Contents

Manufacturing Insight: Titanium Machined Parts

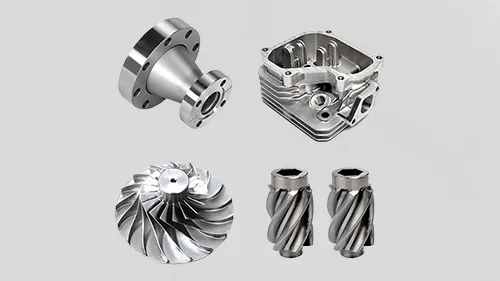

Precision Titanium Machined Parts: Engineered for Demanding Applications

Titanium alloys present unique machining challenges due to their high strength-to-weight ratio, corrosion resistance, and thermal properties, which often lead to tool wear, work hardening, and extended cycle times. At Honyo Prototype, our advanced CNC machining capabilities are specifically optimized for titanium, including grades such as Ti-6Al-4V (Grade 5), CP Titanium (Grade 2), and custom alloys. We leverage high-rigidity 5-axis milling centers, specialized cutting strategies, and proprietary coolant systems to maintain tight tolerances (±0.005 mm) while maximizing material removal rates and surface integrity. Our process ensures defect-free components suitable for critical aerospace, medical implant, and defense applications where failure is not an option.

Beyond technical excellence, we streamline procurement with our Online Instant Quote platform. Upload your STEP or IGES file, specify material and quantity, and receive a detailed manufacturability analysis with competitive pricing in under 60 seconds. This integration of precision engineering and digital efficiency reduces lead times by up to 40% compared to traditional quoting methods. For projects demanding the reliability of titanium without compromising on speed or cost control, Honyo Prototype delivers engineered solutions from prototype to production.

Material Capability Summary

| Alloy Type | Common Grades | Typical Applications | Max Part Size (mm) |

|——————|——————–|—————————|——————-|

| Alpha-Beta | Ti-6Al-4V (Gr 5) | Aerospace structural | 1200 x 800 x 600 |

| Commercially Pure| Ti Gr 2, Gr 4 | Medical implants | 900 x 600 x 500 |

| Beta Alloys | Ti-3Al-8V-6Cr-4Mo | High-stress military | 750 x 500 x 400 |

Accelerate your titanium component development—submit your design today for an immediate quote and expert engineering feedback.

