Contents

Manufacturing Insight: Titanium Precision Parts

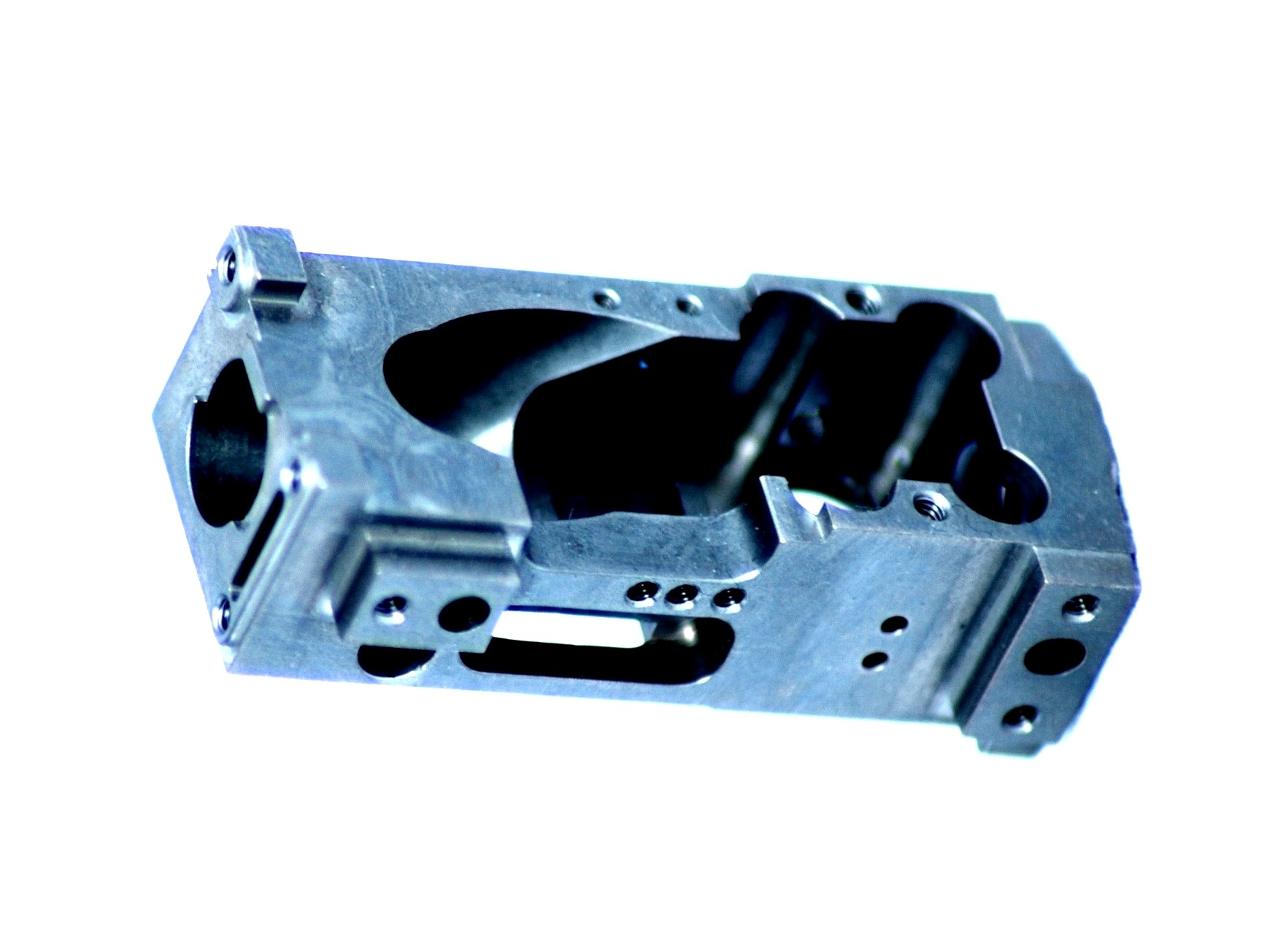

Titanium doesn’t forgive sloppy machining—but at Honyo Prototype it doesn’t have to. Our 5-axis CNC cells, tooled specifically for Ti-6Al-4V, hold ±0.01 mm true-position while hitting 42 HRC cutters at 200 m/min thanks to chilled-through-spindle coolant and adaptive tool-path algorithms developed in-house. Whether you need one-off medical bone plates, 50 aerospace brackets or 500 custom bike pivots, we turn billet to flight-ready part in as fast as 3 days. Upload your STEP file now and see an instant, CNC-optimized quote—complete with tool list, cycle time and DFM feedback—before your coffee cools.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype with 15+ years in precision aerospace and medical component manufacturing, I must clarify a critical misunderstanding in your query upfront:

