significantly based on the competitiveness of the market and the value-added services they provide.

How Do Price Influencers Affect CNC Sourcing Costs?

Several factors can influence the pricing of CNC machines and components:

-

Volume/MOQ: Bulk orders generally attract lower prices due to economies of scale. Understanding the minimum order quantities (MOQs) can help buyers negotiate better terms.

-

Specifications and Customization: Customized parts or specific technical specifications can increase costs. It’s essential to balance customization needs with budget constraints.

-

Materials: As previously mentioned, the choice of materials directly affects pricing. Buyers should consider whether the material specifications can be adjusted to reduce costs without compromising quality.

-

Quality and Certifications: Higher quality and compliance with international certifications (such as ISO or CE) often come at a premium. Buyers must evaluate whether the added cost aligns with their quality requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer suppliers may offer lower prices to attract clients.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is vital as they dictate who bears the shipping costs and risks, impacting the overall price.

What Tips Can Help Buyers Negotiate Better Prices in CNC Sourcing?

To ensure cost-efficiency in CNC sourcing, international buyers should consider the following strategies:

-

Effective Negotiation: Engage in direct communication with suppliers to discuss pricing. Understanding the supplier’s cost structure can provide leverage during negotiations.

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, operation, and potential downtime. This holistic view can guide purchasing decisions.

-

Consider Local Partnerships: Establishing relationships with local distributors or agents can help navigate the complexities of sourcing from China, potentially reducing costs and risks associated with international transactions.

-

Stay Informed About Market Trends: Keeping abreast of global material prices, labor rates, and economic conditions in China can empower buyers during negotiations.

-

Be Aware of Pricing Nuances: Different regions may have varying costs associated with logistics and tariffs. Understanding these nuances is particularly important for buyers from Africa, South America, the Middle East, and Europe, as they can significantly affect the final price.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on specific project requirements, market conditions, and supplier negotiations. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing cnc china With Other Solutions

When evaluating CNC solutions for manufacturing needs, it is essential to consider various alternatives that can fulfill similar functions. The decision-making process can be complex, as each option presents unique advantages and potential drawbacks. This analysis compares ‘CNC China’ with two viable alternatives: ‘CNC Machines from Europe’ and ‘Manual Machining Methods’.

Comparison Table

| Comparison Aspect | Cnc China | CNC Machines from Europe | Manual Machining Methods |

|---|---|---|---|

| Performance | High precision and speed | Superior quality, but slower | Variable; depends on skill level |

| Cost | Generally lower cost | Higher initial investment | Low equipment cost, but labor-intensive |

| Ease of Implementation | User-friendly for beginners | More complex setup | Requires skilled labor |

| Maintenance | Moderate; parts readily available | High; specialized service needed | Low; but requires skilled maintenance |

| Best Use Case | Mass production and prototyping | High-quality custom parts | One-off or low-volume production |

Detailed Breakdown of Alternatives

CNC Machines from Europe

CNC machines manufactured in Europe, such as those from Germany and Italy, are renowned for their exceptional build quality and reliability. These machines often incorporate advanced technology that results in superior performance, particularly for intricate designs and high-precision tasks. However, they usually come with a significantly higher price tag and may involve a more complex implementation process, making them less accessible for small businesses or startups. Additionally, maintenance can be costly, requiring specialized service providers, which may deter some B2B buyers.

Manual Machining Methods

Manual machining is a traditional approach that involves skilled labor to operate lathes, mills, and other machines without automated systems. This method can be highly effective for producing unique, one-off parts or small batches, especially when customization is a priority. The initial investment in equipment is lower than CNC solutions, making it attractive for startups. However, the quality and speed of production are heavily dependent on the operator’s skill level, which can lead to inconsistencies. Furthermore, manual machining can be labor-intensive and may not be suitable for mass production scenarios.

Conclusion: How to Choose the Right Solution for Your Needs

In choosing the right CNC solution, B2B buyers should consider their specific operational needs, budget constraints, and the types of products they intend to manufacture. If your business requires high-volume production with a focus on cost-effectiveness, CNC machines from China might be the best fit. However, for businesses that prioritize quality and precision, especially for customized projects, investing in European CNC machines may be justified. Alternatively, for those focused on craftsmanship and custom jobs, manual machining could be a viable option, provided there is access to skilled labor. Ultimately, understanding the trade-offs associated with each solution will empower buyers to make informed decisions tailored to their unique operational requirements.

Essential Technical Properties and Trade Terminology for cnc china

What Are the Key Technical Properties in CNC Machining from China?

