Contents

Manufacturing Insight: Titanium On Aluminum Friction

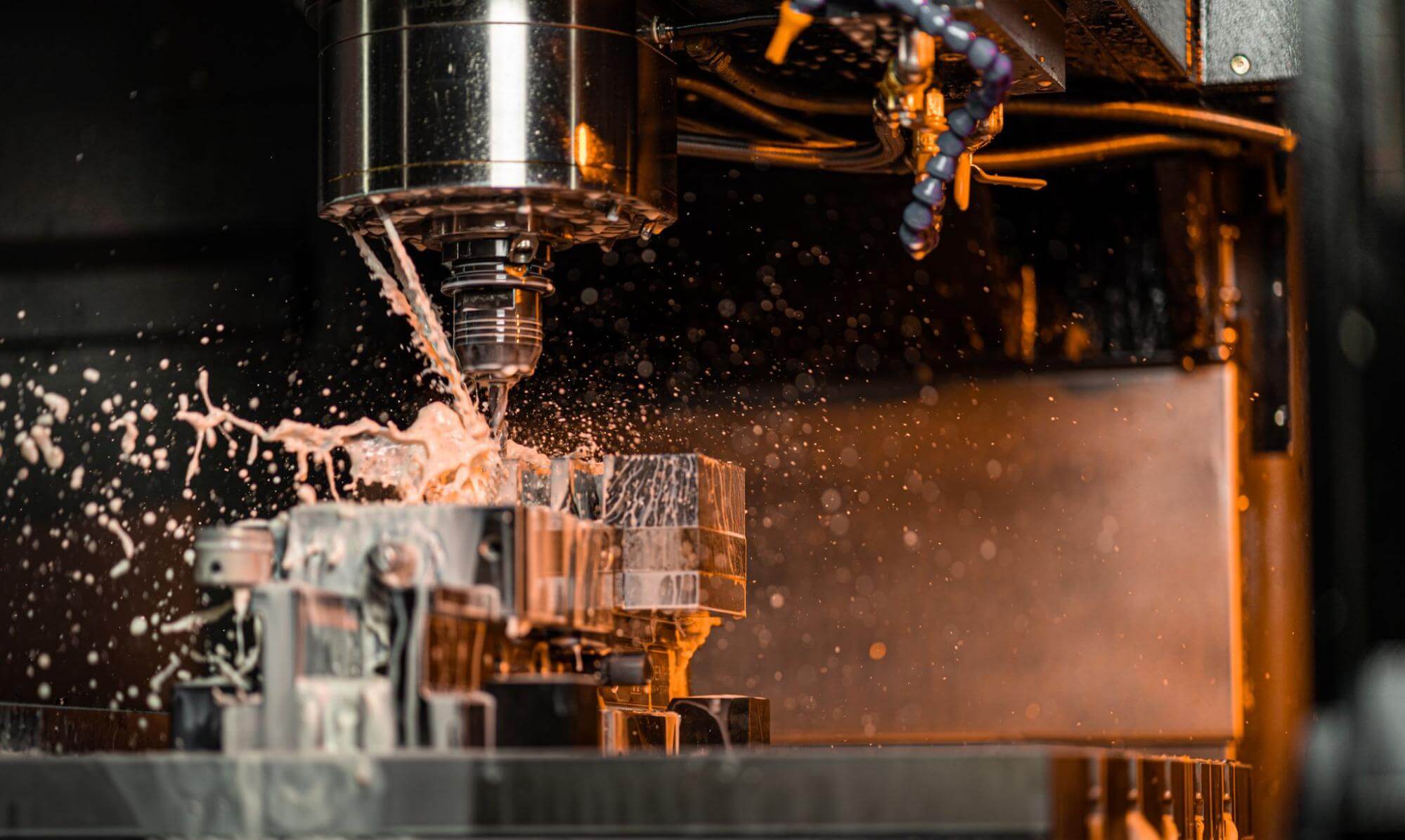

Addressing Titanium-Aluminum Friction Challenges Through Precision CNC Machining

Dissimilar metal contact between titanium and aluminum presents significant engineering hurdles, particularly regarding galvanic corrosion, galling, and accelerated wear under load. These material incompatibilities can compromise assembly integrity, reduce component lifespan, and introduce costly field failures in critical applications like aerospace assemblies or medical devices. At Honyo Prototype, our CNC machining expertise directly mitigates these risks by delivering tightly controlled geometries, optimized surface finishes, and precise dimensional tolerances that minimize unintended contact stresses and interfacial degradation.

