Introduction: Navigating the Global Market for tolerance fit table

In the complex landscape of global manufacturing, sourcing the right tolerance fit table can be a daunting task for B2B buyers. The challenge lies not only in understanding the myriad of fit classifications—clearance, transition, and interference—but also in selecting the appropriate tolerances that align with specific application requirements. This guide provides a comprehensive overview of tolerance fit tables, including detailed classifications, practical applications, and insights into supplier vetting processes. By demystifying these technical specifications, we aim to empower international buyers, particularly those in Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Throughout this guide, we will explore the various types of fits, their implications for product performance, and the cost factors associated with tighter tolerances. Furthermore, we will delve into best practices for assessing suppliers to ensure that they meet the rigorous standards required for precision engineering. With the right knowledge at their fingertips, buyers can confidently navigate the nuances of tolerance fits, ensuring optimal functionality in their machinery and equipment. This resource serves as an essential tool for those seeking to enhance their procurement strategies in a competitive global market.

Understanding tolerance fit table Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

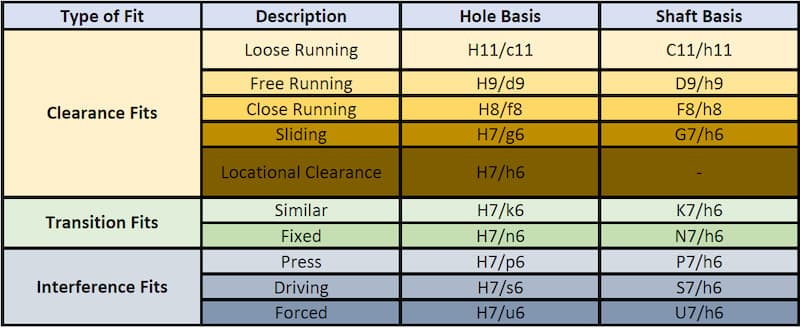

| Clearance Fit | Allows space between parts; easy assembly | General machinery, automotive | Pros: Easy to assemble, reduces wear. Cons: May lead to play in parts, affecting precision. |

| Transition Fit | Intermediate between clearance and interference; precise control over fit | Precision instruments, aerospace | Pros: Balanced fit, minimizes movement. Cons: More complex manufacturing, higher costs. |

| Interference Fit | Parts are tightly fitted; requires force for assembly | Heavy machinery, structural components | Pros: High stability, no movement. Cons: Difficult assembly, potential for damage during installation. |

| Hole Basis System | Diameter of the hole is controlled, shaft is adjusted | General engineering applications | Pros: Simplifies manufacturing, consistent results. Cons: Limited flexibility in shaft design. |

| Shaft Basis System | Diameter of the shaft is controlled, hole is adjusted | Custom machining, specialized parts | Pros: Greater precision in shaft dimensions. Cons: More complex design and production processes. |

What are the Characteristics of Clearance Fits and Their Suitability for B2B Buyers?

Clearance fits are characterized by a deliberate space between mating parts, allowing for ease of assembly and disassembly. This type is particularly suitable for applications where parts need to move freely, such as in general machinery and automotive components. B2B buyers should consider that while clearance fits facilitate assembly and reduce wear, they may introduce play, which can impact precision in critical applications.

How Does Transition Fit Offer a Balanced Solution for Precision?

Transition fits provide a middle ground between clearance and interference fits, allowing for a controlled level of tightness. This type is ideal for precision instruments and aerospace applications, where a snug fit is necessary to minimize movement without being overly tight. Buyers should weigh the benefits of improved precision against the potential for higher manufacturing costs and complexity associated with achieving the required tolerances.

Why Choose Interference Fits for Heavy Machinery Applications?

Interference fits are defined by a tight fit that requires significant force to assemble the parts. This type is commonly used in heavy machinery and structural components where stability and resistance to movement are critical. While interference fits provide high stability and eliminate any potential play, buyers must be aware of the challenges in assembly, including the risk of damaging components during installation.

What Are the Advantages of Using a Hole Basis System in Manufacturing?

The hole basis system maintains a constant measurement for the hole while adjusting the shaft dimensions to achieve the desired fit. This approach simplifies the manufacturing process and ensures consistent results, making it a preferred choice for general engineering applications. Buyers should consider that while the hole basis system is straightforward, it may limit flexibility in shaft design, potentially affecting custom applications.

When Is a Shaft Basis System More Beneficial for Custom Machining?

In a shaft basis system, the shaft dimensions are controlled while the hole size is adjusted. This system is advantageous for custom machining and specialized parts, as it allows for greater precision in shaft dimensions. However, B2B buyers should note that this system can complicate design and production processes, which may lead to increased lead times and costs.

Key Industrial Applications of tolerance fit table

| Industry/Sector | Specific Application of tolerance fit table | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine components assembly | Ensures precise fitting of parts for optimal engine performance | Reliable suppliers with expertise in ISO tolerances |

| Aerospace | Aircraft structural components | Critical for safety and performance under high-stress conditions | Compliance with stringent aviation regulations |

| Machinery Manufacturing | Gear and shaft assemblies | Enhances operational efficiency and reduces wear and tear | Availability of advanced machining capabilities |

| Electronics | Circuit board assembly | Guarantees effective connections and functionality of devices | Precision in component sizing and quality assurance |

| Construction | Structural steel connections | Provides stability and safety in building structures | Durability and resistance to environmental factors |

How is the ‘tolerance fit table’ utilized in the automotive sector?

