Introduction: Navigating the Global Market for top 10 aftermarket auto parts companies

In the complex world of automotive repairs, sourcing quality aftermarket auto parts is a crucial challenge faced by B2B buyers globally. The aftermarket automotive industry is thriving, projected to reach $529.8 billion by 2028, driven by an increasing vehicle age and a demand for innovative solutions. However, navigating this expansive market can be daunting, especially for international buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide to the top 10 aftermarket auto parts companies aims to empower buyers by providing a clear roadmap through the nuances of sourcing, supplier vetting, and cost considerations.

Throughout this guide, we will delve into the various types of aftermarket parts available, their applications across different vehicle makes, and the key factors that distinguish reputable suppliers from the rest. Buyers will learn how to assess product quality, evaluate pricing strategies, and consider logistics for their specific regions, ensuring they make informed purchasing decisions. By highlighting the strengths and specialties of leading manufacturers, this guide equips B2B buyers with actionable insights to enhance their procurement strategies and foster long-term partnerships. Whether you are a retailer, garage owner, or fleet manager, understanding the dynamics of the aftermarket auto parts market is essential to achieving cost-effective and reliable solutions for your automotive needs.

Understanding top 10 aftermarket auto parts companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Performance Parts Manufacturers | Focus on enhancing vehicle performance; often specialize in racing or tuning parts. | Automotive racing, performance upgrades, customization | Pros: High-quality, specialized products. Cons: Higher price points, may require expertise for installation. |

| OEM Aftermarket Suppliers | Offer parts that meet original equipment manufacturer (OEM) standards, ensuring compatibility and quality. | Vehicle repairs, replacements for aging fleets | Pros: Guaranteed compatibility and reliability. Cons: Potentially higher costs compared to non-OEM options. |

| Budget-Friendly Brands | Emphasize cost-effectiveness with a wide range of basic and essential parts. | DIY repairs, small garages, budget-conscious consumers | Pros: Affordable options, good for general repairs. Cons: Quality may vary, potential for shorter lifespan. |

| E-commerce Platforms | Online retailers providing a vast selection of parts with convenient ordering and delivery options. | Direct-to-consumer sales, small business supply | Pros: Wide selection, competitive pricing, ease of access. Cons: Shipping delays, potential for miscommunication on product details. |

| Specialty Parts Suppliers | Focus on niche markets or specific vehicle types, such as electric vehicles or vintage cars. | Restoration projects, specialized vehicle repairs | Pros: Expertise in niche markets, unique products. Cons: Limited availability, potentially higher costs. |

What Are the Key Characteristics of Performance Parts Manufacturers?

Performance parts manufacturers are distinguished by their commitment to enhancing vehicle speed, handling, and overall performance. They often cater to racing enthusiasts and car tuners, providing specialized components such as exhaust systems, suspension upgrades, and engine tuning kits. For B2B buyers, it’s crucial to consider the specific needs of the vehicles being modified and the expertise required for installation, as these parts often demand professional knowledge to maximize their benefits.

How Do OEM Aftermarket Suppliers Ensure Quality and Compatibility?

OEM aftermarket suppliers produce parts that match the specifications and quality of the original manufacturer’s components. This ensures that when repairs are necessary, the replacements will fit perfectly and function reliably. B2B buyers focused on maintaining fleet vehicles or ensuring long-term reliability in repairs should prioritize these suppliers to minimize compatibility issues and enhance customer satisfaction. However, they should also be prepared for potentially higher costs associated with OEM products.

Why Are Budget-Friendly Brands Attractive to Cost-Conscious Buyers?

Budget-friendly brands appeal to a wide audience, especially DIY enthusiasts and small garages looking to manage costs. These suppliers offer a range of essential parts at lower price points, making them accessible for general repairs and maintenance. However, B2B buyers should weigh the pros and cons, as while these parts can be economically advantageous, there may be concerns regarding quality and longevity compared to higher-end options.

What Are the Benefits of E-commerce Platforms for B2B Buyers?

E-commerce platforms have revolutionized the way aftermarket auto parts are purchased, offering vast inventories and competitive pricing. They cater to both direct consumers and small businesses, making it easier to find specific parts without geographical limitations. However, B2B buyers must be cautious about shipping times and ensure clear communication regarding product specifications to avoid discrepancies that could lead to delays in repairs or projects.

How Do Specialty Parts Suppliers Cater to Niche Markets?

Specialty parts suppliers focus on unique vehicle types or specific markets, such as electric vehicles or classic car restorations. They provide expertise and products that may not be available from mainstream suppliers, making them invaluable for B2B buyers engaged in specialized repair or restoration projects. However, the limited availability and potentially higher price points for these specialized components should be considered when planning budgets and timelines.

Key Industrial Applications of top 10 aftermarket auto parts companies

| Industry/Sector | Specific Application of top 10 aftermarket auto parts companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Replacement parts for routine maintenance and repairs | Reduces downtime and enhances customer satisfaction | Quality assurance, compatibility with various vehicle makes, and timely delivery. |

| Fleet Management | Bulk procurement of durable parts for commercial vehicles | Minimizes operational costs and maximizes vehicle uptime | Volume discounts, availability of OEM and aftermarket parts, and reliable supplier relationships. |

| E-commerce Retailers | Online sales of aftermarket parts to consumers | Expands market reach and increases sales volume | E-commerce integration, product range diversity, and effective logistics solutions. |

| Electric Vehicle (EV) Services | Supply of EV components and accessories | Addresses the growing demand for sustainable solutions | Understanding of EV specifications, certifications, and technological advancements. |

| Customization & Tuning | Performance parts for vehicle enhancements | Attracts niche markets and increases customer loyalty | Access to specialized products, performance metrics, and customer support for installation. |

How Do Aftermarket Auto Parts Companies Serve Automotive Repair Shops?

