Contents

Manufacturing Insight: Titanium Strength To Weight Ratio

Titanium Strength-to-Weight Ratio: Precision Engineering for Demanding Applications

Titanium’s exceptional strength-to-weight ratio—approximately 3.2 times higher than steel by weight—makes it indispensable for weight-sensitive, high-performance sectors like aerospace, medical implants, and defense. However, realizing this material’s full potential demands advanced machining expertise to overcome challenges such as galling, thermal conductivity limitations, and precise dimensional control. At Honyo Prototype, our specialized CNC machining services are engineered to transform titanium’s theoretical advantages into mission-critical components. We leverage multi-axis milling, optimized toolpath strategies, and proprietary coolant techniques to maintain tight tolerances while mitigating work hardening and thermal distortion.

Our end-to-end capabilities span from rapid prototyping to low-volume production, ensuring your titanium parts meet stringent industry standards without compromising on lead time or cost efficiency. To accelerate your project validation, Honyo offers an Online Instant Quote platform. Simply upload your CAD file to receive a detailed manufacturability analysis and competitive pricing within hours—eliminating procurement delays and enabling faster design iteration. Partner with us to harness titanium’s performance edge through precision manufacturing engineered for real-world results.

Technical Capabilities

Titanium is renowned for its exceptional strength-to-weight ratio, making it a preferred material in high-performance industries such as aerospace, medical, and defense. When machining titanium—particularly in precision 3-axis, 4-axis, and 5-axis milling and turning operations—its mechanical properties present both advantages and challenges. The high strength-to-weight ratio allows for lightweight yet durable components, but titanium’s low thermal conductivity and high chemical reactivity require careful tool selection, cooling strategies, and machining parameters to maintain tight tolerances (±0.0005″ to ±0.005″ typical).

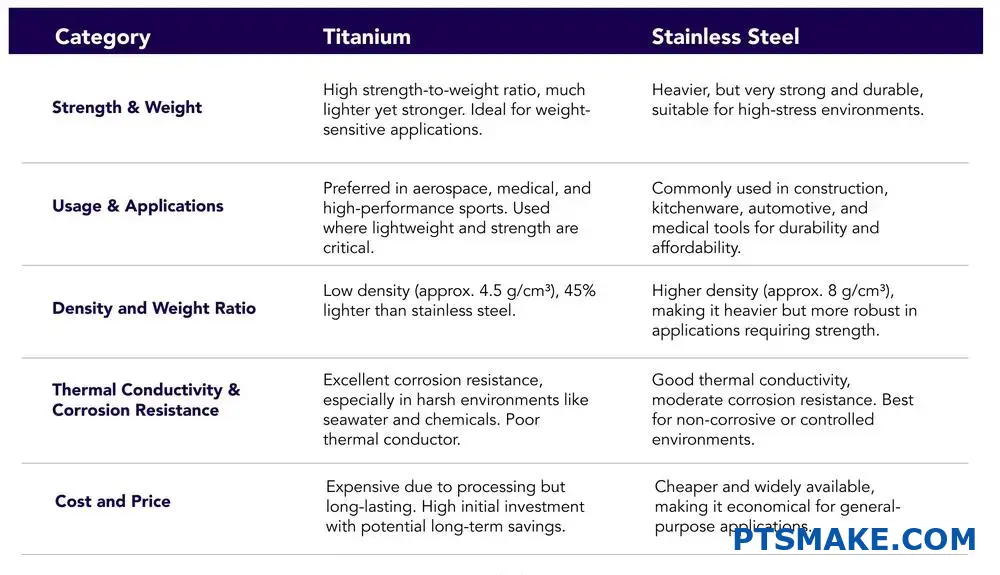

The following table compares titanium with other commonly machined materials—aluminum, steel, ABS, and nylon—highlighting key mechanical and machining characteristics relevant to multi-axis CNC operations and tight tolerance requirements.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Modulus of Elasticity (GPa) | Strength-to-Weight Ratio (MPa/(g/cm³)) | Machinability Notes – 3/4/5-Axis Milling & Turning | Typical Tolerance Capability (± inches) |

|---|---|---|---|---|---|---|---|

| Titanium (Grade 5, Ti-6Al-4V) | 4.43 | 900–950 | 830–860 | 114 | ~210 | Challenging: Low thermal conductivity requires slow speeds, high-pressure coolant, and rigid setups. Prone to work hardening. Use carbide or ceramic tooling. Excellent for high-stress, lightweight precision parts. | 0.0005 – 0.002 |

| Aluminum (6061-T6) | 2.70 | 310 | 275 | 68.9 | ~115 | Excellent: High machinability allows high feed rates and excellent surface finish. Minimal tool wear. Ideal for complex 5-axis geometries and tight tolerances. | 0.0005 – 0.001 |

| Steel (4140, Annealed) | 7.85 | 655 | 415 | 200 | ~83 | Moderate: Requires robust tooling and lower speeds than aluminum. Generates higher cutting forces. Good dimensional stability for precision turning and milling. | 0.0005 – 0.002 |

| ABS (Acrylonitrile Butadiene Styrene) | 1.04 | 40–45 | 40 | 2.0–3.0 | ~40 | Very Good: Low melting point; requires sharp tools and light cuts to prevent melting or burring. Minimal clamping force needed. Suitable for prototypes and jigs. | 0.002 – 0.005 |

| Nylon (PA6/PA66) | 1.13 | 70–85 | 50–60 | 2.5–3.0 | ~70 | Good: Exhibits elasticity and moisture absorption; can lead to post-machining dimensional changes. Must be machined dry or with air cooling. Use sharp tools to avoid deformation. | 0.002 – 0.005 |