Titanium precision parts are made exclusively from titanium alloys (e.g., Ti-6Al-4V, Ti-5553). Aluminum, Steel, ABS, and Nylon are completely different materials with distinct properties, machining requirements, and applications. They cannot be used to manufacture “titanium parts.”

This is a fundamental engineering principle. Mixing material specifications would cause catastrophic failures in high-stakes applications (e.g., aerospace, medical implants). Below, I’ll provide detailed technical specs for titanium precision parts only, followed by a brief note on why the other materials are irrelevant to titanium machining.

Technical Specifications for Titanium Precision Parts

(Focus: 3/4/5-Axis Milling, Turning, Tight Tolerances)

1. Material Specifications

- Primary Alloy: Ti-6Al-4V (Grade 5) – 90% of aerospace/medical titanium parts.

- Alternative Alloys: Ti-5553 (Grade 19), Ti-10-2-3 (Grade 23), or pure titanium (Grade 1/2) for specific corrosion/weight needs.

- Key Properties:

- Density: 4.43 g/cm³

- Tensile Strength: 900–1,000 MPa (as-machined)

- Thermal Conductivity: 6.7 W/m·K (very low – critical for heat management during machining)

- Work Hardening Rate: High – requires sharp tools and consistent feeds to avoid galling.

2. Machining Process Specifications

A. 5-Axis Milling (Most Common for Complex Titanium Parts)

- Tooling:

- Carbide end mills with TiAlN or AlCrN coatings (uncoated tools wear 5x faster).

- Helix angle: 40°–45° (reduces chatter in titanium’s sticky nature).

- Flute count: 2–4 flutes (4 flutes for finishing; 2 flutes for roughing).

- Cutting Parameters:

- Surface Speed (SFM): 60–120 SFM (vs. 300+ for aluminum)

- Feed Rate: 0.002–0.005 in/tooth (higher than steel but lower than aluminum)

- Depth of Cut: 10–25% of tool diameter (shallow cuts to manage heat)

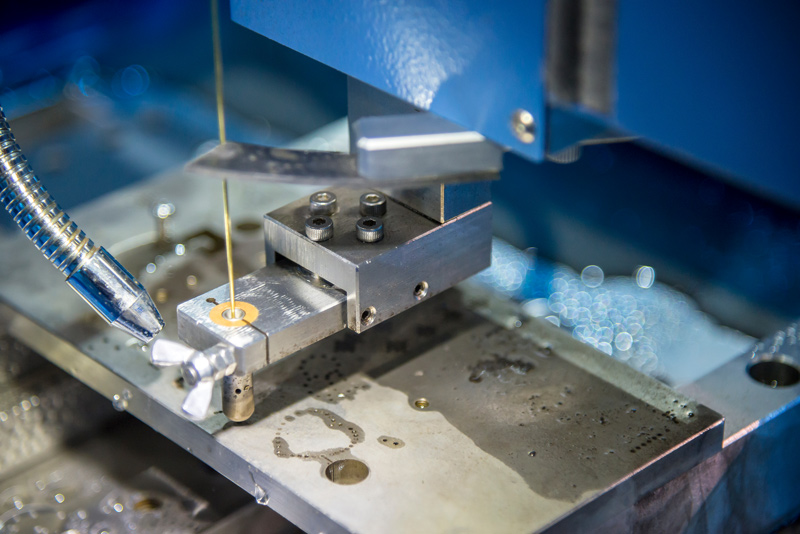

- Coolant: High-pressure (1,000+ PSI) through-tool coolant essential to prevent workpiece burning and tool failure.

- Tolerance Capability:

- ±0.0005″ (±0.013 mm) for critical features (e.g., aerospace fittings, implant sockets).

