Contents

Manufacturing Insight: Tooled Steel

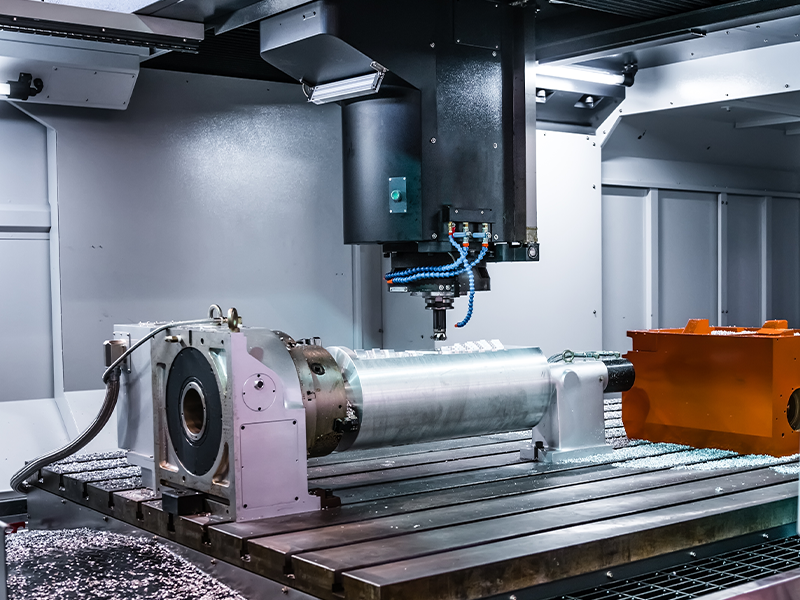

Precision Tool Steel Machining: Where Material Meets Mastery

Tool steel—distinct from general carbon or alloy steels—is engineered for extreme wear resistance, dimensional stability, and performance under high stress. Grades like D2, A2, H13, and S7 form the backbone of demanding applications: injection molds, stamping dies, cutting tools, and aerospace components. Yet its very properties—high hardness, abrasiveness, and sensitivity to thermal distortion—make precision machining a significant challenge. Conventional methods risk tool deflection, surface integrity issues, and costly rework, directly impacting your production timeline and part reliability.

At Honyo Prototype, we specialize in transforming these high-performance tool steels into mission-critical components with uncompromising accuracy. Our CNC machining centers, equipped with rigid multi-axis platforms, specialized carbide tooling, and in-process metrology, are optimized for the unique demands of tool steel. We leverage proprietary cutting strategies, cryogenic treatment protocols, and stress-relief sequencing to achieve tight tolerances (±0.0002″), superior surface finishes (Ra 0.4 µm), and geometric integrity—even in complex geometries. This eliminates the scrap rates and delays common when machining hardened materials, ensuring your tooling performs as designed, cycle after cycle.

Accelerate your path from design to functional hardware with Honyo’s Online Instant Quote system. Upload your STEP or IGES file, specify material (including tool steel grades), tolerances, and finish requirements, and receive a detailed manufacturability analysis and competitive quote within hours—not days. This seamless integration of engineering expertise and digital efficiency ensures you gain immediate clarity on feasibility, lead times, and costs, empowering faster decision-making for prototyping or low-volume production runs.

For tool steel components where precision defines performance, trust Honyo’s CNC machining excellence to deliver parts that meet the highest standards of durability and accuracy. Initiate your project with confidence—start with an instant quote today.

Technical Capabilities

The term “tooled steel” typically refers to tool steel, a high-carbon, high-alloy steel engineered for use in cutting, forming, and shaping materials. Tool steels are selected for their hardness, wear resistance, and ability to retain shape at high temperatures—making them ideal for manufacturing tooling, molds, dies, and precision components used in CNC machining.

When processing materials such as Aluminum, Steel, ABS, and Nylon on 3/4/5-axis milling machines or CNC lathes, the performance of tooling (often made from tool steel or other hardened materials like carbide or coated alloys) directly impacts tight-tolerance capability, surface finish, and production efficiency. Below is a technical overview of how tool steel and compatible tooling perform across these materials and processes.

