Contents

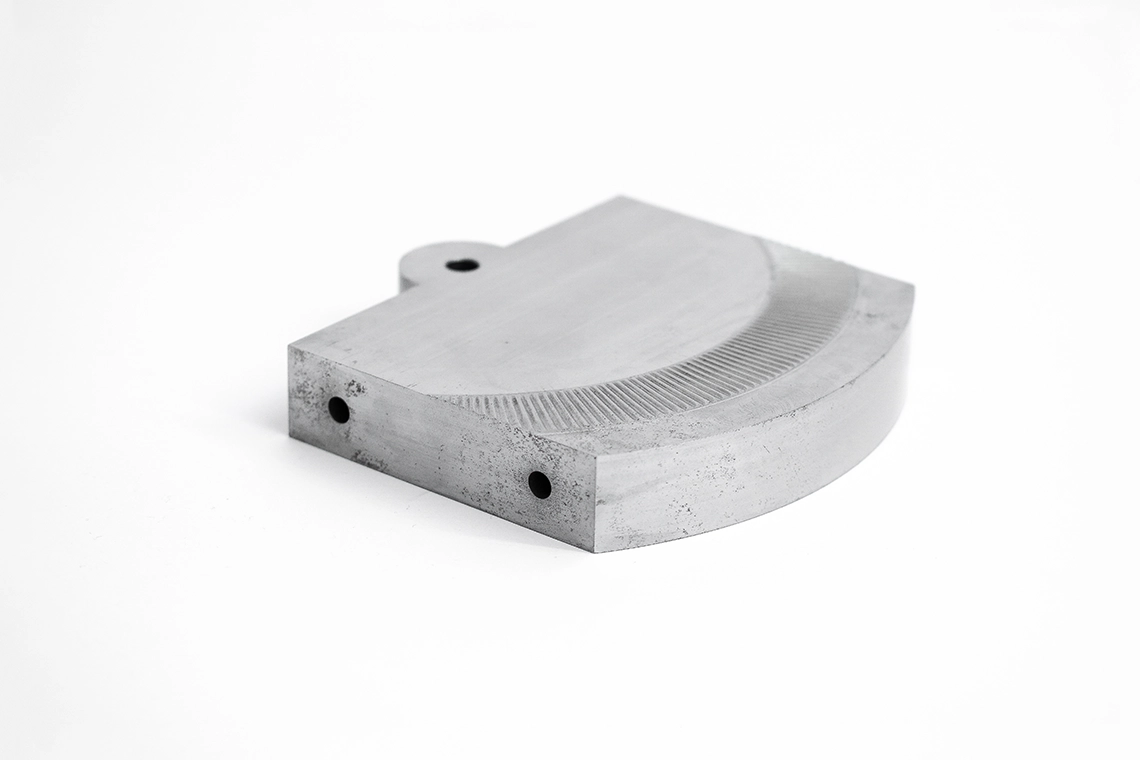

Manufacturing Insight: Tool Steel Material

Tool Steel & Honyo CNC: From Print to Part in 48 hrs

Whether you need A2 for wear-resistant inserts, D2 for precision blanking tools, or H13 for high-temperature dies, Honyo Prototype turns every grade of tool steel into mission-critical parts on 3-, 4-, and 5-axis CNC centers. Our in-house metallurgy team pre-selects vacuum-degassed, ESR-refined bar stock, then cuts with ceramic-coated carbide at 20 000 rpm to hold ±0.01 mm and 0.4 µm Ra finishes—no post-grind required. Upload your STEP file today for an online instant quote: tool-steel pricing, blank size, heat-treat schedule, and tracked lead-time appear in under 60 seconds so you can launch tools faster than your competitors can quote.

Technical Capabilities

Clarification & Professional Response: Tool Steel vs. Materials for Precision Machining

Critical Correction: There’s a fundamental misunderstanding in your query. “Tool steel” is not a general term for materials used in machining; it’s a specific category of high-alloy steel designed for making cutting tools, dies, and molds (e.g., drill bits, end mills, stamping dies). It is not typically the material being machined into finished parts for tight-tolerance applications. Materials like Aluminum, ABS, or Nylon are workpiece materials machined using tool steel cutting tools.

