Introduction: Navigating the Global Market for titanium strength to weight ratio

In the competitive landscape of global manufacturing, sourcing materials with an optimal titanium strength to weight ratio presents a critical challenge for B2B buyers. As industries strive for innovation and efficiency, the demand for lightweight yet durable materials has surged, particularly in sectors like aerospace, automotive, and marine engineering. This guide aims to equip international buyers—especially from regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany—with the insights necessary to navigate this complex market effectively.

Covering a comprehensive range of topics, this guide delves into the various types of titanium, its applications across different industries, and strategies for vetting suppliers. Additionally, we will explore cost considerations and the economic implications of investing in titanium products. By understanding the nuances of titanium’s properties and its market dynamics, procurement managers can make informed decisions that enhance operational performance and drive innovation.

Whether you are looking to enhance your supply chain resilience or seeking ways to reduce costs while maintaining product quality, this guide serves as a vital resource. It empowers you to leverage titanium’s unique attributes, ensuring your projects meet the stringent demands of modern engineering while staying competitive in the global marketplace.

Understanding titanium strength to weight ratio Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercially Pure Titanium | High ductility and corrosion resistance | Aerospace, medical implants, marine | Pros: Biocompatible, excellent fatigue resistance. Cons: Higher cost than alloys. |

| Titanium Alloys (e.g., Ti-6Al-4V) | Enhanced strength and heat resistance | Aerospace, automotive, industrial machinery | Pros: Superior strength-to-weight ratio, good weldability. Cons: More complex machining requirements. |

| Beta Titanium Alloys | Improved workability and formability | Aerospace, sporting goods | Pros: Excellent fatigue resistance, lightweight. Cons: Limited high-temperature performance. |

| Titanium Matrix Composites | Combines titanium with ceramic materials | Aerospace, high-performance automotive | Pros: Exceptional strength, reduced weight. Cons: Higher manufacturing costs and complexity. |

| Low-Alpha Titanium Alloys | Optimized for low-temperature applications | Cryogenic applications, aerospace | Pros: Maintains strength at low temperatures. Cons: Limited applications compared to other types. |

What Are the Characteristics of Commercially Pure Titanium?

Commercially pure titanium is known for its high ductility, excellent corrosion resistance, and biocompatibility, making it a favored choice for industries like aerospace and medical. Its strength-to-weight ratio is impressive, with a tensile strength around 240 MPa. When procuring this type, buyers should consider its higher cost compared to titanium alloys but appreciate its longevity and low maintenance, particularly in applications where human contact is involved, such as surgical implants.

How Do Titanium Alloys Like Ti-6Al-4V Compare?

Titanium alloys, particularly Ti-6Al-4V, are engineered to provide enhanced strength and heat resistance. With a tensile strength reaching up to 960 MPa, these alloys are ideal for demanding applications in aerospace and automotive sectors. Buyers should weigh the benefits of superior strength-to-weight ratios against the complexities of machining, which may require specialized tools and techniques. The initial investment may be higher, but the performance benefits often justify the cost.

What Are the Benefits of Beta Titanium Alloys?

Beta titanium alloys are recognized for their improved workability and formability, making them suitable for applications in aerospace and sporting goods. They exhibit excellent fatigue resistance and maintain a competitive strength-to-weight ratio. B2B buyers should consider their specific application requirements, as these alloys may not perform as well under high-temperature conditions compared to other titanium types. However, their lightweight nature and ease of processing can lead to significant efficiency gains in production.

Why Are Titanium Matrix Composites Gaining Popularity?

Titanium matrix composites combine titanium with ceramic materials, offering exceptional strength and reduced weight, particularly in aerospace and high-performance automotive applications. These composites can withstand extreme conditions, making them a valuable asset in innovative designs. However, buyers need to consider the higher manufacturing costs and complexity associated with these materials, which can impact overall project budgets. The performance advantages may outweigh these costs, especially in high-stakes applications.

What Are the Key Considerations for Low-Alpha Titanium Alloys?

Low-alpha titanium alloys are optimized for low-temperature applications, making them ideal for cryogenic environments and aerospace uses. They maintain strength at low temperatures, which is crucial for specific applications. Buyers should evaluate the limited range of applications compared to other titanium types, as well as potential cost implications. While they may not be as versatile as other alloys, their specialized performance can be critical in niche markets.

Key Industrial Applications of titanium strength to weight ratio

| Industry/Sector | Specific Application of titanium strength to weight ratio | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components (e.g., frames, engine parts) | Significant weight reduction improves fuel efficiency and payload capacity | Certification requirements, sourcing from reputable suppliers, compliance with aviation regulations |

| Automotive | High-performance vehicle parts (e.g., suspension, chassis) | Enhanced performance and durability under stress, leading to longer vehicle lifespans | Material grade specifications, cost considerations, and supplier reliability |

| Marine Engineering | Offshore structures and vessels | Corrosion resistance and reduced weight increase operational efficiency and longevity | Resistance to seawater corrosion, compliance with marine standards, and availability of specific alloys |

| Medical Devices | Surgical instruments and implants | Biocompatibility and strength-to-weight ratio enhance performance and patient outcomes | Certification for medical use, material traceability, and supplier certifications |

| Sports Equipment | High-end sporting goods (e.g., bicycles, golf clubs) | Improved performance through lightweight designs, appealing to professional athletes | Customization options, supplier expertise in titanium alloys, and production capabilities |

How is Titanium’s Strength-to-Weight Ratio Utilized in Aerospace Applications?

