Guide Contents

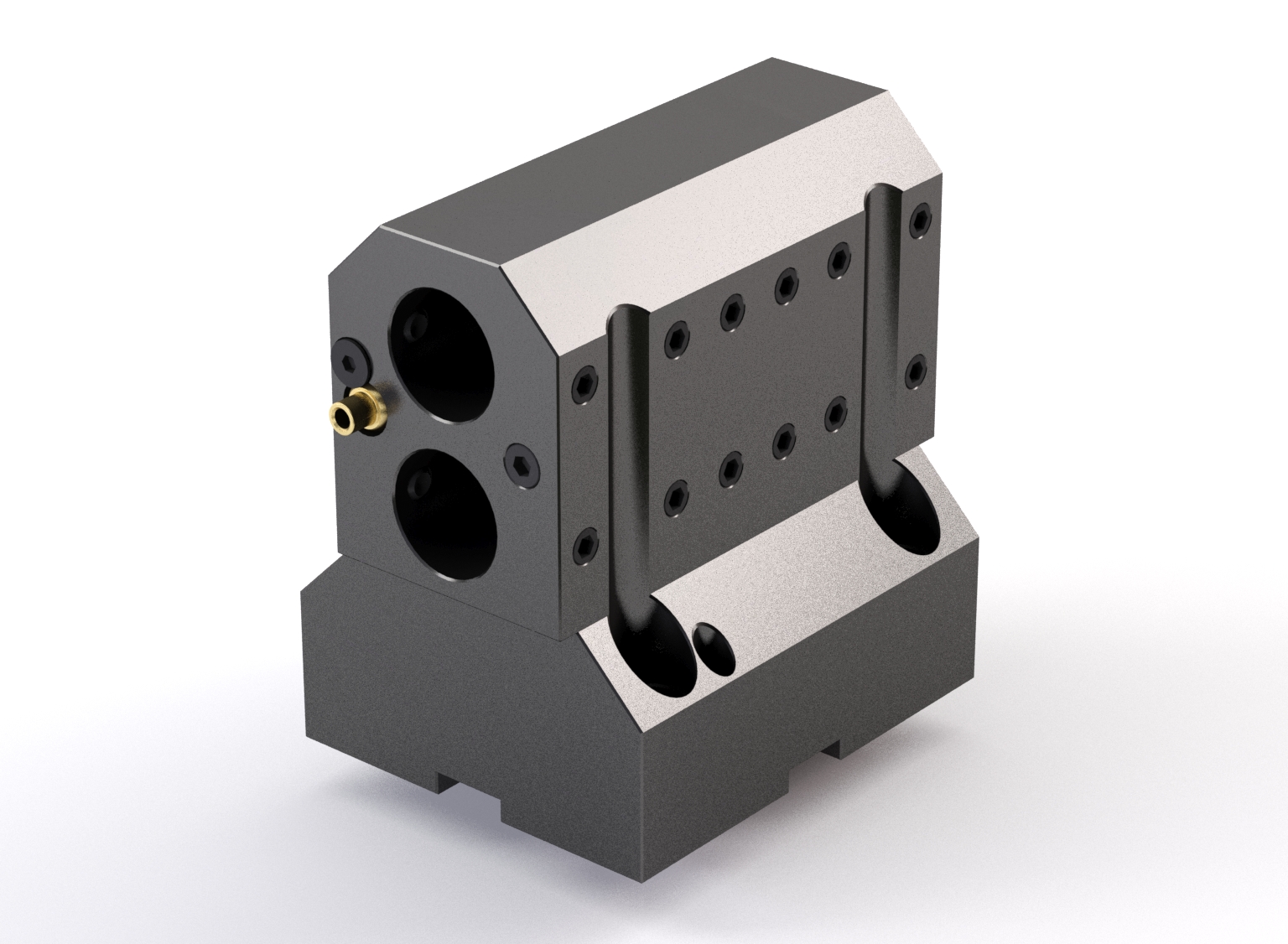

Project Insight: Tool Blocks For Cnc Lathes

Manufacturing Insight: Tool Blocks for CNC Lathes

The Critical Role of Precision Tool Blocks in Modern CNC Machining

Why Speed and Precision Are Non-Negotiable for Product Development

Accelerate Time-to-Market: Every hour of downtime in tool block production cascades into delayed product launches—precision tooling ensures your CNC lathes operate at peak efficiency from day one.

Eliminate Rework Costs: Sub-micron tolerances (+/- 0.01mm) prevent part misalignment and surface defects, slashing scrap rates and rework expenses.

Optimize Machine Performance: Custom-designed tool blocks maximize cutting efficiency and spindle stability, directly impacting part quality and throughput.

