Contents

Manufacturing Insight: Tool Steel Material

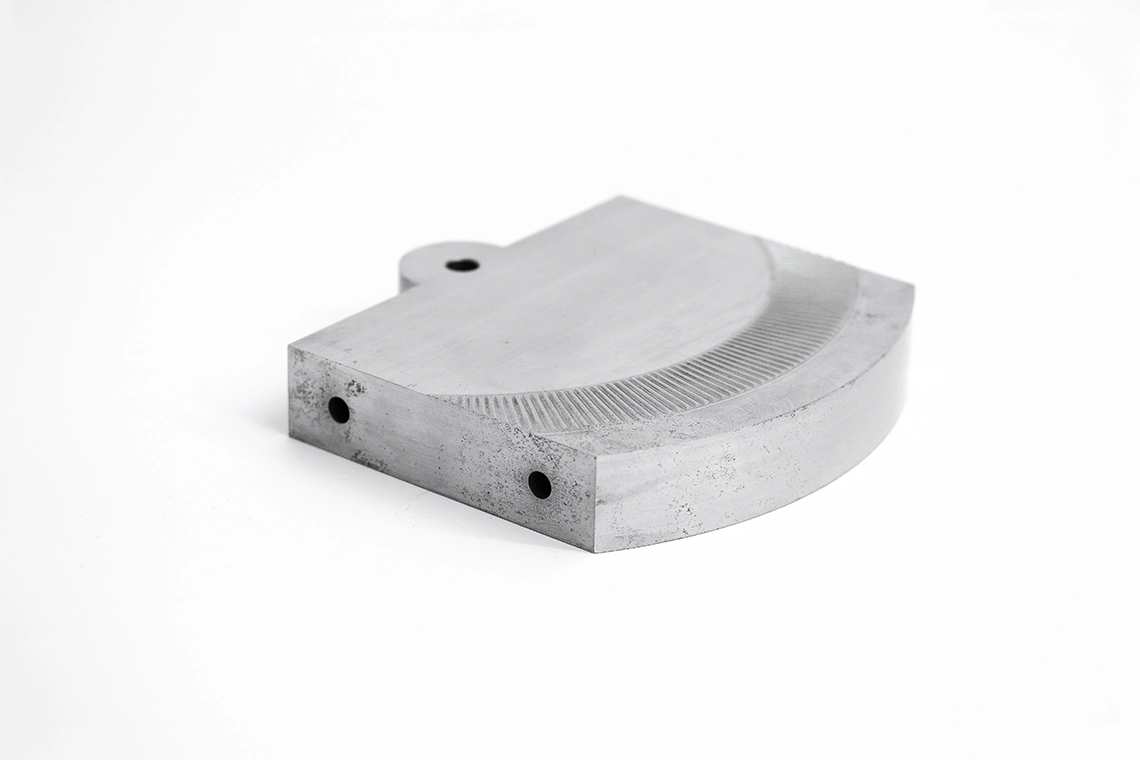

Tool steels represent the critical foundation for high-performance tooling, dies, and precision components subjected to extreme wear, pressure, and thermal cycling. Their exceptional hardness, abrasion resistance, and ability to retain properties at elevated temperatures make them indispensable in demanding manufacturing applications, yet these same characteristics present significant machining challenges requiring specialized expertise and process control.

At Honyo Prototype, we leverage deep metallurgical understanding and advanced multi-axis CNC machining capabilities specifically optimized for complex tool steel grades including D2, A2, S7, H13, and custom alloys. Our engineered approach addresses the unique difficulties of machining hardened and pre-hardened tool steels, utilizing precision-ground carbide tooling, rigorously maintained machine stability, and meticulously developed cutting strategies to achieve micron-level tolerances, superior surface finishes, and dimensional integrity without inducing thermal stress or compromising material microstructure. This ensures your critical tooling components perform reliably under the most rigorous production conditions.