In the aerospace industry, titanium’s strength-to-weight ratio is pivotal for manufacturing aircraft components such as airframes and engine parts. By incorporating titanium, manufacturers can significantly reduce the overall weight of aircraft, leading to enhanced fuel efficiency and increased payload capacities. This is particularly crucial for modern aircraft like the Airbus A350 and Boeing 787, where weight savings translate directly into operational cost reductions. International buyers must consider rigorous certification processes and compliance with aviation safety standards when sourcing titanium for aerospace applications.

What Role Does Titanium Play in Automotive Engineering?

Titanium’s impressive strength-to-weight ratio allows for the development of high-performance automotive parts, such as chassis and suspension components. These parts benefit from titanium’s durability, allowing vehicles to perform under extreme conditions without compromising safety. This is especially relevant in the automotive sector, where lightweight materials can improve fuel efficiency and enhance performance. For procurement managers, understanding material specifications and ensuring supplier reliability are key factors in sourcing titanium for automotive applications, particularly in regions with strict regulations.

How is Titanium Beneficial for Marine Engineering?

In marine engineering, titanium is favored for its excellent corrosion resistance and strength-to-weight ratio, making it ideal for offshore structures and vessels. The ability of titanium to withstand harsh marine environments without degrading enhances the longevity and operational efficiency of these assets, which is critical for industries such as oil and gas extraction. Buyers in this sector must prioritize sourcing titanium that meets specific marine standards and consider the availability of various titanium alloys suited for seawater exposure.

What Advantages Does Titanium Offer in Medical Devices?

Titanium’s strength-to-weight ratio and biocompatibility make it a prime choice for surgical instruments and implants. Its lightweight nature reduces the burden on patients while ensuring the necessary strength for critical applications. For B2B buyers in the medical field, it is essential to ensure that sourced titanium complies with medical regulations and standards, as well as to confirm the traceability of materials used in their products.

How is Titanium Used in Sports Equipment?

In the sports equipment sector, titanium is increasingly utilized in high-end products such as bicycles and golf clubs. The strength-to-weight ratio allows manufacturers to create lightweight designs that improve performance, appealing particularly to professional athletes seeking competitive advantages. Buyers should seek suppliers with expertise in titanium alloys and customization options to meet specific performance requirements, ensuring that the sourced materials align with the latest trends in sports technology.

3 Common User Pain Points for ‘titanium strength to weight ratio’ & Their Solutions

Scenario 1: Navigating High Costs in Titanium Procurement

The Problem: A procurement manager in the aerospace sector is struggling with the high costs associated with titanium components. Despite titanium’s exceptional strength-to-weight ratio being a significant advantage for fuel efficiency and performance, the price volatility of titanium can complicate budgeting and project forecasting. This challenge is particularly pressing for companies in regions like Africa and South America, where import duties and logistics further inflate costs.

The Solution: To mitigate high procurement costs, buyers should consider establishing long-term partnerships with titanium suppliers who can offer bulk pricing agreements. Additionally, engaging with suppliers who provide comprehensive material data can help buyers make informed decisions about the specific grades of titanium that meet their project requirements without unnecessary expenditure. For instance, opting for commercially pure titanium or lower-grade alloys for less critical components can yield significant savings. Furthermore, leveraging digital tools for supply chain management can enhance transparency and predictability in pricing, allowing procurement managers to anticipate market fluctuations better.

Scenario 2: Ensuring Performance Under Extreme Conditions

The Problem: An engineer in the automotive industry faces difficulties when selecting materials for high-performance vehicle components. While titanium’s strength-to-weight ratio promises durability and efficiency, there are concerns regarding its performance in extreme conditions, such as high temperatures and corrosive environments. This is particularly relevant for vehicles designed for regions like the Middle East, where environmental factors can accelerate wear and tear.

The Solution: To ensure optimal performance, it is crucial to specify the right titanium alloy based on the environmental conditions the components will face. For instance, using Ti-6Al-4V, which combines high strength with excellent corrosion resistance, can significantly enhance component longevity. Additionally, integrating advanced coatings or treatments can further improve performance in harsh conditions. Conducting thorough testing and simulations during the design phase can provide insights into how the titanium components will behave under stress, allowing for adjustments before production. Collaborating with material scientists to analyze specific application requirements can lead to more informed material choices that maximize performance.

Scenario 3: Overcoming Machining Challenges with Titanium

The Problem: A manufacturer experiences frequent issues while machining titanium components due to its low thermal conductivity and high reactivity. These problems result in extended production times and increased tool wear, leading to higher operational costs. Buyers in Europe, particularly in precision engineering sectors, find that standard machining techniques do not yield the desired results with titanium, complicating production schedules.

The Solution: To address machining challenges, it is essential to adopt specialized tooling and techniques tailored for titanium. This includes using carbide tools with appropriate coatings designed to withstand the high temperatures generated during machining. Implementing strategies such as lower cutting speeds, increased feed rates, and using coolant can help manage heat and reduce tool wear. Furthermore, investing in training for the machining staff on best practices for titanium processing can lead to improved efficiency and reduced waste. Engaging with tooling manufacturers who offer titanium-specific solutions and support can also provide valuable insights that enhance machining performance and reduce costs over time.

Strategic Material Selection Guide for titanium strength to weight ratio

What Are the Key Properties of Titanium Compared to Other Materials?

Titanium is renowned for its exceptional strength-to-weight ratio, making it a preferred choice in various industries, particularly aerospace and automotive. However, it is essential to consider its properties in comparison to other common materials such as aluminum, steel, and magnesium. Each material has unique characteristics that influence its suitability for specific applications.

