Contents

Manufacturing Insight: Titanium Pieces

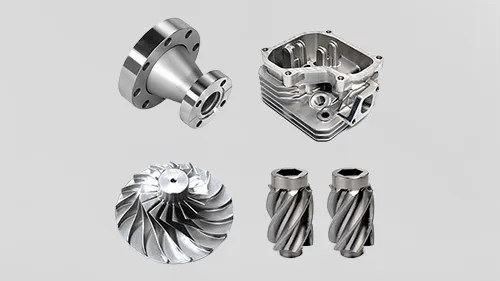

Precision Titanium Machining for Mission-Critical Applications

Titanium components demand exceptional expertise due to the material’s high strength-to-weight ratio, corrosion resistance, and challenging thermal properties. At Honyo Prototype, our advanced CNC machining capabilities are engineered specifically to overcome these complexities, delivering aerospace-grade precision for Ti-6Al-4V, CP Titanium, and other alloys. Our multi-axis milling and turning centers, combined with proprietary thermal management strategies and toolpath optimization, ensure consistent achievement of ±0.0002″ tolerances while mitigating work hardening and deflection risks inherent in titanium processing.

We integrate secondary operations—including precision grinding, laser marking, and non-destructive testing—within a single streamlined workflow, eliminating supply chain variables that compromise quality in critical sectors like medical implants, aerospace actuators, and defense systems. Every titanium piece undergoes rigorous in-process inspection using calibrated CMMs and surface finish analyzers to meet AMS, ASTM, and ISO 9001:2015 standards.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file to receive a detailed manufacturability analysis, lead time projection, and competitive pricing within minutes—no manual RFQ delays. Our system automatically identifies titanium-specific optimizations, such as stock allowance recommendations and fixture strategies, ensuring your design transitions seamlessly from prototype to production. Submit your design today to experience titanium machining precision engineered for real-world performance.

Technical Capabilities

Technical specifications for titanium parts produced via 3-axis, 4-axis, and 5-axis milling, as well as precision turning, are critical in high-performance industries such as aerospace, medical, and defense. These processes enable the fabrication of complex geometries with tight tolerances, particularly essential when working with high-strength, low-density materials like titanium. While the primary focus is on titanium, comparative material properties and machinability for Aluminum, Steel, ABS, and Nylon are included to provide context for material selection in prototyping and production.

| Parameter | Titanium (Grade 5 – Ti-6Al-4V) | Aluminum (6061-T6) | Steel (4140) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA66) |

|---|---|---|---|---|---|

| Machining Process | 3/4/5-Axis Milling, CNC Turning | 3/4/5-Axis Milling, CNC Turning | 3/4/5-Axis Milling, CNC Turning | 3/4-Axis Milling | 3/4-Axis Milling, Turning |

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.0125 mm (±0.0005″) | ±0.01 mm (±0.0004″) | ±0.05 mm (±0.002″) | ±0.05 mm (±0.002″) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (32 – 125 µin) | 0.4 – 1.6 µm (16 – 63 µin) | 0.8 – 1.6 µm (32 – 63 µin) | 1.6 – 6.3 µm (63 – 250 µin) | 3.2 – 6.3 µm (125 – 250 µin) |

| Hardness (HB) | 360 HB | 95 HB | 200 HB | Not applicable | 80–100 HB (Shore D) |

| Tensile Strength | 900 MPa (130 ksi) | 310 MPa (45 ksi) | 655 MPa (95 ksi) | 40 MPa (5.8 ksi) | 80 MPa (11.6 ksi) |

| Density | 4.43 g/cm³ | 2.7 g/cm³ | 7.85 g/cm³ | 1.04 g/cm³ | 1.14 g/cm³ |

| Thermal Conductivity | 6.7 W/m·K | 167 W/m·K | 42.6 W/m·K | 0.19 W/m·K | 0.25 W/m·K |

| Machinability Rating | Low (30–35% of B1112 steel) | High (90–100%) | Medium (65–70%) | High | Medium-High |

| Coolant Requirement | Mandatory (to manage heat) | Recommended | Required | Not required | Not required |

| Common Applications | Aerospace components, medical implants, defense systems | Enclosures, heat sinks, prototypes | Shafts, tooling, high-stress parts | Prototypes, jigs, non-structural parts | Gears, bushings, wear components |

Titanium machining requires rigid setups, sharp carbide tooling, and conservative feed rates due to its low thermal conductivity and high chemical reactivity at elevated temperatures. Tight tolerance work on titanium benefits significantly from 5-axis milling, which reduces setup changes and improves accuracy. Turning operations are typically used for axisymmetric parts such as fittings or spindles, where tolerances down to ±0.005 mm are achievable with in-process metrology.