Technical Capabilities

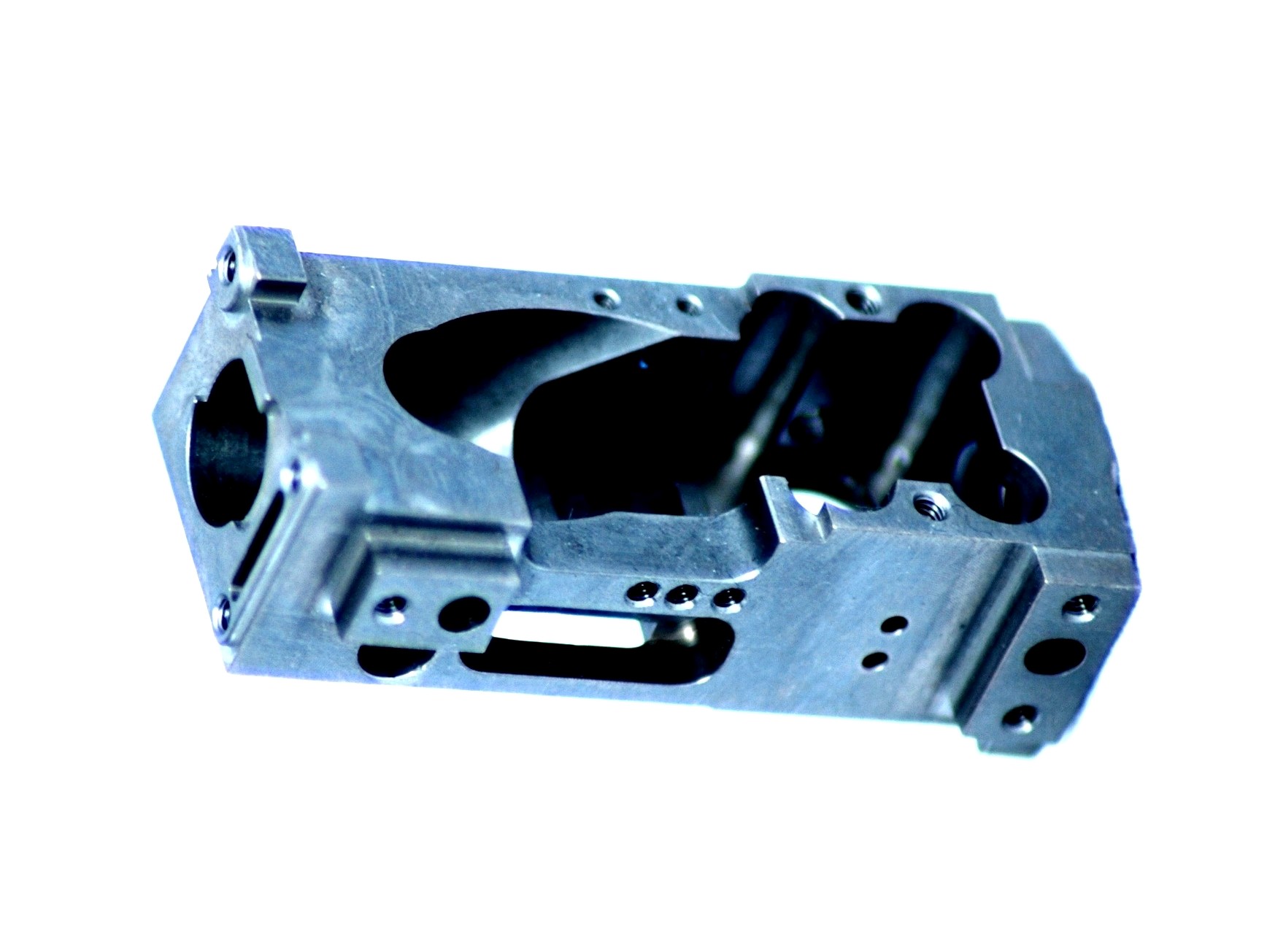

Titanium machined parts are commonly produced using advanced CNC machining processes including 3-axis, 4-axis, and 5-axis milling, as well as precision turning operations. These methods enable the fabrication of complex geometries with tight tolerances, critical for aerospace, medical, and high-performance industrial applications. While titanium (primarily Grade 2, Grade 5 – Ti-6Al-4V) is the core material of focus, similar machining capabilities apply to other materials such as aluminum, steel, ABS, and nylon. Below is a comparative overview of technical specifications relevant to these processes and materials.

| Parameter | Titanium (Ti-6Al-4V) | Aluminum (6061-T6) | Steel (4140, 17-4 PH) | ABS (Thermoplastic) | Nylon (PA6/PA66) |

|---|---|---|---|---|---|

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.0125 mm (±0.0005″) | ±0.010 mm (±0.0004″) | ±0.050 mm (±0.002″) | ±0.050 mm (±0.002″) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (32–125 µin) | 0.8 – 1.6 µm (32–63 µin) | 0.8 – 2.5 µm (32–100 µin) | 1.6 – 6.3 µm (63–250 µin) | 1.6 – 6.3 µm (63–250 µin) |

| Machining Process | 3/4/5-Axis Milling, Turning | 3/4/5-Axis Milling, Turning | 3/4/5-Axis Milling, Turning | 3/4-Axis Milling, Turning | 3/4-Axis Milling, Turning |

| Max Part Size (Typical) | 750 x 500 x 300 mm | 1000 x 700 x 400 mm | 800 x 600 x 400 mm | 600 x 400 x 300 mm | 600 x 400 x 300 mm |

