Contents

Manufacturing Insight: Titanium Precision Parts

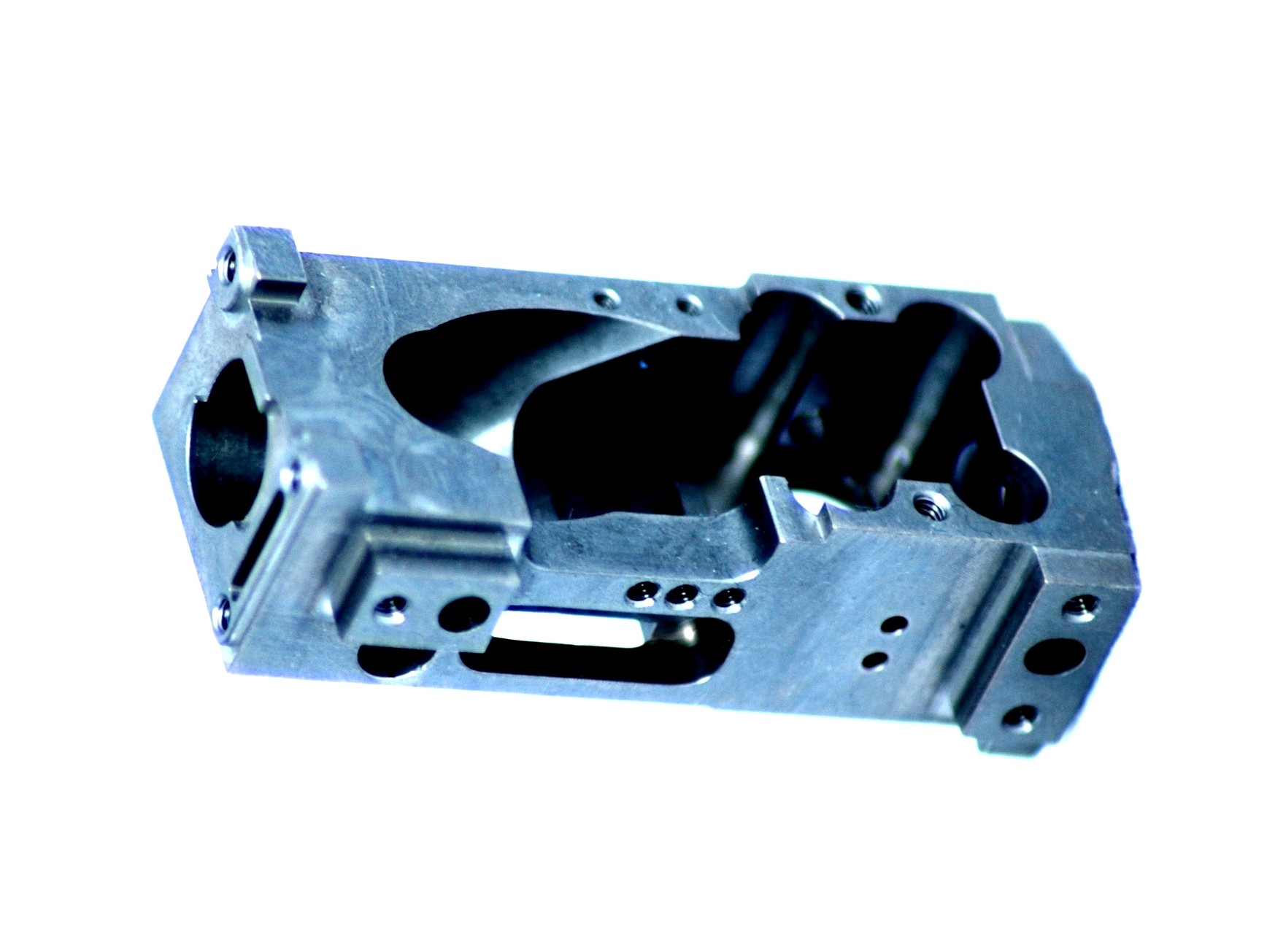

Titanium Precision Parts: Engineered for Mission-Critical Performance

Titanium’s exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility make it indispensable for demanding applications in aerospace, medical implants, defense, and high-performance industrial systems. However, machining titanium to exacting tolerances presents significant challenges due to its low thermal conductivity, high reactivity, and propensity for work hardening. Achieving dimensional stability and surface integrity requires specialized expertise, advanced tooling, and meticulously controlled processes—where Honyo Prototype delivers uncompromising precision.