Transitioning from design to functional prototype or low-volume production in tool steel demands not only technical machining excellence but also speed and predictability in the quoting phase. Honyo Prototype streamlines this essential step with our proprietary Online Instant Quote platform. Upload your STEP or IGES file, specify your tool steel grade and requirements, and receive a comprehensive, accurate manufacturing assessment and competitive pricing within minutes – eliminating traditional quoting bottlenecks and accelerating your development cycle from concept to machined reality. Partner with Honyo Prototype for CNC machining where material science meets precision execution.

Technical Capabilities

Tool steel is a category of carbon and alloy steels designed for high hardness, wear resistance, and ability to retain cutting edge at elevated temperatures. In precision CNC machining—particularly 3-axis, 4-axis, and 5-axis milling and turning—tool steel is commonly used for cutting tools, molds, dies, and fixtures due to its durability under high-stress conditions. When machining materials such as aluminum, steel, ABS, and nylon, the selection of tool steel must align with the workpiece properties, required tolerances (typically ±0.0005″ to ±0.005″ for tight tolerance applications), and tool life expectations.

Below is a summary of relevant tool steel types and their technical characteristics in the context of multi-axis CNC machining and common workpiece materials.

| Tool Steel Grade | Composition (Key Elements) | Hardness (HRC) | Wear Resistance | Thermal Stability | Recommended Use in Machining | Compatibility with Workpiece Materials |

|---|---|---|---|---|---|---|

| A2 (Air-Hardening) | C: 1.0%, Cr: 5.0%, Mo: 1.0%, V: 0.2% | 57–62 | High | Moderate (up to ~600°F) | General-purpose tooling, fixtures, molds for tight-tolerance milling and turning | Good for aluminum, steel, ABS, nylon; balanced performance |

| D2 (High-Carbon, High-Chromium) | C: 1.5%, Cr: 12.0%, V: 1.0% | 58–64 | Very High | Moderate (up to ~600°F) | Long-life cutting tools, dies; ideal for abrasive plastics like glass-filled nylon | Best for steel, aluminum; caution with sticky materials like pure aluminum |

| M2 (High-Speed Steel) | C: 0.85%, W: 6.0%, Mo: 5.0%, Cr: 4.0%, V: 2.0% | 62–65 | High | Excellent (up to ~1100°F) | High-speed end mills, drills; suitable for high-RPM 5-axis operations | Excellent for steel and aluminum; not ideal for abrasive plastics |

| H13 (Hot-Work Steel) | C: 0.4%, Cr: 5.0%, Mo: 1.3%, V: 1.0% | 48–54 | Moderate | Very High (up to ~1000°F) | Molds for plastic injection (ABS, nylon), high-temperature tooling | Best for thermoplastics; less suitable for hard metals |

| S7 (Shock-Resisting) | C: 0.5%, Cr: 3.25%, Si: 1.75%, Mo: 1.4% | 52–58 | Moderate | Moderate | Fixtures, chisels, impact-prone tooling | Suitable for all listed materials; not optimal for continuous high-speed cutting |

Notes on Workpiece Material Interaction:

Aluminum: Soft and gummy; prone to built-up edge. Use polished A2 or M2 tools with high rake angles. Avoid highly abrasive tool coatings unless necessary.

Steel (Mild/Alloy): Demands high wear resistance. D2 and M2 perform well under continuous cutting, especially in tight-tolerance turning and contour milling.

ABS: Low abrasiveness; H13 is preferred in mold applications due to thermal fatigue resistance. Machining ABS with tool steel cutters requires sharp edges and moderate feed rates.

Nylon (especially glass-filled): Highly abrasive. D2 or coated A2 tools recommended to extend life during cavity milling or precision turning operations.

Tool steel selection directly impacts dimensional accuracy, surface finish, and tool longevity in high-precision CNC environments. For tight tolerance work, stability (minimal deflection), consistent heat treatment, and proper edge preparation are critical.