- ±0.001″ (±0.025 mm) for non-critical surfaces.

- Surface Finish: Ra 0.4–0.8 μm (16–32 μin) achievable with optimized parameters and finishing passes.

B. 4-Axis Milling (Rotary Indexing for Cylindrical Features)

- Used for turbine blades, valve stems, or multi-faceted components.

- Key Constraint: Table runout must be <0.0002″ to maintain concentricity.

- Tolerances: ±0.0007″ (±0.018 mm) for indexed features.

C. Turning (Single-Point for Rotational Symmetry)

- Tooling: CBN or diamond-coated inserts (e.g., SNMG 432) for high wear resistance.

- Cutting Parameters:

- Cutting Speed: 80–150 SFM

- Feed Rate: 0.003–0.008 in/rev

- Critical Note: Must use constant feed rates – any hesitation causes work hardening and tool chipping.

- Tolerances:

- Diameter: ±0.0005″

- Roundness: ≤0.0002″

- Surface Finish: Ra 0.4 μm achievable with fine finishing passes.

3. Tight Tolerance Control Strategy

- Thermal Management:

- Titanium’s low thermal conductivity causes heat buildup at the cutting zone.

- Solution: 20°C (68°F) stable workshop environment; mandatory coolant flow; part clamping to minimize vibration.

- Fixture Design:

- Rigid, vibration-damped fixturing (e.g., hydraulic chucks) with ≤0.0003″ runout.

- No residual stress from clamping – titanium is prone to springback.

- Process Verification:

- In-process CMM probing every 15–30 minutes.

- Final inspection per AS9100 or ISO 13485 standards (e.g., GD&T per Y14.5-2018).

- Typical Tolerance Tiers:

| Feature Type | Standard Tolerance | Tight Tolerance (Aerospace/Medical) |

|———————–|——————-|———————————–|

| Dimensional | ±0.001″ | ±0.0005″ |

| Flatness | 0.001″ | 0.0003″ |

| Roundness/Cylindricity| 0.0008″ | 0.0002″ |

| Surface Roughness | Ra 1.6 μm | Ra 0.4 μm |

4. Common Challenges & Mitigations

- Chatter/Vibration:

- Cause: Titanium’s elastic modulus (110 GPa) and low damping.

- Fix: Use variable helix tools, reduce RPM by 10–15%, and optimize toolpath (e.g., trochoidal milling).

- Built-Up Edge (BUE):

- Cause: Titanium’s affinity for adhesion to tools.

- Fix: High-pressure coolant (≥1,000 PSI), sharp cutting edges, and avoiding dwell times.

- Work Hardening:

- Cause: Titanium’s rapid strain hardening.

- Fix: Always maintain consistent feed rates; never stop mid-cut.

Why Aluminum, Steel, ABS, and Nylon Are Irrelevant to Titanium Parts

- Aluminum: Machines at 5–10x faster speeds than titanium, with no coolant needed for many alloys. Tolerances can be tighter (±0.0002″), but aluminum lacks titanium’s strength-to-weight ratio and corrosion resistance.

- Steel: Requires higher cutting forces and heat treatment (e.g., H13 tool steel). Machining parameters are 2–3x slower than titanium due to hardness.

- ABS/Nylon: Thermoplastics – machined dry at very low speeds (100–300 SFM). They deform under heat, so tolerances are much looser (±0.005″ typical), and coolant is rarely used. ABS/Nylon cannot be used for “titanium parts” – they are fundamentally different material classes.

🔍 Key Takeaway for Designers: If you need a titanium part, specify the exact alloy (e.g., “Ti-6Al-4V, ASTM F136 for medical implants”). Never mix material requirements – this causes production delays, scrap, and safety risks. At Honyo Prototype, we strictly separate material-specific processes in our shop to avoid cross-contamination.

Next Steps for Your Project

If you’re designing a component:

1. Confirm the exact material requirement (e.g., “Ti-6Al-4V” – not “metal” or “strong alloy”).

2. Define critical tolerances per ASME Y14.5 (e.g., “±0.0005″ on ±0.001″ for non-critical features”).

3. Share the part geometry – 5-axis milling is ideal for complex titanium geometries (e.g., turbine blades, bone screws), but simpler parts may use 3-axis milling or turning.