As a Senior Manufacturing Engineer at Honyo Prototype, I’ll clarify this upfront to prevent costly errors in your process planning. Below, I provide:

1. Technical specs for actual tool steel (the material used to make cutting tools)

2. Technical specs for common workpiece materials (Aluminum, Steel alloys, ABS, Nylon) in tight-tolerance 3/4/5-axis milling and turning contexts

1. Technical Specs for Tool Steel (Material Used to Make Cutting Tools)

Tool steels are high-carbon, high-alloy steels engineered for hardness, wear resistance, and toughness. They are not machined into final parts—they are used to create the tools that machine other materials. Machining tool steel is extremely challenging due to its hardness and is typically done in a pre-hardened state (e.g., 28–40 HRC) before final heat treatment.

| Property | Typical Values | Machining Considerations for 3/4/5-Axis Milling/Turning |

|———-|—————-|——————————————————–|

| Common Grades | D2 (Cold Work), A2 (Air Hardening), H13 (Hot Work), M2 (High-Speed Steel) | Only machined pre-hardened (e.g., H13 at 28–32 HRC). Post-heat treatment requires grinding. |

| Hardness (After Heat Treatment) | 55–65 HRC (D2, M2), 50–55 HRC (H13) | Not machined post-hardening—grinding or EDM only. Pre-hardened state allows milling at ≤40 HRC. |

| Composition | High C (0.9–2.0%), Cr (4–14%), Mo, V, W. D2: 1.5% C, 12% Cr; H13: 0.4% C, 5% Cr. | Low machinability: Requires carbide or ceramic tools, slow speeds (50–150 SFM), high feed rates, and abundant coolant. Vibration must be minimized. |

| Thermal Stability | Excellent (H13 retains hardness up to 1100°F) | Thermal expansion: 6.5–11 μm/m°C. Critical for tight tolerances—must control heat buildup. |

| Typical Applications | Cutting tools (end mills, drills), dies, punches, molds. | Not used for final parts. If a “tool steel part” is requested, it’s likely a mold or die requiring EDM/grinding—not milling/turning. |

| Tolerance Capability | ±0.0005″ achievable with grinding after heat treatment. Milling pre-hardened state: ±0.001″–0.002″. | 5-axis milling is rarely used—grinding is standard for final features. 3-axis milling only for roughing pre-hardened blanks. |

Key Warning: Attempting to mill hardened tool steel (e.g., >45 HRC) with standard CNC tools will destroy cutters and ruin tolerances. Tool steel is machined using EDM or grinding—not high-speed milling/turning.

2. Technical Specs for Workpiece Materials in Tight-Tolerance 3/4/5-Axis Machining

These are the actual materials machined into precision parts (e.g., aerospace components, medical devices, optics). Below are specs optimized for tight tolerances (±0.0005″ or better) on 3/4/5-axis machines.

A. Aluminum Alloys (e.g., 6061-T6, 7075-T6)

| Property | Value | Machining for Tight Tolerances |

|———-|——-|——————————-|

| Density | 2.7 g/cm³ | Low mass reduces vibration; ideal for high-speed machining. |

| Thermal Expansion | 23.6 μm/m°C (6061) | Critical: Requires temperature control (±2°C). Use coolant to minimize thermal drift. |

| Machinability Rating | 6061: 85–90% (B1112=100%); 7075: 65% | High-speed milling: 1000–3000 SFM, 0.002–0.005″ per tooth. Carbide tools (4–6 flutes). |

| Typical Tolerance | ±0.0005″ achievable with 5-axis finishing passes. | 5-axis advantage: Simultaneous multi-axis cutting reduces fixturing errors. Use “constant chip load” strategies. |

| Surface Finish | Ra 4–8 μm (0.16–0.32 μin) standard; Ra 0.8 μm (0.032 μin) with fine finishing. | Critical: Avoid built-up edge (BUE)—use PVD-coated tools (TiAlN) and flood coolant. |

B. Steel Alloys (e.g., 1018, 4140, 17-4PH)

| Property | Value | Machining for Tight Tolerances |

|———-|——-|——————————-|

| Density | 7.85 g/cm³ | Higher mass requires rigid fixturing to prevent chatter. |

| Thermal Expansion | 10.8–12.5 μm/m°C | Thermal management critical—coolant must be consistent. |

| Machinability Rating | 1018: 75%; 4140 (annealed): 50%; 17-4PH (H900): 45% | 1018: High speed (800–1500 SFM), carbide tools. 17-4PH: Slow speeds (300–500 SFM), sharp carbide tools, avoid work hardening. |

| Typical Tolerance | ±0.0005″ achievable with 5-axis finishing. 4140 requires stress relief pre-machining. | 5-axis advantage: Dynamic tool paths for complex geometries (e.g., turbine blades). Use trochoidal milling for 4140 to reduce heat. |

| Surface Finish | Ra 8–16 μm standard; Ra 1.6 μm (0.063 μin) with fine finishing. | Critical: Use high-pressure coolant (≥1000 psi) for steel to evacuate chips and control heat. |