Honyo Prototype: Your Precision CNC Tool Block Partner

Engineered for Innovation, Delivered at Speed

AI-Powered Instant Quote: Upload your CAD file and receive real-time pricing, material recommendations, and manufacturability feedback in seconds—no manual quotes, no delays.

3-Day Prototype Turnaround: From design to delivery, we compress lead times without compromising quality—ideal for rapid iteration cycles and urgent project needs.

Tight Tolerances Across 3/4/5-Axis Machining: Precision-engineered for complex geometries, ensuring flawless integration with any CNC lathe system.

Why Hardware Startups & Engineers Trust Honyo

Seamless Digital Workflow: Our platform integrates with your design tools, eliminating communication gaps and manual errors.

End-to-End Quality Assurance: Every tool block undergoes rigorous CMM inspection and in-process monitoring to guarantee +/- 0.01mm precision.

Global Support, Local Expertise: Shenzhen-based manufacturing with dedicated engineering support for rapid problem-solving and scalability.

“In precision machining, there’s no room for compromise. At Honyo, we turn your designs into reality—faster, smarter, and with zero margin for error.”

— Susan Leo, Founder

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Advanced Multi-Axis Machining Capabilities

3/4/5-axis precision machining for complex geometries and intricate tool block designs

Seamless compatibility with all major CNC lathe platforms (Haas, Mazak, DMG MORI, Okuma, etc.)

Optimized for both functional prototypes and end-use production parts with minimal setup time

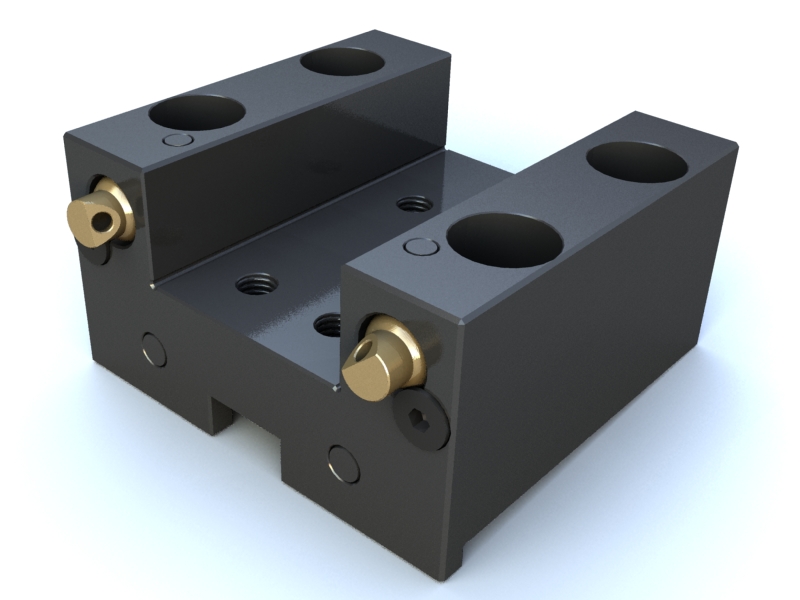

Unmatched Precision & Consistency

Tight tolerances of ±0.01mm for critical dimensions and mating surfaces

Consistent surface finishes (Ra 0.4μm or better) to ensure optimal tool performance and longevity

Real-time in-process monitoring to eliminate dimensional drift during production

Scalable Production from Prototype to Volume

Flexible manufacturing for 1 unit to 10,000+ parts with no minimum order quantity

Seamless transition from R&D to full-scale production—no retooling or cost spikes

Economical pricing for high-volume runs through lean, automated workflows

Rigorous Quality Assurance

ISO 9001 certified processes with full traceability from raw material to final inspection

Comprehensive dimensional reports and material certifications included with every order

100% first-article inspection + statistical process control (SPC) for batch consistency

Streamlined Ordering Experience

AI-powered instant quotes with real-time pricing and lead time estimates (24/7 access)

Automated DFM (Design for Manufacturability) feedback to optimize designs before production

Guaranteed 72-hour prototype delivery and 5-day production turnaround for standard orders

Dedicated account manager for end-to-end project coordination and expedited support

Materials & Surface Finishes

Precision Materials & Finishes for CNC Tool Blocks

At Honyo Prototype, we engineer tool blocks with material and finish options tailored to your specific application requirements, ensuring maximum durability, precision, and performance. Leverage our AI-powered instant quote platform for real-time pricing, material recommendations, and lead times—standard orders ship in 5 days with ±0.01mm tolerances. No minimums, no delays.

Material Options for Maximum Performance

Aluminum 6061: Exceptional machinability and corrosion resistance. Ideal for prototypes and low-stress applications, achieving ±0.01mm tolerances with minimal tool wear.

