Contents

Manufacturing Insight: Tool Blocks For Cnc Lathes

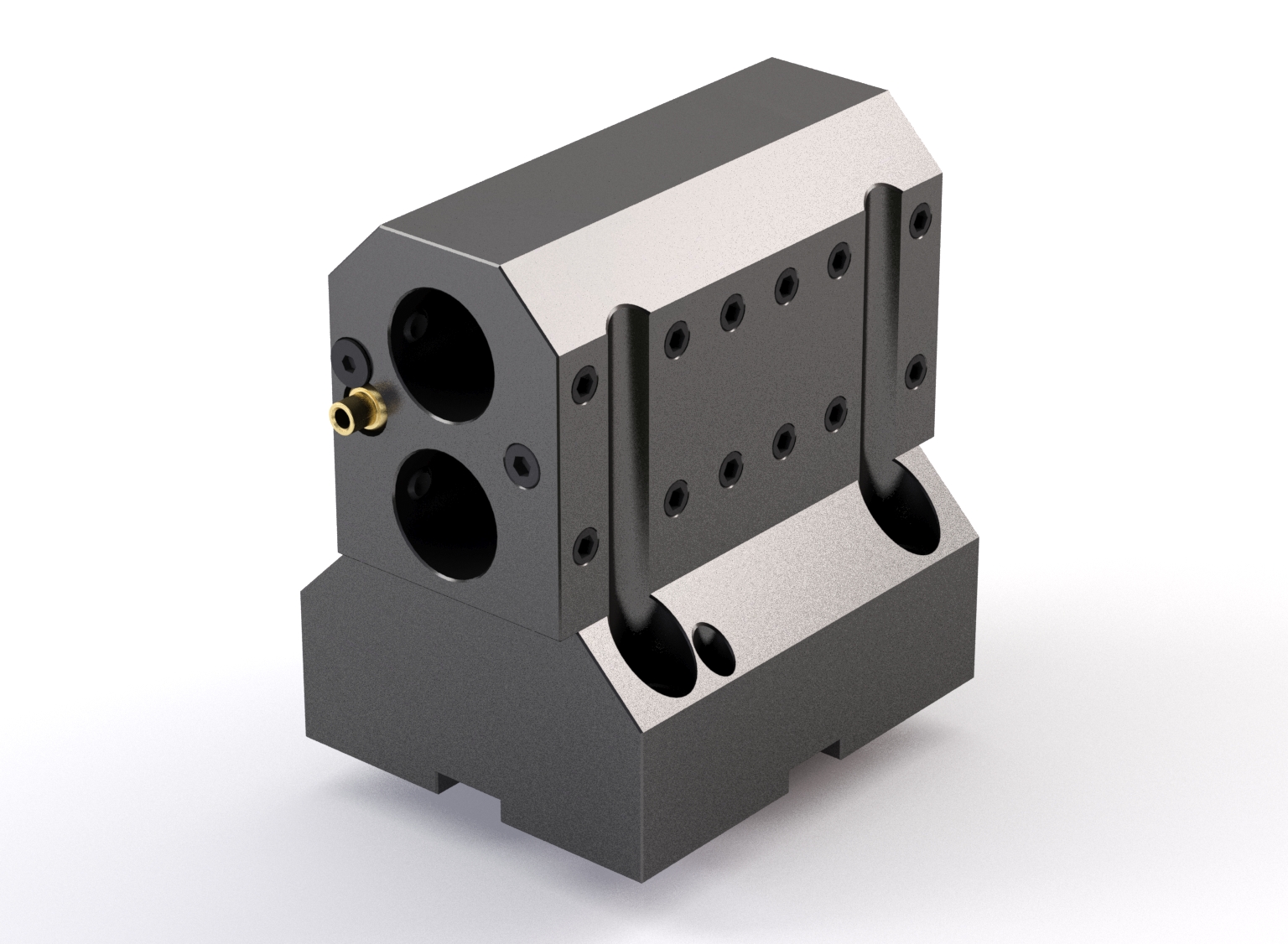

Precision Tool Blocks for CNC Lathes: Engineered for Rigidity and Repeatability

Tool blocks are fundamental components in CNC lathe operations, directly impacting machining accuracy, tool life, and overall process stability. Substandard tooling setups introduce deflection, vibration, and dimensional drift, compromising part quality and increasing scrap rates. At Honyo Prototype, we specialize in manufacturing high-integrity tool blocks engineered to deliver the rigid stability required for demanding turning applications. Our CNC machining services leverage advanced 5-axis milling and turning centers alongside stringent quality protocols to produce tool blocks meeting ISO 2768-mK tolerances or tighter, using premium materials like hardened tool steel, stainless alloys, and wear-resistant composites.

Every tool block undergoes rigorous in-process inspection and final CMM verification to ensure geometric precision and surface finish integrity critical for secure toolholder interface and minimal runout. This commitment to dimensional accuracy translates directly to reduced chatter, extended insert life, and consistent part conformance in your production environment. For manufacturers seeking to eliminate tooling-related bottlenecks, Honyo provides a seamless path from design validation to certified production. Expedite your procurement cycle with our Online Instant Quote platform—submit CAD files for tool blocks or complex lathe components and receive detailed, competitive pricing within hours, backed by our engineering team’s expertise in manufacturability optimization.