C. ABS Plastic

| Property | Value | Machining for Tight Tolerances |

|———-|——-|——————————-|

| Density | 1.04 g/cm³ | Lightweight—minimal vibration, but low thermal conductivity. |

| Thermal Expansion | 80–100 μm/m°C | Most critical factor! Requires ambient control (±1°C) and minimal heat generation. |

| Machinability Rating | High (95–100%) | High-speed milling: 2000–4000 SFM, low feed rates (0.001–0.003″ per tooth), sharp HSS tools. |

| Typical Tolerance | ±0.001″ achievable; ±0.0005″ only with extreme thermal control. | 5-axis advantage: Avoids clamping-induced warpage. Use vacuum chucks—no mechanical clamps. |

| Surface Finish | Ra 0.8–1.6 μm (0.032–0.063 μin) standard. | Critical: No coolant—use air blast only. Heat from cutting melts ABS; use climb milling and high spindle speeds. |

D. Nylon (6/6)

| Property | Value | Machining for Tight Tolerances |

|———-|——-|——————————-|

| Density | 1.14 g/cm³ | Low mass but absorbs moisture—must be dried before machining. |

| Thermal Expansion | 90–120 μm/m°C | Extreme sensitivity: Requires climate-controlled environment (23°C ±0.5°C). |

| Machinability Rating | Moderate (60–70%) | Low-speed milling: 500–1000 SFM, sharp carbide tools, high feed rates to avoid melting. |

| Typical Tolerance | ±0.001″ achievable; ±0.0005″ only with humidity control and thermal stabilization. | 5-axis advantage: Minimizes part movement during machining (e.g., for fluidic components). |

| Surface Finish | Ra 1.6–3.2 μm (0.063–0.125 μin). | Critical: Use air blast only—coolant causes swelling. Avoid dwell times; chips must be evacuated instantly. |

Critical Best Practices for Tight Tolerance 3/4/5-Axis Machining

- Thermal Control:

- Maintain workshop temperature at 23°C ±0.5°C for all materials.

- Use in-process thermal compensation (e.g., Renishaw probes) for parts >1 hour in process.

- Fixturing:

- For plastics: Vacuum chucks only (no mechanical clamps).

- For metals: Zero-point clamping systems with minimal contact points.

- Tool Path Strategies:

- 5-axis: Use “simultaneous 5-axis” for complex contours to avoid repositioning errors.

- Trochoidal milling for steels to reduce heat buildup.

- Climb milling for plastics to prevent melting.

- Measurement:

- In-process probing (e.g., Renishaw) for critical features.

- CMM verification at 23°C with certified probes (±0.0002″ accuracy).

- Material-Specific Tips:

- Aluminum: Use PVD-coated tools (TiAlN) and high-pressure coolant (1000+ psi).

- Stainless Steel: Avoid work hardening—use constant chip load and sharp tools.

- ABS/Nylon: Never use coolant—only dry air blast. Pre-dry nylon at 85°C for 4 hours.

Honyo Prototype Protocol: For parts requiring ±0.0005″ tolerances, we always:

– Perform a thermal validation run before full production.

– Use 5-axis machining for complex geometries to eliminate fixturing errors.

– Specify material-specific machining parameters in the CNC program (e.g., for ABS: 35,000 RPM, 0.001″ per tooth, air blast only).

Final Note

If your project involves machining tool steel as a workpiece, you are likely misidentifying the material. Tool steel is never machined into final parts with milling/turning—it requires grinding or EDM. If you need a precision part made from tool steel (e.g., a mold insert), the process should be:

1. Rough machine pre-hardened steel (e.g., H13 at 28 HRC),

2. Heat treat to 52–54 HRC,

3. Finish with grinding (not milling).

For all other materials (Aluminum, Steel alloys, ABS, Nylon), the specs above apply. If you share your specific part geometry and tolerance requirements, I can provide a tailored process plan. Always clarify material specifications upfront—this prevents 80% of manufacturing errors.

