Contents

Manufacturing Insight: Tool Steel Machining

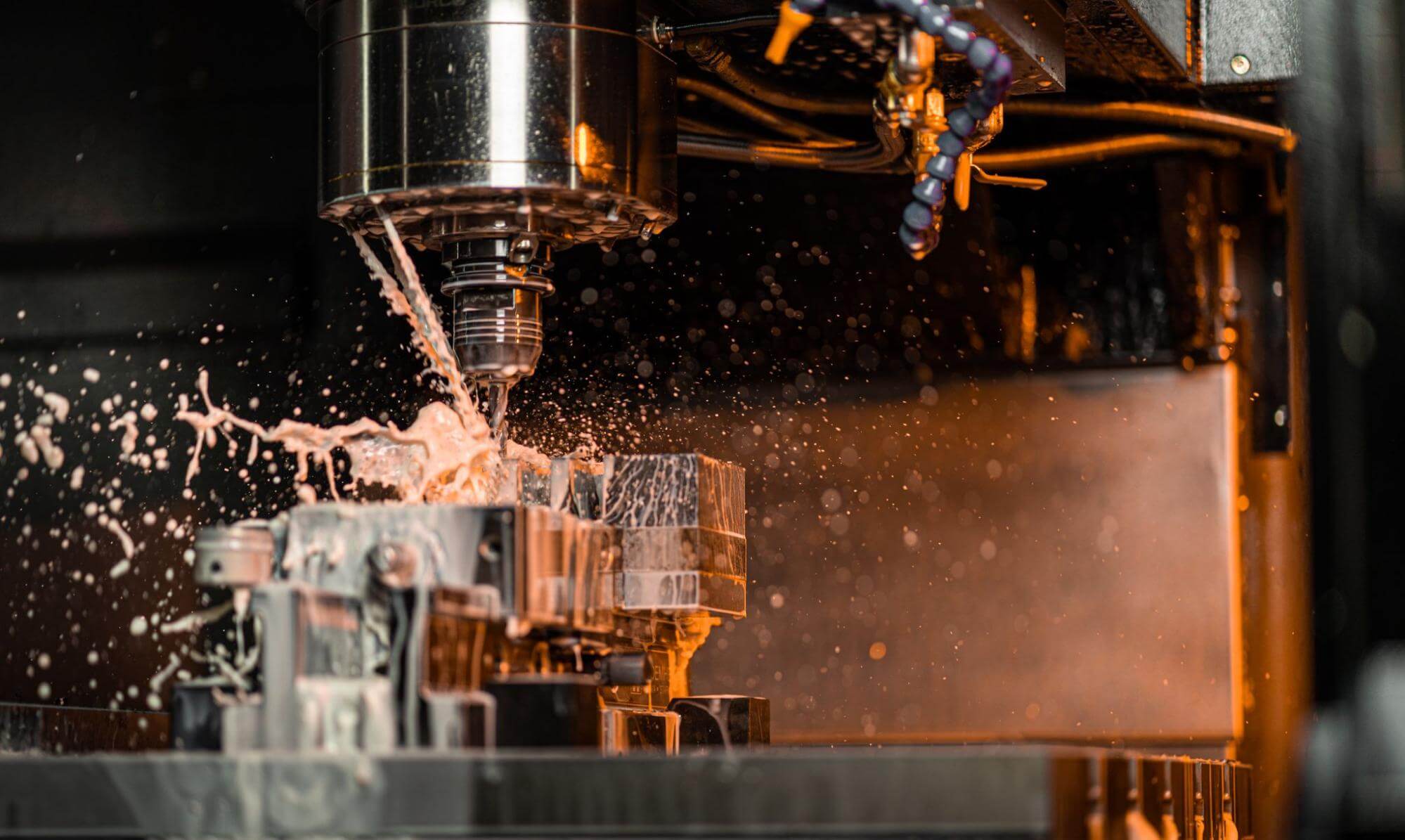

Precision Tool Steel Machining: Engineered for Demanding Applications

Machining tool steels presents unique challenges due to their exceptional hardness, wear resistance, and thermal stability, which are critical for high-performance molds, dies, and cutting tools. These demanding properties require specialized CNC machining expertise to achieve tight tolerances, complex geometries, and superior surface finishes without compromising material integrity. At Honyo Prototype, our advanced CNC machining services are purpose-built for the rigors of tool steel fabrication, leveraging state-of-the-art multi-axis milling and turning centers capable of machining hardened alloys up to 60 HRC. Our processes integrate precision coolant strategies, optimized toolpath programming, and in-process metrology to ensure dimensional accuracy within ±0.005 mm while mitigating thermal distortion and tool wear.