Automotive repair shops frequently rely on aftermarket auto parts for routine maintenance and repairs. These parts are essential for a variety of services, from brake replacements to engine repairs. By sourcing from top aftermarket companies, repair shops can ensure they have high-quality components that meet customer demands for reliability and performance. International buyers, particularly from regions like Africa and South America, should consider the compatibility of parts with local vehicle models and the availability of support services to enhance their repair offerings.

What Benefits Do Fleet Management Companies Gain from Aftermarket Parts?

Fleet management companies benefit significantly from bulk procurement of aftermarket parts designed for commercial vehicles. These parts help reduce operational costs by minimizing vehicle downtime and ensuring that fleets remain operational. When sourcing, fleet managers should prioritize suppliers that offer volume discounts and a wide range of parts compatible with various vehicle brands. Additionally, establishing reliable relationships with manufacturers can lead to better service agreements and timely deliveries, essential for maintaining fleet efficiency.

How Do E-commerce Retailers Leverage Aftermarket Auto Parts?

E-commerce retailers tap into the growing demand for aftermarket auto parts by offering a diverse selection online. This approach allows them to reach a broader audience and increase sales volume significantly. For international buyers, particularly those in Europe, considerations such as e-commerce platform integration, shipping logistics, and product range diversity are crucial. Retailers must also ensure that they maintain competitive pricing while providing excellent customer service, including easy return policies.

What Role Do Aftermarket Parts Play in Electric Vehicle Services?

As the electric vehicle (EV) market expands, aftermarket parts suppliers are vital for providing components and accessories tailored for EVs. These parts can include batteries, charging stations, and specialized maintenance tools. Businesses in this sector must understand the unique specifications of EVs and stay updated on technological advancements to meet customer expectations. International buyers should seek suppliers with expertise in EV components to ensure they are sourcing compliant and innovative products.

How Do Customization and Tuning Applications Benefit from Aftermarket Parts?

Customization and tuning enthusiasts often turn to aftermarket parts to enhance vehicle performance and aesthetics. This sector attracts niche markets that prioritize unique modifications, such as upgraded exhaust systems or suspension kits. For businesses catering to this audience, it is essential to offer specialized products and performance metrics that appeal to consumers’ desires for personalization. Buyers should consider the availability of customer support for installation and the reputation of suppliers in the tuning community to ensure they provide high-quality options.

3 Common User Pain Points for ‘top 10 aftermarket auto parts companies’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality and Compatibility of Parts

The Problem: One of the most significant challenges faced by B2B buyers in the aftermarket auto parts sector is ensuring that the parts they order meet quality standards and are compatible with various vehicle makes and models. This concern is particularly pronounced when purchasing from international suppliers, where differences in manufacturing standards and specifications can lead to costly errors. For instance, a buyer might place a bulk order for brake pads only to find that they don’t fit the intended vehicles, resulting in wasted inventory and potential loss of customer trust.

The Solution: To mitigate this issue, B2B buyers should prioritize establishing robust communication channels with their suppliers, specifically the top aftermarket parts manufacturers. Before placing orders, engage in detailed discussions regarding part specifications, compatibility, and quality certifications. Buyers should also request samples and perform quality checks on a small batch before committing to larger orders. Utilizing platforms that provide detailed product specifications, customer reviews, and compatibility tools can further assist in making informed purchasing decisions. Additionally, buyers can benefit from building long-term relationships with a select few manufacturers known for their reliability and quality assurance processes, ensuring consistency in their supply chain.

Scenario 2: Challenges in Navigating E-commerce Platforms for Auto Parts

The Problem: With the growing trend of e-commerce in the aftermarket auto parts sector, many B2B buyers find it overwhelming to navigate various online platforms. Each site may offer different pricing, shipping options, and product ranges, making it difficult to compare and choose the best suppliers. Moreover, international buyers from regions like Africa and South America may face additional hurdles, such as language barriers and payment processing issues, which can complicate the purchasing process.

The Solution: To streamline the e-commerce purchasing experience, buyers should consider creating a systematic approach to sourcing parts online. Start by identifying a few reputable e-commerce platforms that specialize in automotive parts, focusing on those that offer user-friendly interfaces and robust customer support. Leverage features like advanced filtering options to quickly find compatible parts based on vehicle specifications. Additionally, buyers should take advantage of online forums or communities specific to automotive parts purchasing to gain insights and recommendations. Establishing a clear checklist of essential criteria—such as price, delivery time, return policies, and payment security—can further aid in making informed decisions. Lastly, consider integrating procurement software that aggregates data from various platforms, simplifying comparison shopping and order management.

Scenario 3: Managing Supply Chain Disruptions

The Problem: Supply chain disruptions can pose significant challenges for B2B buyers in the aftermarket auto parts industry, particularly when dealing with global suppliers. Factors such as geopolitical tensions, natural disasters, or even global pandemics can lead to delays in parts delivery, affecting inventory levels and ultimately customer satisfaction. A buyer may find themselves in a situation where they have a backlog of orders but cannot fulfill them due to missing parts from their suppliers.

