Contents

Manufacturing Insight: Tooling Machine

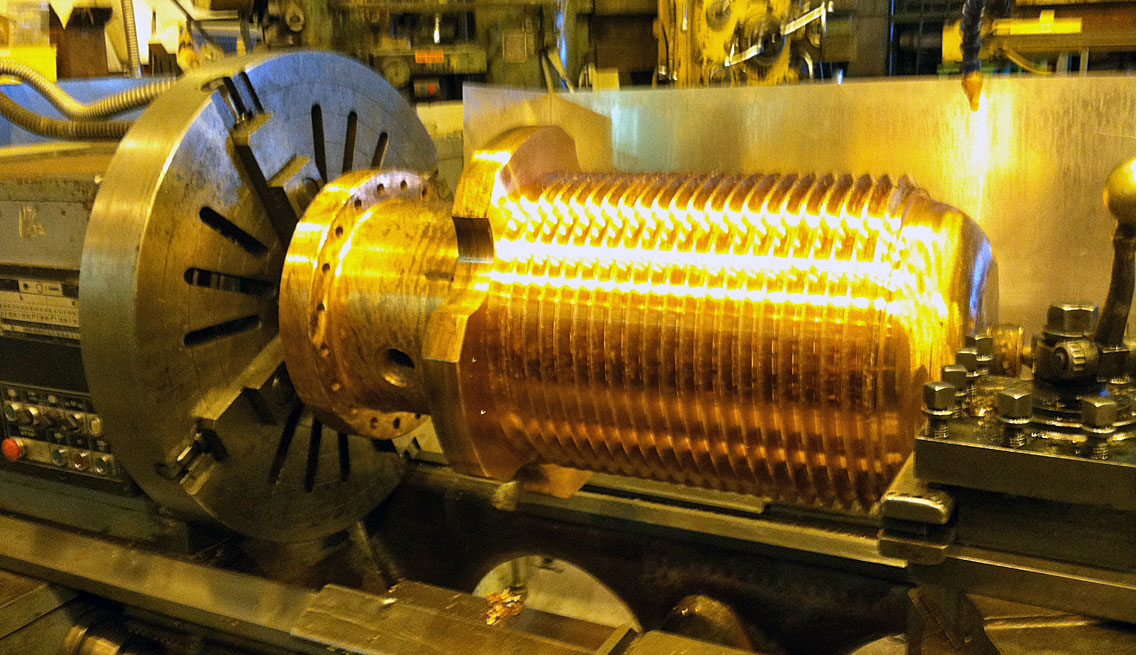

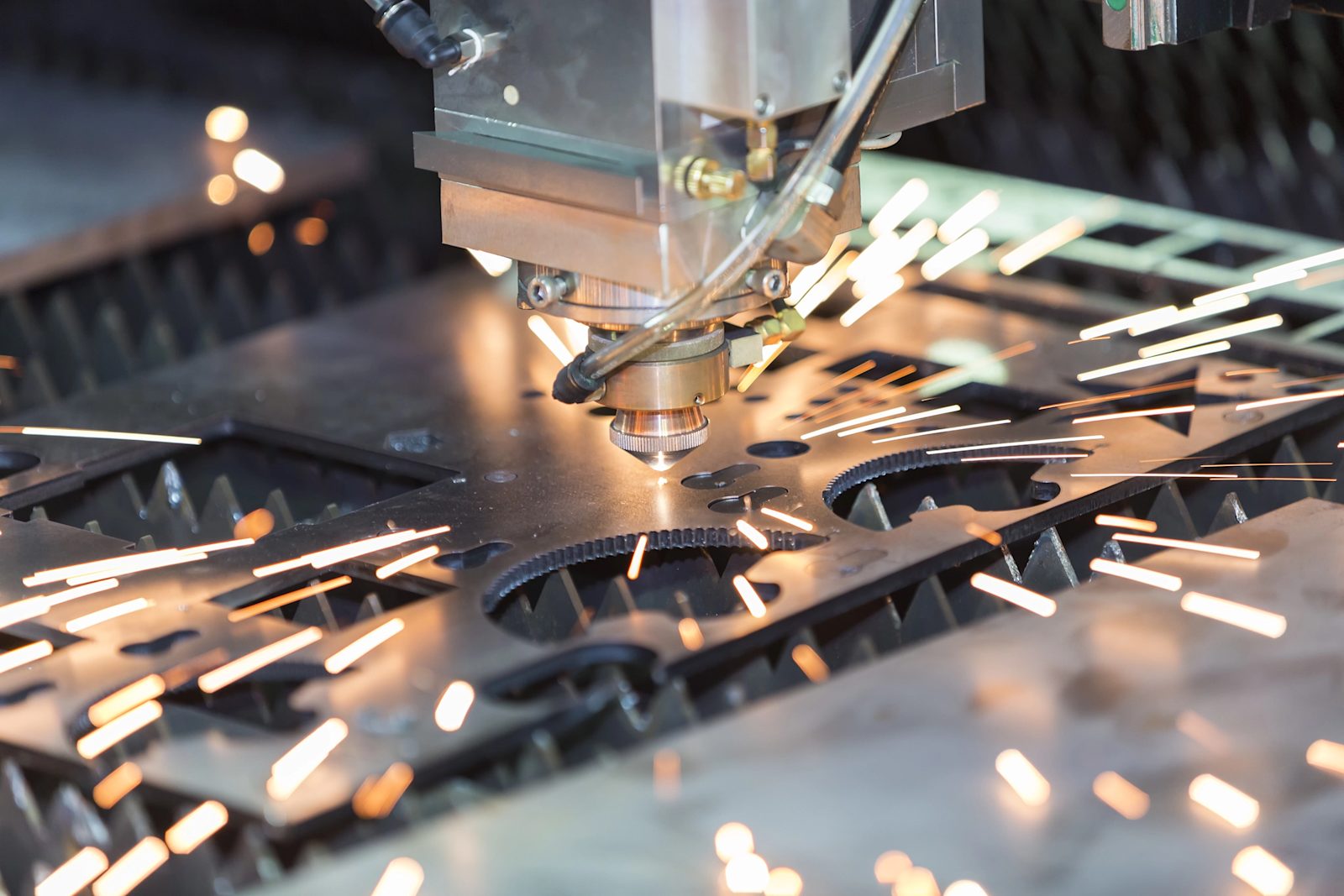

Precision Tooling Solutions Through Advanced CNC Machining

At Honyo Prototype, we specialize in high-integrity CNC machining services engineered specifically for demanding tooling applications. Our expertise spans the production of precision molds, dies, jigs, fixtures, and other critical tooling components where micron-level accuracy and material resilience directly impact your production efficiency and part quality. Leveraging state-of-the-art multi-axis CNC systems—including 5-axis milling and turning centers—we consistently achieve tolerances down to ±0.0002″ across challenging materials like hardened tool steels, aluminum alloys, and high-temperature composites.

Our process integrates rigorous DFMA (Design for Manufacturing and Assembly) analysis with real-time in-process inspection, ensuring tooling performs reliably under high-cycle production environments. This reduces downtime, minimizes scrap rates, and extends tool life—translating directly to your bottom line. For rapid project initiation, our Online Instant Quote platform delivers validated pricing and lead times in under 60 seconds. Simply upload your CAD file, specify materials and quantities, and receive a production-ready quotation without manual intervention—accelerating your time-to-market for critical tooling programs.

Partner with Honyo to transform complex tooling requirements into optimized, field-proven assets with the speed and precision modern manufacturing demands.

Technical Capabilities