In the automotive industry, the tolerance fit table is crucial for the assembly of engine components. The precise fitting of parts, such as pistons and crankshafts, ensures optimal engine performance and efficiency. Problems like excessive wear or operational failures can arise from improper fits, leading to costly repairs and downtime. Buyers in this sector must ensure that suppliers adhere to ISO standards and provide components that meet specific tolerances to maintain reliability and performance.

Why is the ‘tolerance fit table’ important in aerospace applications?

Aerospace applications require the highest standards of precision due to the critical nature of safety and performance. The tolerance fit table assists engineers in selecting the appropriate fits for aircraft structural components, ensuring they can withstand high-stress conditions. Non-compliance with tolerance specifications can result in catastrophic failures. International buyers must prioritize suppliers with a proven track record in aerospace engineering and compliance with stringent regulations to mitigate risks.

What role does the ‘tolerance fit table’ play in machinery manufacturing?

In machinery manufacturing, the tolerance fit table is essential for the assembly of gears and shafts. Proper fits enhance operational efficiency and reduce wear and tear on machinery, leading to longer service life and lower maintenance costs. Buyers must consider sourcing from manufacturers that employ advanced machining techniques to achieve the necessary tolerances. This attention to detail can significantly impact production efficiency and overall operational costs.

How does the ‘tolerance fit table’ contribute to electronics assembly?

In electronics, the tolerance fit table is vital for circuit board assembly, where precise fits ensure effective connections between components. Any deviation from specified tolerances can lead to malfunctioning devices, resulting in financial losses and reputational damage. Buyers must focus on sourcing components with high precision and quality assurance processes to ensure reliability in electronic devices, especially when dealing with international suppliers who may have varying quality standards.

Why is the ‘tolerance fit table’ critical in construction projects?

In the construction industry, the tolerance fit table is used to ensure the proper fitting of structural steel connections, which is essential for stability and safety. Inadequate fits can compromise the structural integrity of buildings, leading to significant safety hazards. Buyers in this sector should prioritize sourcing durable materials that can withstand environmental factors while adhering to specified tolerances to ensure long-lasting construction results.

3 Common User Pain Points for ‘tolerance fit table’ & Their Solutions

Scenario 1: Understanding Tolerance Grades for Precision Engineering

The Problem:

B2B buyers often struggle with the complexity of tolerance grades when selecting components for precision engineering projects. For instance, a manufacturing manager in Germany may encounter difficulties in interpreting the ISO tolerance tables. This can lead to confusion over which tolerance class to apply for specific applications, ultimately resulting in mismatched components that can disrupt production lines or lead to costly reworks.

The Solution:

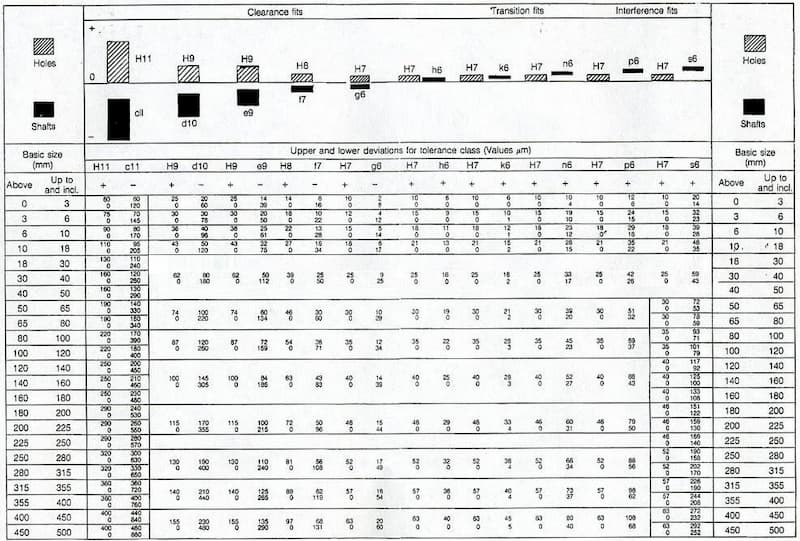

To address this challenge, buyers should invest time in thoroughly understanding the ISO tolerance system. First, familiarize yourself with the difference between hole and shaft basis systems. This foundational knowledge allows you to determine which component’s size will be the reference point. Utilize resources like detailed tolerance fit tables that provide a clear breakdown of grades, including examples of applications for each fit type (clearance, transition, interference). Additionally, consider leveraging advanced tools like limits and fits calculators available online to simplify the selection process. These calculators can help streamline decisions by allowing you to input your specific requirements and quickly receive the appropriate tolerances, minimizing the risk of errors.

Scenario 2: Miscommunication Between Design and Manufacturing Teams

The Problem:

Miscommunication between engineering and manufacturing teams is a prevalent issue that can arise due to differing interpretations of tolerance fit tables. For example, a buyer in South America might specify a tolerance fit for a new product design, but if the manufacturing team misinterprets the specifications, it can lead to production delays and increased costs. This disconnect often stems from a lack of clarity in the design documentation or insufficient knowledge of tolerance implications on manufacturing processes.

