Contents

Manufacturing Insight: Titanium Metal Polish

Precision Titanium Polishing for Demanding Applications

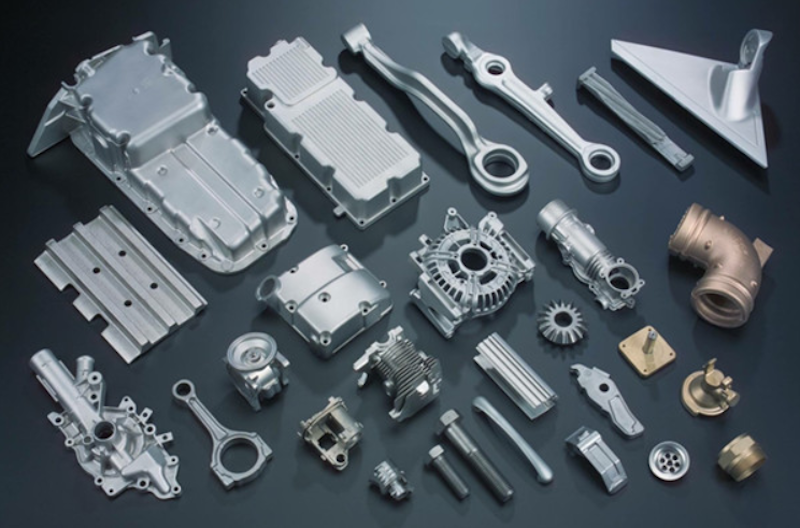

Titanium’s exceptional strength-to-weight ratio and corrosion resistance make it indispensable in aerospace, medical, and high-performance industrial sectors. However, achieving a consistent, high-integrity polished finish requires specialized expertise due to titanium’s reactivity, thermal sensitivity, and tendency toward surface discoloration during processing. At Honyo Prototype, our sheet metal fabrication services integrate advanced titanium polishing capabilities directly into our end-to-end manufacturing workflow. We utilize controlled electrochemical and mechanical polishing techniques compliant with ASTM B600 standards, ensuring mirror finishes, uniform satin textures, or precision matte surfaces that meet stringent functional and aesthetic requirements without compromising material integrity.

Our comprehensive sheet metal fabrication ecosystem supports titanium polishing with in-house laser cutting, precision bending, CNC punching, and welding—eliminating third-party handoffs that risk dimensional inaccuracies or surface contamination. Every titanium component undergoes rigorous process validation, including surface roughness verification (Ra values down to 0.025 µm) and oxide layer management, to deliver finishes that enhance fatigue resistance and biocompatibility. This integrated approach ensures your titanium parts arrive polished, certified, and ready for mission-critical assembly, reducing lead times by up to 30% compared to fragmented outsourcing.

Accelerate your prototyping or low-volume production with Honyo’s Online Instant Quote system. Simply upload your STEP or DXF file to receive a detailed manufacturability analysis and competitive pricing within hours—not days. Our platform automatically evaluates material utilization, geometric complexity, and finish requirements, providing transparent cost breakdowns for titanium polishing and full fabrication. This real-time quoting capability empowers engineering teams to iterate designs rapidly while maintaining budget and schedule control.

Leverage Honyo Prototype’s engineering-driven fabrication expertise to transform titanium concepts into polished, production-ready components. Submit your design today through our Online Instant Quote portal and experience seamless integration from raw sheet to certified finish.

Technical Capabilities

The term “titanium metal polish” refers to a surface finish applied to titanium components, typically achieved through mechanical, chemical, or electropolishing methods. However, this finish does not alter the fundamental processing behavior of titanium in manufacturing operations such as laser cutting, bending, and welding. Below are the technical considerations for laser cutting, bending, and welding of titanium with a polished surface finish. For comparative context, similar processing parameters for aluminum, steel, ABS, and nylon are included.