Technical specifications for a high-precision tooling machine designed for demanding prototyping and low-volume production applications are critical to ensure tight tolerances, surface quality, and material compatibility. The following table outlines key technical capabilities for a multi-axis CNC machine platform capable of 3, 4, and 5-axis milling as well as precision turning operations.

| Specification | Detail |

|---|---|

| Machine Type | 5-Axis CNC Milling and Turning Center (with optional 3 and 4-axis modes) |

| Axis Configuration | Dual rotary tables (A and C axes) or tilting rotary head with trunnion table; full simultaneous 5-axis motion |

| Spindle Speed | 24,000 RPM (high-speed ceramic bearings, through-coolant option) |

| Positioning Accuracy | ±0.002 mm (±0.00008″) |

| Repeatability | ±0.001 mm (±0.00004″) |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical for critical features; down to ±0.002 mm with process optimization |

| Tool Changer | Automatic Tool Changer (ATC) with 30-tool capacity; HSK-63 or CAT-40 interface |

| Control System | Fanuc 31i-B5, Siemens 840D, or Heidenhain TNC7 |

| Rapid Traverse (X/Y/Z) | 40 m/min |

| Surface Finish | As low as 0.4 µm Ra (machined), down to 0.2 µm Ra with finishing passes |

| Work Envelope (Max) | 700 x 500 x 400 mm (X/Y/Z) |

| Turning Capability | Live tooling with C-axis contouring; sub-spindle for backworking |

| Cooling/Lubrication | High-pressure coolant (70 bar), minimal quantity lubrication (MQL) option |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (PA6, PA66), and other engineering plastics |

| Fixturing | Modular fixturing systems compatible with tombstones and vacuum chucks for plastic materials |

| Probing System | On-machine 3D touch probe for in-process inspection and tool setting |

| Application Focus | Precision tooling, molds, fixtures, aerospace components, medical devices, and high-complexity prototypes |