We understand that time-to-prototype is critical in tooling development cycles. To accelerate your project timelines, Honyo Prototype offers an Online Instant Quote platform specifically calibrated for tool steel components. Upload your CAD file, specify material grade (e.g., H13, S7, D2), heat treatment requirements, and tolerance specifications to receive a detailed technical assessment and competitive pricing within minutes—not days. This seamless integration of engineering rigor and digital efficiency allows design teams to iterate faster and reduce time-to-market for mission-critical tooling solutions. Partner with Honyo Prototype for CNC-machined tool steel components where precision, durability, and speed are non-negotiable.

Technical Capabilities

Technical specifications for tool steel machining in 3/4/5-axis milling and turning operations require a high degree of precision, especially when holding tight tolerances (±0.0005″ to ±0.005″ typical). These processes are commonly applied not only to tool steels but also to a range of materials including aluminum, steel, ABS, and nylon. Below is a comparative summary of key technical parameters across these materials when machined using multi-axis CNC equipment.

| Parameter | Tool Steel (e.g., H13, A2, D2) | Aluminum (e.g., 6061-T6, 7075) | Mild/Carbon Steel (e.g., 1018, 4140) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide, e.g., PA6, PA66) |

|---|---|---|---|---|---|

| Typical Tolerance Range | ±0.0005″ to ±0.002″ | ±0.001″ to ±0.005″ | ±0.001″ to ±0.003″ | ±0.005″ to ±0.010″ | ±0.005″ to ±0.010″ |

| Surface Finish (Ra) | 8–32 μin (machined), 4–16 μin (polished) | 16–64 μin (machined), 8–32 μin (polished) | 16–64 μin (machined), 8–32 μin (ground) | 32–125 μin (as-machined) | 32–125 μin (as-machined) |

| Spindle Speed (Milling) | 200–800 SFM (60–240 m/min) | 800–3000 SFM (240–900 m/min) | 200–600 SFM (60–180 m/min) | 1000–3000 SFM (300–900 m/min) | 800–2000 SFM (240–600 m/min) |

| Feed Rate (Milling) | 0.001–0.004 IPT (0.025–0.10 mm/tooth) | 0.003–0.010 IPT (0.076–0.25 mm/tooth) | 0.002–0.006 IPT (0.05–0.15 mm/tooth) | 0.005–0.015 IPT (0.13–0.38 mm/tooth) | 0.004–0.012 IPT (0.10–0.30 mm/tooth) |

| Turning Speed (SFM) | 150–600 SFM (45–180 m/min) | 500–1500 SFM (150–450 m/min) | 200–600 SFM (60–180 m/min) | 800–2500 SFM (240–760 m/min) | 600–1500 SFM (180–450 m/min) |

| Tooling Requirements | Carbide or CBN inserts, high rigidity | Carbide or diamond-coated, sharp edges | Carbide or cermet, rigid setup | Carbide, high rake angles | Carbide, moderate rake, sharp edge |

| Coolant Use | Required (flood or high-pressure) | Recommended (flood or mist) | Required (flood) | Not required (air blast preferred) | Not required (air or light mist) |

| Fixturing Needs | High rigidity, minimal deflection | Moderate rigidity, vibration control | High rigidity, secure clamping | Light clamping, avoid deformation | Light clamping, avoid compression |

| Common Applications | Molds, dies, inserts, gauges | Prototypes, housings, aerospace parts | Shafts, fixtures, structural parts | Prototypes, enclosures, jigs | Wear parts, gears, bushings |

| Challenges | Work hardening, tool wear, heat build-up | Chatter, burring, galling | Heat generation, chip control | Melting, poor chip evacuation | Flexing, dimensional instability |

Note: 3/4/5-axis milling enables complex geometry and high accuracy, particularly beneficial for tight tolerance work in tool steel and aluminum aerospace components. Turning is typically used for rotational parts and is effective across all listed materials when combined with live tooling in multi-axis lathes. Material selection impacts cycle time, tool life, and post-processing requirements.