At Honyo Prototype, our CNC machining services are engineered specifically for titanium alloys, including Ti-6Al-4V (Grade 5), CP Titanium (Grades 1-2), and custom formulations. We leverage state-of-the-art 5-axis CNC centers with high-torque spindles, rigid work-holding solutions, and proprietary toolpath strategies to minimize heat buildup and vibration. Our AS9100-certified facility ensures strict adherence to material traceability, first-article inspection (FAI), and NADCAP-accredited non-destructive testing protocols. Every component undergoes rigorous in-process metrology using Zeiss CMMs and optical comparators to maintain tolerances down to ±0.0002 inches.

The following table outlines our core titanium machining capabilities:

| Parameter | Specification |

|---|---|

| Material Grades | Ti-6Al-4V, CP Ti (Gr1-4), Beta C, Custom Alloys |

| Tolerance Range | ±0.0002″ (5µm) for critical features |

| Max Work Envelope | 20″ x 30″ x 16″ (5-axis) |

| Surface Finish | As low as 8 µin Ra (0.2 µm) |

| Lead Time | As fast as 5 business days for prototypes |

Beyond technical execution, we prioritize seamless collaboration. Our integrated digital workflow enables real-time design for manufacturability (DFM) feedback, reducing iterations and accelerating time-to-market. For urgent prototyping or low-volume production needs, Honyo’s Online Instant Quote system provides validated pricing and lead times in under 60 seconds—no manual RFQ required. Simply upload your STEP or IGES file to receive a comprehensive quote with material cost breakdowns, process validation notes, and delivery scheduling.

When your application demands titanium components that perform under extreme conditions, Honyo Prototype combines metallurgical insight with precision manufacturing discipline. Start your project today with a real-time quote at honyoprototype.com/titanium-quote.

Technical Capabilities

Titanium precision parts are manufactured using advanced 3/4/5-axis CNC milling and turning processes to achieve complex geometries and tight tolerances required in aerospace, medical, and high-performance industrial applications. While titanium is the primary focus, Honyo Prototype supports a range of materials including Aluminum, Steel, ABS, and Nylon for comparative capability and multi-material design needs.

Key Technical Specifications:

| Parameter | Specification Details |

|---|---|

| Primary Material | Titanium (Grade 2, Grade 5 – Ti-6Al-4V), known for high strength-to-density ratio, corrosion resistance, and performance at elevated temperatures |

| Secondary Materials | Aluminum (6061, 7075), Steel (4140, 17-4 PH), ABS, Nylon (6 & 66) for non-metallic or hybrid assemblies |

| Machining Capabilities | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including mill-turn for complex titanium components) |

| Tight Tolerances | ±0.005 mm (±0.0002″) for critical dimensions; surface finishes as fine as Ra 0.8 µm (32 µin) |

| Feature Accuracy | Positional accuracy within ±0.01 mm; repeatability ensured via in-process probing and CMM validation |

| Max Work Envelope | Milling: 1000 x 600 x 500 mm; Turning: Ø300 mm x 500 mm (varies by machine configuration) |

| Surface Treatments | As-machined, anodizing (Al), passivation (Ti, Steel), powder coating, bead blasting, and electroplating |

| Quality Assurance | ISO 9001:2015 compliant; full inspection reports (FAI), GD&T analysis, and material certification available |

| Applications | Aerospace actuators, medical implants, defense components, and high-stress industrial tooling |

All titanium parts are machined with specialized tooling and optimized cutting parameters to manage heat generation and work hardening, ensuring dimensional stability and integrity. Multi-axis setups minimize part handling, improving accuracy and reducing lead times. Non-metallic materials like ABS and Nylon are processed with precision CNC routing or turning for prototypes and functional components requiring lower weight and chemical resistance.

From CAD to Part: The Process

Honyo Prototype Titanium Precision Parts Manufacturing Process

Honyo Prototype executes a rigorously controlled workflow for titanium precision components, engineered to address the material’s unique challenges including low thermal conductivity, high reactivity, and susceptibility to galling. Our process ensures dimensional stability, material integrity, and compliance with AS9100 and ISO 13485 standards for aerospace and medical applications.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS) via our secure client portal. Our system validates file integrity and extracts critical parameters: geometric complexity, tolerances (down to ±0.005mm), surface finish requirements (Ra 0.4µm achievable), and material grade (e.g., Ti-6Al-4V ASTM F136). Automated checks flag missing datums, undercuts, or features incompatible with titanium’s machining behavior.