Our advanced 5-axis milling and turning capabilities ensure critical interfaces—such as bolted joints, bushings, or sliding surfaces—are machined to exacting specifications, reducing micro-movement and eliminating material adhesion points. We implement rigorous material handling protocols and proprietary finishing processes to maintain surface integrity, preventing embedded contaminants that exacerbate friction-induced failure. This precision-engineered approach extends component service life while ensuring compliance with stringent industry standards.

For projects demanding flawless titanium-aluminum integration, Honyo provides actionable manufacturing insights from the earliest design phase. Leverage our Online Instant Quote system to upload CAD files and receive detailed feasibility feedback, material-specific machining recommendations, and competitive pricing within hours—accelerating your path from prototype to production-ready solution.

Technical Capabilities

Technical specifications for machining operations involving titanium and aluminum, particularly in high-precision 3/4/5-axis milling and turning applications, require careful consideration of material interactions, tooling, thermal management, and achievable tolerances. Friction between titanium and aluminum is inherently problematic due to galling, built-up edge formation, and differential thermal expansion. These factors significantly impact tool life, surface finish, and dimensional accuracy, especially when tight tolerances (±0.0005″ or better) are required.

Below is a comparison of key technical considerations for machining aluminum, titanium, steel, ABS, and nylon in multi-axis and turning environments:

| Parameter | Aluminum (e.g., 6061-T6, 7075) | Titanium (e.g., Ti-6Al-4V) | Steel (e.g., 4140, 17-4 PH) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide) |

|---|---|---|---|---|---|

| Typical Machining Process | 3/4/5-axis milling, high-speed turning | 5-axis milling, slow-speed turning | 4/5-axis milling, precision turning | 3-axis milling, trimming | 3/4-axis milling, turning |

| Tool Material | Carbide, PCD (for high volume) | Carbide with TiAlN or AlCrN coating | Carbide, CBN (for hardened steel) | High-speed steel, carbide | Carbide, high-speed steel |

| Spindle Speed (RPM) | 8,000 – 20,000 (milling), high | 3,000 – 8,000 (milling), low to medium | 2,000 – 10,000 (varies with hardness) | 10,000 – 20,000 | 8,000 – 15,000 |

| Feed Rate (in/tooth) | 0.005 – 0.015 | 0.002 – 0.006 (low due to work hardening) | 0.003 – 0.010 | 0.003 – 0.008 | 0.004 – 0.010 |

| Coolant Requirement | Flood coolant or air blast | High-pressure flood coolant required | Flood coolant recommended | Air blast or no coolant | Air blast preferred |

| Friction Behavior (vs. tool) | Low friction, high thermal conductivity | High friction, prone to galling | Moderate to high friction | Low friction, soft material | Moderate friction, sticky when hot |

| Thermal Conductivity (W/m·K) | 150 – 200 | 6 – 7 | 40 – 50 | 0.1 – 0.2 | 0.25 |

| Coefficient of Thermal Expansion | High (23 µm/m·°C) | Moderate (8.6 µm/m·°C) | Low to moderate (11–13 µm/m·°C) | Very high (70–100 µm/m·°C) | High (80 µm/m·°C) |

| Typical Tolerance Capability | ±0.0005″ (tight) | ±0.001″ (challenging below) | ±0.0005″ with grinding/finishing | ±0.005″ (limited by creep) | ±0.005″ (hygroscopic issues) |

| Surface Finish (Ra, µin) | 16 – 32 (milling), 8 – 16 (turning) | 32 – 64 (milling), sensitive to tool wear | 16 – 32 | 64 – 125 | 32 – 64 |

| Key Challenges | Burrs, chatter in thin walls | Galling, work hardening, heat buildup | Tool wear in hardened states | Melting, poor chip evacuation | Moisture absorption, dimensional drift |

| Use in Multi-Axis Applications | Excellent, high material removal rate | Limited by tool life and rigidity | Good with proper setup | Limited to non-critical components | Limited due to flexibility |

Notes on Titanium–Aluminum Friction in Machining Context:

When machining assemblies or fixtures involving titanium and aluminum in contact (e.g., clamping, tooling plates), galvanic corrosion and galling are critical concerns. Direct metal-to-metal contact under load and movement should be avoided. Use insulating materials (e.g., nylon or PTFE shims) or coatings to prevent adhesive wear.