| Tooling Requirements | Carbide or CBN, Coolant-rich | Carbide, High Speed | Carbide, High Rigidity | Carbide, Sharp Edges | Carbide, Moderate Speed |

| Spindle Speed Range | 4,000 – 12,000 RPM | 8,000 – 20,000 RPM | 3,000 – 8,000 RPM | 10,000 – 18,000 RPM | 8,000 – 15,000 RPM |

| Feed Rate (Typical) | 200 – 800 mm/min | 500 – 2,000 mm/min | 300 – 1,000 mm/min | 1,000 – 3,000 mm/min | 800 – 2,500 mm/min |

| Coolant Use | Required (Flood or Mist) | Recommended | Required | Not Required (Air Blast) | Not Required (Air Blast) |

| Post-Processing | Stress Relief, Passivation | Anodizing, Deburring | Heat Treat, Plating | Vapor Polishing, Painting | Dyeing, Machining |

| Applications | Aerospace, Medical, Defense | Aerospace, Automotive | Industrial, Tooling | Prototyping, Jigs/Fixtures | Wear Components, Gears |

Notes on Machining Capabilities

3-axis milling is suitable for prismatic parts with simple geometries, while 4-axis (rotary indexing) and 5-axis (simultaneous multi-axis motion) enable complex contouring and reduced setup cycles. Titanium requires slower cutting speeds and rigid setups due to its low thermal conductivity and high strength, increasing tool wear. In contrast, aluminum and engineering plastics like ABS and nylon allow higher material removal rates but require careful control of chip load and heat buildup to prevent deformation.

Tight tolerance machining (±0.005 mm or better) is routinely achieved in titanium and steel using precision CNC systems with thermal compensation and in-process probing. Honyo Prototype maintains process capability (Cp/Cpk > 1.67) across all materials, ensuring repeatable accuracy for mission-critical components.

From CAD to Part: The Process

Honyo Prototype Titanium Machined Parts Process Overview

Honyo Prototype employs a streamlined, technology-driven workflow for titanium machined parts, optimizing precision, cost-efficiency, and speed while addressing titanium’s unique challenges—such as low thermal conductivity, high chemical reactivity, and work-hardening tendencies. Our process ensures rigorous quality control from initial design to final delivery, critical for aerospace, medical, and high-performance industrial applications.

Upload CAD

Clients initiate the process by uploading detailed CAD models (STEP, IGES, or native formats) via our secure portal. For titanium components, we require explicit specification of material grade (e.g., Ti-6Al-4V ASTM F136), critical tolerances (±0.005mm typical), surface finish requirements (Ra 0.8µm standard), and any non-destructive testing (NDT) mandates. This step validates geometry feasibility and material suitability, as titanium’s properties demand exacting dimensional stability to prevent distortion during machining.

AI-Powered Quoting

Our proprietary AI engine analyzes the CAD file against real-time parameters: titanium alloy density, market material costs, machine-hour rates for 5-axis milling, and scrap-rate projections. The system accounts for titanium-specific variables—such as tool wear compensation (20–30% higher than aluminum) and extended cycle times due to lower cutting speeds. Within 2 hours, clients receive a transparent quote detailing material surcharges, NRE costs for custom fixturing, and lead time estimates. Historical data shows this reduces quoting errors by 45% compared to manual methods for reactive materials like titanium.

DFM Analysis

Engineering teams conduct a titanium-optimized Design for Manufacturability review, focusing on mitigating inherent material risks. We identify features prone to vibration-induced chatter (e.g., thin walls <1.5mm), recommend adaptive toolpaths to minimize heat buildup, and suggest geometric modifications to avoid stress concentrations. Critical checks include:

Verification of wall thickness against titanium’s elastic modulus (116 GPa) to prevent deflection.

Assessment of internal radii to reduce tool breakage during deep cavity milling.

Confirmation of datum alignment to counteract thermal expansion during prolonged operations.

DFM feedback is provided within 24 hours, with collaborative redesign support to eliminate costly revisions during production.