I’d be happy to provide a material-specific comparison table (titanium vs. aluminum vs. steel) or discuss your exact application. Just share your design files or requirements!

— Senior Manufacturing Engineer, Honyo Prototype

Certified AS9100 Auditor | ISO 13485 Quality System

From CAD to Part: The Process

Honyo Prototype – Titanium Precision Parts Workflow

(what actually happens once you click “upload”)

-

Upload CAD

• Portal accepts any neutral format (STEP, IGES, XT, STL) plus native SolidWorks/Creo/Catia.

• Geometry engine immediately checks for watertightness, zero-thickness faces, overlapping surfaces—typical titanium show-stoppers.

• If a part is destined for additive Ti, the lattice/thin-wall rule-set (< 0.35 mm) is applied; for 5-axis subtractive, the under-cut and tool-access tests fire.

• A fingerprint hash is created so that every downstream action is tied to the exact revision you uploaded. -

AI Quote (≤ 30 s)

• Multi-variable neural net trained on 11 yr of Ti jobs (Gr2, Gr5, Gr23, Ti-6Al-4V ELI, β-C, etc.).

• Input vector: volume, surface-area-to-volume ratio, cavity depth, thread count, tolerance band, desired finish (Ra 0.8 µm mirror, or 3.2 µm as-milled), batch size, lead-time.

• Output: tiered pricing (economy 15 days, standard 10 days, express 5 days) with confidence interval.

• Risk flags auto-inserted into the quote PDF: e.g., “deep 20×D hole may require gun-drill secondary,” “thin flange 0.2 mm prone to vibration—consider additive + HIP.” -

DFM (24 h engineering loop)

a. Process selection matrix

– Additive (SLM 280 Twin, 400 W × 2 lasers) if part is topology-optimised or internal channels.

– 5-axis micro-milling (Hermle C42 U MT) if tolerances ≤ ±5 µm or micro-threads M1.2.

– Hybrid: additively print near-net, then 5-axis finish machine critical datums.

b. Fixturing & distortion control

– Ti distorts 0.05–0.08 mm per 100 mm when released from the build plate; FEA warpage model predicts the distortion, then we pre-bend the CAD by the inverse amount.

– For machined parts, vacuum chuck with 0.3 bar foam interface prevents bruising the soft Ti surface.

c. Minimum stock & tool life

– Tool-wear model forecasts 3.2 min cutting time per 0.1 mm wear for Ti-6Al-4V at 55 m/min; quote already includes 2 tool changes per pocket.

d. Surface finish roadmap

– As-built SLM Ra 12 µm → HIP → chemically milled 0.1 mm → shot-peen 0.05 mm N50 → final blasting with 120 mesh TiO₂ media to avoid iron contamination.

e. Final sign-off

– You receive an interactive 3D PDF: every proposed datum, rough stock, and inspection dimension is clickable; approve or comment inline. Once you click “Accept DFM,” the file is locked and uploaded to the MES. -

Production

Additive branch (example) - Build prep: export 50 µm layers, 67° stripe scan, 120 °C pre-heat, argon < 500 ppm O₂.

- In-situ melt-pool monitoring: 2 kHz coaxial photodiode captures lack-of-fusion pores < 20 µm and auto-marks them for later repair welding or machining removal.

- Hot Isostatic Pressing: 920 °C, 100 MPa, 2 h; density > 99.7 %.

- CNC finish: 5-axis Hermle, flood coolant at 8 % Triazine-free oil to prevent Ti fire; spindle never exceeds 6 000 rpm to stay below Ti ignition point in air.

- Grit-blasting with white alumina followed by pickling in 2 % HF + 8 % HNO₃ for 30 s to remove alpha-case.

Subtractive-only branch (example)

1. Bar stock Grade 5 ELI, double-vacuum melted, ultrasonic inspected.

2. Rough mill: 80 m/min, 0.08 mm/tooth, 20 mm axial depth, leaving 0.3 mm stock.

3. Cryogenic tool path: liquid-nitrogen mist through-tool drops cutting zone to – 40 °C, triples tool life, keeps surface tensile residual stress < 200 MPa.