For tight-tolerance components, especially in aerospace and medical applications, hybrid setups involving aluminum housings with titanium inserts require precise thermal compensation strategies during 5-axis milling due to mismatched expansion rates.

ABS and nylon are typically used for non-metallic fixtures or prototypes but are not suitable for high-precision reference surfaces in titanium–aluminum mixed setups due to their dimensional instability.

From CAD to Part: The Process

Honyo Prototype specializes in precision metal prototyping but does not offer a process termed “titanium on aluminum friction” as this phrasing misrepresents established manufacturing methodologies. Titanium and aluminum cannot be directly joined via conventional friction-based processes like Friction Stir Welding (FSW) due to brittle intermetallic compound formation, which compromises joint integrity. Instead, Honyo addresses dissimilar metal joining challenges through validated techniques. Below is our actual workflow for complex metal prototyping projects, including critical considerations for titanium-aluminum interfaces:

Upload CAD

Clients submit detailed 3D models via our secure portal. For assemblies involving dissimilar metals like titanium and aluminum, we require explicit documentation of interface requirements, load conditions, and environmental exposure. Generic “friction” terminology triggers immediate engineering review to clarify technical intent and prevent misinterpretation of the joining method.

AI-Powered Quoting & Feasibility Screening

Our AI system analyzes CAD geometry, material selections, and tolerances to generate initial cost/time estimates. Crucially, it flags incompatible material combinations. If titanium and aluminum are specified for direct contact, the system mandates human intervention. A Senior Manufacturing Engineer evaluates whether alternative strategies—such as mechanical fastening, adhesive bonding, or intermediate transition joints—are required instead of attempting direct fusion.

Engineering-Driven DFM Analysis

This phase is non-negotiable for dissimilar metal projects. Our engineers conduct a rigorous Design for Manufacturability review focusing on:

Material compatibility risks including galvanic corrosion and thermal expansion mismatches

Joining method validation (e.g., confirming FSW is unsuitable for Ti/Al direct bonds)

Recommendation of proven alternatives such as laser-welded bimetallic transition inserts or isolated mechanical interfaces

Revised design proposals with annotated CAD markups are provided before proceeding.

Production Execution

Only after DFM sign-off does production commence. For titanium-aluminum assemblies, standard processes include:

| Joining Method | Application Case | Honyo Implementation Details |

|---|---|---|

| Mechanical Fastening | Structural assemblies with isolators | Precision-machined insulators (e.g., PEEK) between metals; torque-controlled assembly |

| Adhesive Bonding | Non-load-bearing enclosures/sensors | Surface pretreatment per ASTM D2093; aerospace-grade epoxies |

| Bimetallic Transition | High-stress interfaces (e.g., aerospace) | Laser deposition of graded interlayers; outsourced to certified FSW specialists for compatible alloys |

Direct titanium-aluminum fusion welding is never performed due to industry-recognized failure risks.

Quality-Controlled Delivery

All dissimilar metal assemblies undergo:

Interfacial inspection via cross-section microscopy to verify absence of intermetallics

Salt-spray testing per ASTM B117 for corrosion-prone designs

Dimensional validation of critical alignment features

Documentation includes material certificates, process parameters, and DFM compliance report. Typical lead time for Ti/Al prototypes is 18-25 business days due to multi-stage verification.

We emphasize that successful titanium-aluminum integration requires upfront engineering collaboration. Honyo mandates a DFM consultation for such projects to prevent costly rework or field failures. Our process prioritizes technical validity over simplified marketing terminology—ensuring your prototype meets functional requirements while adhering to metallurgical best practices. Contact our applications engineering team to discuss viable joining strategies for your specific use case.

Start Your Project

For expert guidance on titanium-on-aluminum friction solutions, contact Susan Leo at [email protected]. Our engineering team at Honyo Prototype leverages precision manufacturing and material science expertise to optimize performance and durability in demanding applications. With our ISO-certified factory located in Shenzhen, we deliver high-integrity metal assemblies with tight tolerances and repeatable quality. Reach out today to discuss your project requirements and learn how we can support your prototyping and production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.