The Solution:

To bridge this communication gap, it is essential to implement standardized documentation practices that clearly outline tolerance specifications. Use explicit language in design drawings, incorporating visual aids such as annotated diagrams that highlight critical tolerance limits. Regular training sessions for both engineering and manufacturing teams can enhance understanding of tolerance fits and their impact on product quality. Furthermore, fostering an open dialogue between teams can help clarify any uncertainties early in the process, allowing for adjustments before production begins. Utilizing collaborative software tools that allow real-time updates and feedback can also facilitate better alignment.

Scenario 3: Sourcing High-Quality Components with Correct Tolerances

The Problem:

B2B buyers often find it challenging to source high-quality components that meet specific tolerance requirements. For instance, a procurement officer in the Middle East may receive multiple supplier offers, but they struggle to determine which ones can consistently deliver components within the desired tolerances. This uncertainty can lead to operational inefficiencies and increased costs due to the need for further inspection and rework.

The Solution:

To effectively source components that adhere to strict tolerance specifications, buyers should develop a comprehensive supplier evaluation process. Start by creating a detailed checklist that includes criteria such as the supplier’s quality control processes, historical performance data, and certifications (e.g., ISO 9001). Conduct audits or request samples to assess the accuracy of their tolerance claims. Additionally, establish long-term partnerships with suppliers who demonstrate a commitment to quality and reliability. Sharing your specific tolerance requirements upfront can also help suppliers understand your needs better and tailor their offerings accordingly. Finally, consider using third-party inspection services to verify that the components meet your tolerance specifications before they are integrated into your production processes.

Strategic Material Selection Guide for tolerance fit table

What Are the Key Properties of Common Materials Used in Tolerance Fit Tables?

When selecting materials for components that will be referenced in a tolerance fit table, several factors must be considered, including mechanical properties, environmental resistance, and manufacturing complexities. Below are analyses of four common materials used in various applications.

How Do Steel Alloys Perform in Tolerance Fit Applications?

Steel alloys are widely used in manufacturing due to their excellent strength, durability, and versatility. They typically offer high tensile strength and good wear resistance, making them suitable for applications involving high pressure and temperature. However, their susceptibility to corrosion can be a significant drawback unless they are treated or alloyed with corrosion-resistant elements.

Pros: Steel alloys are durable and can withstand significant mechanical stress. They are also readily available and can be machined to precise tolerances, which is crucial for ensuring proper fits.

Cons: The primary disadvantage is their weight and potential for rusting if not properly treated. Additionally, the cost of high-quality steel alloys can be high, particularly for specialized grades.

Impact on Application: Steel alloys are ideal for applications that require high strength and durability, such as automotive and industrial machinery. However, their compatibility with corrosive environments must be assessed.

International Considerations: Buyers in regions like Europe (e.g., Germany) should be aware of compliance with standards such as DIN and EN. In contrast, buyers from Africa and South America may need to consider local availability and pricing variations.

What Advantages Do Aluminum Alloys Offer in Tolerance Fit Applications?

Aluminum alloys are known for their lightweight properties and excellent corrosion resistance, making them suitable for applications where weight is a critical factor. They also have good thermal and electrical conductivity, which can be beneficial in specific engineering applications.

Pros: The lightweight nature of aluminum alloys makes them ideal for aerospace and automotive applications. They are also easy to machine, allowing for precise tolerances.

Cons: Aluminum alloys generally have lower tensile strength compared to steel, which may limit their use in high-stress applications. Additionally, they can be more expensive than some steel options.

Impact on Application: Aluminum is often preferred in applications that require corrosion resistance and weight savings, such as in the aerospace industry. However, it may not be suitable for high-load-bearing components.

International Considerations: Buyers should consider compliance with international standards such as ASTM and JIS. In regions like the Middle East, where extreme temperatures can occur, selecting the right alloy grade is crucial.

Why Are Plastics Important in Tolerance Fit Applications?

Plastics, particularly engineering plastics like polycarbonate and nylon, are increasingly used in tolerance fit applications due to their lightweight and corrosion-resistant properties. They can be manufactured to tight tolerances and are often less expensive than metals.

Pros: Plastics are resistant to corrosion and chemicals, making them suitable for various environments. They also offer good insulation properties.

Cons: The primary limitation is their lower strength compared to metals, which can restrict their use in high-load applications. Additionally, plastics may have lower temperature resistance.

Impact on Application: Plastics are ideal for applications in the consumer goods and electronics sectors, where weight and corrosion resistance are essential. They may not be suitable for heavy machinery or high-temperature environments.

International Considerations: Buyers should be aware of the varying standards for plastics across regions, such as ASTM for North America and EN for Europe. Understanding local regulations regarding plastic recyclability is also essential.

How Do Composites Enhance Tolerance Fit Applications?

Composite materials, such as carbon fiber and fiberglass, combine the benefits of various materials to achieve specific performance characteristics. They are lightweight and can be engineered for high strength and stiffness.

Pros: Composites offer excellent strength-to-weight ratios and can be tailored for specific applications. They are also resistant to corrosion and fatigue.

Cons: The manufacturing process for composites can be complex and costly, which may limit their use in some applications. Additionally, they can be challenging to machine to tight tolerances.