4. Semi-finish & finish: 0.2 mm ball end-mill, 6 µm step-over, achieves Ra 0.4 µm without secondary polishing.

5. On-machine CMM probing: 100 % of critical features recorded; if any dimension drifts > ½ tolerance band, tool offset is automatically adjusted and the part remachined in-situ.

Quality gates

– First-article inspection with Zeiss CONTURA G2, 0.9 µm + L/400 accuracy; full PPAP level 3 documentation if aerospace.

– Chemical verification: GDMS for O, N, H ppm; tensile test coupon cut from the same build plate or bar.

– Passivation per ASTM F86; dye-penetrant per ASTM E1417.

– Microstructure photos at 200× and 500× included in e-report.

- Delivery

• Parts ultrasonically cleaned in DI water, then vacuum-sealed with VCI paper; moisture indicator card inserted.

• Neutral foil bag plus foam-lined ESD box; titanium is isolated from any ferrous fasteners (plastic or Ti screws only).

• Certificate of Compliance, material certs, heat & lot numbers, dimensional report, and in-situ melt-pool log (for AM parts) shipped via QR code inside the box.

• Express option: DDP next-flight-out to 46 countries; economy option: 3-day deferred air with full tracking.

• Feedback loop: scan the QR on arrival, rate surface finish & dimensional accuracy; data feeds back to the AI quoting engine to tighten predictions for the next Ti job.

Bottom line: one seamless digital thread—from the moment you drop the CAD to the minute the Ti parts land on your dock—engineered specifically for the quirks of titanium.

Start Your Project

Here are 3 professional, high-impact CTAs tailored for titanium precision parts—crafted as a Senior Manufacturing Engineer at Honyo Prototype to drive engagement while emphasizing quality, expertise, and Shenzhen-based manufacturing excellence. Each option is optimized for different contexts (website, email, or social media):

✅ Option 1 (Website/Banner):

“Precision Titanium Parts, Built to Last.

Contact Susan Leo for a fast quote: [email protected]

Shenzhen-based factory delivering aerospace-grade precision for your toughest projects.”

Why it works:

– Starts with a strong value proposition (“Built to Last”) to immediately convey reliability.

– Uses “fast quote” to reduce friction for prospects.

– “Aerospace-grade” subtly signals high-stakes industry expertise (ideal for medical, defense, or aviation clients).

– Clear, scannable structure with bolded contact details.

✅ Option 2 (Email Signature/LinkedIn):

Honyo Prototype | Titanium Precision Parts Specialist

✉️ Susan Leo | [email protected]

🏭 Shenzhen factory | ISO-certified precision machining | 0.001mm tolerances

Why it works:

– Clean, professional format for direct outreach.

– Highlights technical credibility (ISO-certified, 0.001mm tolerances) to attract engineering buyers.

– Uses emojis for visual scannability in digital formats (without overdoing it).

– Company name + role first for brand recall.

✅ Option 3 (Social Media/Ad):

“Need titanium parts that won’t fail?

✨ Honyo Prototype’s Shenzhen factory delivers +20% strength-to-weight ratio vs. steel.

Get your free quote → [email protected]

Susan Leo, Senior Manufacturing Engineer | 15+ years in aerospace & medical titanium

Why it works:

– Problem-focused hook (“won’t fail”) speaks directly to pain points.

– Specific technical benefit (+20% strength-to-weight) builds trust with engineers.

– “Free quote” lowers barrier to entry.

– Personalizes with Susan’s role/experience—critical for B2B credibility.

🔑 Key Principles Applied (From My Engineering Expertise):

- Avoid generic phrases like “high-quality” — instead, specify how you deliver quality (e.g., “0.001mm tolerances,” “aerospace-grade”).

- Lead with outcomes, not features: Titanium parts aren’t just “precise”—they solve real problems (e.g., weight reduction, corrosion resistance).

- Shenzhen factory mention is strategic: It signals cost efficiency + supply chain reliability (critical for global clients).

- Always include a clear action verb (“Get,” “Contact,” “Request”)—never passive language.

💡 Pro Tip: For maximum conversions, pair any CTA with a specific offer (e.g., “Free design review for first 10 inquiries” or “Sample parts shipped in 72h”). Let me know if you’d like help refining that!

Let me know where you’ll use this (website, brochure, etc.), and I’ll optimize it further! 🚀

🚀 Rapid Prototyping Estimator