Technical Capabilities

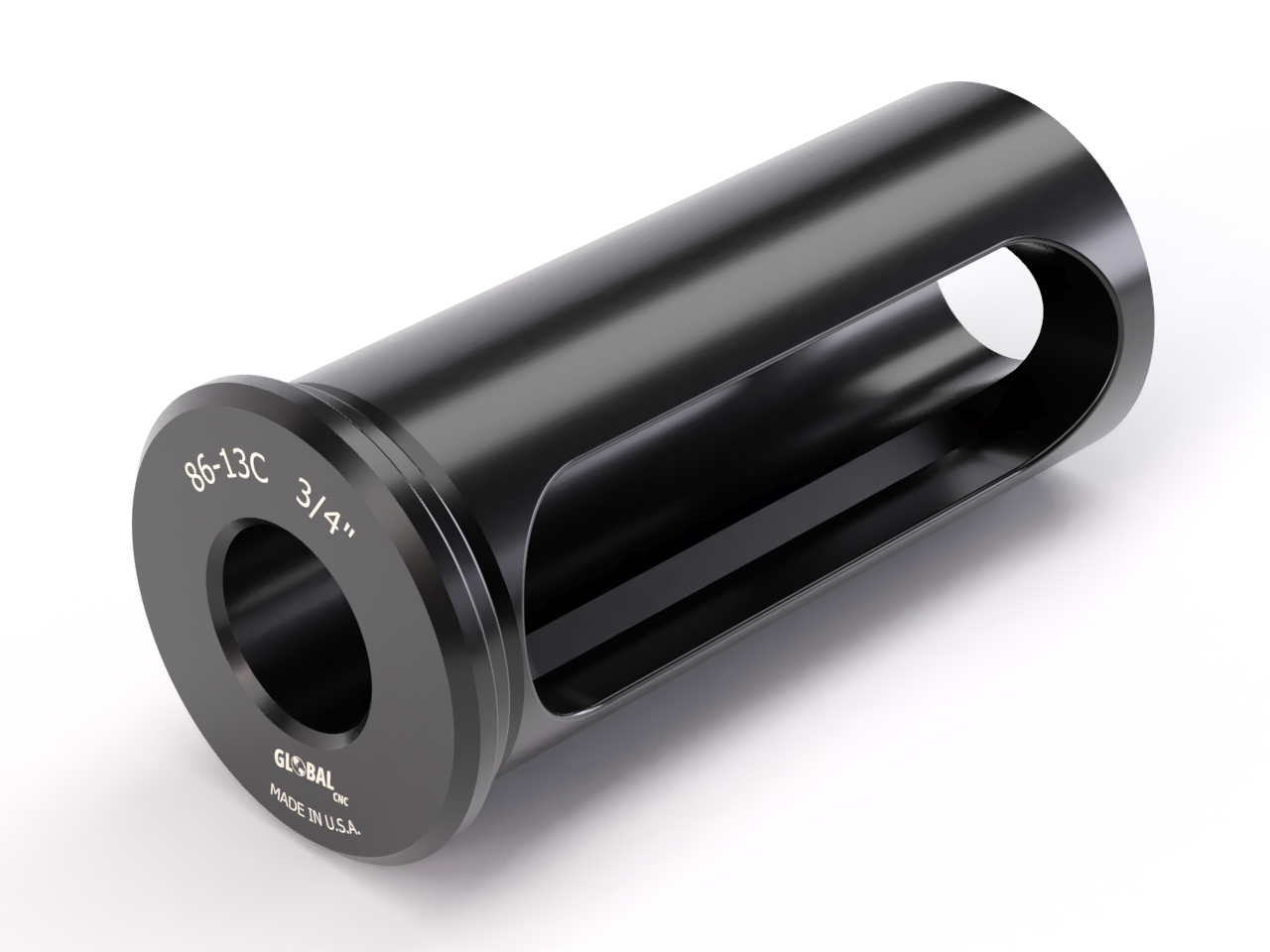

Tool blocks for CNC lathes are precision workholding components used to securely hold cutting tools or fixtures during machining operations. In advanced multi-axis environments—particularly 3, 4, and 5-axis milling and turning setups—tool blocks must maintain high rigidity, thermal stability, and dimensional accuracy to support tight-tolerance machining. These blocks are commonly used in prototyping and production applications where repeatability and alignment are critical.

The choice of material for tool blocks depends on the application requirements, including strength, weight, damping characteristics, and cost. Common materials include aluminum for lightweight rigidity, steel for maximum durability, and engineering polymers like ABS and nylon for non-marring or low-load scenarios.

Below is a summary of technical specifications and material properties relevant to tool blocks used in high-precision CNC lathe and mill-turn environments:

| Parameter | Aluminum (e.g., 6061-T6) | Steel (e.g., 4140, A2) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide) |

|---|---|---|---|---|

| Typical Use Case | 3/4/5-axis milling, turning | High-force turning, heavy cuts | Prototyping, light fixturing | Low-friction, non-marring support |

| Tensile Strength | 45,000 psi | 90,000–120,000 psi | 6,000 psi | 8,000–10,000 psi |