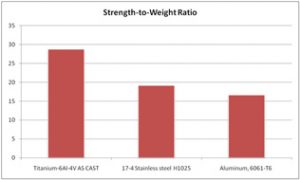

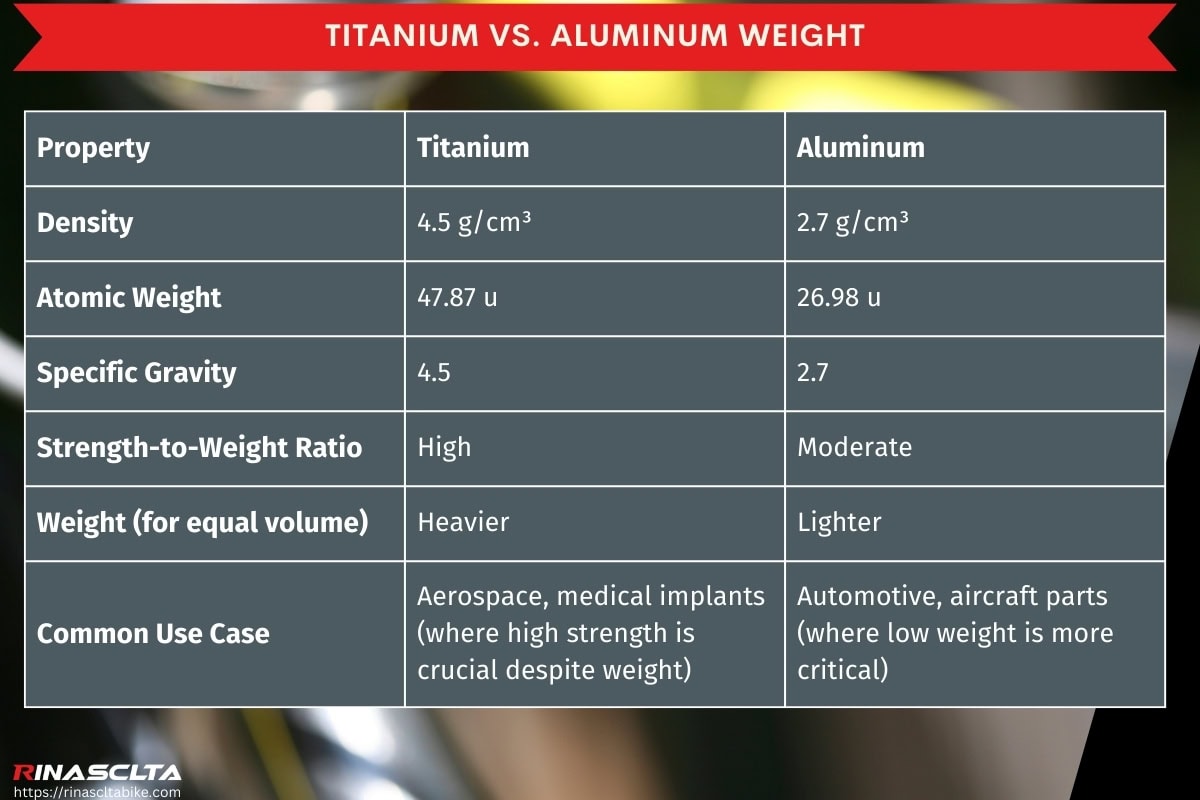

How Does Aluminum Compare to Titanium in Strength-to-Weight Ratio?

Aluminum is widely used due to its low density and good corrosion resistance. With a density of approximately 2.7 g/cm³, aluminum is lighter than titanium, but its tensile strength typically ranges around 70 ksi (480 MPa). While aluminum’s strength-to-weight ratio is decent, it falls short of titanium’s capabilities, especially in high-temperature applications.

Pros: Aluminum is less expensive and easier to fabricate, making it suitable for mass production. Its lightweight nature is beneficial for applications where weight reduction is critical.

Cons: Aluminum’s lower strength limits its use in high-stress environments. It also has a lower melting point, which can be a disadvantage in applications exposed to extreme heat.

Impact on Application: Aluminum is often used in automotive frames and aircraft skins, where weight savings are essential. However, in high-performance aerospace components, titanium is often favored.

Considerations for International Buyers: Buyers should be aware of local standards such as ASTM and DIN that govern aluminum specifications. Additionally, the cost of aluminum can fluctuate based on global market conditions, impacting procurement decisions.

What Advantages Does Steel Offer Over Titanium?

Steel, specifically high-strength low-alloy (HSLA) steel, is another common material used in various applications. With a density of about 7.85 g/cm³, steel is significantly heavier than titanium but offers excellent tensile strength, often exceeding 100 ksi (690 MPa).

Pros: Steel is highly durable, cost-effective, and widely available, making it a go-to material for structural applications.

Cons: Its weight can be a drawback in applications where reducing mass is critical. Additionally, steel is prone to corrosion unless treated, which can lead to increased maintenance costs.

Impact on Application: Steel is commonly used in construction and heavy machinery, where strength is prioritized over weight. However, in aerospace applications, the weight disadvantage often leads to the selection of titanium.

Considerations for International Buyers: Compliance with various international standards for steel, such as JIS and ASTM, is crucial. Buyers should also consider the environmental impact of steel production, which may influence their sourcing decisions.

How Does Magnesium Compare to Titanium in Terms of Performance?

Magnesium is another lightweight material with a density of about 1.74 g/cm³, making it lighter than both titanium and aluminum. Its tensile strength can reach around 80 ksi (550 MPa), which is lower than titanium.

Pros: Magnesium is highly machinable and offers excellent damping properties, making it suitable for applications requiring vibration reduction.