Impact on Application: Composites are often used in aerospace and automotive applications where performance and weight savings are critical. However, their cost and manufacturing complexity should be considered.

International Considerations: Buyers should look for compliance with international standards such as ASTM and ISO. In regions with developing markets, understanding local manufacturing capabilities is essential.

Summary Table of Material Selection for Tolerance Fit Applications

| Material | Typical Use Case for tolerance fit table | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Alloys | Automotive and industrial machinery | High strength and durability | Susceptible to corrosion | High |

| Aluminum Alloys | Aerospace and automotive applications | Lightweight and corrosion resistant | Lower tensile strength compared to steel | Medium |

| Plastics | Consumer goods and electronics | Corrosion resistant and lightweight | Lower strength and temperature resistance | Low |

| Composites | Aerospace and automotive applications | Excellent strength-to-weight ratio | Complex and costly manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for tolerance fit table

What Are the Main Stages of Manufacturing Tolerance Fit Tables?

Manufacturing tolerance fit tables involves several critical stages to ensure precision and quality in the final product. Each stage plays a significant role in achieving the desired tolerances and fits for components used in various industrial applications.

Material Preparation: How Is Raw Material Selected and Processed?

The first step in manufacturing tolerance fit tables is the selection and preparation of raw materials. Common materials include metals like steel, aluminum, and brass, chosen based on their mechanical properties and application requirements.

Once selected, materials undergo processes such as cutting, shearing, or grinding to achieve specific dimensions. This initial processing ensures that the material meets the tolerances needed for subsequent manufacturing stages. For example, precision machining may be required to attain the necessary diameter for shafts or holes.

What Forming Techniques Are Used in Manufacturing Tolerance Fits?

Forming is a crucial stage where raw materials are shaped into their desired forms. Techniques such as turning, milling, and drilling are commonly employed to create parts with specified tolerances.

- Turning involves rotating the workpiece against a cutting tool, allowing for high precision in creating cylindrical shapes.

- Milling utilizes rotating cutters to remove material, effectively producing complex geometries.

- Drilling is essential for creating holes that will later be fitted with shafts.

Advanced CNC (Computer Numerical Control) machines are often used in this stage to enhance accuracy and repeatability, which are vital for achieving the tight tolerances required in tolerance fit tables.

How Does Assembly Fit into the Manufacturing Process?

The assembly stage involves bringing together various components that have been manufactured individually. This step is critical as it determines how well the parts will fit together, which directly impacts functionality.

During assembly, manufacturers often use jigs and fixtures to ensure that components are held in the correct position. This stage may also include processes such as welding or fastening, depending on the design requirements. Careful attention is given to ensure that tolerances are maintained, as any deviation can lead to operational issues.

What Finishing Techniques Are Commonly Employed?

Finishing processes are essential for enhancing the surface quality and performance of the components. Techniques such as grinding, polishing, and coating may be used.

- Grinding is often employed to achieve precise dimensions and surface finishes. It is particularly useful for achieving the required tolerances in shafts and holes.

- Polishing improves surface quality, reducing friction and wear during operation.

- Coating can provide additional benefits, such as corrosion resistance, which is crucial for components used in harsh environments.

These finishing processes ensure that the final product meets both functional and aesthetic requirements.

How Is Quality Assurance Managed in Manufacturing Tolerance Fit Tables?

Quality assurance (QA) is integral to the manufacturing process, ensuring that products meet international standards and customer specifications. Implementing a robust QA system helps manufacturers maintain consistency and reliability.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with various international standards that govern quality management systems. ISO 9001 is a widely recognized standard that outlines requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer has established processes for ensuring quality throughout the production cycle.

In addition to ISO standards, industry-specific certifications, such as CE marking for products sold in the European Economic Area and API standards for oil and gas applications, may also be relevant. These certifications demonstrate adherence to safety and performance criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that products meet established tolerances. Key checkpoints include:

- Incoming Quality Control (IQC): This initial inspection assesses raw materials and components before they enter production. It ensures that all materials meet specified requirements.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC checks for compliance with tolerances at various stages, such as during machining and assembly.

- Final Quality Control (FQC): The final inspection occurs once products are completed. This stage verifies that all components meet the required specifications and tolerances before they are shipped to customers.

These checkpoints help identify issues early in the production process, reducing the risk of defects in the final product.

What Common Testing Methods Are Used in Quality Assurance?

Manufacturers employ various testing methods to ensure that components meet their specifications. Common testing methods include:

- Dimensional Inspection: Using tools like calipers and micrometers to measure dimensions and tolerances.

- Functional Testing: Assessing the operational performance of components under simulated conditions.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle inspection are used to detect internal flaws without damaging the component.

These testing methods provide valuable data that can be used to refine manufacturing processes and improve product quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers. This verification process can include:

What Are the Best Practices for Conducting Supplier Audits?

Conducting thorough supplier audits is an effective way to assess a manufacturer’s quality control systems. Buyers should consider the following steps:

- On-Site Audits: Visiting the supplier’s facility allows buyers to observe manufacturing processes and quality control measures in action.

- Reviewing Documentation: Buyers should request and review quality assurance documentation, including quality manuals, inspection reports, and certifications.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can be particularly beneficial for international buyers who may face language and cultural barriers.