Notes on Machining for Tight Tolerances:

Titanium demands stable, vibration-free setups due to its high notch sensitivity and tendency to gall.

In 5-axis milling, tool path optimization is critical to minimize heat buildup and ensure consistent tool engagement.

Aluminum and steel are more forgiving in high-precision environments but differ significantly in weight and performance trade-offs.

Plastics like ABS and nylon are easier to machine rapidly but require environmental conditioning and post-machining stabilization for critical dimensions.

At Honyo Prototype, we optimize CNC strategies per material, leveraging advanced tooling, in-process inspection, and thermal compensation to achieve tight tolerances across titanium and other engineering materials.

From CAD to Part: The Process

Honyo Prototype delivers optimized titanium components by rigorously applying material science principles throughout our integrated workflow. The strength-to-weight ratio advantage of titanium alloys like Ti-6Al-4V is not an isolated step but a core engineering outcome woven into every phase of our process. Here is how we systematically achieve this:

CAD Upload and Material Specification

Customers submit detailed CAD models with explicit titanium grade requirements (e.g., ASTM F136 for medical, AMS 4928 for aerospace). Our system validates model integrity and flags geometric features critical to strength-to-weight optimization such as thin-wall sections, complex lattices, or stress-concentrated radii. Material certification standards are cross-referenced immediately to ensure compliance with end-use requirements.

AI-Powered Quoting with Material Physics Integration

Our AI engine analyzes the CAD geometry against titanium-specific machining parameters: thermal conductivity (7.2 W/m·K), elastic modulus (114 GPa), and galling tendencies. The quote dynamically calculates machine time penalties for titanium’s low thermal diffusivity (0.044 mm²/s) versus aluminum, incorporating necessary allowances for slow feed rates (typically 30-50% of aluminum) and high-pressure coolant requirements. Cost estimates reflect scrap rate mitigation strategies for this reactive metal.

Titanium-Specific DFM Engineering

Our manufacturing engineers conduct deep-dive reviews focused on preserving titanium’s strength-to-weight integrity:

| DFM Parameter | Titanium-Specific Consideration | Honyo Mitigation Strategy |

|---|---|---|

| Wall Thickness | Minimum 0.5mm for structural stability | Recommend topology optimization over uniform thinning |

| Toolpath Strategy | Heat buildup risks microstructure alteration | Mandate trochoidal milling with 85-90% stepover |

| Fixturing | Clamping pressure causes surface embrittlement | Implement vacuum chucks or low-pressure soft jaws |

| Surface Finish | Ra < 0.8µm required for fatigue resistance | Specify multi-pass finishing with polished inserts |

Critical attention is given to avoiding hydrogen contamination during machining, which degrades tensile strength. We enforce strict coolant pH monitoring (8.5-9.2) and exclude chlorinated compounds.

Precision Production Execution

Titanium machining occurs in dedicated climate-controlled cells with ISO Class 7 air filtration. Key protocols include:

Solid carbide tools with AlTiN coatings running at 60-80 m/min surface speed to prevent adhesion. High-pressure through-spindle coolant (70+ bar) maintains chip evacuation and thermal stability. In-process CMM checks verify dimensional stability of thin features, with real-time thermal compensation algorithms active during machining. All scrap titanium is segregated for certified recycling to maintain material traceability.

Verified Delivery and Certification

Each titanium component undergoes mandatory mechanical validation:

ASTM E8 tensile testing confirming yield strength ≥ 830 MPa

Archimedes density verification (4.43 g/cm³ for Ti-6Al-4V)

Microhardness mapping across critical sections

Full material traceability from mill certificate through machining logs is provided. Final packaging includes desiccant-controlled containers with oxygen absorbers to prevent surface oxidation during transit. This closed-loop process ensures the as-delivered part achieves the theoretical strength-to-weight ratio (228 kN·m/kg for Ti-6Al-4V) without compromise.

Start Your Project

Titanium offers an exceptional strength-to-weight ratio, making it ideal for high-performance applications in aerospace, automotive, and medical industries. Its durability, corrosion resistance, and lightweight properties ensure reliable performance under demanding conditions.

For engineering support or custom titanium part prototyping, contact Susan Leo at [email protected]. Honyo Prototype operates a precision manufacturing facility in Shenzhen, equipped for rapid prototyping and low-volume production with strict quality control.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.