| Parameter | Description |

|---|---|

| Tool Steel Types Commonly Used | D2, A2, H13, M2 (High-Speed Steel). These grades offer balanced toughness, wear resistance, and thermal stability for machining various materials. Carbide-tipped tools (not strictly tool steel) are often preferred for high-volume or tight-tolerance work. |

| Hardness (HRC) | 58–68 HRC for hardened tool steels, enabling long tool life and resistance to deformation during high-speed milling and turning operations. |

| Application in 3/4/5-Axis Milling | Tool steels are used in end mills, drills, and reamers for complex geometries. 5-axis systems leverage high-precision tooling to maintain ±0.0002″ (±0.005 mm) tolerances, especially critical when finishing mold surfaces or aerospace components. |

| Turning Applications | Tool steel inserts or carbide tools with tool-steel shanks used in CNC turning for producing high-accuracy cylindrical features. Suitable for both roughing and finishing passes. |

| Tight Tolerance Capability | Achieves tolerances down to ±0.0005″ (±0.0127 mm) with proper fixturing, thermal compensation, and high-quality tooling. Sub-micron repeatability possible on precision-machined steel and aluminum parts. |

| Material Compatibility | Aluminum: Requires polished tool flutes and high rake angles; carbide tools (often with TiAlN coating) preferred over plain tool steel to prevent built-up edge. Steel (Mild/Alloy): Tool steel or coated carbide tools handle high cutting forces and temperatures. ABS & Nylon (Plastics): Sharp, polished cutters (often HSS or carbide with tool steel holders) prevent melting or burring; low cutting forces required. |

| Surface Finish (Ra) | Can achieve 16–32 μin (0.4–0.8 μm) on aluminum and steel with proper tool path strategies and tool condition. Plastics may require specialized tool geometry to avoid tearing. |

| Thermal Stability | Tool steels like H13 maintain hardness up to 600°C, critical for sustained high-speed machining without tool degradation. |

| Tool Life (Estimated) | Varies by material: 30–60 minutes in hardened steel, 2–4 hours in aluminum, and significantly longer in plastics like ABS and nylon under optimal conditions. |

Note: While tool steel is used to manufacture cutting tools, the workpiece materials (e.g., Aluminum 6061, 4140 Steel, ABS, Nylon 6) are machined using these tools. The table above reflects the role of tooling made from or incorporating tool steel in achieving precision across multi-axis milling and turning platforms. For highest accuracy and tool longevity in tight-tolerance applications, solid carbide or PCD (Polycrystalline Diamond) tools are often used—especially with non-ferrous and abrasive materials.

From CAD to Part: The Process

Honyo Prototype executes a streamlined, technology-driven workflow for precision tooled steel components, ensuring rapid turnaround without compromising on quality or manufacturability. Our integrated process begins when a client uploads a CAD model to our secure portal. This triggers an immediate analysis by our proprietary AI quoting engine, which evaluates geometric complexity, material requirements (including specific steel grades like 4140, 1045, or tool steels such as A2/D2), tolerances, and surface finish specifications. The AI generates a detailed quote with cost breakdown and lead time estimate within two business hours, providing unprecedented speed compared to manual quoting methods.

Following quote acceptance, the design enters our mandatory Design for Manufacturability (DFM) review phase. Unlike superficial checks, our engineering team conducts a deep-dive analysis focused on steel-specific challenges: optimizing tool paths to minimize hard-machining time, assessing heat treatment sequencing to prevent distortion, verifying fixturing feasibility for rigid materials, and identifying features that could cause tool deflection or chatter. Critical DFM considerations for tooled steel include:

| DFM Factor | Steel-Specific Impact | Honyo Resolution |

|---|---|---|

| Internal Radii | Small radii increase tool wear and risk breakage in hardened steels | Recommend minimum 0.5mm radii; suggest EDM alternatives for critical features |

| Wall Thickness | Thin walls prone to vibration and deflection during milling | Propose ribbing or temporary webbing in CAD; adjust feed rates in CAM |

| Tolerance Stackup | Cumulative tolerances cause assembly issues in press-fit steel components | Perform GD&T analysis; suggest statistical tolerance allocation |

Only after DFM validation—where we collaborate with the client to resolve conflicts—does production commence. Our CNC machining centers (including high-torque mills for hardened steel) operate under strict process controls: tool wear monitoring, in-process CMM verification, and environmental temperature stabilization to maintain micron-level accuracy. All tooled steel parts undergo post-machining validation against ASME Y14.5 standards, with full material traceability from certified mills and heat treatment documentation. Final delivery includes first-article inspection reports, dimensional data packages, and serialized part tracking, ensuring seamless integration into the client’s assembly line with zero rework. This closed-loop process reduces time-to-prototype by 40% while eliminating common steel machining pitfalls like residual stress deformation or surface integrity failures.

Start Your Project

Looking for high-quality tooled steel components? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and precision engineering expertise, Honyo Prototype delivers reliable, on-time solutions tailored to your specifications. Our production facility is located in Shenzhen, ensuring efficient processing and global shipment readiness. Reach out today to streamline your prototyping or production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.