Cons: Magnesium is more susceptible to corrosion than titanium and often requires protective coatings. Its lower strength limits its use in demanding applications.

Impact on Application: Magnesium is often used in automotive components and electronic housings where weight savings are essential. However, in high-stress environments, titanium is preferred.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards for magnesium alloys, as these can vary significantly by region. Additionally, the cost of magnesium can be volatile, affecting long-term procurement strategies.

Summary Table of Material Comparisons

| Material | Typical Use Case for titanium strength to weight ratio | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Aerospace components, high-performance automotive parts | Exceptional strength-to-weight ratio | Higher cost compared to aluminum and steel | High |

| Aluminum | Aircraft skins, automotive frames | Lightweight and cost-effective | Lower strength and melting point | Medium |

| Steel | Construction, heavy machinery | High durability and availability | Heavier and prone to corrosion | Low |

| Magnesium | Automotive components, electronic housings | Extremely lightweight and machinable | Susceptible to corrosion, lower strength | Medium |

This analysis provides B2B buyers with a comprehensive understanding of the materials available for applications requiring a strong yet lightweight solution. By considering the specific properties and implications of each material, procurement managers can make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for titanium strength to weight ratio

What Are the Main Stages of Titanium Manufacturing Processes?

The manufacturing of titanium components, particularly those emphasizing its strength-to-weight ratio, involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is vital for ensuring the material’s exceptional properties are preserved and optimized for end-use applications.

Material Preparation: How Is Titanium Processed for Manufacturing?

Material preparation begins with the sourcing of titanium, often in the form of ingots or bars. Titanium is typically produced through the Kroll process, which involves reducing titanium tetrachloride with magnesium. The resultant sponge is then melted in a vacuum arc remelting (VAR) furnace to remove impurities and achieve desired material properties.

Once prepared, the titanium is often subjected to additional processes such as hot isostatic pressing (HIP) to enhance its microstructure, which is crucial for maintaining its strength-to-weight ratio. During this phase, it’s essential to monitor the titanium’s composition and microstructure to ensure it meets specific engineering requirements.

What Key Techniques Are Used in Titanium Forming?

The forming stage employs various techniques, including forging, casting, and machining. Forging is particularly common for high-strength applications, as it aligns the grain structure of the metal, enhancing its mechanical properties. Techniques such as superplastic forming are also utilized, allowing for complex shapes to be created without compromising the material’s integrity.

In addition, machining processes, including milling and turning, are crucial for achieving precise dimensions and surface finishes. Given titanium’s low thermal conductivity, specialized tooling and cooling methods are often employed to manage heat buildup during machining, which can adversely affect both tool life and the titanium’s properties.

How Is Titanium Assembled and Finished for Optimal Performance?

Assembly of titanium components typically involves joining methods such as welding, bolting, or adhesive bonding. Due to titanium’s reactivity at elevated temperatures, specialized welding techniques, like gas tungsten arc welding (GTAW), are often preferred to minimize contamination and ensure strong, durable joints.

Finishing processes, including surface treatment and coating, are essential for enhancing corrosion resistance and wear characteristics. Techniques such as anodizing or applying titanium nitride coatings not only improve surface hardness but also enhance the aesthetic appeal of titanium components.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the titanium manufacturing process, ensuring that components meet stringent performance and safety standards. Internationally recognized standards such as ISO 9001 provide a framework for quality management systems, while industry-specific certifications like CE marking and API (American Petroleum Institute) compliance ensure adherence to sector-specific requirements.

For B2B buyers, understanding these standards is crucial. They serve as benchmarks for evaluating suppliers, ensuring that products meet both regulatory and quality expectations.

Which QC Checkpoints Are Critical in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process, typically categorized into three main phases: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. For titanium, this may include verifying material certification, chemical composition analysis, and mechanical property testing to ensure that the materials meet specified standards.

-

In-Process Quality Control (IPQC): During production, IPQC involves continuous monitoring of manufacturing processes. Techniques such as non-destructive testing (NDT), including ultrasonic and radiographic testing, are employed to detect internal defects without compromising the material.

-

Final Quality Control (FQC): This final checkpoint ensures that the finished products meet all specifications before shipment. Comprehensive testing, including tensile testing, fatigue testing, and surface finish inspections, is performed to guarantee the components’ strength-to-weight ratio and overall quality.

What Common Testing Methods Are Used to Ensure Quality?

Common testing methods for titanium components include:

- Tensile Testing: Measures the material’s strength and ductility, ensuring it meets required specifications.

- Hardness Testing: Assesses the material’s hardness, which is essential for applications requiring wear resistance.

- Corrosion Testing: Evaluates the titanium’s resistance to corrosion, particularly important in marine and chemical applications.

By employing these testing methods, manufacturers can verify that their titanium products conform to the required standards, ensuring reliability and performance in demanding environments.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying supplier quality control is essential for ensuring product reliability. This can be achieved through several methods:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their quality management systems, manufacturing processes, and adherence to international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their testing methods, material certifications, and historical performance data.

-

Third-Party Inspections: Engaging third-party inspection services can offer unbiased evaluations of the supplier’s manufacturing processes and product quality, ensuring compliance with specified standards.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing titanium products internationally, B2B buyers should be aware of various certification nuances that may impact procurement. Different regions may have specific regulatory requirements that suppliers must meet. For instance, European buyers may require CE marking, while those in the Middle East might look for compliance with GSO standards.

Furthermore, understanding the implications of different material grades and specifications, such as ASTM or AMS standards, is crucial for ensuring compatibility with regional applications. International buyers should also consider the logistical aspects of shipping and delivery, including documentation required for customs clearance and potential tariffs.