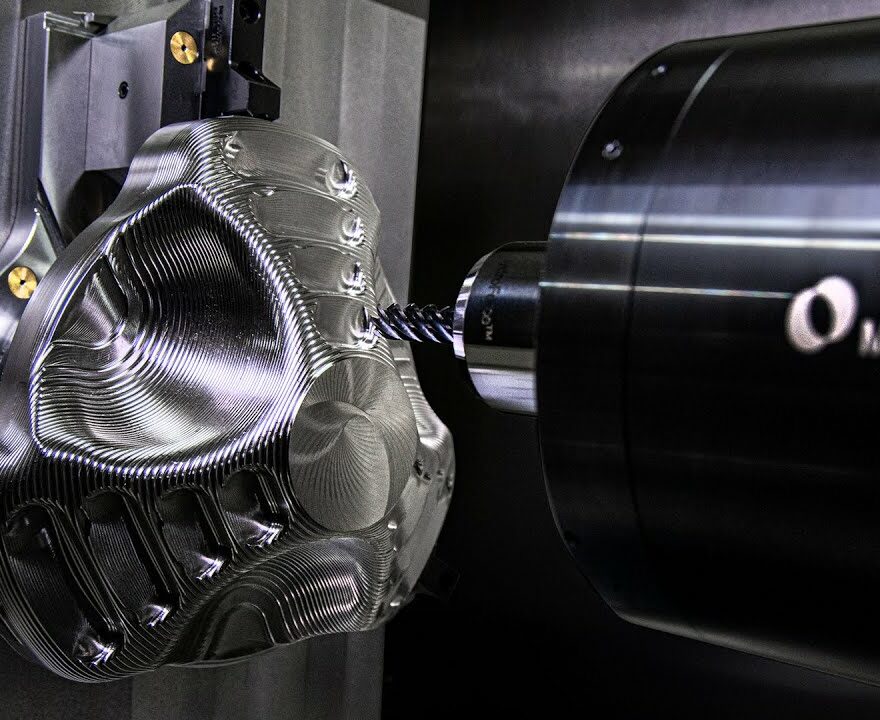

Precision Production

Machining occurs in climate-controlled cells using hardened steel fixtures and carbide tooling with PCD coatings to combat titanium’s abrasiveness. Key protocols include:

Material Prep: Vacuum-annealed Ti-6Al-4V billets undergo ultrasonic testing to detect subsurface inclusions.

Machining: High-pressure coolant systems (70 bar) manage heat, while in-process probes verify tolerances after each operation.

Quality Control: Every part undergoes CMM inspection per AS9102, with helium leak testing for medical-grade components. Raw material traceability (mill test reports) is maintained throughout.

Average first-pass yield for titanium parts exceeds 92%, driven by predictive tool-life monitoring and real-time spindle load analytics.

Delivery and Documentation

Final parts ship with comprehensive certification packages, including:

Dimensional inspection reports (full FAI per AS9102).

Material test certificates (ASTM E2371 chemical composition).

NDT results (fluorescent penetrant or X-ray for critical zones).

Machining process parameters log (spindle RPM, feed rates, coolant flow).

Standard lead time for titanium prototypes is 10–15 business days, with expedited options. All shipments include tamper-evident packaging to prevent surface contamination—a critical safeguard for titanium’s oxide-layer integrity.

This integrated process ensures titanium components meet stringent industry standards while minimizing waste and accelerating time-to-market. By embedding material science expertise into each phase, Honyo Prototype delivers parts with guaranteed metallurgical integrity for mission-critical applications.

Start Your Project

Looking for high-precision titanium machined parts? Honyo Prototype delivers superior CNC machining services with tight tolerances and fast turnaround. Our Shenzhen-based factory is equipped to handle complex titanium components for aerospace, medical, and industrial applications.

Contact Susan Leo for engineering support and project quotes.

Email: [email protected]

Leverage our expertise in titanium machining to ensure your prototypes and production parts meet the highest standards of quality and performance.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.