What Are the Quality Control Nuances for International Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances. Factors such as local regulations, cultural attitudes towards quality, and logistical challenges can affect the quality assurance process.

Buyers should also consider the potential impact of currency fluctuations and shipping delays on the quality of materials and components. Establishing clear communication channels with suppliers and utilizing technology for real-time monitoring can help mitigate these risks.

In summary, understanding the manufacturing processes and quality assurance practices for tolerance fit tables is crucial for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and robust quality control measures, buyers can ensure they source high-quality components that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tolerance fit table’

In the realm of engineering and manufacturing, selecting the right tolerance fit table is crucial for ensuring seamless interactions between mating parts. This guide serves as a practical checklist for B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. It will help you navigate the procurement process for tolerance fit tables effectively.

Step 1: Define Your Technical Specifications

Before sourcing a tolerance fit table, it’s essential to outline your specific technical requirements. Consider the types of fits you need, such as clearance, transition, or interference fits, and the range of nominal sizes relevant to your applications.

– Identify the materials and components that will interact with these fits.

– Specify the acceptable tolerances based on your engineering standards to ensure compatibility with your existing systems.

Step 2: Research Supplier Credentials

Engaging with reputable suppliers is vital for quality assurance. Investigate potential suppliers’ certifications, such as ISO 9001, to ensure they adhere to international quality standards.

– Check for industry-specific certifications that may apply to your region or sector.

– Look for testimonials or reviews from other B2B buyers to gauge their reliability and customer service.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Inquire about their experience with tolerance fit tables and the specific applications they cater to.

– Assess their capacity to provide custom solutions if your project requires unique specifications.

Step 4: Request Samples and Technical Data

To ensure the products meet your standards, ask suppliers for samples of their tolerance fit tables along with technical data sheets. This will allow you to evaluate the quality and precision of their offerings.

– Examine the provided data for compliance with international standards, such as ISO 286.

– Test samples in your application environment to verify performance before making bulk purchases.

Step 5: Discuss Pricing and Payment Terms

Engage in transparent discussions regarding pricing structures and payment terms. Understanding the cost implications of different fits and tolerances is essential for budgeting.

– Compare quotes from multiple suppliers to ensure competitive pricing.

– Negotiate payment terms that align with your cash flow requirements, particularly for large orders.

Step 6: Confirm Delivery and Support Services

Timely delivery and ongoing support are critical factors in supplier selection. Confirm lead times for orders and the supplier’s ability to provide technical support post-purchase.

– Clarify the logistics involved in shipping, especially if sourcing internationally, to avoid delays.

– Ensure that the supplier offers customer support for troubleshooting and guidance on fit applications.

Step 7: Establish a Long-Term Partnership

Once you’ve selected a supplier, aim to build a long-term relationship. A reliable supplier can provide ongoing support, updates on new products, and insights into industry trends.

– Communicate regularly to discuss future needs and any adjustments to your specifications.

– Evaluate their performance periodically to ensure they continue to meet your expectations.

By following this checklist, B2B buyers can effectively source tolerance fit tables that align with their technical needs while ensuring quality and reliability in their supply chain.

Comprehensive Cost and Pricing Analysis for tolerance fit table Sourcing

When sourcing tolerance fit tables, international B2B buyers must navigate a complex cost structure that significantly influences pricing. Understanding the various components and factors at play can empower buyers to make informed decisions, optimize their procurement strategies, and ultimately enhance their competitive edge.

What Are the Key Cost Components in Tolerance Fit Table Sourcing?

-

Materials: The choice of materials for tolerance fit tables can vary widely, impacting costs. Common materials include steel, aluminum, and specialized alloys. Higher quality materials may incur a premium but can improve durability and performance, justifying the additional expense in the long run.

-

Labor: Labor costs encompass the wages of skilled technicians and engineers involved in the design and manufacturing processes. Regions with lower labor costs, such as parts of Africa and South America, may offer competitive pricing, but buyers should also consider the expertise and quality of workmanship, which can vary significantly.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and administrative costs. Overhead can vary based on the supplier’s location and operational efficiency. Understanding these factors can help buyers assess the overall value offered by different suppliers.

-

Tooling: The initial setup for manufacturing tolerance fit tables requires specialized tooling, which can be a significant upfront investment. Buyers should inquire about tooling costs, especially if custom specifications are involved, as these can drastically affect the price.

-

Quality Control (QC): Implementing rigorous quality control measures is essential for ensuring the accuracy and reliability of tolerance fit tables. While this may increase costs, it is crucial for maintaining product standards and minimizing defects, which could lead to higher expenses down the line.

-

Logistics: Shipping and handling costs must also be factored into the total cost. International shipping can introduce complexities, including customs duties and tariffs, which vary by region. Understanding Incoterms is vital for clarifying responsibilities and costs associated with transportation.

-

Margin: Supplier margins can vary significantly based on competition and market conditions. Buyers should seek transparency about how pricing is structured to ensure they are receiving fair value.

How Do Pricing Influencers Impact Tolerance Fit Table Costs?

Several factors influence the pricing of tolerance fit tables:

-

Volume/MOQ: Higher order volumes often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs and specific tolerances can increase costs. Buyers should balance their requirements against potential cost implications and consider whether standard options might suffice.

