Contents

Manufacturing Insight: Titanium Machining Services

Precision Titanium Machining Services for Demanding Applications

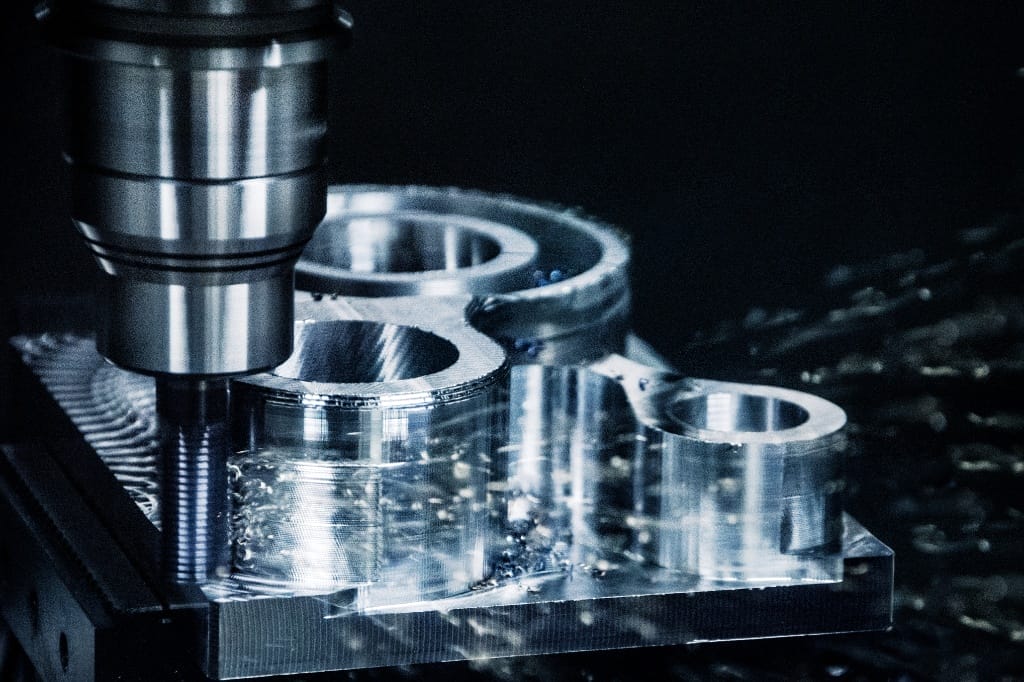

Titanium alloys present significant machining challenges due to their high strength-to-weight ratio, low thermal conductivity, and propensity for work hardening and galling. Achieving tight tolerances and superior surface finishes requires specialized expertise, advanced CNC equipment, and meticulously optimized processes. Honyo Prototype delivers exceptional titanium machining services specifically engineered to overcome these obstacles for critical aerospace, medical, and defense components.

Our facility leverages state-of-the-art multi-axis CNC machining centers, including precision 5-axis platforms, combined with proprietary toolpath strategies and rigorously selected cutting tool geometries designed for titanium. We implement controlled high-pressure coolant delivery and adaptive machining techniques to manage heat generation, minimize tool wear, and prevent material distortion. This integrated approach ensures consistent production of complex titanium parts meeting stringent AS9100 and ISO 13485 quality standards, with tolerances held to ±0.0002 inches and superior surface integrity.

Engineers and procurement specialists can now accelerate project timelines significantly through our Online Instant Quote system. Simply upload your titanium part CAD file to receive a comprehensive, no-obligation machining quote within hours—not days—providing clear visibility into lead times, cost drivers, and manufacturability feedback before formal order placement. This transparent digital workflow eliminates procurement bottlenecks for prototypes and low-to-medium volume production runs.

Technical Capabilities

Titanium machining services at Honyo Prototype are engineered to deliver high-precision components for aerospace, medical, and industrial applications. Our capabilities include 3, 4, and 5-axis CNC milling, as well as CNC turning, all optimized for titanium alloys such as Ti-6Al-4V (Grade 5) and CP Titanium (Grades 1–2). These processes are supported by advanced tooling, high-rigidity machines, and in-process inspection to maintain tight tolerances down to ±0.0002″ (5 µm). While titanium is our primary focus, our multi-axis systems are also adept at machining other engineering materials including Aluminum, Steel, ABS, and Nylon, enabling hybrid prototyping and production.