The Solution: To effectively manage potential supply chain disruptions, B2B buyers should adopt a proactive and diversified sourcing strategy. This involves not only relying on a single supplier but establishing relationships with multiple top aftermarket parts manufacturers. By doing so, buyers can create a contingency plan where they can quickly pivot to alternative suppliers if delays occur. Implementing inventory management software that provides real-time tracking of parts orders and inventory levels can also help identify potential shortages ahead of time. Furthermore, staying informed about global supply chain trends and maintaining open lines of communication with suppliers can enable buyers to anticipate disruptions and adjust their purchasing strategies accordingly. Lastly, consider negotiating favorable terms that allow for flexibility in order quantities and delivery schedules, providing an additional buffer against unexpected delays.

Strategic Material Selection Guide for top 10 aftermarket auto parts companies

What Are the Key Materials Used by Top Aftermarket Auto Parts Companies?

When selecting materials for aftermarket auto parts, manufacturers often consider several factors, including performance, cost, and compliance with international standards. Here, we analyze four common materials used in the production of aftermarket automotive components, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Affect Performance in Aftermarket Auto Parts?

Steel is one of the most widely used materials in automotive parts due to its strength and durability. It typically has high tensile strength, making it suitable for components that must withstand significant stress, such as chassis and suspension parts. Steel exhibits excellent temperature resistance, withstanding high pressures and temperatures without deforming.

Pros: Steel is relatively inexpensive and readily available, making it a cost-effective choice for mass production. Its durability ensures long-lasting performance, which is crucial for aftermarket applications.

Cons: While steel is strong, it is prone to corrosion if not properly treated or coated. This can be a significant drawback in regions with high humidity or salt exposure, such as coastal areas in Africa and South America.

Impact on Application: Steel parts are often used in structural components, where strength is paramount. However, buyers must consider corrosion resistance treatments to ensure longevity.

Considerations for International Buyers: Compliance with standards like ASTM or DIN is essential, especially in Europe and the Middle East. Buyers should also consider local environmental conditions that may affect the performance of steel components.

What Role Does Aluminum Play in Aftermarket Auto Parts?

Aluminum is increasingly popular in automotive applications due to its lightweight nature and resistance to corrosion. It typically has a lower density than steel, which helps improve fuel efficiency in vehicles.

Pros: The lightweight characteristic of aluminum allows for better performance and fuel economy. Additionally, aluminum has excellent corrosion resistance, making it suitable for various climates.

Cons: Aluminum can be more expensive than steel, and its manufacturing processes may be more complex, potentially increasing production costs.

Impact on Application: Aluminum is commonly used in engine components, wheels, and body panels, where weight reduction is essential for performance.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure that aluminum parts meet specific standards for strength and durability, such as those outlined in JIS or DIN.

How Does Plastic Influence Aftermarket Auto Parts Design?

Plastics, particularly engineered polymers, are frequently used in automotive parts due to their versatility and lightweight properties. They can be molded into complex shapes, allowing for innovative designs in components like dashboards, interior fittings, and even some structural parts.

Pros: Plastics are generally lower in cost and can be produced quickly, making them ideal for high-volume applications. They also offer good resistance to corrosion and chemicals.

Cons: While plastics can be durable, they may not withstand high temperatures or heavy loads as well as metals, which can limit their use in certain applications.

Impact on Application: Plastics are often used in non-structural components, where weight savings and design flexibility are more critical than load-bearing capacity.

Considerations for International Buyers: Compliance with safety standards is vital, especially in regions like Europe, where regulations on materials used in vehicles can be stringent.

Why Is Rubber Essential for Aftermarket Auto Parts?

Rubber is essential for various automotive applications, particularly in sealing and vibration-damping components. It has excellent flexibility and resilience, which makes it suitable for parts like gaskets, hoses, and suspension bushings.

Pros: Rubber’s elasticity allows it to absorb shocks and vibrations, enhancing vehicle comfort and performance. It also provides effective sealing against fluids and contaminants.

Cons: Rubber can degrade over time due to exposure to heat, ozone, and certain chemicals, which may limit its lifespan in harsh environments.

Impact on Application: Rubber is crucial in applications requiring flexibility and sealing, such as in brake systems and engine components.

Considerations for International Buyers: Buyers should ensure that rubber components meet international standards for durability and chemical resistance, particularly in regions with extreme weather conditions.

Summary Table of Material Selection for Aftermarket Auto Parts

| Material | Typical Use Case for top 10 aftermarket auto parts companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis, suspension components | High strength and durability | Prone to corrosion without treatment | Low |

| Aluminum | Engine components, wheels | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Plastic | Dashboards, interior fittings | Cost-effective and versatile | Limited high-temperature performance | Low |

| Rubber | Seals, hoses, suspension bushings | Excellent flexibility and shock absorption | Degrades over time in harsh conditions | Medium |

This analysis provides valuable insights for B2B buyers in diverse markets, enabling informed decisions when selecting materials for aftermarket automotive parts.

In-depth Look: Manufacturing Processes and Quality Assurance for top 10 aftermarket auto parts companies

What Are the Main Stages of Manufacturing in Aftermarket Auto Parts Production?

The manufacturing processes employed by top aftermarket auto parts companies typically consist of several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring that the final products meet the desired specifications and quality standards.

-

Material Preparation: This initial phase involves selecting and preparing raw materials, such as metals, plastics, and composites, that meet the specifications for the intended auto parts. Suppliers often utilize advanced technologies like laser cutting and CNC machining to ensure precision in material sizing and shaping.

-

Forming: In this stage, the prepared materials undergo various forming techniques, which may include stamping, extrusion, casting, or injection molding. For example, companies like DENSO and Bosch may use injection molding to create complex components like air conditioning systems or electrical connectors. These techniques are essential for achieving the required strength and durability of the parts.

