Contents

Manufacturing Insight: Tooling Steel Grades

Tooling Steel Grades Selection for Precision CNC Machined Components

Selecting the appropriate tooling steel grade is a critical engineering decision that directly impacts component longevity, dimensional stability, and performance under operational stress. At Honyo Prototype, we specialize in machining high-performance tool steels—including D2, A2, H13, S7, and M2—each chosen for specific attributes such as wear resistance, toughness, thermal stability, and machinability. Our advanced CNC machining capabilities, including multi-axis milling and precision turning, are optimized to handle the unique challenges posed by these hardened alloys, ensuring tight tolerances down to ±0.0002″ and superior surface finishes critical for dies, molds, and industrial tooling.

Our engineering team collaborates with clients to validate material suitability against application requirements, mitigating risks like premature tool failure or thermal deformation. This expertise, combined with in-house heat treatment coordination and rigorous quality control, guarantees components that meet exacting industry standards. For rapid project initiation, leverage Honyo’s Online Instant Quote system to receive detailed machining cost and lead time estimates within minutes—simply upload your CAD file and specify material requirements. Accelerate your prototyping or production timeline with precision-engineered solutions backed by decades of metallurgical and machining proficiency.

Technical Capabilities

Tooling Steel Grades for High-Precision Machining Applications

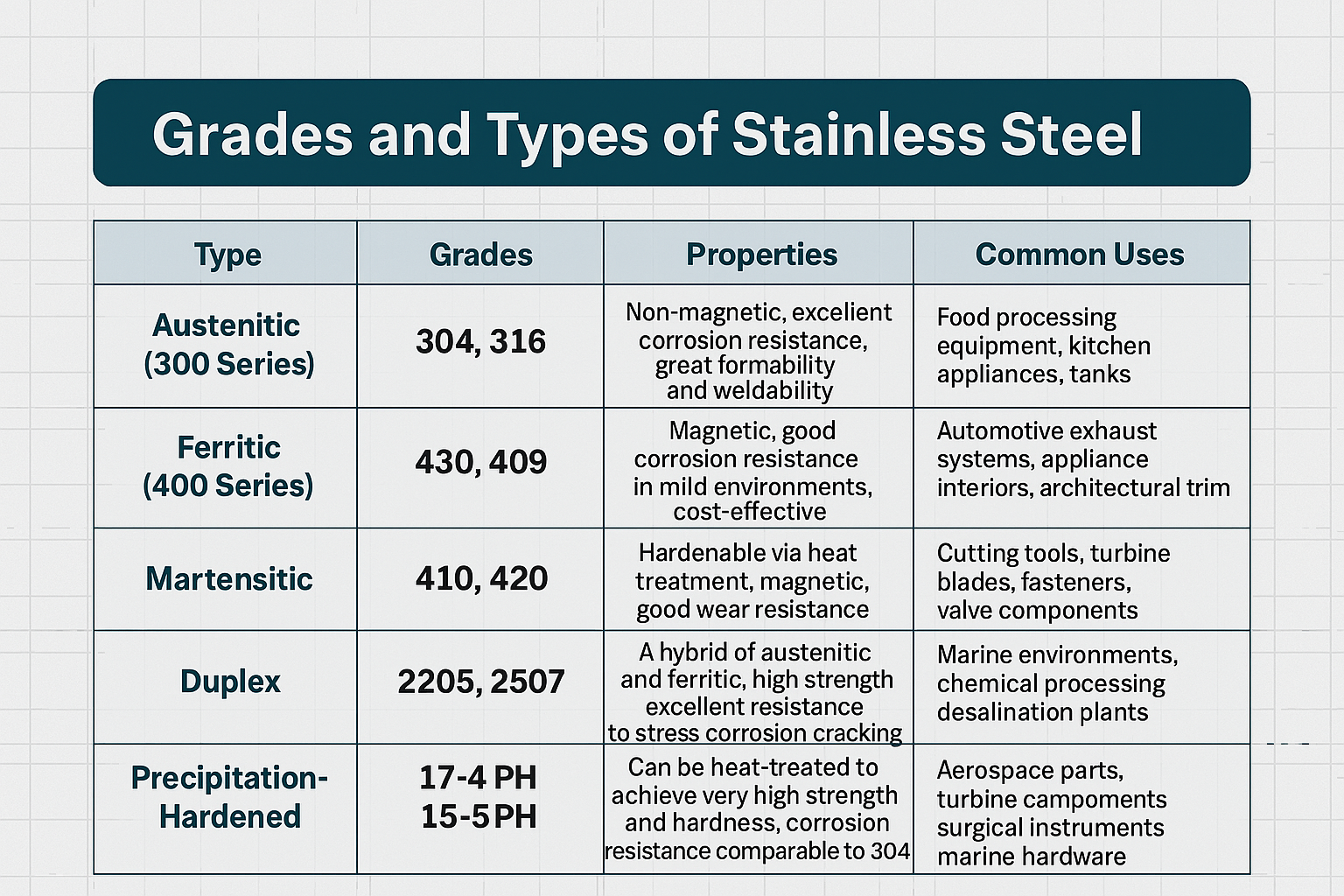

When selecting tooling steel grades for 3/4/5-axis milling and turning operations involving tight tolerance components, material compatibility, wear resistance, thermal stability, and machinability are critical factors. The chosen steel grade must support extended tool life, maintain dimensional accuracy, and withstand the mechanical and thermal loads encountered when machining materials such as aluminum, steel, ABS, and nylon. Below is a comparison of common tooling steel grades used in precision manufacturing environments.

| Steel Grade | Hardness (HRC) | Key Properties | Machining Suitability – Aluminum | Machining Suitability – Steel | Machining Suitability – ABS | Machining Suitability – Nylon | Recommended Use in 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|---|---|

| H13 (Hot Work) | 48–52 | High toughness, excellent thermal fatigue resistance, good machinability after heat treatment | Excellent – low adhesion, resists built-up edge | Good – suitable for intermittent cutting, moderate wear resistance | Excellent – minimal residue, clean cuts | Excellent – low friction, heat control | Ideal for high-speed milling of aluminum molds and inserts; good for interrupted cuts in steel |