Aluminum 7075: High-strength alloy for heavy-duty tooling. Superior fatigue resistance and rigidity, perfect for high-load CNC lathe applications where vibration control is critical.

Stainless Steel 304: Non-magnetic and corrosion-resistant. Best for wet or mildly corrosive environments without extreme chemical exposure (e.g., food processing equipment).

Stainless Steel 316: Enhanced chloride resistance. Critical for marine, chemical processing, or high-moisture industrial settings where long-term reliability is non-negotiable.

Brass: Superior thermal conductivity and machinability. Ideal for electrical applications or where non-sparking properties are required (e.g., explosive environments).

PEEK: High-temperature stability (up to 250°C) and chemical inertness. Used in specialized applications requiring extreme thermal resilience and low friction.

Surface Finishes for Enhanced Durability & Functionality

Anodizing (Type II/III): Boosts wear resistance and corrosion protection. Type III (hard coat) for high-stress environments where surface hardness is critical.

Powder Coating: Durable, custom-color finishes for non-functional surfaces (e.g., identification marks). Ideal for visual branding without compromising precision.

Mirror Polishing (Ra < 0.4µm): Achieves ultra-smooth surfaces for low-friction applications, critical for precision fit and coolant flow optimization.

Black Oxide: Reduces glare, minimizes dimensional changes, and enhances corrosion resistance for steel components.

Passivation: Removes surface contaminants from stainless steel, maximizing natural corrosion resistance and extending tool life.

Electroless Nickel Plating: Uniform coating for wear resistance and dimensional stability in high-precision, high-wear scenarios.

How to Choose the Right Material for Your Tool Block

Selecting the optimal material depends on your application’s specific demands. Consider these key factors:

Load Requirements: High-stress applications require 7075 aluminum or stainless steel; 6061 aluminum balances cost and performance for lighter loads.

Environmental Factors: Moisture or chemicals? Stainless 316 or anodized aluminum. Dry environments? Standard aluminum suffices.

Thermal Conditions: PEEK for high-temperature stability; brass for thermal conductivity in electrical applications.

Precision Needs: All materials meet ±0.01mm tolerances, but 6061 and brass offer faster machining for rapid prototyping.

Cost Efficiency: Aluminum typically provides the best value for most prototypes; stainless steel is ideal for demanding environments.

Accelerate Your Project with Honyo’s AI-Powered Platform

Upload your CAD file or specifications for an instant quote—our AI analyzes material suitability, surface finish options, and lead times in seconds. Standard tool blocks ship in 5 days with ±0.01mm precision. No minimums, no delays.

Start Your Project Now → [Get Instant Quote]

From Quote to Part: Our Process

How It Works: From CAD to Part

Transform your design vision into precision parts with Honyo’s AI-powered workflow—designed for speed, accuracy, and complete transparency. Here’s how it works:

1. Upload Your CAD File

Instantly upload STEP, IGES, SolidWorks, or native CAD files via our secure cloud platform

Auto-detection of geometry and tolerances—no manual formatting required

Enterprise-grade encryption ensures end-to-end data security

2. Get Instant Quote with AI-Powered Analysis

AI-driven platform delivers real-time quotes in under 60 seconds—no waiting for sales reps

Transparent pricing with no hidden fees; see exact costs for materials, machining, and finishes

Instant manufacturability assessment with optimization suggestions to reduce costs

3. DFM-Optimized Design Review

Automated design-for-manufacturability (DFM) analysis flags potential issues before production begins

Expert engineers provide actionable feedback to refine tolerances and enhance part performance

Collaborative revision platform for seamless iterations—minimize delays and rework

4. Precision Production & On-Time Delivery

Shenzhen-based 3/4/5-axis CNC machining with ±0.01mm tolerances for functional prototypes and end-use parts

Real-time quality monitoring and automated inspection at every production stage

Live order tracking with proactive delivery updates—guaranteed on-time shipment

Start Your Project with Honyo

Start Your Project with Honyo

Engineered for Precision. Delivered at Speed.

AI-Powered Instant Quote: Get real-time pricing and lead times in seconds—no phone calls required. Our digital platform eliminates guesswork and accelerates decision-making.

±0.01mm Tolerance Precision: Certified accuracy for functional prototypes and end-use parts. Every tool block meets rigorous aerospace and medical-grade standards.

3-Day Prototype Turnaround: Rapid production cycles to compress your time-to-market. Scalable solutions for volume orders without compromising quality.

Custom Solutions for All CNC Platforms: Tailored tool blocks for Haas, Mazak, DMG, and all major systems—no machine left behind.

Ready to accelerate your project? Contact Susan Leo & Team Today:

📧 [email protected] | 📞 +86 139 2843 8620

📍 Visit our Shenzhen & Dongguan facilities for a live demonstration of our ISO-certified precision manufacturing process.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.