-

Assembly: After forming, components are assembled into final products. This could involve manual assembly or automated processes using robotics, which enhances efficiency and accuracy. Quality checks are often integrated into this stage to identify any defects before the products move to the finishing phase.

-

Finishing: The final stage includes surface treatments such as painting, coating, or polishing, which not only enhance the aesthetic appeal but also protect against corrosion and wear. Companies often employ advanced finishing techniques like powder coating or electroplating to ensure longevity and performance.

How Do Aftermarket Auto Parts Companies Ensure Quality Control?

Quality assurance is vital in the aftermarket auto parts industry, and leading companies adhere to international standards to maintain product integrity. Most manufacturers comply with ISO 9001, which sets the criteria for a quality management system, and other industry-specific certifications like CE for safety and environmental standards.

-

Quality Control Checkpoints: Effective quality control involves multiple checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): This involves monitoring production processes to identify and rectify any issues in real-time, ensuring that all parts are manufactured according to specifications.

– Final Quality Control (FQC): Before products are shipped, they undergo rigorous testing and inspections to verify that they meet both internal and external quality standards. -

Common Testing Methods: Various testing methods are employed to validate the quality and performance of the parts. These may include:

– Durability Testing: Simulating real-world conditions to assess the longevity of parts.

– Functional Testing: Ensuring that components function as intended within the vehicle systems.

– Compliance Testing: Verifying that products meet regulatory requirements specific to different markets, such as emissions standards or safety regulations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those operating in international markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are effective strategies to do so:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards. Audits can be performed by the buyer’s quality assurance team or through third-party inspection agencies.

-

Quality Reports: Requesting quality reports from suppliers can help buyers understand their quality management systems and recent performance metrics. Reports should include information on defect rates, testing results, and compliance with relevant standards.

-

Third-party Inspections: Engaging independent third-party inspection companies can provide unbiased assessments of a supplier’s manufacturing and quality control processes. These inspections can be particularly useful for verifying compliance with international standards and local regulations.

What Are the Quality Certification Nuances for International B2B Buyers?

Navigating quality certification nuances is crucial for international B2B buyers, as different markets may have varying standards. Here are key considerations:

-

Regional Standards: Buyers should be aware of specific regional certifications that may be required for aftermarket parts. For instance, parts sold in the European market must comply with CE marking requirements, while products in the U.S. may require adherence to SAE standards.

-

Documentation and Traceability: Ensure that suppliers provide comprehensive documentation that outlines their quality control processes, certifications, and testing results. This information is vital for establishing traceability and accountability in the supply chain.

-

Cultural and Regulatory Differences: International buyers must consider cultural and regulatory differences that may impact quality expectations. For example, suppliers in developing regions may have different approaches to quality assurance compared to those in established markets like Germany or the U.S. Understanding these nuances can help buyers make informed decisions.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices of top aftermarket auto parts companies is essential for B2B buyers seeking reliable suppliers. By focusing on the main stages of manufacturing, implementing effective quality control checkpoints, and verifying supplier practices, businesses can ensure that they procure high-quality parts that meet their operational needs. Additionally, being aware of quality certification nuances across different regions will further enhance the buyer’s ability to navigate the global aftermarket landscape successfully.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘top 10 aftermarket auto parts companies’

In the competitive landscape of the automotive aftermarket, sourcing the right parts from reputable companies is crucial for maintaining quality and reliability. This guide provides a practical checklist for B2B buyers looking to procure products from the top 10 aftermarket auto parts companies, ensuring informed decisions that align with business needs.

Step 1: Identify Your Specific Needs

Before diving into the sourcing process, clearly define what you require. This includes the types of parts needed—whether for maintenance, repair, or performance upgrades. Understanding your needs helps streamline your search and ensures you target suppliers that specialize in those areas.

- Consider vehicle compatibility: Identify the makes and models for which you need parts.

- Assess volume requirements: Determine if you need bulk orders or individual components.

Step 2: Research the Market

Conduct thorough research on the aftermarket parts market to understand trends, pricing, and the competitive landscape. This knowledge helps you identify potential suppliers who meet your quality and budget requirements.

- Utilize online resources: Leverage industry reports, forums, and reviews.

- Benchmark against competitors: See what brands and suppliers are favored by similar businesses.

Step 3: Verify Supplier Credentials

Before engaging with any supplier, it’s essential to verify their credentials. Look for certifications, industry affiliations, and compliance with international standards. This step ensures that you’re dealing with a reputable company.

- Check for ISO certifications: These indicate adherence to quality management systems.

- Look for industry recognition: Awards or endorsements from automotive associations can signal reliability.

Step 4: Evaluate Product Quality

Quality is paramount in the automotive industry. Assess the quality of parts offered by potential suppliers through samples or product specifications. High-quality parts not only ensure vehicle performance but also reduce long-term costs related to replacements and repairs.

- Request samples: Test parts for compatibility and durability.

- Review warranty terms: Strong warranty offers often indicate confidence in product quality.

Step 5: Assess Supply Chain Capabilities

A supplier’s ability to deliver on time is critical to your operations. Evaluate their logistics and distribution capabilities, including lead times, shipping methods, and inventory management.

- Inquire about stock levels: Ensure they can meet your demand without delays.

- Understand shipping processes: Familiarize yourself with their shipping partners and methods.

Step 6: Negotiate Pricing and Terms

Once you’ve identified a shortlist of suppliers, initiate discussions on pricing and contract terms. Negotiating favorable terms can significantly impact your bottom line and establish a long-term partnership.