By taking these factors into account, B2B buyers can make informed decisions when selecting titanium suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘titanium strength to weight ratio’

To help B2B buyers navigate the procurement of titanium based on its strength-to-weight ratio, this guide provides a step-by-step checklist. Understanding the unique properties of titanium is essential for making informed decisions that meet technical requirements while optimizing costs and performance.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical needs. This includes specifying the desired strength-to-weight ratio, tensile strength, and specific applications (e.g., aerospace, automotive). Knowing these details will help you filter suppliers and products that meet your performance criteria.

Step 2: Research Available Titanium Grades

Titanium comes in various grades, each with distinct properties. Familiarize yourself with commercially pure titanium and its alloys, such as Ti-6Al-4V, which offers the highest strength-to-weight ratio. Understanding the differences will enable you to select the most suitable grade for your application, ensuring durability and performance.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers to ensure they can meet your specifications. Request detailed company profiles, product certifications, and case studies from industries similar to yours. Look for testimonials and references that confirm their experience with titanium products, especially in your region.

Step 4: Verify Supplier Certifications

Ensure that the suppliers hold relevant certifications, such as ISO 9001, that guarantee quality management standards. Certifications provide assurance that the materials meet international standards, which is crucial for industries like aerospace and automotive where safety is paramount.

Step 5: Request Material Test Reports

Before finalizing a purchase, request material test reports that validate the strength-to-weight ratio and other mechanical properties of the titanium. This documentation should include tensile strength, hardness, and density measurements. Confirming these properties will help mitigate risks associated with performance failures.

Step 6: Consider Cost vs. Performance

While titanium can be more expensive than alternatives like aluminum, its superior strength-to-weight ratio often justifies the cost. Assess your budget against the performance benefits titanium offers, especially in high-stress applications. Factor in long-term savings from reduced maintenance and improved efficiency.

Step 7: Plan for Logistics and Supply Chain Management

Lastly, consider the logistics of sourcing titanium, including delivery times and supplier location. Evaluate whether the supplier has a reliable supply chain and can meet your timelines. Effective logistics planning ensures you have the materials when needed, preventing delays in production.

By following this checklist, B2B buyers can confidently navigate the complexities of procuring titanium, leveraging its superior strength-to-weight ratio to enhance their product offerings and operational efficiencies.

Comprehensive Cost and Pricing Analysis for titanium strength to weight ratio Sourcing

What Are the Key Cost Components in Sourcing Titanium for Strength-to-Weight Applications?

When sourcing titanium, particularly for its strength-to-weight ratio, several cost components must be considered. The primary elements include:

-

Materials: The cost of titanium itself can fluctuate significantly based on market demand and global supply chains. Prices are influenced by the purity of the titanium and the specific alloys used. Grade 5 titanium (Ti-6Al-4V) tends to be more expensive due to its superior properties compared to commercially pure grades.

-

Labor: Skilled labor is essential for the processing and machining of titanium. The complexity of working with titanium, given its unique properties, requires experienced personnel, which can drive up labor costs.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Given titanium’s specific machining requirements, such as specialized tools and machinery, overhead costs can be significant.

-

Tooling: The cost of tooling is critical, as titanium’s properties can cause rapid wear on standard machining tools. Custom tooling may be necessary to ensure precision and efficiency, impacting overall costs.

-

Quality Control (QC): Implementing rigorous quality control processes is vital to ensure that the titanium products meet industry standards and specifications. This can involve additional testing and certifications, contributing to the overall cost.

-

Logistics: Transporting titanium, especially for international buyers, can add to the cost. Factors such as shipping method, distance, and handling requirements for hazardous materials must be considered.

-

Margin: Suppliers typically apply a margin to cover their costs and profit. This margin can vary depending on the supplier’s size, market position, and the level of service they provide.

How Do Pricing Influencers Affect the Cost of Titanium Sourcing?

Several factors can influence the pricing of titanium, particularly for international B2B buyers:

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Understanding the minimum order quantities (MOQs) can help buyers negotiate better deals based on their projected needs.

-

Specifications and Customization: Custom specifications, such as specific alloys or dimensions, can lead to higher costs. Buyers should weigh the necessity of these customizations against potential price increases.

-

Material Quality and Certifications: Higher quality materials and specific certifications (such as ASTM standards) can increase costs but may be essential for certain applications, particularly in aerospace and medical industries.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge a premium, but this can also result in lower total costs due to reduced risks.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is crucial for budgeting. These terms define the responsibilities of buyers and sellers, impacting shipping costs and risk management.

What Are the Best Practices for Negotiating Titanium Pricing?

To achieve cost efficiency in titanium sourcing, consider the following strategies:

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs and benefit from volume discounts. This approach can significantly reduce per-unit costs.

-

Explore Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also factors like maintenance, lifespan, and performance. A higher upfront cost for titanium may result in lower TCO when considering durability and performance.

-

Understand Pricing Nuances for International Buyers: Different regions may have unique pricing structures influenced by local market conditions, tariffs, and import duties. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these dynamics.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing, improved service, and enhanced collaboration on future projects.

-

Stay Informed on Market Trends: Keeping abreast of global titanium market trends, including supply chain disruptions and technological advancements, can provide leverage during negotiations.

Conclusion

Sourcing titanium for its exceptional strength-to-weight ratio involves navigating a complex landscape of costs and pricing factors. By understanding these elements and employing strategic negotiation techniques, international B2B buyers can optimize their procurement processes and achieve better value in their titanium investments.

