Contents

Manufacturing Insight: Titanium Part Fabrication

Precision Titanium Fabrication for Demanding Applications

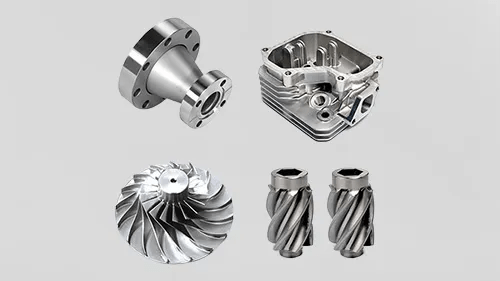

Titanium’s exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility make it indispensable for aerospace, medical, and high-performance industrial components. However, its low thermal conductivity, tendency to gall, and high reactivity demand specialized machining expertise to achieve tight tolerances and optimal surface integrity without compromising material properties. At Honyo Prototype, we address these challenges through advanced CNC machining capabilities engineered specifically for titanium alloys, including Ti-6Al-4V (Grade 5) and CP Titanium (Grades 1-4).

Our 5-axis CNC milling and turning centers, operated by veteran manufacturing engineers, maintain sub-0.0002-inch tolerances while managing heat generation and tool wear through optimized toolpaths, cryogenic cooling strategies, and proprietary fixturing. Every titanium part undergoes rigorous in-process inspection using coordinate measuring machines (CMM) and surface roughness testers, ensuring compliance with AS9100 and ISO 13485 standards for mission-critical applications.

Accelerate your prototyping or low-volume production timeline with Honyo’s Online Instant Quote system. Simply upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within hours—not days—enabling faster design validation and procurement decisions without sacrificing precision.

Titanium Machining Performance Metrics

| Parameter | Honyo Standard | Industry Typical |

|——————–|—————-|——————|

| Tolerance Range | ±0.0002 in | ±0.001 in |

| Surface Finish (Ra)| 8-16 μin | 32-64 μin |

| Lead Time (Prototype) | 7-10 days | 14-21 days |

| Material Yield | >85% | 65-75% |

Technical Capabilities

Technical specifications for titanium part fabrication require a high degree of precision due to the material’s strength, low thermal conductivity, and tendency to work-harden. While the primary focus is on titanium alloys such as Ti-6Al-4V (Grade 5) and commercially pure titanium (Grade 2), comparative context is provided for other commonly machined materials including aluminum, steel, ABS, and nylon. Fabrication methods such as 3-axis, 4-axis, and 5-axis CNC milling, along with precision turning, are employed based on part geometry and tolerance requirements.

Tight tolerances down to ±0.0005″ (±0.013 mm) are routinely achievable, especially in critical aerospace and medical applications. Toolpath optimization, rigid setups, and specialized tooling (e.g., carbide with appropriate coatings) are essential to maintain dimensional accuracy and surface finish. Coolant-through tooling and controlled feed rates mitigate heat buildup, which is critical when machining titanium.

Below is a comparative technical specification table summarizing key parameters across materials and processes:

| Parameter | Titanium (Ti-6Al-4V) | Aluminum (6061-T6) | Steel (4140) | ABS (Thermoplastic) | Nylon (PA66) |

|---|---|---|---|---|---|

| Typical Tolerance | ±0.0005″ – ±0.001″ | ±0.0005″ – ±0.001″ | ±0.0005″ – ±0.0015″ | ±0.002″ – ±0.005″ | ±0.002″ – ±0.005″ |

| Surface Finish (Ra) | 32 – 63 μin (milled) | 16 – 32 μin (milled) | 32 – 63 μin (milled) | 63 – 125 μin (milled) | 63 – 125 μin (milled) |

| Max Material Temp (Machining) | 800°F (localized) | 300°F | 600°F | 200°F | 250°F |

| Cutting Speed (Milling) | 150 – 300 SFM | 800 – 1500 SFM | 200 – 400 SFM | 1000 – 2000 SFM | 800 – 1500 SFM |