- Discuss bulk pricing: Explore discounts for larger orders.

- Clarify payment terms: Ensure terms are aligned with your cash flow requirements.

Step 7: Establish a Communication Plan

Effective communication with your chosen supplier is vital for a successful partnership. Develop a clear plan for regular updates, order tracking, and addressing any issues that may arise.

- Set up regular check-ins: This can help preemptively address potential issues.

- Utilize digital tools: Consider using platforms for order management and communication.

By following this structured checklist, B2B buyers can make informed decisions when sourcing aftermarket auto parts, ultimately leading to successful partnerships with reputable suppliers in the global market.

Comprehensive Cost and Pricing Analysis for top 10 aftermarket auto parts companies Sourcing

What Are the Key Cost Components in Aftermarket Auto Parts Sourcing?

When sourcing aftermarket auto parts, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality raw materials tend to be more expensive but ensure durability and performance, which is crucial for aftermarket parts.

-

Labor: Labor costs vary based on the country of production. Regions with lower labor costs can offer competitive pricing, but this may sometimes compromise quality.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and factory operations. Efficient production processes can help reduce overhead costs, benefiting buyers.

-

Tooling: Initial tooling costs for manufacturing specific parts can be substantial. However, these costs are often amortized over large production runs, which can lead to lower unit prices for high-volume orders.

-

Quality Control (QC): Investing in robust QC processes ensures the reliability of parts. However, this also adds to the overall cost. Buyers should consider suppliers with strong QC measures to avoid costly returns.

-

Logistics: Transportation and shipping costs can vary widely depending on the supplier’s location and the Incoterms agreed upon. This is especially relevant for international buyers who must navigate customs and import duties.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the typical margins in the aftermarket parts industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Aftermarket Auto Parts Costs?

Several factors influence the pricing of aftermarket auto parts:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Establishing a minimum order quantity (MOQ) can also provide leverage in negotiations.

-

Specifications/Customization: Customized parts may incur additional costs due to unique tooling and manufacturing processes. Buyers should evaluate whether customization is necessary for their needs.

-

Materials and Quality Certifications: Parts that meet stringent quality certifications (e.g., ISO, TS) may cost more but provide assurance regarding performance and reliability.

-

Supplier Factors: The reputation, reliability, and production capabilities of suppliers significantly influence pricing. Established brands may command higher prices due to perceived quality.

-

Incoterms: Understanding the agreed-upon Incoterms can help buyers anticipate additional costs related to shipping, insurance, and duties.

What Buyer Tips Can Help Achieve Cost Efficiency in International Sourcing?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Many suppliers are willing to negotiate to secure long-term contracts.

-

Evaluate Total Cost of Ownership: Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and potential failures. Investing in higher-quality parts can lead to lower overall costs.

-

Research Market Prices: Keep abreast of market trends and average prices for aftermarket parts. This knowledge can be instrumental in negotiation.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce shipping costs and lead times, particularly for buyers in regions with developing automotive markets.

-

Utilize Online Platforms: Leverage e-commerce platforms that specialize in aftermarket parts. These platforms often provide competitive pricing and allow for easy price comparisons.

Are There Any Price Disclaimers Buyers Should Be Aware Of?

It is crucial for buyers to note that prices can fluctuate based on market conditions, availability, and geopolitical factors. Therefore, while indicative prices can provide a baseline for negotiations, they should always be confirmed with suppliers. Engaging in thorough due diligence and maintaining open communication with suppliers will ensure a more favorable sourcing experience.

Alternatives Analysis: Comparing top 10 aftermarket auto parts companies With Other Solutions

Understanding Alternatives in the Aftermarket Auto Parts Sector

In the dynamic landscape of the automotive aftermarket, businesses often face the challenge of selecting the most suitable solutions for their needs. While the top 10 aftermarket auto parts companies provide a reliable source for parts, several alternative approaches can also meet various requirements. This analysis compares these leading manufacturers with two viable alternatives: OEM (Original Equipment Manufacturer) Parts and DIY (Do-It-Yourself) Repair Solutions. Each of these alternatives offers distinct advantages and potential drawbacks that can influence a buyer’s decision.

Comparison Table

| Comparison Aspect | Top 10 Aftermarket Auto Parts Companies | OEM Parts | DIY Repair Solutions |

|---|---|---|---|

| Performance | High reliability and variety | Best fit and performance | Variable; depends on skill |

| Cost | Competitive pricing, but varies by brand | Generally higher cost | Cost-effective for basic repairs |

| Ease of Implementation | Easy to order online or in-store | Requires specific sourcing | High learning curve, requires tools |

| Maintenance | Ongoing support and warranty options | Limited to manufacturer | Self-managed; can be time-consuming |

| Best Use Case | General repairs and customizations | Specific vehicle repairs | Simple repairs, personal projects |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of OEM Parts?

OEM parts are designed and manufactured by the original vehicle manufacturers. Their primary advantage lies in their perfect compatibility with specific vehicle models, ensuring optimal performance and reliability. However, this comes at a premium cost, often making OEM parts significantly more expensive than aftermarket options. Additionally, sourcing OEM parts can be cumbersome, requiring buyers to engage directly with dealerships or certified suppliers, which may not always be feasible, especially in emerging markets.

How Do DIY Repair Solutions Compare?