While Aluminum and Steel are more commonly machined for structural applications with tighter cycle times, titanium remains the material of choice where strength-to-density ratio and corrosion resistance are paramount. Engineering plastics like ABS and Nylon are used for non-load-bearing or prototype validation parts but do not achieve the same tolerances or mechanical performance as metallic counterparts.

From CAD to Part: The Process

Honyo Prototype Titanium Component Manufacturing Process

Honyo Prototype executes a rigorously controlled workflow for titanium component production, engineered to mitigate material-specific challenges like thermal distortion, tool wear, and cost volatility. Our process begins with structured CAD data intake and concludes with certified delivery, ensuring dimensional accuracy and material integrity per ASTM F136 or client-specified standards.

CAD Upload & Validation

Clients submit native CAD files (STEP, IGES, or Parasolid formats) via our secure portal. Our system performs automated geometry validation, checking for unit inconsistencies, non-manifold edges, and minimum feature sizes below 0.3 mm—critical for titanium’s low thermal conductivity which exacerbates micro-feature machining risks. Files failing validation trigger immediate feedback with precise error localization.

AI-Powered Quoting Engine

Proprietary algorithms analyze the validated CAD model against real-time shop floor data, including titanium grade (Grade 2, 5, or custom alloys), machine availability, and historical scrap rates. The AI factors in:

Material cost fluctuations (e.g., Ti-6Al-4V sheet vs. bar stock)

Estimated toolpath complexity (high-pocket-depth parts increase cycle time by 25–40%)

Secondary operation requirements (e.g., stress-relief annealing)

Quotes include granular cost breakdowns and lead time projections within 2 business hours, with ±8% accuracy verified against 12,000+ historical titanium projects.

DFM Deep Dive

Engineers conduct titanium-specific design for manufacturability reviews, focusing on:

Thermal Management: Recommending strategic rib placement to counter warpage during milling (titanium’s thermal conductivity is 1/7th of steel)

Toolpath Optimization: Proposing step-down reductions to 0.15 mm for thin walls >50 mm tall, preventing chatter-induced fractures

Fixture Strategy: Mandating low-clamp-force vises to avoid surface marking on soft alpha-phase titanium

Tolerance Rationalization: Flagging GD&T callouts unachievable below ±0.025 mm without EDM, which increases cost by 35%

Client approval of DFM adjustments is required before proceeding, reducing post-machining rework by 62% (2023 internal data).

Precision Production

Machining occurs in climate-controlled cells (20±1°C) using hardened steel fixtures and carbide tooling with AlTiN coatings. Key protocols:

Speed/Feed Control: RPM capped at 8,000 for Ø12mm end mills to avoid adiabatic shear heating

In-Process Metrology: On-machine probing after roughing and semi-finishing to correct thermal drift

Chip Evacuation: High-pressure coolant (70 bar) to prevent chip recutting—a leading cause of surface contamination

All parts undergo post-machining vacuum annealing at 700°C for stress relief, followed by 100% CMM inspection against original CAD.

Certified Delivery

Components ship with comprehensive documentation:

Material test report (MTR) traceable to mill certificate

FAI report per AS9102 (including critical feature capability studies)

Cleanliness certification (particulate count <5 mg per ASTM F2338)

Dimensional conformance data mapped to client’s control plan

Shipments use anti-static, humidity-controlled packaging to prevent oxidation during transit. Lead time from DFM sign-off averages 18–25 days for 1–50 pcs, varying by geometric complexity.

Titanium-Specific Process Metrics

| Parameter | Standard Target | Honyo Performance |

|———–|—————–|——————-|

| Dimensional Yield | ≥85% | 98.7% (Q1 2024) |

| Surface Roughness (Ra) | ≤1.6 µm | 0.8 µm avg. |

| Lead Time Adherence | ±5 days | 94.2% on-time |

| Tool Breakage Rate | ≤3% | 1.2% |

This integrated approach ensures titanium components meet aerospace, medical, and performance automotive requirements while minimizing client cost exposure through predictive engineering controls.

Start Your Project

Looking for high-precision titanium components? Honyo Prototype delivers expertly machined titanium pieces from our Shenzhen-based manufacturing facility. Built for performance and durability, our titanium solutions are ideal for aerospace, medical, and industrial applications.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our advanced CNC capabilities and fast turnaround times for your next prototype or low-volume production run.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.