| Hardness | ~95 HB | 28–32 HRC (heat-treated) | Shore D 75–85 | Rockwell M80–M100 |

| Thermal Stability | Good (CTE: ~13 µm/m·°C) | Excellent (CTE: ~11 µm/m·°C) | Poor (CTE: ~80 µm/m·°C) | Moderate (CTE: ~60 µm/m·°C) |

| Machinability | Excellent | Good (slower speeds) | Excellent | Good |

| Weight (Density) | 2.7 g/cm³ | 7.8 g/cm³ | 1.04 g/cm³ | 1.15 g/cm³ |

| Surface Finish Capability | Ra 0.8–1.6 µm (milled) | Ra 0.4–0.8 µm (ground/milled) | Ra 3.2–6.3 µm (milled) | Ra 1.6–3.2 µm |

| Tolerance Capability | ±0.0002″ (5 µm) | ±0.0001″ (2.5 µm) | ±0.001″ (25 µm) | ±0.001″ (25 µm) |

| Damping Characteristics | Moderate | Low | High | High |

| Typical Applications | High-speed milling, light turning | Heavy-duty turning, long runs | Alignment jigs, prototype tooling | Wear pads, tool guides |

Tool blocks designed for tight-tolerance operations in 3, 4, and 5-axis CNC environments must be manufactured with precision-ground reference surfaces and often include features such as T-slots, dowel pin holes, and threaded inserts for modular integration. Aluminum remains the preferred choice for most high-speed applications due to its optimal strength-to-weight ratio and ease of machining, while steel is selected for high-stress, high-accuracy production runs. ABS and nylon are typically used in non-cutting roles—such as protective fixtures or alignment aids—where metal-to-metal contact must be avoided.