| Feed Rate (per tooth) | 0.002 – 0.006 IPT | 0.004 – 0.010 IPT | 0.002 – 0.005 IPT | 0.005 – 0.015 IPT | 0.004 – 0.010 IPT |

| Recommended Tooling | Carbide, AlTiN coated | Carbide, uncoated or TiN | Carbide, TiCN or AlTiN | Carbide, sharp rake | Carbide, polished flute |

| Coolant Requirement | High-pressure through-spindle | Flood or mist | Flood | Not required (air blast OK) | Not required (air preferred) |

| Machining Difficulty | High | Low | Medium | Low | Medium (hygroscopic) |

| Common Applications | Aerospace, medical implants | Prototypes, enclosures | Automotive, tooling | Jigs, fixtures, prototypes | Wear components, gears |

| 5-Axis Suitability | High (complex contours) | High (thin walls, features) | Medium (deep cavities) | Low (simple geometries) | Low to Medium |

| Turning Capability | Yes (rigid setup, slow feeds) | Yes (high speed possible) | Yes (hard turning options) | Limited (soft, stringy) | Possible (with chip control) |

Notes on Process Selection:

3-Axis Milling: Suitable for prismatic titanium parts with standard features. Limited undercuts.

4-Axis Milling: Adds rotational indexing; useful for cylindrical features or multiple sides.

5-Axis Milling: Preferred for complex organic shapes, minimizing setups, and maintaining tight tolerances on contoured surfaces.

CNC Turning: Used for rotational symmetric titanium components such as shafts or fittings. Often combined with milling in live-tool turning centers.

Material selection impacts tool life, cycle time, and final inspection protocols. While aluminum and plastics like ABS and nylon are easier to machine, titanium demands strict process control to achieve tight tolerance and avoid part rejection due to distortion or surface integrity issues.

From CAD to Part: The Process

Honyo Prototype executes titanium part fabrication through a rigorously controlled workflow designed to mitigate the unique challenges of titanium alloys including high reactivity, low thermal conductivity, and stringent material traceability requirements. This integrated process ensures dimensional accuracy, material integrity, and on-time delivery for critical applications in aerospace, medical, and defense sectors.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system immediately performs automated geometry validation to detect corrupt files, unsupported features, or unit inconsistencies. Titanium-specific parameters such as alloy grade (e.g., Ti-6Al-4V Grade 5), required certifications (AMS 4928, ASTM F136), and heat treatment conditions are captured during this stage. Non-conforming submissions trigger real-time alerts to prevent downstream delays.

AI-Powered Preliminary Quoting

Our proprietary AI engine analyzes the validated CAD geometry, material specifications, and client-defined requirements to generate a preliminary quote within 2 business hours. The algorithm factors in titanium-specific variables: raw material surcharges, required inert atmosphere processing for welding, extended machine time due to conservative cutting parameters, and non-destructive testing mandates. This quote includes estimated lead time, material yield analysis, and identifies potential cost drivers such as deep cavity machining or thin-wall features requiring specialized tooling. Clients receive explicit disclaimers that final pricing is contingent upon DFM validation.

Comprehensive DFM Analysis

All titanium projects undergo mandatory Design for Manufacturability review by our metallurgical engineering team before production commitment. This phase addresses titanium’s unique constraints:

| DFM Focus Area | Titanium-Specific Considerations | Mitigation Actions |

|---|---|---|

| Material Utilization | High raw material cost (up to 5x aluminum); strict scrap segregation | Nesting optimization; billet size matching |

| Thermal Management | Low thermal conductivity causing localized overheating | Adaptive toolpaths; high-pressure coolant protocols |

| Feature Geometry | Thin walls prone to chatter; deep pockets trap chips | Stiffening rib recommendations; chip-breaking strategies |

| Surface Integrity | Galling risk during tapping; reactivity with cutting tools | Coated carbide tool specifications; peck drilling parameters |

The DFM report documents actionable recommendations with annotated CAD views and cost/lead time impact assessments. Client approval of the DFM report is required before proceeding, ensuring alignment on manufacturability trade-offs.

