Contents

Manufacturing Insight: Titanium Vs Steel Strength

Material Selection Precision: Titanium Versus Steel in High-Performance Applications

The critical decision between titanium and steel alloys fundamentally shapes the performance, longevity, and cost-efficiency of engineered components across aerospace, medical, and defense sectors. While both materials deliver exceptional strength, their distinct metallurgical properties demand expert evaluation against specific application requirements. Titanium excels with its unparalleled strength-to-weight ratio and corrosion resistance, making it indispensable for weight-sensitive, high-stress environments. Conversely, certain steel alloys provide superior absolute strength, hardness, and wear resistance at lower material costs, ideal for structural components where mass is less constrained.

Honyo Prototype leverages advanced CNC machining expertise to transform these high-performance materials into precision-engineered prototypes and low-volume production parts. Our specialized processes address the unique challenges of each alloy—managing titanium’s work hardening tendencies with optimized toolpaths and coolant strategies, while maximizing steel’s machinability through precision tool selection and rigidity control. This ensures dimensional accuracy, superior surface finishes, and material integrity from raw billet to final component.

Below highlights key comparative properties influencing design decisions:

| Property | Titanium (Grade 5 Ti-6Al-4V) | Steel (AISI 4140) |

|---|---|---|

| Tensile Strength (MPa) | 900–950 | 655–1000 |

| Yield Strength (MPa) | 830–860 | 415–850 |

| Density (g/cm³) | 4.43 | 7.85 |

| Corrosion Resistance | Excellent | Moderate (varies) |

| Machinability Rating | Poor (20–30% of B1112) | Good (65% of B1112) |

Understanding these nuances is where Honyo’s engineering partnership delivers immediate value. Our team collaborates with clients to select the optimal material and machining strategy, ensuring performance targets are met without compromising manufacturability or timeline. Accelerate your next project by leveraging Honyo’s Online Instant Quote system—receive detailed manufacturability feedback and competitive pricing for titanium or steel components within hours, not days. Make informed material decisions with precision manufacturing expertise at your fingertips.

Technical Capabilities

When evaluating titanium versus steel for high-precision machining applications such as 3/4/5-axis milling and turning with tight tolerances, several mechanical and thermal properties must be considered. These include tensile strength, machinability, thermal conductivity, and tool wear characteristics. The choice between titanium and steel also impacts process parameters and tooling selection, especially when compared to more easily machinable materials like aluminum, ABS, and nylon.

Below is a comparative technical specification table highlighting key properties relevant to precision CNC machining:

| Material | Tensile Strength (Ultimate) | Yield Strength | Hardness (Brinell) | Thermal Conductivity (W/m·K) | Machinability Rating (%) | Typical Use in Precision Machining | Notes for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|---|---|

| Titanium (Grade 5, Ti-6Al-4V) | 900–1000 MPa | 830 MPa | 330–360 HB | 6.7 | 20–30% | Aerospace, medical implants, high-performance automotive | Low thermal conductivity leads to heat buildup; requires rigid setups, sharp tools, lower cutting speeds, and high-pressure coolant. Prone to work hardening. |

| Steel (4140 Alloy Steel, Annealed) | 850–1000 MPa | 655 MPa | 200–220 HB | 42 | 65% | Tooling, shafts, structural components | Better thermal conductivity than titanium; more predictable chip formation. Moderate tool wear. Suitable for tight-tolerance turning and milling with standard HSS or carbide tools. |

| Aluminum (6061-T6) | 310 MPa | 275 MPa | 95 HB | 167 | 90–100% | Enclosures, prototypes, aerospace parts | Excellent for high-speed 3/4/5-axis milling. Minimal tool wear. Easy to hold tight tolerances. Low cutting forces. |

| ABS (Acrylonitrile Butadiene Styrene) | 40–50 MPa | 40 MPa | 100–110 HB | 0.18 | >100% (very easy) | Prototypes, jigs, housings | Very low heat resistance. Requires sharp tools, high RPM, and low feed to avoid melting. Minimal clamping force needed. |

| Nylon (PA6/PA66) | 70–80 MPa | 60–70 MPa | 80–90 HB | 0.25 | >100% (very easy) | Wear strips, gears, insulators | Prone to dimensional instability due to moisture absorption. Requires dry machining or post-stabilization. Machining tolerances depend on environmental control. |

Key Observations for Tight Tolerance Machining:

Titanium offers superior strength-to-density ratio and excellent corrosion resistance, making it ideal for performance-critical applications. However, its low thermal conductivity and high chemical reactivity with cutting tools lead to accelerated tool wear and necessitate conservative machining parameters. In contrast, alloy steel provides higher thermal conductivity and more consistent chip control, allowing for tighter process repeatability in high-tolerance turning and multi-axis milling operations.