Disclaimer: Prices and cost structures are indicative and can vary based on market conditions, supplier relationships, and specific project requirements. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing titanium strength to weight ratio With Other Solutions

Introduction: Exploring Alternatives to Titanium’s Strength-to-Weight Ratio

In the pursuit of advanced materials that offer a superior strength-to-weight ratio, titanium stands out as a leading option for industries ranging from aerospace to automotive. However, various alternatives can provide comparable benefits depending on specific applications, cost considerations, and performance requirements. This section will delve into a comparative analysis of titanium’s strength-to-weight ratio against two notable alternatives: aluminum alloys and carbon fiber composites. Understanding these options enables B2B buyers to make informed decisions that align with their operational needs.

Comparison Table

| Comparison Aspect | Titanium Strength To Weight Ratio | Aluminum Alloys | Carbon Fiber Composites |

|---|---|---|---|

| Performance | Exceptional; tensile strength up to 960 MPa, density 4.51 g/cm³ | Moderate; tensile strength up to 570 MPa, density 2.7 g/cm³ | High; tensile strength up to 600 MPa, density 1.6 g/cm³ |

| Cost | Higher; raw material and processing costs are significant | Moderate; generally less expensive than titanium | Higher; costs driven by raw materials and manufacturing |

| Ease of Implementation | Requires specialized machining techniques | Easier to work with; conventional machining | Complex; requires specialized fabrication techniques |

| Maintenance | Low; excellent corrosion resistance | Moderate; prone to fatigue over time | Low; excellent fatigue resistance but can be damaged by impact |

| Best Use Case | Aerospace, high-performance automotive | General automotive, structural applications | Aerospace, high-performance sports equipment |

Detailed Breakdown of Alternatives

Aluminum Alloys

Aluminum alloys are a popular alternative due to their lower density and cost-effectiveness. While they offer a reasonable strength-to-weight ratio, they generally do not match titanium’s performance under high-stress conditions, particularly at elevated temperatures. Aluminum is easier to work with and can be machined using standard techniques, making it a practical choice for many industries. However, its susceptibility to fatigue limits its application in high-stress environments, such as in aerospace or heavy machinery.

Carbon Fiber Composites

Carbon fiber composites are increasingly favored for their lightweight and high tensile strength, making them suitable for applications where performance is critical. They can provide a superior strength-to-weight ratio compared to both titanium and aluminum, with densities as low as 1.6 g/cm³. However, the manufacturing process can be complex and expensive, requiring specialized techniques for fabrication and repair. While they offer excellent fatigue resistance, they can be vulnerable to impact damage, which may necessitate careful handling and maintenance.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a material based on strength-to-weight ratio, B2B buyers should consider the specific requirements of their projects, including performance expectations, budget constraints, and implementation capabilities. Titanium remains an optimal choice for applications demanding the highest performance, especially in extreme conditions. However, aluminum alloys may be more suitable for cost-sensitive projects where moderate performance suffices. Meanwhile, carbon fiber composites present a compelling option for high-performance applications but come with higher costs and complexity. By weighing these factors, buyers can identify the best material solution that aligns with their operational goals and project demands.

Essential Technical Properties and Trade Terminology for titanium strength to weight ratio

What Are the Key Technical Properties of Titanium Relevant to Strength-to-Weight Ratio?

1. Material Grades

Titanium is categorized into several grades based on its purity and alloying elements. The most commonly used grades are commercially pure titanium (Grades 1-4) and titanium alloys (Grades 5, 6, and others). For instance, Grade 5 titanium (Ti-6Al-4V) is known for its high strength and excellent corrosion resistance, making it ideal for aerospace applications. Understanding these grades is crucial for buyers, as they directly impact performance, cost, and suitability for specific applications.

2. Tensile Strength

Tensile strength measures how much force a material can withstand while being stretched or pulled before breaking. Titanium alloys can achieve tensile strengths upwards of 140 ksi (960 MPa), significantly surpassing that of aluminum and many steels. This property is essential for industries like aerospace and automotive, where components must endure high stress without adding excessive weight.

3. Density

The density of titanium is approximately 4.51 g/cm³, which is lighter than steel but denser than aluminum. This characteristic plays a critical role in applications where weight reduction is paramount, such as in aircraft design. A lower density allows for more efficient fuel consumption and better overall performance, making titanium an attractive choice for manufacturers aiming to optimize their products.

4. Young’s Modulus

Young’s modulus is a measure of a material’s stiffness or rigidity. Titanium exhibits a Young’s modulus of about 120 GPa, indicating its ability to resist deformation under load. This property is particularly important for structural applications where maintaining shape and integrity under stress is necessary. For B2B buyers, selecting materials with appropriate stiffness can enhance the longevity and reliability of end products.

5. Corrosion Resistance

Titanium is highly resistant to corrosion, especially in harsh environments like marine applications. Its ability to form a passive oxide layer protects it from aggressive substances, making it ideal for use in chemical processing and offshore structures. Understanding the corrosion resistance of titanium is vital for procurement managers who need to ensure long-term performance and reduce maintenance costs in their projects.

Which Trade Terms Are Essential for Understanding Titanium Procurement?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of titanium, OEMs often require specific grades and specifications to meet their product standards. Understanding OEM requirements helps B2B buyers align their sourcing strategies with industry standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For titanium, MOQs can vary significantly based on the grade and supplier, which can impact procurement strategies and inventory management. Buyers must consider MOQs to optimize costs and ensure adequate supply without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products. In the titanium market, RFQs are crucial for obtaining competitive pricing and understanding the supply landscape. B2B buyers should craft detailed RFQs to ensure they receive accurate and comprehensive responses from potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in the delivery of goods. For titanium procurement, understanding Incoterms is essential for clarifying shipping costs, risk management, and delivery responsibilities. This knowledge helps B2B buyers navigate international transactions effectively.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. In the titanium supply chain, lead times can vary based on material availability, manufacturing processes, and logistics. Awareness of lead times is vital for procurement managers to ensure timely project execution and avoid delays.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and improve overall project outcomes.