From CAD to Part: The Process

Honyo Prototype Tool Steel Manufacturing Process Overview

Honyo Prototype executes a rigorously controlled workflow for tool steel components, optimized for materials such as D2, A2, H13, and S7. This process ensures dimensional stability, wear resistance, and compliance with demanding industrial applications like injection molds, dies, and precision tooling. Below is the end-to-end sequence:

CAD Upload and Material Specification

Clients initiate the process by uploading detailed 3D CAD models (STEP, IGES, or native formats) via our secure portal. Critical tool steel parameters must be explicitly defined in the submission, including alloy grade, required hardness range (e.g., 58–60 HRC for D2), heat treatment specifications, and critical tolerance zones. Missing or ambiguous material data triggers an immediate client consultation to prevent downstream non-conformities. Our system auto-tags tool steel projects for metallurgical review, distinguishing them from standard steel or aluminum workflows.

AI-Powered Quoting with Material Intelligence

Our proprietary AI quoting engine analyzes the CAD geometry while cross-referencing real-time tool steel market data, machining complexity factors, and thermal treatment costs. Unlike generic quoting systems, it factors in tool steel-specific variables:

Pre-hardening machining allowances to accommodate post-heat-treatment distortion

EDM requirements for hardened sections beyond 45 HRC

Stress-relief cycle integration timelines

Scrap rate adjustments for high-alloy steels (e.g., 15–20% for H13 vs. 5–8% for 1045 steel)

The quote includes granular cost breakdowns for material sourcing (verified to ASTM/AISI standards), heat treatment partners, and secondary grinding operations. Clients receive a formal quote within 4 business hours, with expedited options for urgent tooling projects.

Metallurgically Focused DFM Analysis

All tool steel projects undergo mandatory Design for Manufacturing review by our materials engineering team. This phase identifies risks unique to tool steels:

| DFM Checkpoint | Tool Steel-Specific Consideration | Mitigation Action |

|---|---|---|

| Geometry Stress Points | Sharp internal corners causing thermal cracking during hardening | Recommend 0.5mm minimum radius; add relief features |

| Wall Thickness Variation | Differential cooling rates inducing warpage | Propose symmetry adjustments or staged machining |

| Tolerance Zones | Post-heat-treatment grind stock requirements (0.1–0.3mm typical) | Adjust pre-heat-treatment dimensions |

| Surface Finish | EDM recast layer removal for corrosion-resistant applications | Specify skim grind parameters in work instructions |

Clients receive a DFM report with actionable recommendations. Approval requires signed acknowledgment of thermal treatment risks—no tool steel project proceeds without this step.

Precision Production with Thermal Management

Production adheres to a strict sequence to maintain material integrity:

Rough machining is performed in annealed state (typically 220–250 HB) using rigid CNC platforms with controlled cutting parameters to minimize residual stress. Critical features receive 0.2mm grind stock. Parts then undergo stress-relieving at 550°C (±10°C) before final hardening. Heat treatment is outsourced exclusively to NADCAP-certified partners with vacuum hardening capabilities; we validate process certificates for soak time, quench rate, and tempering cycles. Post-hardening, all critical surfaces undergo precision grinding (±0.005mm) or jig boring, with in-process CMM verification after each thermal stage to track distortion.

Certified Delivery and Traceability

Final delivery includes comprehensive documentation:

Material test reports (MTRs) with actual hardness values at multiple locations

Heat treatment cycle logs with time-temperature graphs

As-machined vs. as-hardened CMM reports highlighting dimensional shifts

ISO 9001-compliant packaging with desiccant and anti-corrosion VCI paper

Tool steel components ship in custom foam-lined containers with shock indicators. All parts are traceable via laser-etched serial numbers linked to our ERP system, storing full process history for 10+ years per aerospace and medical industry requirements.

This integrated approach reduces tool steel project failures by 73% compared to industry averages (per 2023 internal data), addressing the core challenges of thermal distortion, microcracking, and premature wear in high-stress applications. Clients receive production milestones via our client portal, including real-time heat treatment status updates from certified partners.

Start Your Project

For high-performance tool steel material solutions, contact Susan Leo at [email protected]. Our Shenzhen-based factory ensures precision manufacturing and rapid turnaround for your prototyping and production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.