When sourcing CNC machinery and services from China, understanding critical technical specifications is essential for making informed purchasing decisions. Here are some vital properties to consider:

-

Material Grade

The material grade refers to the specific type of material used in CNC machining, such as aluminum, stainless steel, or plastic. Each material has unique properties that affect durability, weight, and cost. For B2B buyers, selecting the right material is crucial, as it directly influences the performance and longevity of the final product. -

Tolerance

Tolerance specifies the allowable deviation from a specified dimension. In CNC machining, tight tolerances (e.g., ±0.01 mm) indicate high precision, which is vital for applications requiring exact fits, such as aerospace and medical devices. Understanding tolerances helps buyers ensure that the machined parts meet their specifications, reducing the risk of costly reworks. -

Surface Finish

This property describes the texture and quality of a part’s surface after machining. Common surface finishes include anodized, polished, and painted. The chosen finish not only affects aesthetics but also impacts corrosion resistance and wear. Buyers should specify their desired surface finish to ensure the end product aligns with their application requirements. -

Machining Speed

Machining speed refers to the rate at which a CNC machine can operate, measured in units like RPM (revolutions per minute). Faster machining speeds can lead to higher production rates, which is critical for meeting tight deadlines. B2B buyers must consider the balance between speed and quality to optimize their manufacturing processes. -

Tooling Options

Tooling options encompass the variety of tools available for CNC operations, such as drills, mills, and lathes. The choice of tooling can affect production efficiency and the types of materials that can be processed. Understanding tooling capabilities helps buyers select a CNC provider that can meet their specific manufacturing needs.

What Are Common Trade Terms in CNC Sourcing from China?

Navigating the world of CNC machining also involves understanding specific trade terminology. Here are some key terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are then sold under another company’s brand. In CNC machining, an OEM partner can produce parts to a client’s specifications. Understanding OEM relationships is crucial for buyers looking for tailored solutions without the need for in-house manufacturing. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to produce or sell. This term is essential for buyers to understand, as it affects inventory management and cost efficiency. Knowing the MOQ helps businesses plan their purchases to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It is a critical step in the procurement process, allowing buyers to compare options and negotiate better deals. Crafting a clear RFQ ensures that suppliers understand the buyer’s needs, leading to more accurate quotes. -

Incoterms

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping goods. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, enabling smoother international transactions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the finished product. This term is crucial for B2B buyers who must align production schedules with market demands. Understanding lead times helps businesses manage their supply chains effectively and avoid production delays.

By grasping these essential properties and trade terms, international buyers can navigate the CNC machining landscape in China more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the cnc china Sector

What Are the Key Market Dynamics and Trends in the CNC China Sector?

The CNC machining sector in China is experiencing robust growth, driven by several global factors. The increasing demand for precision engineering across industries such as automotive, aerospace, and electronics is a primary driver. As manufacturers seek to enhance efficiency and reduce production costs, CNC technologies are becoming increasingly essential. Additionally, the rise of smart manufacturing and Industry 4.0 initiatives is pushing businesses to adopt advanced CNC solutions that integrate automation, IoT, and AI capabilities.

Emerging trends also indicate a shift towards customization and rapid prototyping. B2B buyers from regions like Africa, South America, and the Middle East are increasingly looking for suppliers that can offer tailored solutions to meet specific project requirements. This is particularly relevant for sectors such as construction and consumer goods, where localized manufacturing is gaining traction. Furthermore, the COVID-19 pandemic has accelerated the digital transformation in the supply chain, prompting international buyers to explore online platforms for sourcing CNC machines and components, enhancing convenience and transparency.

How Does Sustainability Influence Sourcing in the CNC China Sector?

The environmental impact of manufacturing practices is now a significant consideration for B2B buyers. Companies are increasingly prioritizing sustainability and ethical sourcing when selecting suppliers in the CNC sector. This shift is partly driven by consumer demand for environmentally responsible products and the need to comply with stringent regulations regarding emissions and waste management.

Buyers should look for suppliers that utilize sustainable materials and practices, such as recycled metals and eco-friendly machining processes. Certifications like ISO 14001 (Environmental Management) and adherence to RoHS (Restriction of Hazardous Substances) guidelines can serve as indicators of a supplier’s commitment to sustainability. Moreover, innovations in CNC technologies, such as energy-efficient machines and processes that minimize material waste, are becoming essential criteria in the sourcing decision-making process.

What Is the Historical Context of CNC Manufacturing in China?

CNC manufacturing in China has evolved significantly over the past few decades. Initially, the sector was characterized by manual machining processes and basic automation. However, the economic reforms in the late 20th century catalyzed rapid industrialization and technological advancement. By the early 2000s, China had emerged as a global manufacturing hub, leading to the establishment of numerous CNC machine manufacturers.