Aluminum remains the benchmark for high-speed precision machining due to its excellent machinability and dimensional stability. Engineering plastics like ABS and nylon are significantly easier to machine but require environmental and thermal management to maintain tight tolerances, especially post-machining.

For applications demanding micron-level tolerances across complex geometries, steel often provides a more predictable balance between strength and machinability than titanium, while aluminum and select polymers are preferred for non-structural, high-accuracy components where weight and corrosion are secondary concerns.

From CAD to Part: The Process

Honyo Prototype integrates material science expertise throughout our standard prototyping workflow to address strength considerations between titanium and steel. This is not a standalone test but a systematic evaluation embedded within our process to ensure optimal material selection and manufacturability. Below is the precise sequence with technical emphasis on how strength properties are analyzed.

Upload CAD

Clients submit detailed 3D models with specified requirements including load conditions, environmental factors, and functional constraints. Our engineering team immediately identifies critical stress points and validates whether the requested material (e.g., Ti-6Al-4V vs. 4140 steel) aligns with the part’s structural demands. Material property databases are cross-referenced against geometric features to flag early-stage mismatches.

AI Quote Generation

Our AI-driven quoting engine processes the CAD geometry alongside material specifications. The system compares mechanical properties using certified reference data, focusing on key strength metrics relevant to the application. For titanium versus steel, the analysis prioritizes:

| Property | Ti-6Al-4V (ASTM B348) | 4140 Steel (ASTM A29) | Engineering Implication |

|---|---|---|---|

| Tensile Strength | 900-950 MPa | 655-1000 MPa | Steel offers higher absolute strength in thick sections; titanium excels in strength-to-weight ratio |

| Yield Strength | 830 MPa | 415-655 MPa | Titanium maintains structural integrity under higher elastic deformation |

| Density | 4.43 g/cm³ | 7.85 g/cm³ | Titanium reduces mass by ~43% for equivalent volume |

| Fatigue Limit | ~500 MPa (10⁷ cycles) | ~415 MPa (10⁷ cycles) | Titanium superior for cyclic loading applications |

The quote includes a preliminary strength assessment note if material selection appears suboptimal for the stated loads.

DFM Analysis

Our manufacturing engineers conduct rigorous Design for Manufacturability review with explicit strength validation. This phase involves:

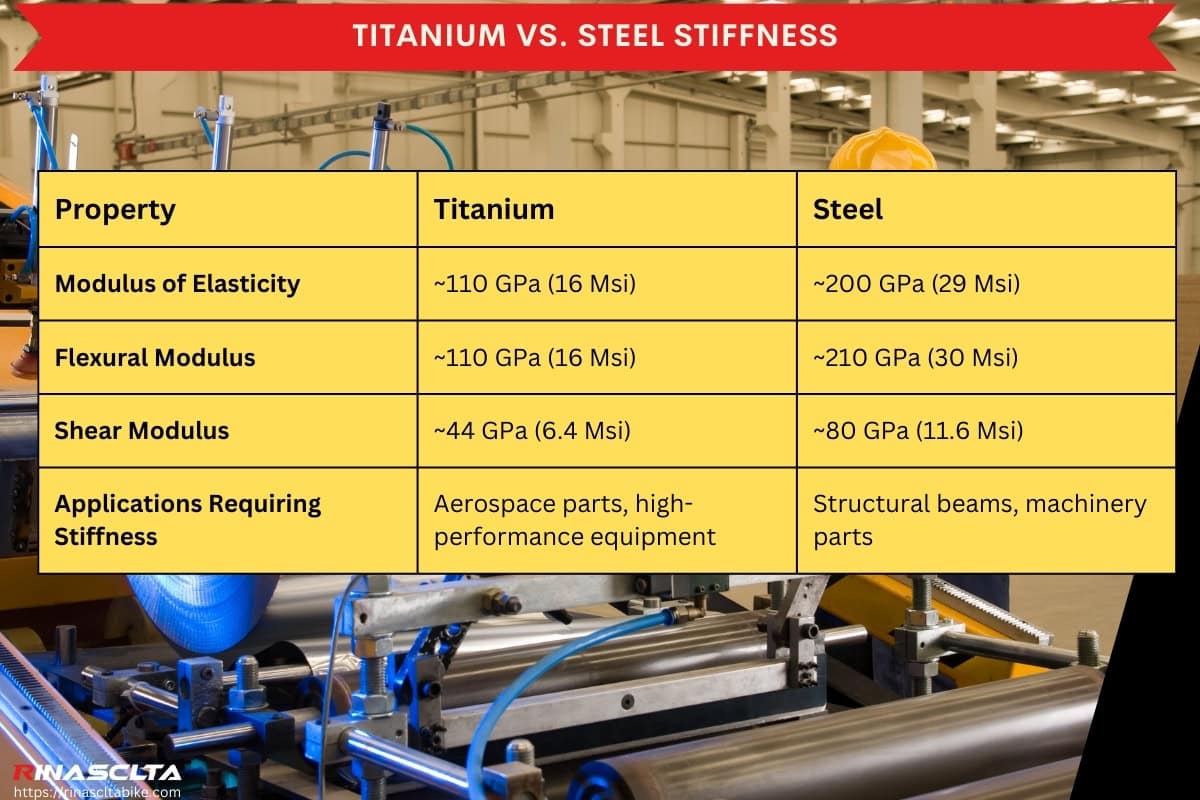

Finite Element Analysis (FEA) simulations applying ISO 12107-compliant stress models to compare deflection, buckling resistance, and safety factors between titanium and steel under client-specified loads. We evaluate work hardening behavior during machining—critical for titanium’s galling susceptibility versus steel’s chip formation characteristics. Thermal expansion coefficients (Ti: 8.6 μm/m·°C vs. Steel: 12.0 μm/m·°C) are assessed for dimensional stability in post-process heat treatment. Clients receive a formal DFM report with strength-based recommendations, including scenarios where steel’s higher modulus of elasticity (200 GPa vs. titanium’s 110 GPa) may prevent deflection issues despite lower strength-to-weight ratio.

Production

Material procurement follows AMS 4928 (titanium) or AMS 6349 (steel) specifications with full mill test reports. In-process quality controls include:

Hardness verification per ASTM E18 at critical zones to confirm strength consistency

Real-time force monitoring during CNC milling to detect abnormal tool stresses indicating material property deviations

Optional tensile coupon testing per ASTM E8/E8M for mission-critical components, with results traceable to individual heat lots

Delivery

All parts ship with a comprehensive material compliance package containing:

Mill certificates confirming chemical composition and mechanical properties

DFM strength analysis summary with FEA screenshots

As-built dimensional reports showing critical tolerances affected by material stiffness

Recommendations for secondary operations (e.g., anodizing for titanium corrosion resistance or nitriding for steel surface hardness)

This integrated approach ensures clients receive not just a prototype, but validated engineering data proving whether titanium’s weight savings or steel’s absolute strength better serves their application—without requiring separate destructive testing. Our ISO 9001:2015-certified workflow guarantees traceability from CAD input to certified material performance.

Start Your Project

When evaluating titanium vs steel strength for your next project, understanding material performance is critical to achieving optimal design and durability. At Honyo Prototype, our engineering team provides in-depth material analysis and prototyping services to help you make the right choice based on strength-to-weight ratio, corrosion resistance, and application requirements.

For technical consultation or material testing support, contact Susan Leo at [email protected]. With our precision manufacturing facility located in Shenzhen, we deliver fast turnaround on prototypes and low-volume production runs using both titanium and high-strength steel alloys.

| Material | Tensile Strength (Typical) | Density (g/cm³) | Common Applications |

|---|---|---|---|

| Titanium | 900 – 1,100 MPa | 4.5 | Aerospace, Medical, Automotive |

| Stainless Steel | 500 – 900 MPa | 7.9 | Industrial, Marine, Construction |

Partner with Honyo Prototype to leverage expert insight and advanced fabrication capabilities. Reach out today to discuss your material selection with Susan Leo.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.