-

Quality and Certifications: Suppliers offering higher quality materials and certifications (such as ISO standards) may charge more. However, these investments can lead to improved performance and reliability, reducing long-term operational costs.

-

Supplier Factors: The supplier’s reputation, experience, and location can significantly impact pricing. Established suppliers with a track record of quality may command higher prices, but they can also offer greater reliability.

What Are Effective Buyer Tips for Cost-Efficiency?

-

Negotiation: Engage in discussions with suppliers to negotiate prices based on volume, long-term partnerships, or bundled purchases. Building relationships can often lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the long-term costs associated with maintenance, replacement, and potential downtime. A lower upfront cost may lead to higher TCO if quality is compromised.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, local market conditions, and potential trade barriers that can affect pricing. Building a diverse supplier base can mitigate risks associated with these factors.

Conclusion

Understanding the cost structure and pricing influencers associated with tolerance fit tables is essential for international B2B buyers. By strategically evaluating each component and leveraging negotiation tactics, buyers can achieve greater cost efficiency and ensure they are making sound investments in their manufacturing processes. Always remember to obtain indicative prices, as these can fluctuate based on market conditions and specific project requirements.

Alternatives Analysis: Comparing tolerance fit table With Other Solutions

Understanding the Importance of Alternative Solutions

When considering the optimal method for ensuring precise fits in engineering applications, a tolerance fit table is a widely accepted tool. However, various alternative solutions can achieve similar objectives, offering unique advantages and disadvantages depending on specific requirements. By comparing the tolerance fit table with other viable methods, B2B buyers can make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Tolerance Fit Table | CAD Software Solutions | Limits and Fits Calculators |

|---|---|---|---|

| Performance | High accuracy in fit calculations | Excellent for design visualization and analysis | Quick calculations for fit types |

| Cost | Generally low cost | Higher initial investment | Typically low cost |

| Ease of Implementation | Requires understanding of standards | Requires training and expertise | User-friendly and intuitive |

| Maintenance | Minimal, periodic updates needed | Regular software updates required | Minimal, often web-based |

| Best Use Case | Traditional manufacturing contexts | Complex designs and simulations | Quick reference for fits |

Analyzing Alternatives to the Tolerance Fit Table

CAD Software Solutions: How Do They Compare?

CAD (Computer-Aided Design) software provides advanced modeling capabilities that allow engineers to visualize and analyze fits before production. This software can simulate various fit scenarios, including clearance and interference fits, offering a detailed perspective that a tolerance fit table cannot provide. However, the initial cost and the necessity for training can be significant drawbacks. CAD tools are best suited for complex designs where visual representation and simulation enhance the decision-making process.

Limits and Fits Calculators: What Advantages Do They Offer?

Limits and fits calculators are specialized tools designed to simplify the process of determining fits based on specified tolerances. These calculators are generally user-friendly, allowing engineers to quickly input parameters and receive immediate results. They are particularly beneficial for quick reference and can streamline operations in environments where rapid calculations are necessary. However, they may lack the depth of analysis that CAD software provides and can be limited in handling more complex engineering scenarios.

Conclusion: Choosing the Right Solution for Your Needs

In selecting the best method for achieving precise fits, B2B buyers must consider their unique operational demands. The tolerance fit table remains a reliable choice for traditional manufacturing processes that prioritize accuracy and standardization. However, for organizations engaged in complex design work, CAD software may provide the necessary capabilities for advanced simulations. On the other hand, limits and fits calculators serve as effective tools for quick calculations and operational efficiency. By evaluating performance, cost, ease of implementation, and maintenance, buyers can determine which solution aligns best with their business objectives and engineering requirements.

Essential Technical Properties and Trade Terminology for tolerance fit table

What Are the Key Technical Properties in a Tolerance Fit Table?

Understanding the essential technical properties of a tolerance fit table is crucial for B2B buyers, as these specifications directly impact product performance, compatibility, and manufacturing efficiency. Here are some critical specs:

-

Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension. It is essential in ensuring that parts fit together without excessive play or interference. In B2B contexts, selecting the correct tolerance can reduce assembly time and improve product reliability, which is vital for maintaining competitive advantage. -

Material Grade

This refers to the quality and type of material used in manufacturing components. Different grades have varying properties, such as strength, corrosion resistance, and machinability. For B2B buyers, understanding material grades helps in selecting the right components for specific applications, ensuring durability and performance. -

Fit Type

Fit types define how two parts will interact with each other, categorized mainly into clearance, transition, and interference fits. Each type has specific applications depending on the required movement or snugness between parts. Choosing the right fit type is crucial for the functionality of the final product, influencing factors like wear and tear and maintenance needs. -

Nominal Size

The nominal size represents the intended size of a component before accounting for tolerances. It serves as the baseline for all measurements and is critical for ensuring that parts manufactured by different suppliers will align correctly. In a global marketplace, understanding nominal sizes helps buyers communicate specifications clearly across borders. -

Deviation

Deviation refers to the difference between the actual size and the nominal size, expressed in positive or negative values. This property is vital for ensuring that parts meet functional requirements. For B2B transactions, managing deviations effectively can lead to reduced waste and increased efficiency in production processes. -

ISO Standards Compliance

Compliance with ISO standards ensures that products meet international quality and safety benchmarks. This is particularly important for B2B buyers who operate in regulated industries or need to guarantee product quality across different regions. Familiarity with ISO compliance can also facilitate smoother international transactions.