| Material | Laser Cutting (Fiber Laser Recommended) | Bending (Minimum Bend Radius & Notes) | Welding (Process & Shielding Requirements) | Notes on Polished Surface Interaction |

|---|---|---|---|---|

| Titanium (Grade 2/5) | Wavelength: 1.06 µm; Power: 1–3 kW; Assist Gas: High-purity nitrogen or argon to prevent oxidation; Cut Speed: 2–5 m/min (1mm thick) | Minimum Bend Radius: 2× material thickness; Springback: ~2–3°; Requires clean tooling to avoid contamination | TIG or Laser Welding preferred; Full inert gas shielding (argon) required on both sides; Contamination leads to embrittlement | Polished surface improves inspection for cracks/defects; no impact on cutting/welding but must be cleaned pre-weld |

| Aluminum (6061-T6) | High-reflectivity risk; use high-power fiber laser; Assist Gas: Nitrogen or argon; Cut Speed: 4–8 m/min (1mm) | Minimum Bend Radius: 1.5× thickness; Moderate springback (5–7°); Lubrication recommended | TIG or MIG; Shielding gas: Argon or Ar/He mix; Pre-cleaning essential due to oxide layer | Polishing not typical for structural parts; reflective surface may interfere with laser alignment |

| Steel (Mild, 1018) | CO₂ or fiber laser; Assist Gas: Oxygen (for ignition-assisted cutting) or nitrogen; Cut Speed: 3–6 m/min (1mm) | Minimum Bend Radius: 1× thickness; Springback: 1–2°; Standard tooling sufficient | MIG, TIG, or spot welding; No special shielding beyond standard practices | Polished finish rare in structural applications; increases visibility of weld spatter and heat marks |

| ABS (Thermoplastic) | Not recommended for fiber/CO₂ laser due to melting and toxic fumes; if used, low power, high speed, ventilation | Possible with heated tooling; Minimum Radius: 3× thickness; prone to cracking | Ultrasonic or hot-plate welding; not suitable for arc processes | Surface polish can be achieved post-processing; laser cutting degrades surface quality |

| Nylon (PA6/PA66) | CO₂ laser possible with caution; high melting point but prone to charring; assist air recommended | Limited bendability at room temp; heating required for forming; Minimum Radius: 4× thickness | Hot gas or vibration welding; not compatible with traditional metal welding | Polished surface may melt or discolor during thermal processes; pre-drying required to avoid porosity |

Summary Notes:

A polished surface on titanium does not influence laser cutting parameters, bending limits, or welding procedures but enhances visual inspection of final part quality.

Contamination control is critical for titanium and aluminum during all processes, especially welding.

Polishing is generally a post-fabrication finish and should be performed after welding and forming to maintain aesthetic and functional integrity.

Non-metallic materials such as ABS and nylon require entirely different processing methods and are incompatible with metal-focused techniques like TIG welding or high-force bending.

From CAD to Part: The Process

Honyo Prototype Titanium Metal Polishing Process Overview

Honyo Prototype executes titanium metal polishing through a rigorously controlled five-stage workflow optimized for precision, material integrity, and client transparency. This process addresses titanium’s unique challenges—including low thermal conductivity, high reactivity, and susceptibility to surface contamination—to achieve mirror finishes meeting aerospace, medical, and high-performance industrial standards.

CAD Upload and Initial Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS) via our secure portal. Our system performs an automated geometry check for manufacturability constraints specific to titanium, including minimum wall thickness validation (≥0.5mm for polished features), undercuts, and internal radii. Critical dimensions requiring tight tolerances (±0.005mm for optical surfaces) are flagged for priority review.

AI-Powered Quoting with Material-Specific Analytics

Our proprietary AI engine generates instant quotes by analyzing 12+ titanium-specific parameters: alloy grade (e.g., Grade 5 Ti-6Al-4V), surface area-to-volume ratio, geometric complexity, and required finish class (e.g., Ra 0.05µm for medical implants). The algorithm cross-references real-time data on titanium scrap value, abrasive consumption rates, and historical cycle times from 12,000+ past titanium projects. Clients receive cost breakdowns showing how finish requirements (e.g., #8 mirror vs. #4 brushed) impact pricing and lead time.

DFM Analysis with Titanium Process Optimization

Engineers conduct a dual-phase DFM review:

First, geometric feasibility is assessed for polishing accessibility—identifying blind cavities requiring custom tooling or features needing manual intervention. Second, material-specific protocols are applied: thermal stress mapping to prevent localized overheating (critical for titanium’s 660°C phase transition), abrasive sequence planning to avoid iron contamination (using non-ferrous 3M Trizact films exclusively), and vibration analysis to eliminate chatter marks on thin-walled structures. Clients receive annotated DFM reports with actionable recommendations, such as adding temporary machining tabs for secure fixturing during polishing.