| 4140 (Low-Alloy) | 28–32 (annealed), up to 45 (heat treated) | Good strength, toughness, and dimensional stability | Good – adequate for general-purpose tooling | Fair – limited wear resistance under high loads | Good – stable for fixturing and prototypes | Good – low cost, adequate for non-abrasive plastics | Suitable for jigs, fixtures, and moderate-precision turning; pre-hardened versions reduce post-machining distortion |

| 4340 (Aircraft Grade) | 30–36 (annealed), up to 50 (heat treated) | High tensile strength, good fatigue resistance, deep hardening | Fair – prone to galling with aluminum without coatings | Good – effective for high-stress tool components | Fair – overkill for pure plastic applications | Fair – adequate, but higher cost | Recommended for high-strength tool bodies and aerospace-related precision tooling |

| A2 (Tool Steel) | 58–60 | High wear resistance, good dimensional stability, moderate toughness | Good – with proper coating or polishing | Good – excellent for forming and blanking tools | Excellent – clean edge retention | Excellent – low wear with abrasive fillers | Preferred for long-run tooling, gauges, and tight-tolerance fixtures in multi-axis setups |

| S7 (Shock-Resistant) | 48–52 | High impact resistance, good thermal conductivity | Good – suitable for high-feed milling | Fair – less wear resistance than D2 or A2 | Good – durable for repetitive plastic tooling | Good – handles cyclic loading | Best for chisels, ejector pins, and high-impact tooling in automated turning cells |

| D2 (High-Carbon, High-Chromium) | 58–62 | Exceptional wear resistance, high compressive strength | Poor – high adhesion with aluminum, prone to built-up edge | Excellent – ideal for hard milling and finishing | Good – good for long production runs | Good – handles glass-filled grades | Used in precision dies and wear plates; not recommended for aluminum without PVD coating |

Notes on Material Compatibility:

Aluminum: Sticky material requiring low-adhesion surfaces. H13 and A2 (with TiN or similar coating) are preferred. D2 should be avoided unless coated.

Steel: Demands high wear and thermal resistance. A2, D2, and H13 perform well in finishing and semi-finishing operations.

ABS & Nylon: Less demanding thermoplastics, but glass-filled variants increase abrasiveness. A2 and 4140 offer cost-effective durability.

Tight Tolerance Requirements: A2 and H13 are most commonly used due to their dimensional stability post-heat treatment and ability to hold ±0.0005” (12.7 µm) tolerances in multi-axis environments.