This machine platform is engineered for tight-tolerance machining across a wide range of materials. Aluminum and steel components benefit from high rigidity and thermal compensation, while engineered thermoplastics such as ABS and Nylon are machined using optimized feed rates, sharp tooling, and MQL to prevent melting or deformation. The integration of multi-axis milling and turning enables complex geometries to be completed in a single setup, reducing cumulative error and improving dimensional consistency.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for custom tooling machine production, designed to maximize efficiency, minimize risk, and ensure seamless client collaboration from concept to delivery. Our process integrates advanced digital tools with deep manufacturing expertise, structured into five critical phases as outlined below.

CAD Upload and Project Initiation

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs an immediate automated validation check for file integrity, unit consistency, and geometric completeness. This step ensures manufacturability data is captured upfront, eliminating delays from incompatible or corrupted files. Project managers assign a unique tracking ID and confirm receipt within one business hour, establishing clear communication channels.

AI-Powered Preliminary Quoting

Within 24 hours of validated CAD receipt, our proprietary AI engine generates a comprehensive preliminary quote. This system analyzes over 200 geometric and material parameters—including part complexity, feature density, tolerance stringency, and material utilization—against real-time machine shop data (current capacity, material costs, labor rates). The output provides estimated cost ranges, lead time brackets, and key risk flags (e.g., “thin wall section below 0.5mm requires EDM consideration”). Crucially, this is a data-driven starting point for discussion, not a final commitment, enabling rapid project scoping.

Collaborative DFM Analysis

Following quote acceptance, our engineering team conducts an in-depth Design for Manufacturability review. This phase involves direct collaboration between Honyo’s manufacturing engineers and the client’s design team through scheduled virtual workshops. We identify optimization opportunities such as:

Tolerance relaxation without functional impact

Material substitution for cost or lead time reduction

Feature modification to enable high-speed machining

Consolidation of multi-part assemblies

A formal DFM report details all recommendations with annotated CAD visuals and quantified impacts (e.g., “Reducing chamfer from 2×45° to 1×45° cuts machining time by 18%”). Client sign-off on the revised design is mandatory before production proceeds.

Precision Tooling Production

Approved designs move to our dedicated tooling cell equipped with multi-axis CNC machines (milling, turning, grinding), wire/sinker EDM, and coordinate measuring machines. Production follows strict protocols:

Material certification verification prior to machining

In-process inspections at critical stage gates

Real-time SPC data collection on dimensional stability

Dedicated project managers providing weekly progress dashboards

All tooling undergoes final validation against the client’s functional requirements using calibrated metrology equipment, with full inspection reports archived.

Quality-Controlled Delivery

Upon successful validation, tooling is prepared for shipment using custom crating designed for shock and moisture protection. Each delivery includes:

Complete dimensional inspection report (AS9102 format available)

Material traceability documentation

Operational certification for functional tooling

Digital twin of the as-manufactured part (optional)

Shipments are tracked in real-time via our logistics partner, with delivery confirmation requiring client signature. Post-delivery, our team schedules a handover review to confirm tooling performance in the client’s production environment.

Typical Timeline and Cost Structure

The table below illustrates representative benchmarks for common tooling projects. Actual metrics vary based on complexity and client-specific requirements.

| Phase | Standard Tooling (e.g., Jig/Fixture) | Complex Tooling (e.g., Progressive Die) |

|---|---|---|

| CAD to AI Quote | ≤ 24 hours | ≤ 48 hours |

| DFM Completion | 3-5 business days | 7-10 business days |

| Production Lead Time | 10-15 business days | 25-40 business days |

| Total Process Duration | 14-22 business days | 35-55 business days |

This integrated approach ensures predictable outcomes while leveraging technology to compress traditional tooling timelines by 30-40% compared to industry averages. We maintain transparency at every stage through our client portal, providing real-time access to project data without requiring manual status inquiries.

Start Your Project

Interested in high-precision tooling machines engineered for performance and reliability? Contact Susan Leo today to discuss your requirements and discover how our advanced manufacturing solutions can support your production goals.

Email: [email protected]

Our state-of-the-art factory in Shenzhen ensures rapid turnaround, strict quality control, and scalable capacity to meet both prototyping and high-volume needs. Partner with Honyo Prototype for precision, efficiency, and technical excellence.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.