DIY repair solutions empower car owners to tackle repairs and maintenance tasks themselves, often resulting in substantial cost savings. This approach is particularly appealing for those with basic mechanical skills, as it allows for greater flexibility and control over the repair process. However, the effectiveness of DIY solutions heavily depends on the individual’s skill level and access to proper tools. For complex repairs, the learning curve can be steep, and mistakes can lead to further issues or additional costs.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating aftermarket auto parts companies against alternatives like OEM parts and DIY solutions, B2B buyers must consider their specific requirements, such as budget, vehicle type, and technical expertise. Top aftermarket companies are ideal for businesses seeking reliable, diverse parts with comprehensive support, while OEM parts are better suited for those prioritizing compatibility and performance. Conversely, DIY solutions can be an economical choice for skilled individuals willing to invest time and effort into repairs. Ultimately, understanding these options will empower buyers to make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for top 10 aftermarket auto parts companies

What Are the Key Technical Properties That B2B Buyers Should Consider for Aftermarket Auto Parts?

In the competitive landscape of aftermarket auto parts, understanding technical specifications is crucial for B2B buyers. Here are several critical properties that should be evaluated:

-

Material Grade

– Definition: The classification of materials based on their mechanical properties, such as tensile strength, ductility, and corrosion resistance.

– B2B Importance: Selecting the right material grade ensures durability and performance, particularly for components exposed to harsh conditions. Buyers must align material specifications with the intended use of the parts to avoid premature failures. -

Tolerance

– Definition: The allowable variation in a physical dimension or property of a part, typically expressed in units of measurement.

– B2B Importance: Tolerance affects how well parts fit and function together. For instance, tighter tolerances can lead to better performance in precision applications, making it vital for buyers to understand the tolerances of parts to ensure compatibility with existing systems. -

Finish Type

– Definition: The surface treatment applied to a part, which can include coatings, polishing, or plating.

– B2B Importance: The finish type can influence the part’s aesthetic appeal, corrosion resistance, and friction characteristics. Buyers should consider the operating environment when selecting finish types to enhance longevity and performance. -

Load Capacity

– Definition: The maximum load that a component can safely support during operation.

– B2B Importance: Understanding load capacity is essential for safety and functionality, particularly in suspension or structural components. Buyers must ensure that the parts can handle the expected loads to prevent failures. -

Lifecycle and Warranty

– Definition: The expected operational lifespan of a part and the warranty coverage provided by the manufacturer.

– B2B Importance: A longer lifecycle coupled with a robust warranty can significantly reduce total cost of ownership. B2B buyers should assess these factors to minimize replacement frequency and associated costs.

What Are Common Trade Terms in the Aftermarket Auto Parts Industry?

Familiarity with industry jargon can enhance communication and negotiation between B2B buyers and suppliers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts that are used in the manufacturing of a vehicle and are often sold under the vehicle manufacturer’s brand.

– Importance: Understanding OEM parts is vital for buyers seeking quality and compatibility. OEM parts are typically associated with higher reliability compared to generic alternatives. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers manage inventory levels and budget constraints. It can also influence purchasing decisions, especially for smaller businesses. -

RFQ (Request for Quotation)

– Definition: A formal request from a buyer to suppliers to provide pricing and terms for specific products or services.

– Importance: An RFQ is crucial for comparing suppliers and negotiating terms. It allows buyers to gather competitive offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of buyers and sellers in the delivery of goods.

– Importance: Understanding Incoterms is critical for international transactions. They clarify who is responsible for shipping costs, insurance, and risks, reducing the potential for disputes. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the goods.

– Importance: Lead time impacts inventory management and project timelines. Buyers need to factor in lead times when planning purchases to avoid disruptions in their operations.

By grasping these essential technical properties and trade terminology, B2B buyers in regions like Africa, South America, the Middle East, and Europe can make informed decisions when selecting aftermarket auto parts, ensuring they meet their operational needs efficiently.

Navigating Market Dynamics and Sourcing Trends in the top 10 aftermarket auto parts companies Sector

What Are the Key Market Dynamics and Trends Shaping the Aftermarket Auto Parts Industry?

The global aftermarket auto parts market has been experiencing robust growth, projected to reach approximately $529.8 billion by 2028, driven by several key factors. The increasing average age of vehicles, particularly in developed markets like Europe and North America, creates heightened demand for replacement parts. In regions like Africa and South America, rapid urbanization and a growing vehicle population contribute significantly to market expansion.

Emerging technologies, such as e-commerce platforms, are transforming how B2B buyers source parts. Online sales accounted for $57 billion in 2022, and this trend is expected to continue, offering international buyers the convenience of comparing prices and accessing a broader range of products. Furthermore, the rise of electric vehicles (EVs) is reshaping the aftermarket landscape, presenting new opportunities for suppliers of battery and charging components, with the EV aftermarket projected to reach $50 billion by 2030.

B2B buyers should also pay attention to the growing emphasis on digital tools and platforms that facilitate real-time inventory management and order tracking. These technologies are critical for optimizing supply chain efficiency and enhancing customer satisfaction, particularly for international buyers who face logistical challenges.

How Is Sustainability Influencing Sourcing Decisions in the Aftermarket Auto Parts Sector?

Sustainability has become a pivotal concern in the aftermarket auto parts industry, influencing sourcing decisions for B2B buyers. The environmental impact of automotive parts production and disposal has prompted companies to adopt more sustainable practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability through ethical sourcing, reduced carbon footprints, and responsible waste management.

Top aftermarket companies are actively pursuing ‘green’ certifications, such as ISO 14001, which indicates a commitment to effective environmental management systems. Additionally, the use of eco-friendly materials in manufacturing processes is gaining traction. For instance, parts made from recycled materials not only help reduce waste but also appeal to environmentally-conscious consumers and businesses alike.