What Are Common Trade Terms Related to Tolerance Fit Tables?

Navigating the B2B landscape requires familiarity with specific trade terms that streamline communication and transactions. Here are some commonly used jargon:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers seeking reliable suppliers and ensuring compatibility of parts. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of a product that a supplier is willing to sell. This term is vital for B2B buyers as it impacts inventory management and budgeting. Knowing the MOQ can help businesses plan their procurement strategies effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. This is an essential step in the procurement process, enabling buyers to compare costs and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, costs, and risks, ensuring smoother logistics and fewer disputes. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is crucial for supply chain management and inventory planning, allowing businesses to align production schedules with availability. -

Quality Assurance (QA)

QA encompasses the processes and measures taken to ensure that products meet certain standards of quality. For B2B buyers, understanding QA protocols can help in selecting suppliers that maintain high standards, ultimately leading to fewer defects and returns.

In summary, a solid grasp of technical properties and trade terminology associated with tolerance fit tables empowers B2B buyers to make informed decisions that enhance product quality and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the tolerance fit table Sector

Global demand for tolerance fit tables is increasingly shaped by technological advancements, regulatory frameworks, and evolving market needs. Key drivers include the expansion of manufacturing sectors across Africa, South America, the Middle East, and Europe, particularly in countries like Germany and Vietnam. As industries push for greater precision in engineering applications, the importance of accurate fit specifications is paramount. The introduction of Industry 4.0 technologies, such as IoT and AI, is transforming the sourcing landscape, enabling manufacturers to optimize production processes and enhance quality control. Furthermore, the shift toward customized manufacturing solutions is prompting businesses to adopt advanced tolerance fit systems tailored to specific applications.

Emerging trends indicate a growing preference for digital solutions in sourcing tolerance fit tables. Online platforms that facilitate real-time access to specifications, inventory levels, and supplier capabilities are gaining traction among international B2B buyers. Additionally, as global supply chains become more interconnected, the need for standardization in fit tolerances is crucial for ensuring compatibility across diverse manufacturing environments. Companies are increasingly seeking partnerships that offer comprehensive support, from prototyping to large-scale production, emphasizing the value of collaboration and communication in navigating market dynamics.

How is Sustainability and Ethical Sourcing Influencing the Tolerance Fit Table Sector?

Sustainability and ethical sourcing are becoming integral considerations for B2B buyers in the tolerance fit table sector. As environmental awareness grows, companies are increasingly held accountable for their supply chain practices. The manufacturing of tolerance fit tables often involves materials and processes that can have significant environmental impacts, including waste generation and resource depletion. Therefore, businesses are prioritizing suppliers that demonstrate a commitment to sustainable practices, such as reducing emissions and utilizing eco-friendly materials.

Moreover, certifications such as ISO 14001 and adherence to standards for sustainable materials are gaining importance. Buyers are now more inclined to request transparency regarding the sourcing of materials and the environmental impact of production processes. This shift not only addresses regulatory pressures but also aligns with consumer expectations for corporate responsibility. As a result, suppliers that can showcase their commitment to sustainability will have a competitive edge in the market, appealing to a growing demographic of environmentally-conscious buyers.

What is the Brief History and Evolution of Tolerance Fit Tables in B2B Context?

The concept of tolerance fits has evolved significantly since its inception in the early 20th century. Initially, engineering practices relied heavily on trial and error, leading to inefficiencies and inconsistencies in manufacturing. The establishment of standardized tolerances, such as those outlined in ISO 286, marked a turning point, enabling engineers to define precise fit specifications that enhance performance and compatibility.

Over the decades, advancements in machining technologies and materials science have further refined tolerance fitting processes. The introduction of computer-aided design (CAD) and manufacturing (CAM) systems has allowed for more accurate and efficient production methods, resulting in tighter tolerances and improved product quality. This evolution has paved the way for the modern tolerance fit table, which serves as a critical tool for engineers and manufacturers globally, ensuring that components work harmoniously in increasingly complex machinery and applications.

As businesses continue to navigate the complexities of global manufacturing, understanding the historical context of tolerance fits can inform better sourcing decisions and foster innovation within the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of tolerance fit table

-

1. How do I determine the appropriate tolerance fit for my application?

To select the right tolerance fit, first assess the specific requirements of your application, including the types of loads, environmental conditions, and desired movement between parts. You can choose from three primary types of fits: clearance, transition, and interference. Review the ISO limits and fits tables to match your nominal sizes with the corresponding tolerance grades. Consulting with an engineering professional can also provide valuable insights tailored to your specific needs. -

2. What are the key differences between clearance, transition, and interference fits?

Clearance fits allow for space between the mating parts, facilitating relative movement. Transition fits offer a balance, where parts may fit tightly or have slight clearance, depending on their dimensions. Interference fits are tight, requiring force to assemble the parts, ensuring they act as a single unit. Understanding these differences will help you choose the appropriate fit for your application, ensuring optimal performance and longevity of the components. -

