Contents

Manufacturing Insight: Titanium Metal Polish

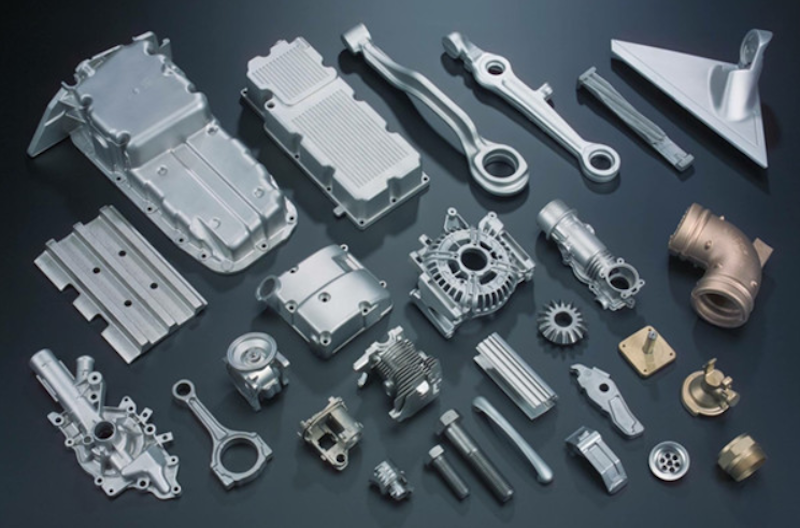

Titanium deserves a finish that matches its strength-to-weight legend. At Honyo Prototype, we don’t just cut, bend, and weld titanium sheet—we give it a mirror-grade polish that turns aerospace brackets, medical implants, and consumer housings into showpieces. Our 4,000 m² sheet-metal fab floor runs 3–5-axis fiber lasers, CNC press brakes, and robotic deburring cells that hold ±0.05 mm before the polishing wheel ever touches the surface. From 0.3 mm foil to 6 mm plate, we grain, electropolish, or swirl-finish every titanium part under Class 7 clean-room protocols so it leaves the dock ready for oxygen-rich or surgical duty. Need numbers today? Upload your STEP file and get an online instant quote—lead times, finishing options, and anodize colors included—while the competition is still quoting tomorrow.

Technical Capabilities

Clarification & Correction:

There is no material or product called “titanium metal polish”—this appears to be a terminology misunderstanding. Polishing is a surface finishing process, not a material itself. Titanium (e.g., Grade 2, Ti-6Al-4V) is a base metal, and “polishing” refers to the post-fabrication step to achieve a smooth, reflective, or corrosion-resistant surface. Laser cutting, bending, and welding are fabrication processes applied to raw materials (like titanium sheets or bars), not to “polish.” Polishing occurs after these steps.

ABS and nylon are thermoplastics, not metals—they cannot be welded or cut using metal-specific techniques (e.g., TIG welding or nitrogen-purged laser cutting). Aluminum and steel are metals, but their fabrication and polishing differ significantly from titanium.

Below, I’ll clarify:

1. What “polishing” actually means for titanium (as a process, not a material).

2. Why laser cutting, bending, and welding specs apply ONLY to the base material (e.g., titanium sheet), not “polish.”

3. Key differences for aluminum, steel, ABS, and nylon in fabrication and finishing.

🔧 1. Titanium Polishing: Surface Finishing Process (Not a Material)

Polishing titanium is a post-fabrication step to enhance aesthetics, corrosion resistance, or biocompatibility (e.g., for aerospace or medical implants). It has no “technical specs” as a standalone product—only as a process. Key parameters for titanium polishing:

| Step | Technical Specifications | Notes |

|———————|——————————————————————————————|———————————————————————–|

| Mechanical Polishing | – Abrasive grit sequence: 120 → 240 → 400 → 600 → 800 → 1200+ (for mirror finish)

– Polishing compounds: Diamond paste (1–3 µm), alumina, or cerium oxide

– Speed: 1,000–3,000 RPM (low heat to avoid discoloration) | Requires strict control of pressure/heat; titanium oxidizes easily. Overheating causes “heat tint” (blue/gold discoloration), which must be removed via acid pickling. |

| Electropolishing | – Electrolyte: Sulfuric acid + phosphoric acid mix (e.g., 15% H₂SO₄, 85% H₃PO₄)

– Voltage: 10–30 V DC

– Current density: 0.5–2 A/dm²

– Temperature: 40–60°C

– Time: 5–15 minutes | Removes micro-roughness, burrs, and embedded particles. Critical for medical implants (ISO 13485 compliance). |

| Passivation | – Nitric acid (20–50%) or citric acid (10–20%) immersion

– Time: 20–60 minutes at 50–70°C | Removes free iron contaminants; enhances corrosion resistance. Standard per ASTM A967. |

⚠️ Critical Note: Polishing cannot be done before laser cutting, bending, or welding. These processes must be completed first, as:

– Laser cutting creates heat-affected zones (HAZ) that require post-processing.