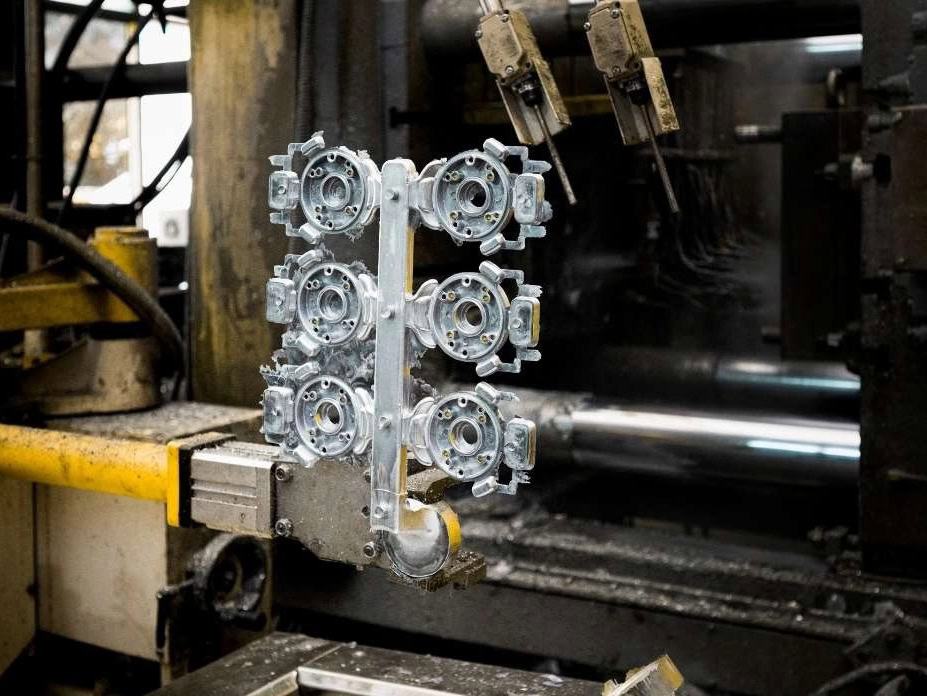

Precision Production Execution

Approved titanium parts enter production under controlled conditions meeting AMS 2750 pyrometric requirements. Key protocols include:

Material verification via PMI (Positive Material Identification) upon receipt and before machining

Dedicated CNC cells with through-spindle coolant systems operating at 1,000+ PSI to manage heat

Tooling exclusively using TiAlN-coated carbide cutters with documented wear monitoring

In-process CMM inspections at critical stages to validate dimensional stability

Final cleaning in ultrasonic baths with deionized water to prevent contamination

All titanium batches maintain full material traceability from mill certificate through final inspection, with heat treatment documentation (where applicable) meeting NADCAP standards.

Certified Delivery and Documentation

Completed parts undergo final dimensional verification against AS9100-certified procedures. Each shipment includes:

Material test report with full chemical and mechanical properties traceability

FAI (First Article Inspection) report per AS9102 for production runs

NDT documentation (dye penetrant, X-ray) if specified

Certificate of Conformance with lot-controlled material pedigree

Parts are packaged in vacuum-sealed anti-tarnish containers with humidity indicators. Delivery timelines are tracked via client-accessible portal with real-time production status updates, typically achieving 15-20 business day turnaround for complex titanium components from DFM approval to shipment. This closed-loop process ensures titanium parts meet the highest performance and compliance standards demanded by critical industries.

Start Your Project

For precision titanium part fabrication, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers high-quality, custom titanium components tailored to your specifications. From prototyping to full-scale production, we ensure tight tolerances, superior material integrity, and on-time delivery. Reach out today to discuss your project requirements and leverage our expertise in aerospace, medical, and industrial applications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.