Below is a summary of our technical specifications across key parameters:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Max Work Envelope | 24″ × 18″ × 12″ | 20″ × 16″ × 10″ | 16″ × 14″ × 12″ | Ø16″ × 20″ length |

| Positioning Accuracy | ±0.0002″ (5 µm) | ±0.0002″ (5 µm) | ±0.0001″ (2.5 µm) | ±0.0002″ (5 µm) |

| Repeatability | ±0.0001″ (2.5 µm) | ±0.0001″ (2.5 µm) | ±0.0001″ (2.5 µm) | ±0.0001″ (2.5 µm) |

| Typical Surface Finish | 32–64 µin (Ra) | 32–64 µin (Ra) | 16–32 µin (Ra) | 16–64 µin (Ra) |

| Spindle Speed (Milling) | Up to 15,000 RPM | Up to 12,000 RPM | Up to 12,000 RPM | N/A |

| Spindle Speed (Turning) | N/A | N/A | N/A | Up to 4,500 RPM |

| Materials Supported | Ti-6Al-4V, CP Ti, Aluminum 6061/7075, Steel 4140/17-4PH, ABS, Nylon | Ti-6Al-4V, CP Ti, Aluminum 6061/7075, Steel 4140/17-4PH, ABS, Nylon | Ti-6Al-4V, CP Ti, Aluminum 6061/7075, Steel 4140/17-4PH, ABS, Nylon | Ti-6Al-4V, CP Ti, Aluminum 6061/7075, Steel 4140/17-4PH, ABS, Nylon |

| Coolant & Lubrication | High-pressure through-spindle coolant, mist cooling for thermoplastics | High-pressure through-spindle coolant, mist cooling for thermoplastics | High-pressure through-spindle coolant, mist cooling for thermoplastics | High-pressure coolant, air blast for ABS/Nylon |

| In-Process Inspection | Available (touch probe, laser) | Available (touch probe, laser) | Available (on-machine probing, laser) | Available (laser micrometry) |