Production Execution with Traceable Process Control

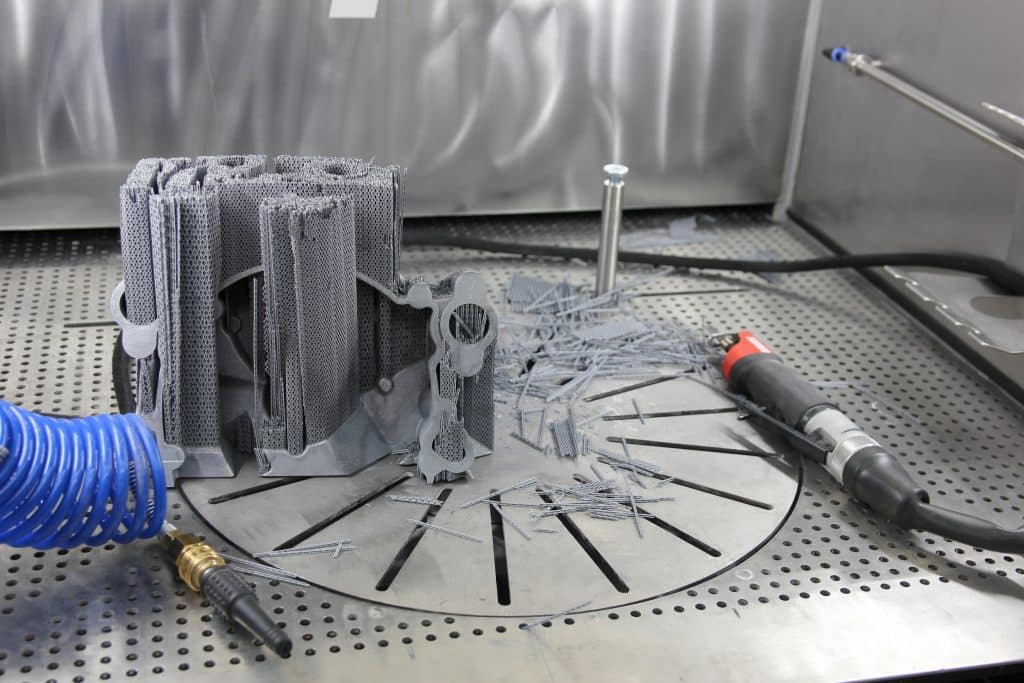

Polishing occurs in a dedicated ISO Class 8 cleanroom with humidity control (45±5% RH) to prevent oxide layer inconsistencies. The sequence follows strict stages:

1. Pre-polish: Robotic deburring with ceramic media to remove machining marks (Ra 1.6µm target).

2. Fine polishing: Multi-axis CNC polishing using diamond-impregnated belts (grit progression 120→400→800).

3. Mirror finishing: Manual polishing with non-woven nylon wheels and colloidal silica slurry under magnification for Ra ≤0.025µm.

Each stage includes in-process metrology via handheld laser interferometers and cross-contamination checks using XRF spectroscopy to verify absence of iron particles. All parameters (pressure, speed, dwell time) are logged against the work order for full traceability.

Delivery with Certification and Surface Validation

Final inspection includes:

100% verification of surface roughness (per ASTM E29) using profilometry at 5+ locations per part

Visual inspection under 10,000-lux lighting per ISO 11670

Certificate of Conformance detailing Ra/Rz values, abrasive types used, and operator certifications

Parts ship in anti-static VCI packaging with humidity indicators. Digital delivery packages include 3D surface maps, polish progression videos, and raw metrology data for client archival.

Titanium-Specific Process Metrics

| Phase | Key Titanium Considerations | Typical Duration Impact vs. Steel |

|——-|—————————–|——————————–|

| DFM | Thermal distortion modeling; Contamination risk mitigation | +1.5 days (vs. aluminum) |

| Production | 3-stage abrasive sequence; Mandatory oxide layer removal between stages | 2.5x longer than 304 stainless |

| Inspection | Mandatory iron contamination testing; Stricter Ra validation | +8 hours (vs. non-critical metals) |

This integrated workflow ensures Honyo delivers titanium components with consistent, certified surface finishes while minimizing rework risks inherent to reactive metals. All processes comply with AMS 2700 and ASTM F86 standards for critical applications.

Start Your Project

Looking to achieve a flawless finish on titanium components? Our precision titanium metal polishing services deliver superior surface quality for aerospace, medical, and high-performance industrial applications.

All processes are carried out at our Shenzhen manufacturing facility, ensuring tight quality control and fast turnaround for both prototypes and production runs.

For technical inquiries or to request a quote, contact Susan Leo at [email protected].

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.