Navigating Market Dynamics and Sourcing Trends in the titanium strength to weight ratio Sector

What Are the Key Market Drivers and Trends Influencing the Titanium Strength-to-Weight Ratio Sector?

The titanium strength-to-weight ratio sector is experiencing robust growth, driven by several global factors. The aerospace and automotive industries are the primary drivers, demanding materials that can enhance fuel efficiency and performance while reducing overall weight. This trend is particularly evident in regions such as Europe and the Middle East, where regulatory pressures for lower emissions are pushing manufacturers to innovate with lightweight materials. In Africa and South America, the demand for titanium is growing in sectors like mining and energy, where durability and strength are paramount.

Emerging technologies such as additive manufacturing and advanced alloy development are also reshaping the titanium market landscape. These innovations enable the production of complex geometries and customized solutions that traditional manufacturing processes cannot achieve. Additionally, the rise of digital procurement platforms is streamlining sourcing processes, allowing international B2B buyers to access a broader range of suppliers and materials. The integration of AI and data analytics in supply chain management further enhances decision-making, helping buyers to optimize inventory and reduce costs.

How Does Sustainability and Ethical Sourcing Impact the Titanium Strength-to-Weight Ratio Sector?

Sustainability is becoming increasingly important in the titanium sector, with buyers prioritizing ethical sourcing practices. The environmental impact of titanium extraction and processing necessitates a focus on responsible supply chains. Many suppliers are adopting ‘green’ certifications to demonstrate their commitment to sustainable practices, which is essential for gaining the trust of eco-conscious buyers.

Furthermore, the use of recycled titanium is gaining traction, as it significantly reduces the carbon footprint associated with mining new titanium. This shift not only helps in conserving natural resources but also aligns with global sustainability goals. B2B buyers are encouraged to inquire about suppliers’ sustainability certifications and practices when sourcing titanium products. This not only mitigates risk but also enhances brand reputation in an increasingly environmentally aware market.

What Is the Historical Context of Titanium’s Use in Engineering Applications?

The evolution of titanium in engineering applications dates back to the mid-20th century when its remarkable strength-to-weight ratio began to be recognized. Initially used in aerospace applications, titanium’s unique properties quickly garnered attention for military and commercial aircraft design. Over the decades, advancements in metallurgy and processing techniques have expanded its applications across various industries, including automotive, marine, and medical.

Today, titanium is not only a staple in aerospace engineering but also a preferred material in high-performance automotive components and marine applications due to its corrosion resistance and strength. As industries continue to evolve, titanium’s role is expected to expand further, driven by ongoing innovations and the quest for materials that meet stringent performance and sustainability standards.

In conclusion, international B2B buyers should stay informed about market trends, prioritize sustainable sourcing, and understand the historical context of titanium to make informed procurement decisions that enhance their operational efficiencies and align with global sustainability initiatives.

Frequently Asked Questions (FAQs) for B2B Buyers of titanium strength to weight ratio

-

How do I determine the optimal titanium grade for my application?

To select the best titanium grade, assess the specific requirements of your application, including strength, corrosion resistance, and temperature tolerance. Common grades like Ti-6Al-4V offer high strength and good weldability, making them suitable for aerospace and automotive applications. Alternatively, commercially pure titanium is ideal for environments requiring excellent corrosion resistance but lower strength. Consulting with suppliers who understand your industry needs can also provide tailored recommendations based on your project’s unique demands. -

What is the best titanium alloy for aerospace applications?

For aerospace applications, Ti-6Al-4V (Grade 5) is widely regarded as the best titanium alloy due to its superior strength-to-weight ratio and excellent fatigue resistance. It performs exceptionally well in high-temperature environments, making it ideal for components like airframes, landing gear, and engine parts. Additionally, other alloys such as Ti-10-2-3 are gaining traction for specific applications due to their enhanced properties. It’s essential to collaborate with experienced suppliers who can offer alloys that meet aerospace certification standards. -

What factors should I consider when sourcing titanium internationally?

When sourcing titanium internationally, consider factors such as supplier reliability, compliance with industry standards, and logistical capabilities. Ensure that potential suppliers can provide certifications for their materials, such as ASTM or ISO standards. Evaluate their experience in your industry and their ability to meet your specific requirements regarding customization and delivery timelines. Additionally, understanding local regulations and tariffs can help avoid unexpected costs and delays in the procurement process. -

What are the typical minimum order quantities (MOQs) for titanium products?

Minimum order quantities for titanium products can vary significantly based on the supplier, the type of product, and the specifications required. Generally, MOQs can range from a few kilograms for standard grades to several tons for specialized alloys. It’s advisable to discuss your project needs with potential suppliers to negotiate favorable terms, especially if you require smaller quantities for prototyping or testing. Many suppliers may offer flexibility in MOQs for long-term partnerships or bulk orders. -

How can I ensure quality assurance in my titanium supply chain?

To ensure quality assurance in your titanium supply chain, select suppliers with robust quality management systems and certifications such as ISO 9001. Request detailed documentation, including material test reports (MTRs) and certificates of compliance, to verify the quality and traceability of the materials. Regular audits and inspections can also help maintain quality standards. Establishing a clear communication channel with your supplier regarding quality expectations will facilitate ongoing quality assurance throughout the procurement process. -

What payment terms are common for international titanium purchases?