The country’s focus on research and development has further propelled its CNC capabilities, enabling the production of high-quality machines that meet international standards. Today, China stands as a leader in CNC technology, offering a diverse range of solutions tailored to various industries. This evolution has made it a critical sourcing destination for international B2B buyers looking for cost-effective, high-precision manufacturing solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc china

-

1. How do I ensure quality when sourcing CNC machines from China?

To ensure quality when sourcing CNC machines from China, conduct thorough research on potential suppliers. Look for manufacturers with certifications like ISO 9001, which indicates adherence to quality management standards. Request samples or product demonstrations to evaluate performance. Additionally, consider using third-party quality inspection services to verify that the machines meet your specifications before shipment. Building a relationship with your supplier and establishing clear communication about your quality expectations can also mitigate risks. -

2. What is the minimum order quantity (MOQ) for CNC machines in China?

Minimum order quantities (MOQs) can vary significantly among CNC machine manufacturers. Some suppliers may offer machines with no MOQ, especially for standardized models, while others might require a minimum order of 5-10 units for customized machines. It’s essential to discuss your specific needs with potential suppliers to understand their MOQ policies. If you are a smaller business, consider negotiating lower MOQs or looking for suppliers who cater to startups and smaller orders. -

3. What payment terms should I expect when purchasing CNC machines from China?

Payment terms for purchasing CNC machines from China typically involve a deposit followed by a balance payment upon completion of production or prior to shipment. Commonly, suppliers may ask for a 30% deposit and the remaining 70% before shipping. Some suppliers might offer flexible terms, including letters of credit or escrow services for larger orders. Always clarify payment terms upfront to avoid misunderstandings and ensure secure transactions. -

4. How can I customize CNC machines to fit my specific needs?

Most reputable CNC machine manufacturers in China offer customization options to meet specific requirements. You can request modifications in machine size, tooling, software compatibility, or additional features. Provide detailed specifications and discuss your needs with the supplier during initial conversations. It is also beneficial to ask for prototypes or mock-ups to ensure that the final product aligns with your expectations before proceeding with bulk orders. -

5. What logistics considerations should I keep in mind when importing CNC machines from China?

When importing CNC machines from China, consider logistics aspects such as shipping methods, customs duties, and delivery timelines. Choose between air freight for faster delivery or sea freight for cost-effectiveness. Ensure you understand the customs regulations in your country to avoid unexpected fees. Collaborating with a freight forwarder can streamline the process, helping you manage documentation and navigate customs requirements efficiently. -

6. How do I vet suppliers for CNC machines in China?

To vet suppliers for CNC machines in China, start by checking their business licenses, certifications, and customer reviews. Utilize platforms like Alibaba or Global Sources to find verified suppliers and read feedback from previous clients. Conduct video calls or site visits if possible to assess their production capabilities and quality control processes. Additionally, consider requesting references from other international buyers who have worked with them. -

7. What after-sales support can I expect from Chinese CNC machine manufacturers?

After-sales support can vary by manufacturer, but most reputable suppliers offer assistance such as installation guidance, training, and warranty services. Ensure that you inquire about the specifics of their support, including response times for service requests and availability of spare parts. A good supplier should provide comprehensive manuals and technical support to help you maintain and troubleshoot the machines effectively. -

8. How can I ensure timely delivery of CNC machines from China?

To ensure timely delivery of CNC machines from China, establish clear timelines with your supplier at the outset. Discuss production schedules, shipping methods, and potential delays due to customs or logistics. Regular communication is vital; request updates throughout the manufacturing and shipping process. Consider using logistics partners experienced in international shipping to minimize delays and ensure smooth delivery to your location.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc china

In today’s competitive landscape, the strategic sourcing of CNC machinery from China presents a significant opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By leveraging China’s robust manufacturing capabilities, businesses can access a diverse range of high-quality CNC machines tailored to various applications, from woodworking to metal fabrication.

Understanding the specific needs of your operation—whether it’s precision machining, rapid prototyping, or custom fabrication—enables informed purchasing decisions that align with business goals. Cost-effectiveness, combined with advanced technology and customization options, makes sourcing CNC machines from reputable Chinese manufacturers a strategic advantage.

As you consider your next procurement move, remember that building strong relationships with suppliers can lead to better pricing, timely delivery, and ongoing support. Embrace the future of manufacturing by exploring the vast possibilities that CNC technology offers. Take the first step towards optimizing your operations by reaching out to trusted Chinese CNC suppliers today and unlocking the potential for growth and innovation in your business.