B2B buyers from regions such as Europe, known for stringent environmental regulations, should focus on suppliers that align with these values. Ethical supply chains are becoming a standard expectation rather than a competitive advantage, and buyers that prioritize sustainability can enhance their brand reputation and meet regulatory requirements.

What Is the Historical Context Behind the Growth of the Aftermarket Auto Parts Industry?

The aftermarket auto parts industry has evolved significantly over the decades, driven by technological advancements and changing consumer preferences. Initially focused on basic replacement parts, the sector has shifted towards more sophisticated components, including those for electric and hybrid vehicles. The growth of e-commerce has also transformed the landscape, allowing for greater accessibility and convenience in sourcing parts.

As the automotive industry continues to innovate, particularly with the rise of autonomous and electric vehicles, the aftermarket sector is poised for further evolution. B2B buyers must stay informed about these changes to effectively navigate sourcing decisions and align with the latest market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of top 10 aftermarket auto parts companies

-

How do I choose the right aftermarket auto parts supplier for my business?

Selecting the right aftermarket auto parts supplier involves assessing several key factors. Start by evaluating the supplier’s reputation within the industry, including customer reviews and their experience in the market. Check their product range to ensure they offer parts compatible with the vehicles your customers need. Additionally, consider their pricing, minimum order quantities (MOQs), and payment terms. Establishing a strong communication channel for ongoing support and product knowledge is also crucial for a successful partnership. -

What are the benefits of sourcing from top aftermarket auto parts manufacturers?

Sourcing from top aftermarket auto parts manufacturers can provide numerous advantages, including higher product quality, reliability, and better warranty terms. These manufacturers typically invest in advanced technologies and materials, which can lead to enhanced performance and durability of the parts. Furthermore, established brands often have robust supply chains, ensuring timely deliveries and consistent availability of parts, which is essential for minimizing downtime in your operations. -

What should I know about international shipping and logistics for auto parts?

When dealing with international shipping of auto parts, it’s important to understand customs regulations, tariffs, and shipping costs that can affect your overall budget. Ensure your supplier has experience in exporting to your country and can handle the necessary documentation. Evaluate the shipping methods they offer, considering factors like delivery time and reliability. Additionally, inquire about insurance options for shipments to protect against potential losses during transit. -

What are the common payment terms offered by aftermarket parts suppliers?

Payment terms can vary significantly among aftermarket parts suppliers. Common options include advance payment, net 30 or net 60 days, and letters of credit for larger orders. Some suppliers may also offer discounts for early payments or bulk purchases. It’s vital to discuss and agree on payment terms upfront to avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure quality assurance (QA) when sourcing auto parts?

To ensure quality assurance when sourcing auto parts, request detailed specifications and certifications from your suppliers. Look for manufacturers that adhere to international standards, such as ISO certification. Implement a quality control process that includes regular inspections and testing of the parts upon arrival. Building a strong relationship with your supplier can also facilitate transparency regarding quality practices and any potential issues that may arise. -

What customization options are typically available for aftermarket auto parts?

Many aftermarket auto parts suppliers offer customization options to meet specific business needs. This can include modifications to size, color, or material based on your customer preferences. Some suppliers may also provide branding opportunities, allowing you to label parts with your company logo. It’s important to discuss customization capabilities with potential suppliers early in the negotiation process to ensure they can meet your requirements. -

What are the advantages of online sourcing for aftermarket auto parts?

Online sourcing for aftermarket auto parts offers significant advantages, including a broader selection of products and competitive pricing. It allows for easy comparison of different suppliers and their offerings, facilitating informed purchasing decisions. Moreover, many online platforms provide user-friendly interfaces for bulk ordering, tracking shipments, and managing inventory. This convenience can lead to improved operational efficiency and cost savings for your business. -

How do I vet potential suppliers in the aftermarket auto parts industry?

Vetting potential suppliers in the aftermarket auto parts industry involves thorough research and due diligence. Start by checking their business credentials, including registration and licenses. Review customer testimonials and case studies to gauge their reliability and service quality. Conduct interviews or meetings to discuss their production capabilities, lead times, and responsiveness. Additionally, consider requesting samples to assess product quality before committing to larger orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