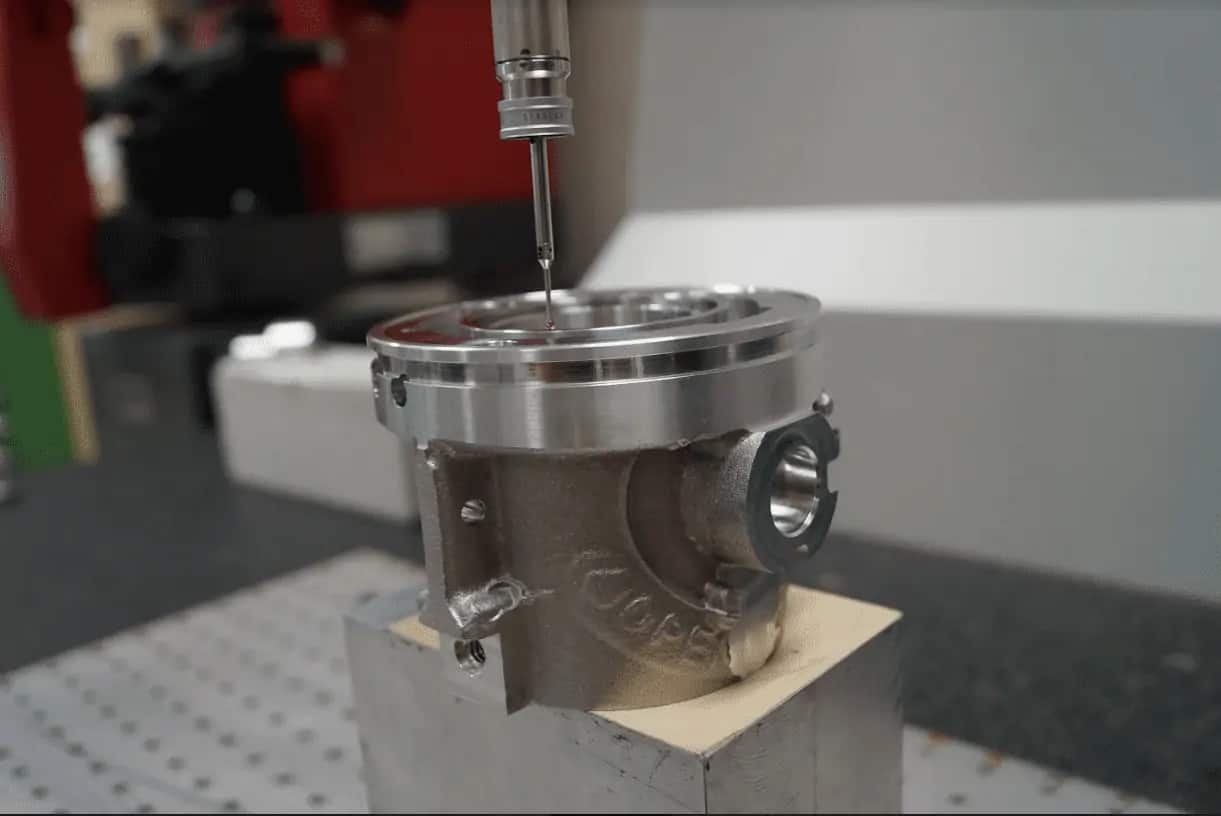

All titanium machining operations are performed under strict process controls to manage heat buildup and tool wear, using carbide or polycrystalline diamond (PCD) tooling as appropriate. For non-metallic materials such as ABS and Nylon, dedicated toolpaths and reduced feed rates ensure dimensional stability and minimize burring. Tight tolerance features such as bores, slots, and complex contours are routinely held within customer specifications, supported by post-process CMM validation.

From CAD to Part: The Process

Honyo Prototype delivers precision titanium machining services through a rigorously controlled five-phase workflow designed for technical excellence and client transparency. Our process begins when clients upload native CAD files or STEP/IGES formats to our secure customer portal. This initiates immediate geometric analysis by our proprietary AI quoting engine, which cross-references over 12,000 titanium machining data points including grade-specific parameters (Grades 1-5, 23), historical toolpath efficiency metrics, and material waste algorithms. The system generates a detailed quote within 90 minutes, specifying critical factors like helium-cooled deep-hole drilling requirements for Grade 5 or low-RPM strategies for Grade 2 to prevent work hardening.

Following quote acceptance, the Design for Manufacturability (DFM) phase engages our titanium-specialized engineering team. Unlike generic DFM checks, we perform material-specific validation focusing on titanium’s unique challenges. Key assessment criteria include:

| DFM Parameter | Titanium-Specific Consideration | Action Threshold |

|---|---|---|

| Wall Thickness | Minimum 0.8mm for Grade 5 to prevent chatter-induced resonance | Redesign if < 0.75mm |

| Internal Radii | Minimum 0.5mm radius to avoid micro-cracking in alpha-beta alloys | Mandate EDM if sharp corners |

| Tolerance Stack-up | Thermal growth compensation for Ti-6Al-4V (8.6 μm/m°C) in multi-axis setups | Adjust fixture design if > ±0.025mm |

| Surface Finish | Ra 0.8μm maximum achievable without chemical polishing for medical implants | Flag if specified < Ra 0.4μm |

Upon DFM approval, production commences in our ISO 13485-certified titanium-dedicated facility. All titanium components are machined on Haas UMC-750 5-axis centers with through-spindle coolant (pressure-optimized for Ti’s low thermal conductivity) and carbide tooling with AlTiN coatings. Critical process controls include:

In-process CMM verification after roughing to prevent thermal distortion

Strict humidity control (<40% RH) to eliminate chloride-induced stress corrosion

Dedicated toolpaths that maintain minimum 0.1mm chip thickness to avoid built-up edge

Final inspection employs Zeiss coordinate measuring machines with titanium-specific probe calibration, followed by mandatory fluorescent penetrant inspection for aerospace/medical parts. All components ship with full material traceability including mill test reports, process validation records, and first-article inspection data. Typical delivery cycles range from 7-12 business days for prototypes depending on complexity, with expedited 72-hour options available for critical path components. Every shipment includes a digital quality passport accessible via blockchain-verified QR code for full production chain auditability.

Start Your Project

For precision titanium machining services, contact Susan Leo at [email protected]. Our state-of-the-art manufacturing facility in Shenzhen delivers high-accuracy components for aerospace, medical, and industrial applications. With advanced CNC capabilities and strict quality control, Honyo Prototype ensures consistent, repeatable results for both prototypes and production runs.

Reach out today to request a quote or discuss your project specifications with our engineering team.

Contact:

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.