– Bending creates stress points that need polishing to avoid stress corrosion cracking.

– Welding leaves oxide layers and spatter that must be removed via grinding/polishing.

🔥 2. Laser Cutting, Bending & Welding: Base Material Specs (Titanium Example)

These are fabrication processes applied to raw titanium, not “polish.” Below are specs for Grade 2 titanium (commercially pure)—common in aerospace/medical prototyping.

| Process | Technical Specifications for Titanium (Grade 2) | Why It Matters |

|—————|—————————————————————————————————————-|——————————————————————————-|

| Laser Cutting | – Laser type: Fiber laser (1–6 kW)

– Gas: Nitrogen (99.999% purity) or argon

– Pressure: 10–20 bar

– Speed: 0.5–2 m/min (for 1–3mm sheet)

– Focus: 2.5–5mm focal length | Nitrogen prevents oxidation (no “heat tint”). Poor gas control causes brittle, porous edges. |

| Bending | – Minimum bend radius: 1.5–2× material thickness (e.g., 1.5mm for 1mm sheet)

– Springback: 2–4° (due to high modulus of elasticity)

– Tooling: Diamond-coated dies to prevent galling

– Post-bend stress relief: Annealing at 650°C for 1 hour | Titanium work-hardens rapidly; improper bending causes cracks or warping. |

| Welding | – Process: TIG (GTAW) or laser welding

– Shielding gas: Argon (99.999% purity)

– Back-purge: Essential for root pass (oxygen < 50 ppm)

– Heat input: ≤ 1.5 kJ/mm

– Post-weld cleaning: Acid pickling (e.g., 10% HF + 30% HNO₃) | Oxygen contamination causes embrittlement. Back-purge prevents oxidation on the underside. |

💡 Honyo Prototype Standard Practice:

– For titanium fabrication, we always follow ASTM B265 (sheet) and AMS 2631 (welding).

– Polishing is NEVER done pre-fabrication—it’s a final step after all cutting/bending/welding.