For optimal performance in 3/4/5-axis CNC operations, pre-hardened steels like H13 and A2 are often selected to minimize post-machining distortion, ensuring high repeatability and surface finish integrity.

From CAD to Part: The Process

Honyo Prototype’s Tooling Steel Grade Integration Process

Honyo Prototype executes a rigorously controlled workflow for tooling steel grade selection and implementation, ensuring material properties align precisely with functional requirements. This process begins upon CAD file submission and extends through final validation, with steel grade integrity maintained at every phase.

Upload CAD Phase

Upon receiving the customer’s CAD model, Honyo’s system initiates automated material requirement analysis. Critical parameters such as part geometry, thermal exposure, load conditions, and surface finish specifications are extracted. For tooling applications (e.g., injection molds, stamping dies), the system flags high-stress or wear-prone features requiring specific steel grades like H13, S7, or 420SS. This pre-analysis ensures steel grade considerations are embedded before quoting.

AI-Powered Quoting Phase

Honyo’s proprietary AI engine evaluates the CAD geometry against its material science database, generating a preliminary steel grade recommendation. The algorithm cross-references factors including:

Required hardness (e.g., 50–54 HRC for wear resistance)

Machinability constraints (e.g., P20 for complex cavities)

Thermal stability needs (e.g., H13 for high-temp molding)

Corrosion exposure (e.g., 420SS for medical molds)

The quote details the recommended grade, rationale, and cost implications of alternatives, providing transparent technical justification.

DFM Validation Phase

During Design for Manufacturability review, Honyo’s engineering team conducts a steel-specific audit:

Verifying recommended grade suitability against part topology (e.g., thin ribs requiring pre-hardened P20 to avoid distortion)

Identifying potential hardening-induced deformation risks in critical zones

Confirming compatibility with secondary processes (e.g., EDM suitability for tool steels)

Validating grade compliance with industry standards (e.g., AISI, ISO 4957)

Steel grade finalization occurs here, documented in the DFM report with material substitution options if requested.

Production Execution Phase

Material procurement strictly adheres to the DFM-approved grade. All tool steel ingots undergo:

Mill certificate verification (chemical composition, heat treatment history)

Incoming hardness testing (Rockwell C scale)

Ultrasonic testing for internal defects (critical for large mold bases)

Machining parameters are dynamically adjusted per steel properties (e.g., reduced feed rates for hardened H13). Post-machining, stress-relief annealing is performed per grade-specific protocols to prevent in-service failure.

Delivery and Documentation Phase

Final delivery includes comprehensive material traceability:

Certified mill test reports for each steel component

Hardness verification certificates at designated locations

Heat treatment records (austenitizing temperature, quench medium, temper cycles)

Dimensional validation against as-machined tolerances (±0.005mm typical for tooling)

This documentation package ensures compliance with aerospace, automotive, or medical tooling standards (e.g., NADCAP, ISO 9001).

Critical Steel Grade Selection Matrix

The following table illustrates Honyo’s standard grade recommendations based on application drivers:

| Application Requirement | Recommended Steel Grade | Key Properties | Typical Hardness Range |

|---|---|---|---|

| High thermal fatigue resistance | H13 | Chromium-molybdenum alloy, excellent toughness | 48–52 HRC |

| Complex geometry, moderate wear | P20 (Pre-hardened) | Good machinability, uniform hardness | 28–32 HRC |

| Corrosive environments | 420 Stainless | High chromium content, corrosion-resistant | 48–52 HRC |

| Heavy impact loading | S7 | Shock resistance, minimal distortion | 52–56 HRC |

| Precision wear components | D2 | High carbon-chromium, abrasive resistance | 58–62 HRC |

This integrated approach ensures tooling steel grades are not merely selected but engineered into the solution, minimizing field failures and maximizing tool life. Honyo maintains a 98.5% first-pass yield rate for steel-critical tooling projects through this validated workflow.

Start Your Project

Learn more about our precision tooling steel grades engineered for high-performance prototyping and production applications.

Contact Susan Leo at [email protected] to request technical specifications, material certifications, or custom solutions tailored to your project requirements.

Manufactured with precision at our Shenzhen factory, our tooling steel grades ensure superior durability, dimensional accuracy, and consistency for demanding industrial applications.

Reach out today to discuss your next project with Honyo Prototype’s materials engineering team.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.