Common payment terms for international titanium purchases include letters of credit, advance payments, and open account terms, depending on the relationship between the buyer and supplier. Letters of credit are often preferred for large transactions, offering security to both parties. Payment terms may also vary based on the order size, supplier reputation, and the buyer’s creditworthiness. It’s essential to discuss and agree upon payment terms early in the negotiation process to avoid misunderstandings later. -

How does titanium’s strength-to-weight ratio compare to other metals?

Titanium boasts a superior strength-to-weight ratio compared to many metals, including aluminum and steel. With a tensile strength reaching up to 140 ksi (960 MPa) and a density of 0.16 lb/in³ (4.51 g/cm³), titanium’s strength-to-weight ratio often exceeds 0.875. This unique property makes it particularly valuable in applications where both strength and weight savings are critical, such as in aerospace and automotive industries. Understanding these comparisons can guide you in selecting the right material for your specific applications. -

What logistics considerations should I be aware of when importing titanium?

When importing titanium, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose reliable freight forwarders experienced in handling metal shipments to ensure timely delivery. Familiarize yourself with the import duties and taxes applicable to titanium in your region, as these can significantly affect your overall cost. Additionally, ensure that your supplier can provide proper documentation for customs clearance to facilitate a smooth import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Titanium Strength To Weight Ratio Manufacturers & Suppliers List

1. Kyocera – SG Tool Solutions

Domain: kyocera-sgstool.co.uk

Registered: 2019 (6 years)

Introduction: {“Atomic number”: 22, “Atomic weight”: 47.9, “Atomic volume”: 10.6, “Covalent radius”: “1.32 Å”, “Ionization potential”: “6.8282 V”, “Thermal neutron absorption cross section”: “5.6 barns/atom”, “Crystal structure”: {“Alpha”: “Close-packed hexagonal”, “Beta”: “Body-centered cubic”}, “Color”: “Dark gray”, “Density”: “4.51 g/cm3 (0.163 lb/in.3)”, “Melting point”: “1668 ± 10 °C (3035 °F)”, “Solidus/l…

2. Jiga – Titanium and Aluminum Solutions

Domain: jiga.io

Registered: 2020 (5 years)

Introduction: Titanium and Aluminum are both lightweight metals with distinct properties and versatility of application. Titanium is known for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. It has a low density, high melting point, and excellent heat and chemical resistance. Titanium is widely used in aircraft, rocket, satellite, and engine components, artificial joints, d…

3. HowStuffWorks – Titanium Strength and Applications

Domain: science.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Titanium has the highest ratio of tensile strength to density of any metal on Earth. It is as strong as steel but 45% lighter. Titanium alloys are used in airplane engines, rockets, and missiles due to their strength-to-weight ratio. It is not particularly rare but is expensive to mine and produce. Titanium does not rust; it forms a protective layer of titanium dioxide when exposed to oxygen, maki…

4. Dorsetware – Titanium and Steel Alloys

Domain: dorsetware.com

Registered: 2000 (25 years)

Introduction: Steel and titanium are both strong metals used in various applications. Titanium, when alloyed with metals like aluminium or vanadium, becomes stronger than many steels, especially low-to-medium grade stainless steels. However, the highest grade of stainless steel surpasses titanium alloys in strength. Titanium is significantly lighter than steel, being 45% lighter while maintaining comparable str…

5. TN Titanium – High Strength Titanium Alloys

Domain: tntitanium.com

Registered: 2015 (10 years)

Introduction: This company, TN Titanium – High Strength Titanium Alloys, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Stamping Simulation – Strength-to-Weight Ratio Insights

Domain: stampingsimulation.com

Registered: 2004 (21 years)

Introduction: The article discusses the strength-to-weight ratio of metals, emphasizing its importance in material selection for applications like automotive and aerospace. Key points include: 1. Definition: The strength-to-weight ratio is the strength of a material divided by its mass, also referred to as specific strength. 2. Material Choices: High strength-to-weight ratio materials such as aluminum, titanium…

7. Morsel’s Spork – Aluminum vs. Titanium Comparison

Domain: morselspork.com

Registered: 2017 (8 years)

Introduction: Aluminum is lightweight, corrosion-resistant, and cost-effective, making it suitable for various applications. Titanium, while heavier and more expensive, offers superior strength, durability, and resistance to extreme temperatures and corrosion. The comparison highlights that aluminum is ideal for applications where weight and cost are critical, whereas titanium is preferred for high-performance …

Strategic Sourcing Conclusion and Outlook for titanium strength to weight ratio

In summary, the titanium strength-to-weight ratio positions it as a crucial material across various industries, particularly aerospace, automotive, and marine engineering. Its unique properties, such as high tensile strength and excellent corrosion resistance, provide significant advantages over traditional materials like aluminum and steel. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding these attributes is essential for making informed sourcing decisions that enhance product performance and sustainability.

Strategic sourcing of titanium not only leads to improved operational efficiencies but also supports innovation in design and manufacturing processes. As industries increasingly focus on sustainability and efficiency, the demand for titanium is set to rise, making it imperative for procurement managers to leverage its benefits in their supply chains.

Looking ahead, companies that prioritize titanium in their material selection will be better equipped to meet the challenges of tomorrow’s market. Now is the time to engage with trusted suppliers and explore how incorporating titanium can drive your business forward. Seize the opportunity to enhance your projects with this exceptional material, positioning your organization for success in an evolving landscape.