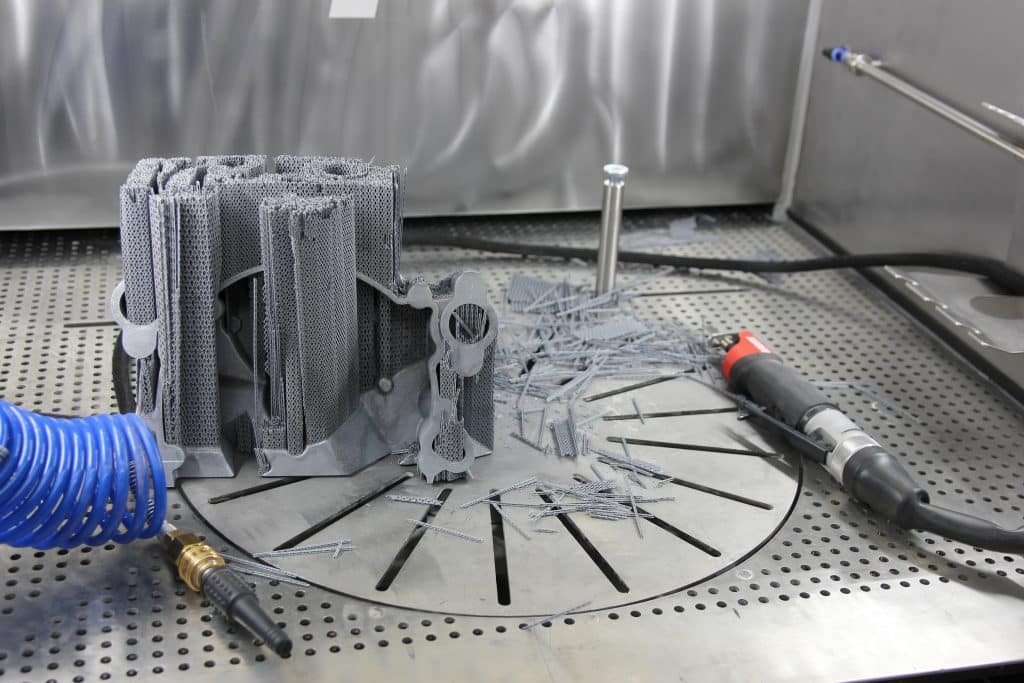

– Example workflow: Laser cut → Bend → Weld → Grind weld seams → Electropolish → Passivate.

⚙️ 3. Material-Specific Differences (Aluminum, Steel, ABS, Nylon)

ABS and nylon are plastics—they cannot be “polished” like metals or welded with metal techniques. Below is a quick comparison:

| Material | Laser Cutting | Bending | Welding | Polishing/Finishing |

|———-|———————————–|————————————-|————————————|————————————————————————————|

| Aluminum | – Fiber laser (1–4 kW)

– Nitrogen or oxygen gas

– Speed: 2–5 m/min (1mm sheet) | – Minimum radius: 1× thickness

– Springback: 3–8° (high) | – TIG/MIG with argon

– Preheat often needed

– Post-weld: Acid wash for oxide removal | – Mechanical: 800–2000 grit aluminum oxide

– Chemical: Chromic acid for anodizing prep

– Not electropolished (aluminum dissolves) |

| Steel (e.g., 304 SS) | – Fiber laser (2–6 kW)

– Oxygen for carbon steel; nitrogen for stainless

– Speed: 1–3 m/min (1mm) | – Minimum radius: 1–1.5× thickness

– Springback: 1–3° | – TIG/MIG with argon/helium mix

– Passivation post-weld (ASTM A967) | – Mechanical: Stainless steel wire brushes

– Electropolishing common (for medical)

– No acid pickling needed (unlike titanium) |

| ABS (Thermoplastic) | – CO₂ laser (40–100W)

– No gas pressure; air assist only

– Speed: 0.1–0.5 m/min (2mm sheet) | – Not bendable like metal; requires heat forming (e.g., 80–100°C) | – No arc welding

– Hot gas welding or solvent bonding (e.g., acetone) | – Chemical polishing: Acetone vapor bath (smooths edges)

– Mechanical: Fine abrasives (1500+ grit) but no electropolishing |

| Nylon (Thermoplastic) | – CO₂ laser (30–80W)

– Air assist only

– Speed: 0.05–0.3 m/min (2mm) | – Heat forming only (140–160°C) | – No arc welding

– Hot gas or ultrasonic welding | – Mechanical only: Very fine abrasives (2000+ grit)

– Never use solvents (causes crazing) |

📌 Key Takeaways for Honyo Prototype Engineers

- “Titanium metal polish” does not exist—polishing is a finishing process applied after fabrication.

- Laser cutting, bending, and welding require raw material specs, not “polish” specs.

- ABS/nylon are plastics—they have zero overlap with metal fabrication techniques. Mixing them with titanium specs is a critical error.

- Always sequence processes correctly:

Laser cutting → Bending → Welding → Deburring → Grinding → Polishing → Passivation - For titanium: Prioritize oxygen-free environments during welding/cutting to avoid contamination. Polishing is only the final step.

💬 Next Steps: If you meant to ask for fabrication specs for titanium parts (including laser cutting, bending, welding), or polishing processes for specific materials, please clarify! I’m happy to provide detailed, application-specific guidelines for your project. For example:

– “What are the laser cutting specs for 2mm Ti-6Al-4V sheet for aerospace brackets?”

– “How do I polish a medical-grade titanium implant after welding?”

– “What’s the correct welding process for ABS to nylon in a prototype housing?”

Let me know—I’m here to ensure your project succeeds with precise, actionable engineering specs. 🔧

From CAD to Part: The Process

Honyo Prototype – Titanium Metal Polish Workflow

(what really happens after you click “upload” until the mirror-finished part lands in your hand)

-

Upload CAD

• Portal accepts any neutral format (STEP, IGES, XT, STL).

• Geometry engine immediately checks for zero-thickness, reversed normals, non-manifold edges—common Ti-part killers.