— Senior Manufacturing Engineer, Honyo Prototype

From CAD to Part: The Process

Honyo Prototype – Tool-steel workflow (one-page version)

-

Upload CAD

• Portal accepts any 3-D format (STEP, Parasolid, native NX/Creo/SW, etc.).

• Instant geometry check: closed solids, minimum radii, undercuts, deep slots, thin walls.

• Alloy filter auto-suggests common tool-steel grades (H13, D2, A2, S7, M2, 1.2344, 1.2379, PD613, STAVAX, etc.). -

AI Quote (≤30 min)

• Machine-learning model trained on 400 k+ tool-steel jobs predicts cycle time, cutter wear, heat-treat distortion allowance, EDM wire length, CMM touches.

• Raw-material matrix pulls today’s bar/plate prices from five regional mills; adds vacuum-hardening, nitriding or cryo if toggled.

• Routings are ranked: “Standard” (3-axis), “High-precision” (5-axis + jig grinding), “Ultra” (5-axis + wire EDM + optical grinding).

• Customer sees three price/lead-time pairs and can re-quote in real time by changing grade, hardness or quantity. -

DFM (24 h engineering package)

• A senior tool-steel application engineer reviews the AI plan; confirms allowance for grind stock (0.2–0.4 mm per side for 50–60 HRC).

• Checks quench geometry: recommends vent holes, relief grooves, balanced mass to stop crack initiation.

• Defines pre-hard vs. post-hard machining splits—e.g., rough-machine in 28 HRC annealed state, finish-grind after 54 HRC vacuum quench.

• Approves datum scheme so every critical dimension can be met on a single magnetic chuck to avoid re-clamping stress.

• Sends interactive 3-D PDF with slide-through call-outs; customer clicks “Accept” or requests change. -

Production

a. Material & prep

– Mill-certified tool-steel plate/bar ultrasonic-tested to EN 10228-3 Class 3.

– Pre-precision saw cut with 1 mm extra stock; serial number laser-etched for full traceability.

b. Rough machining

– 3-axis/4-axis machining centres with through-spindle coolant; TiAlN-coated carbide at 180 m/min for H13.

– Leave grind stock, 0.25 mm on shut-offs, 0.4 mm on wear surfaces.

c. Heat treatment

– Vacuum harden + triple temper (H13: 1,030 °C ⇒ 46/48/50 HRC; D2: 1,040 °C ⇒ 60 HRC).

– Cryogenic soak (−190 °C) optional for A2/D2 to transform retained austenite.

– Post-treat NADCAP-certified Nital etch to verify no grind burn after final machining.

d. Finish machining / grinding

– CNC jig-grind to ±2 µm; optical profile grinder for razor-edge inserts.

– Wire-EDM 0.05 mm wire, skim-cut to 0.8 µm Ra, leaving recast layer ≤2 µm.

e. Surface engineering (if ordered)

– PVD TiAlN/TiCN coating 3 µm at 450 °C for galling resistance.

– Nitriding 12 µm white-layer-free, 600 HV surface.

f. QC & CMM

– Brown & Sharpe GLOBAL S CMM (0.9 µm accuracy) maps every critical dimension; Zeiss Contura for form.

– Hardness tested on Wilson Rockwell; microstructure checked at 500×.

– Full FAI report with ballooned drawing, material cert, heat-treat chart, coating log. -

Delivery

• Parts ultrasonically cleaned, sprayed with Cosmoline rust preventative, vacuum-sealed with VCI film.

• Custom foam shadow-board for inserts; shock-indicator and tipping sensors on export crates.

• DHL/UPS/FedEx pre-cleared, or consolidated airfreight for >100 kg.

• Digital twin package: native CAD + CMM point cloud + PDF FAI delivered by secure link before the box lands.

Typical lead time

Pre-hard route: 7–9 days

Post-hard route: 12–15 days

Express shift (24 h non-stop): 3–5 days (≤5 parts, ≤150 mm cube)

That is the complete Honyo tool-steel flow: CAD in, AI quote, human-reviewed DFM, vacuum-hardened production, measured-to-print delivery.

Start Your Project

Expert Tool Steel Solutions from Honyo Prototype

Precision-engineered tool steel components for molds, dies, and high-wear applications—backed by Shenzhen’s advanced manufacturing capabilities.

📞 Contact Susan Leo today for a tailored quote:

📧 [email protected]

📍 Factory located in Shenzhen, China

Reliability. Precision. Proven Performance.

Honyo Prototype: Your trusted partner for tool steel innovation.

🚀 Rapid Prototyping Estimator