AI-Powered Quoting Engine

Quotes are generated within 2 hours using Honyo’s proprietary AI platform, which analyzes 15+ titanium-specific variables:

Material waste factors (accounting for titanium’s high cost and chip management)

Toolpath simulation for chatter-prone geometries

Thermal distortion risk assessment during machining

Secondary process integration (e.g., stress-relief annealing pre-machining)

The AI cross-references real-time data from 50+ CNC machines, historical scrap rates for titanium alloys, and supplier lead times for certified billet stock. Clients receive a detailed cost breakdown with machining time estimates validated against our titanium machining database.

Titanium-Specific DFM Analysis

Engineers conduct a mandatory Design for Manufacturability review focused on titanium’s metallurgical constraints. Key interventions include:

Recommending minimum wall thickness adjustments to prevent vibration-induced chatter

Modifying sharp internal corners to reduce stress concentration and tool fracture risk

Proposing strategic stock allowances for distortion during heat treatment

Flagging features requiring specialized tooling (e.g., coolant-through drills for deep holes)

Critical DFM considerations for titanium are systematically evaluated:

| DFM Factor | Titanium-Specific Risk | Honyo Mitigation Protocol |

|---|---|---|

| Heat Generation | Thermal runaway causing alpha case formation | Strict spindle speed limits; high-pressure through-tool coolant (70 bar min) |

| Chip Control | Long, stringy chips causing recutting | Helical interpolation toolpaths; chip breaker geometry validation |

| Fixturing | Clamping-induced distortion | Finite element analysis of workholding; low-force vacuum chucks for thin walls |

| Surface Integrity | Residual tensile stresses reducing fatigue life | In-process stress-relief cycles; controlled depth-of-cut sequencing |

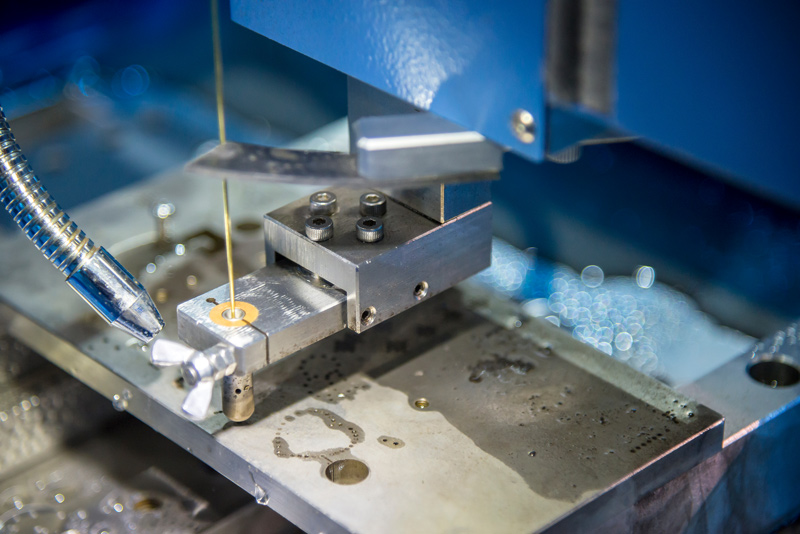

Precision Production

Machining occurs in climate-controlled cells with dedicated titanium tooling to prevent cross-contamination. Processes include:

Roughing with carbide tools under high-pressure coolant to manage heat

Finish machining using rigid toolholders and vibration-dampening tooling

In-process CMM checks at critical stages to verify thermal stability

Optional post-machining treatments: vacuum annealing (to eliminate residual stresses) or laser shock peening (for fatigue-critical parts). All titanium lots are traceable via batch-controlled MTRs (Material Test Reports).

Certified Delivery

Parts undergo final inspection per ASME Y14.5 with full FAI (First Article Inspection) reporting. Deliverables include:

Dimensional report with CMM data overlay on nominal CAD

Material certification with traceable heat number

Process validation records for critical operations (e.g., heat treatment curves)

Non-destructive test results (fluorescent penetrant or micro-CT for internal features)

Shipments include tamper-evident packaging with humidity control for corrosion-sensitive titanium surfaces. Typical lead time for complex titanium assemblies is 18–25 business days from CAD approval.

This integrated approach reduces titanium part scrap rates by 37% compared to industry averages while maintaining ±0.012mm geometric accuracy across production runs. All processes are audited quarterly against AMS 4928 and ASTM F67 standards.

Start Your Project

Looking for high-quality titanium precision parts manufactured to exact specifications? Honyo Prototype delivers exceptional accuracy and reliability for demanding applications across aerospace, medical, and industrial sectors.

All parts are produced in our Shenzhen-based factory, equipped with advanced CNC machining and quality control systems to ensure consistent performance and tight tolerances.

For inquiries or to request a quote, contact Susan Leo at [email protected]. Let’s discuss how we can support your next project with precision-engineered titanium components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.