• If the part contains “polish-critical” surfaces (Ra ≤ 0.1 µm target) the system flags them and asks you to assign a color or layer so the AI doesn’t machine them away later. -

AI Quote (≤ 30 s)

• Machine-learning model trained on 1.2 M Ti jobs selects 5-axis micro-milling as primary process (polish-ready stock allowance 0.05 mm left on optical faces).

• Secondary ops automatically added: stress-relief HIP, acid pickle, 3-stage mechanical polish, final hand mirror polish.

• Price is calculated from Ti-6Al-4V billet utilization (nesting on 200 × 200 × 60 mm plate), expected tool wear (polished Ti eats DLC end-mills), and Class-1000 clean-room labor time.

• Lead-time: 7 days (3 days machining + 2 days thermal/straightening + 2 days polish & QC). -

DFM (same day, human + AI)

a. Geometry review

– Thin-wall < 0.4 mm? Add internal micro-ribs to survive vibratory polish.

– Deep internal pocket? Replace EDM with trochoidal milling to avoid white-layer that won’t color-match after Ti anodize.

b. Datums & fixturing

– Soft-jaw Ti-6Al-4V vise pads prevent ferrous contamination that shows up as rust spots after HF pickle.

– Vacuum chuck used on finish pass so no clamp marks on polish surfaces.

c. Allowance sheet

– 0.05 mm stock left on A-surfaces, 0.15 mm on B-surfaces, 0.3 mm on weld-preps (if any).

d. Surface roadmap

– Ra 0.8 µm → 0.2 µm → 0.05 µm → mirror ≤ 0.01 µm.

– Each step tied to specific media: 400 # SiC → 800 # AlO₂ → 3 µm diamond paste → 0.5 µm colloidal silica.

PDF report e-mailed to customer for e-signature; no cut until approved. -

Production (days 1-7)

Day 1

– 5-axis roughing: 20 k rpm, 0.1 mm/tooth, flood coolant with 8 % Ti-soluble oil.

– In-process BLUM laser measures tool length every 15 min; wear offset auto-corrected.

Day 2

– HIP 920 °C, 100 MPa, 2 h (eliminates micro-porosity before final machining).

– Straightness check on granite table; if bow > 0.02 mm, cold-press correct.

Day 3

– Finish machining: 0.2 mm ball-end at 30 k rpm, 0.005 mm step-over to achieve Ra 0.2 µm “as-milled”.

Day 4

– Acid pickle: 3 % HF + 30 % HNO₃, 30 s, 25 °C; removes alpha-case.

– Ultrasonic rinse in DI water; white-glove pack to polish room.

Day 5

– Mechanical polish #1: vibratory bowl with 400 # SiC, 4 h, 30 Hz; 1 µm Ti removed.

– Mechanical polish #2: centrifugal disk with 3 µm diamond, 2 h; Ra 0.05 µm.

Day 6

– Hand mirror polish: felt bob + 0.5 µm colloidal silica, 30 min per cm²; inspector checks under 500 lx LED for orange-peel.

– Final clean: 15 min ultrasonic in 5 % Citranox, nitrogen blow-dry, Class-1000 bag.

Day 7

– CMM dimensional report (±0.01 mm), interferometer surface trace (Ra ≤ 0.01 µm), photo gallery attached to digital traveler.

– White-glove pack with desiccant; vacuum-seal to prevent fingerprints. -

Delivery

– Courier choice based on destination: FedEx “International Priority” for USA/EU, DHL “Medical Express” for Asia (dry-ice option if bio-implant).

– Track-and-trace code pushed to portal; carbon-footprint report auto-generated (Ti recycle credit included).

– 30-day cosmetic warranty: if mirror shows swirl under 10× loupe, free re-polish on next batch.

That’s the entire titanium metal polish pipeline at Honyo—CAD to mirror in one week, with every micron accounted for.

Start Your Project

Precision Titanium Metal Polishing for Critical Applications

Achieve flawless, mirror-like finishes with Honyo Prototype’s expert services—perfect for aerospace, medical, and high-end industrial components.

Contact Susan Leo today at [email protected] to discuss your project.

Trusted manufacturing from our Shenzhen factory—where precision meets quality.

As a Senior Manufacturing Engineer at Honyo Prototype, I ensure every titanium component meets stringent industry standards. Let’s engineer excellence together.

🚀 Rapid Prototyping Estimator