3. How do I verify the quality of a tolerance fit table supplier?

When vetting suppliers for tolerance fit tables, check for certifications like ISO 9001 that demonstrate adherence to quality management standards. Review their reputation through customer testimonials and case studies. Request samples or a small batch to assess the quality of their products firsthand. Additionally, inquire about their manufacturing processes and quality assurance measures to ensure they meet your specifications. -

4. What customization options are available for tolerance fit tables?

Many suppliers offer customization options for tolerance fit tables to meet specific project requirements. You can request adjustments in size, tolerance grades, and even material selection based on your application needs. It’s advisable to communicate your requirements clearly and discuss potential custom solutions with the supplier to ensure they can accommodate your needs effectively. -

5. What is the typical minimum order quantity (MOQ) for tolerance fit tables?

The MOQ for tolerance fit tables can vary widely among suppliers, depending on their production capabilities and business model. Typically, MOQs may range from a few units to several hundred. It’s important to discuss your project requirements upfront, as some suppliers may be flexible with MOQs for first-time orders or larger contracts. Always clarify this aspect to avoid unexpected costs or delays. -

6. What payment terms should I expect when sourcing tolerance fit tables internationally?

Payment terms for international transactions can differ significantly based on the supplier and your negotiating power. Common terms include upfront payments, deposits, or net payment terms (e.g., 30, 60, or 90 days). Consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always ensure you have a clear agreement on payment terms before finalizing any orders. -

7. How do logistics and shipping impact the sourcing of tolerance fit tables?

Logistics and shipping are crucial factors in sourcing tolerance fit tables, especially for international transactions. Consider the supplier’s location, shipping methods, and estimated delivery times. Customs regulations can also affect lead times and costs, so ensure your supplier has experience in international shipping. Collaborate closely with logistics providers to streamline the process and avoid potential delays. -

8. What quality assurance measures should I expect from a tolerance fit table supplier?

Reputable suppliers typically implement rigorous quality assurance measures, including regular inspections, testing of materials, and adherence to industry standards. Ask about their quality control processes, including any certifications they hold. Request documentation of testing results and quality checks to ensure that the tolerance fit tables meet your specific requirements and industry standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Tolerance Fit Table Manufacturers & Suppliers List

1. Engineers Edge – Mechanical Tolerance Charts

Domain: engineersedge.com

Registered: 2000 (25 years)

Introduction: General Mechanical Tolerance Table Charts for Standard Shaft Hole Fits; Class I – Loose fit; Class II – Free Fit; Class III – Medium Fit; Class IV – Transitional Fit (Snug); Class V – Interference Fit; Material basis is steel; Coefficient of expansion considered at 70 deg F.

2. Reddit – H10 Shaft Fits and Tolerances

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around choosing fits and tolerances for parts that need to fit together with h10 shafts. The user is seeking guidance on finding tables for fits related to h10 shafts and expresses a lack of experience in the topic. A suggestion is made to consider the type of fit required based on the application, such as whether the shaft needs to rotate smoothly or be located accurately….

3. Eng-Tips – 4mm x 10mm SS Dowel Pin

Domain: eng-tips.com

Registered: 1997 (28 years)

Introduction: 4mm x 10mm SS dowel pin with a tolerance of +0.004mm to +0.012mm, creating a tolerance zone of m6. The 4H7 hole provides a clearance fit with the 4m6 pin. Possible fits include: 4H7/m6 (0.008mm clearance to 0.012mm interference), 4J7/m6 (0.002mm clearance to 0.018mm interference), 4K7/m6 (0.001mm interference to 0.021mm interference), and 4M7/m6 (0.004mm interference to 0.024mm interference).

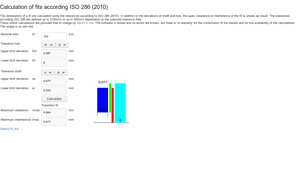

4. Mesys – ISO 286 Fit Calculator

Domain: mesys.ch

Introduction: Online calculation of fits according to ISO 286 (2010). Dimensions of a fit calculated using tolerances defined up to 3150mm or 500mm depending on the selected tolerance field. Results include deviations of shaft and hub, span, clearance, or interference of the fit. Free online calculations provided by MESYS AG, with no warranty for correctness or availability. Key parameters include nominal size,…

Strategic Sourcing Conclusion and Outlook for tolerance fit table

How Can Strategic Sourcing Enhance Your Understanding of Tolerance Fits?

In the realm of engineering and manufacturing, understanding tolerance fits is crucial for optimizing product performance and ensuring the longevity of components. By leveraging a well-structured tolerance fit table, international B2B buyers can make informed decisions that directly impact their operational efficiency and product quality. The strategic sourcing of components, aligned with precise tolerance specifications, allows companies to enhance their competitive edge by minimizing production errors and assembly issues.

Moreover, the choice between clearance, transition, and interference fits not only affects the assembly process but also influences manufacturing costs. As such, investing time in understanding these fits can lead to significant cost savings in production and maintenance. For businesses in Africa, South America, the Middle East, and Europe, this knowledge is particularly valuable, as it enables them to source high-quality components that meet rigorous international standards.

Looking ahead, the demand for precision engineering will only increase. By prioritizing strategic sourcing and understanding tolerance fits, you can position your business for success in a competitive global market. Take the next step: explore suppliers who can provide detailed tolerance fit tables and expert guidance to support your sourcing strategy.