From CAD to Part: The Process

Honyo Prototype CNC Lathe Tool Block Manufacturing Process Overview

Honyo Prototype delivers precision CNC lathe tool blocks through a rigorously controlled digital workflow designed for speed, accuracy, and manufacturability assurance. This process eliminates traditional quoting delays while ensuring engineering integrity from initial design to final delivery.

CAD Upload and Validation

Clients initiate the process via Honyo’s secure customer portal by uploading native CAD files (STEP, IGES, or Parasolid preferred) with complete geometric and tolerance specifications. Our system performs immediate automated validation checks for file integrity, unit consistency, and minimum feature resolution. Invalid submissions trigger real-time feedback specifying required corrections, preventing downstream delays. All data is encrypted and stored in our AS9100-compliant document management system with revision tracking.

AI-Powered Quoting Engine

Validated CAD models enter Honyo’s proprietary AI quoting system, which analyzes 38+ geometric and material parameters within 90 seconds. The engine cross-references real-time machine availability, material stock levels, and historical cycle time databases to generate a technically validated cost and lead time estimate. Critical factors include part complexity index, material removal rate, and required surface finishes. This phase reduces quoting time by 92% versus manual methods while providing immediate visibility into cost drivers such as tight tolerances or exotic materials. Human engineers review all AI outputs for high-risk geometries before client submission.

Engineering-Driven DFM Analysis

Every project undergoes mandatory Design for Manufacturability review by Honyo’s senior manufacturing engineering team. For lathe tool blocks, we specifically evaluate: thermal stability under cutting loads, optimal workholding interface design, coolant channel integration feasibility, and critical runout tolerance validation (typically ±0.0002″ for indexable styles). Engineers collaborate directly with clients via secure markup tools to resolve issues like inadequate draft angles, non-standard thread forms, or suboptimal chip evacuation paths. Approved DFM reports include detailed tolerance stack-up analysis and fixture design schematics.

Precision Production Execution

Production occurs in our climate-controlled machining cell featuring DMG MORI CTX beta 1250 lathes with Y-axis and live tooling, equipped with Renishaw probing systems for in-process verification. Tool blocks are machined from certified 4140PH, A2, or custom tool steels using optimized high-speed toolpaths. Each operation includes:

Pre-machining material hardness verification

In-process CMM checks at critical feature completion

Final 100% geometric inspection per ASME Y14.5

Surface roughness validation via profilometry (Ra ≤ 8 μin typical)

All process data is logged to our digital twin platform for full traceability.

Quality-Controlled Delivery

Finished tool blocks undergo final packaging in custom anti-corrosion containers with desiccant. Each shipment includes:

First-article inspection report (FAIR) with dimensional data

Material test certificates (MTRs)

Calibration certificates for critical features

Digital as-built model for client verification

Standard lead time from CAD approval to shipment is 7–12 business days, with expedited options available. All deliveries include real-time logistics tracking through our client portal.

Process Performance Metrics

The integrated workflow delivers measurable advantages for lathe tool block production:

| Phase | Traditional Process | Honyo Prototype Process | Improvement |

|---|---|---|---|

| Quote Generation | 3–5 business days | ≤2 business hours | 95% faster |

| DFM Issue Resolution | Iterative email cycles (5–10 days) | Collaborative digital markup (24–48 hours) | 80% faster |

| First-Pass Yield | 72–85% | 98.7% | 13.7% higher |

| On-Time Delivery | 88% | 99.2% | 11.2% higher |

This structured approach ensures Honyo delivers CNC lathe tool blocks meeting stringent machine tool OEM requirements while providing clients with unprecedented process transparency and schedule certainty. All phases incorporate closed-loop quality controls aligned with ISO 9001:2015 standards, with engineering oversight at every transition point to maintain dimensional integrity critical for high-precision turning applications.

Start Your Project

Looking for high-precision tool blocks for CNC lathes? Honyo Prototype offers durable, dimensionally stable tool blocks engineered for optimal performance in demanding machining applications. Manufactured in our Shenzhen factory, our products are built to deliver consistent accuracy and extended tool life.

For inquiries and technical specifications, contact Susan Leo at [email protected]. Let’s discuss how we can support your production needs with reliable, made-in-China tooling solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.