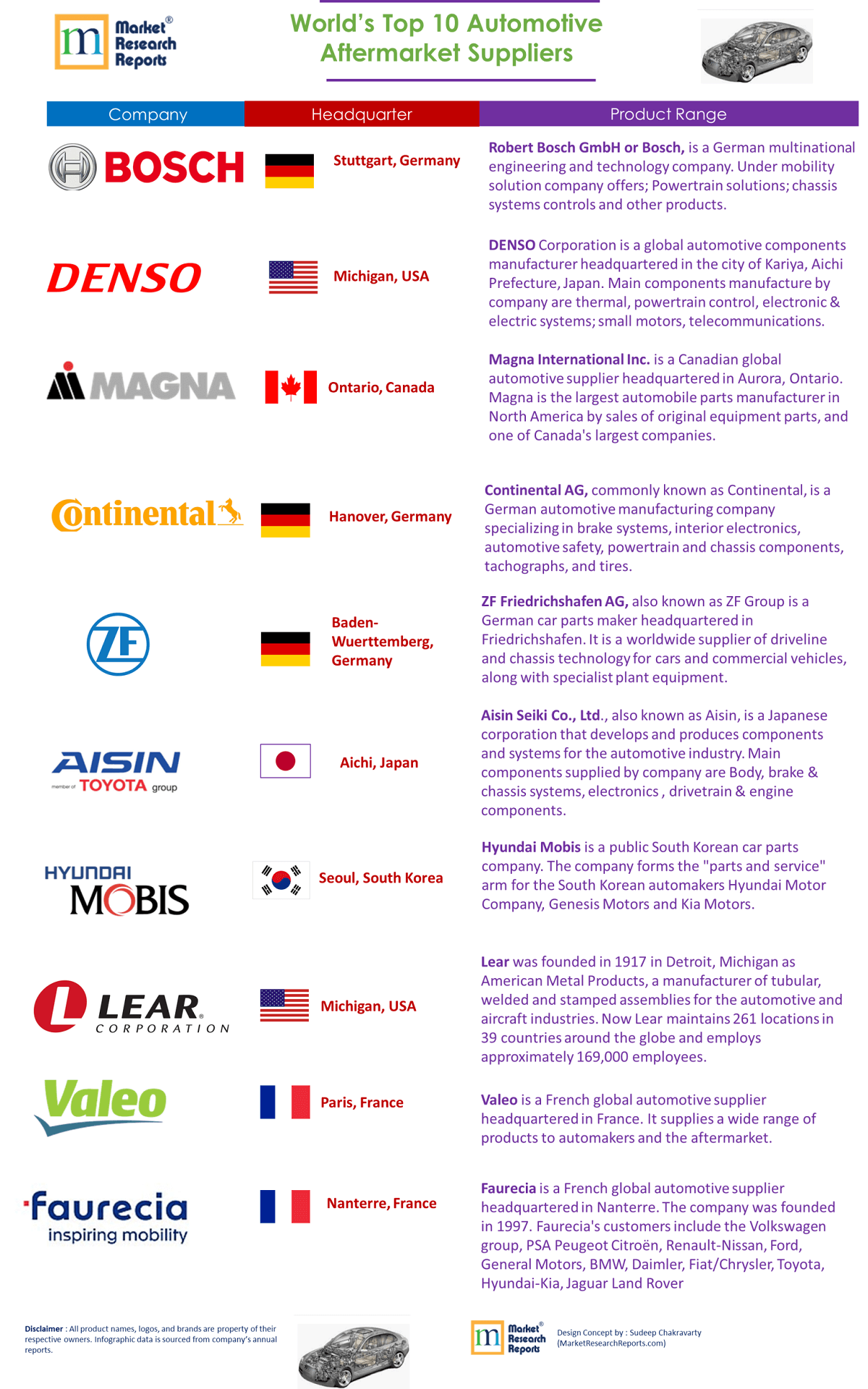

Top 5 Top 10 Aftermarket Auto Parts Companies Manufacturers & Suppliers List

1. Aftermarket Parts – Key Manufacturers and Products

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Aftermarket parts manufacturers mentioned include: Rockauto, Delphi, Spectra, Bosch, AC Delco, Motorcraft, Hawk, Centric, Motul, Powerstop, Moog, Gabriel, Monroe, KYB, and AST. Specific product types referenced are brakes (Brembo, Powerstop), suspension (Moog), shocks/struts (Gabriel, Monroe, KYB), and fluids (Motul). Users express trust in brands based on quality, cost, and reputation.

2. Auto Parts Giants – Daily Market Rankings

Domain: companiesmarketcap.com

Registered: 2020 (5 years)

Introduction: This company, Auto Parts Giants – Daily Market Rankings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Magna International – Powertrain Systems

Domain: mordorintelligence.com

Registered: 2013 (12 years)

Introduction: Top 5 United States Aftermarket Automotive Parts & Components Companies: 1. Magna International Inc. – Specializes in powertrain and chassis systems, focuses on innovation and R&D. 2. Continental AG – Known for electronic and safety components, advanced sensor and software integration. 3. ZF Friedrichshafen AG – Expertise in driveline, transmission, and safety systems, growth in electrified and au…

4. JEGS – Aftermarket Auto Parts

Domain: jegs.com

Registered: 1996 (29 years)

Introduction: JEGS Aftermarket Auto Parts & High Performance Racing & Replacement Accessories Online. Promotions: $5 off $49, $15 off $249, $30 off $499, $65 off $999 with promo code CLASSICS. Free Shipping over $199, Same Day Shipping before 10pm, Price Match Guarantee. Categories include: Brakes & Drivetrain, Engines & Components, Exhaust Systems, Fuel, Carbs & Intakes, Ignition & Electrical, Restoration Part…

5. Auto Parts & OEM Stocks – Key Investments

Domain: fool.com

Registered: 1995 (30 years)

Introduction: This company, Auto Parts & OEM Stocks – Key Investments, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for top 10 aftermarket auto parts companies

How Can Strategic Sourcing Enhance Your Auto Parts Procurement?

In navigating the dynamic landscape of the aftermarket auto parts industry, strategic sourcing emerges as a critical factor for B2B buyers aiming to optimize their supply chains. By engaging with the top 10 manufacturers—such as Bosch, DENSO, and COWTOTAL—buyers can leverage their extensive product ranges, innovative technologies, and competitive pricing structures. Understanding the strengths and specialties of these companies allows for informed decisions that can lead to enhanced product reliability and customer satisfaction.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize establishing strong partnerships with these leading manufacturers. This will not only ensure access to high-quality components but also facilitate better negotiation terms and supply chain efficiencies. As the automotive aftermarket continues to grow, especially with the rise of electric vehicles and online sales, the importance of sourcing strategies will only increase.

Looking ahead, now is the opportune moment to reassess your sourcing strategies. Embrace the potential of these top manufacturers to stay ahead in a competitive market. Take action today to secure your position as a leader in the aftermarket auto parts sector.