From CAD to Part: The Process

Honyo Prototype Tool Steel Machining Process Overview

Tool steel machining demands exceptional precision due to material hardness, thermal stability requirements, and stringent application tolerances. Our integrated workflow ensures optimal manufacturability, cost efficiency, and part performance. Below is a technical breakdown of our end-to-end process.

CAD File Upload and Initial Assessment

Clients submit 3D CAD models in industry-standard formats (STEP, IGES, Parasolid). Our system validates geometry integrity, checks for non-manufacturable features, and confirms material specification alignment with tool steel grades (e.g., D2, A2, H13). Incomplete metadata or ambiguous tolerances trigger automated client notifications for clarification prior to quoting.

AI-Powered Quoting Engine

Uploaded CAD data feeds our proprietary AI quoting system, which analyzes over 200 parameters including: geometric complexity, feature density, stock-to-part volume ratio, and grade-specific machinability factors. The AI cross-references historical tool wear data, coolant requirements, and thermal deformation profiles unique to tool steel. Quotes include detailed cost drivers such as electrode requirements for EDM operations, stress-relief cycle counts, and secondary hardening considerations. Typical turnaround time is under 90 minutes for standard tool steel components.

Engineering-Driven DFM Analysis

All tool steel projects undergo mandatory Design for Manufacturability (DFM) review by our senior tooling engineers. This phase identifies critical risks and optimization opportunities:

| DFM Focus Area | Tool Steel-Specific Considerations | Honyo Mitigation Strategy |

|---|---|---|

| Material Selection | Risk of cracking during hardening; mismatched grade for application temperature | Recommend alternate grades (e.g., S7 for impact resistance) with thermal analysis report |

| Wall Thickness | Differential cooling rates causing distortion in thin sections (>3:1 aspect ratio) | Propose staged machining with intermediate stress relief |

| Tight Tolerances | Hardness-induced tool deflection (e.g., ±0.005mm at 60 HRC) | Specify diamond-coated toolpaths; adjust cutting parameters |

| Internal Corners | Stress concentration points leading to premature failure | Mandate minimum 0.5mm radii; suggest post-machining peening |

DFM findings are compiled into a formal report with actionable recommendations. Client approval is required before proceeding to production.

Precision Production Execution

Tool steel machining follows a rigorously controlled sequence:

Rough machining occurs in pre-hardened state (28-32 HRC) using high-pressure coolant systems to minimize thermal shock. Critical thermal management protocols include maintaining coolant temperature at 18±2°C and enforcing 30-minute part soak periods between operations. After roughing, parts undergo stress-relief annealing per AMS 2750 standards. Final hardening to 58-62 HRC is performed by certified third-party heat treaters with NADCAP accreditation. Finish machining employs sub-micron CBN tooling on temperature-stabilized CNC platforms, with in-process CMM verification at critical datum points. All operations adhere to ISO 2768-mK geometric tolerancing standards.

Quality-Controlled Delivery

Every tool steel component undergoes multi-stage validation:

First-article inspection includes full FAI per AS9102B with hardness mapping (Rockwell C scale at 5+ locations), residual stress testing via XRD, and microstructure verification. Production lots receive batch-level material certification (MTRs traceable to heat number), 100% critical dimension verification, and surface integrity analysis. Parts ship in anti-corrosion packaging with humidity indicators, accompanied by a comprehensive quality dossier including heat treat certificates, inspection reports, and DFM compliance documentation. Standard lead time is 12-18 business days from DFM sign-off, with expedited options for qualifying applications.

This structured approach ensures tool steel components meet the extreme performance demands of die casting, stamping, and injection molding applications while minimizing total cost of ownership through proactive risk mitigation.

Start Your Project

Looking for precision tool steel machining for your next project? Honyo Prototype offers high-accuracy CNC machining services with extensive experience in hard materials, including tool steels such as D2, A2, H13, and more. Our in-house facility in Shenzhen ensures tight tolerances, fast turnaround, and consistent quality control—all under one roof.

Partner with us for reliable, scalable production of tooling components, molds, dies, and engineering prototypes. We support both low-volume and high-mix manufacturing needs with full material traceability and post-processing options including heat treatment, surface finishing, and polishing.

Contact Susan Leo today at [email protected] to discuss your tool steel machining requirements. Let our Shenzhen factory be your trusted manufacturing partner.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.