Contents

Manufacturing Insight: Titanium Machinability

Mastering Titanium Machinability for Precision-Critical Applications

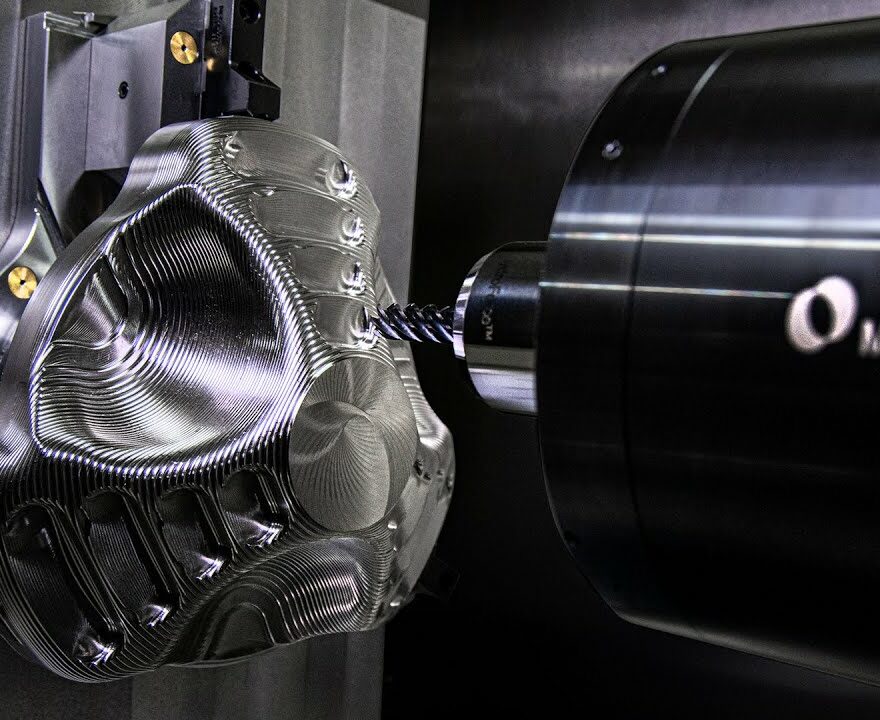

Titanium alloys present significant machining challenges due to their high strength-to-weight ratio, low thermal conductivity, and pronounced work-hardening tendencies. These properties demand specialized CNC machining strategies to prevent tool wear, thermal distortion, and dimensional inaccuracies—risks that can derail prototyping and low-volume production timelines. At Honyo Prototype, our senior engineering team leverages decades of materials science expertise and advanced 5-axis CNC capabilities to overcome these obstacles. We implement rigorously validated toolpath strategies, optimized coolant delivery systems, and proprietary fixturing solutions to ensure consistent surface integrity, tight tolerances (±0.0002″), and extended tool life when machining titanium grades including Ti-6Al-4V, CP Titanium, and exotic alloys.

Our end-to-end titanium machining process is engineered for mission-critical sectors like aerospace, medical implants, and defense, where component failure is not an option. By controlling chip evacuation dynamics and thermal loads through precision spindle harmonics and adaptive feed-rate algorithms, Honyo consistently delivers parts that meet stringent AS9100 and ISO 13485 requirements. Reduce your development risk and accelerate time-to-test with manufacturing partners who treat titanium’s complexities as routine.

Experience the Honyo advantage immediately: Upload your STEP or IGES file to our Online Instant Quote platform for a detailed manufacturability analysis and competitive pricing within hours—not days. This technical-first quoting system evaluates geometric constraints, material utilization, and process-specific lead times, giving you actionable data to move forward with confidence.

Technical Capabilities

Titanium alloys are known for their high strength-to-density ratio, excellent corrosion resistance, and performance at elevated temperatures. However, these same properties contribute to poor machinability compared to materials such as aluminum, steel, ABS, and nylon. In precision 3-, 4-, and 5-axis milling and turning operations—especially when tight tolerances (±0.0005″ or better) are required—titanium presents unique challenges including low thermal conductivity, high chemical reactivity, work hardening, and significant tool wear.

Below is a comparative technical overview of machinability characteristics, with a focus on multi-axis milling and turning under tight tolerance conditions.

| Material | Machinability Rating (Relative) | Typical Cutting Speed (SFM) | Tool Wear Resistance | Heat Dissipation | Work Hardening Tendency | Recommended Tooling | Notes for Tight Tolerance Machining |

|---|---|---|---|---|---|---|---|

| Titanium (Ti-6Al-4V) | Poor (20–30% of free-machining steel) | 30–60 SFM (milling), 50–100 SFM (turning) | Low to Moderate | Poor (retains heat in cut zone) | High (rapid work hardening) | Carbide with AlTiN or TiAlN coating, polycrystalline diamond (PCD) for finishing | Use sharp, positive rake tools; low, consistent feed rates; high-pressure coolant required to manage heat and prevent galling; peck milling and climb milling strategies recommended |

| Aluminum (6061-T6) | Excellent (100–150%) | 500–1500 SFM | High | Excellent | Very Low | Carbide or HSS with polished flutes; PCD for high-volume | High MRR achievable; minimal tool pressure allows sub-micron tolerances; non-stick coatings help prevent built-up edge |

| Steel (4140, hardened) | Moderate (40–60%) | 150–300 SFM (annealed), 80–150 SFM (hardened) | Moderate to High | Moderate | Medium | CBN or coated carbide for hard turning; indexable inserts for milling | Rigid setups critical; thermal growth compensation needed in 5-axis; consistent tool path strategies for dimensional stability |

| ABS (Thermoplastic) | Very Good (80–90%) | 500–1000 SFM | High (but low melting point) | Poor (melts under heat) | None | High-speed steel or carbide, sharp cutting edges | Low cutting forces; high feed rates; cooling via air blast; avoid dwell to prevent melting; excellent for rapid prototyping with moderate tolerances |

| Nylon (PA6/PA66) | Good (70–85%) | 400–800 SFM | High | Poor | None | Carbide with polished flutes | Slight moisture absorption may affect dimensions; pre-dry material; use sharp tools to minimize deformation; suitable for tight tolerance non-structural parts |

Key Considerations for Titanium in Multi-Axis Machining:

Tool Path Optimization: In 5-axis milling, continuous tool engagement with minimal step-overs reduces heat buildup and vibration. Adaptive clearing strategies are preferred.

Fixturing and Rigidity: Titanium’s high cutting forces require robust fixturing to maintain tight tolerances, especially in thin-wall or complex geometries.

Coolant Delivery: High-pressure through-spindle coolant (1000+ psi) is essential to evacuate chips and cool the cutting zone, reducing the risk of thermal distortion.

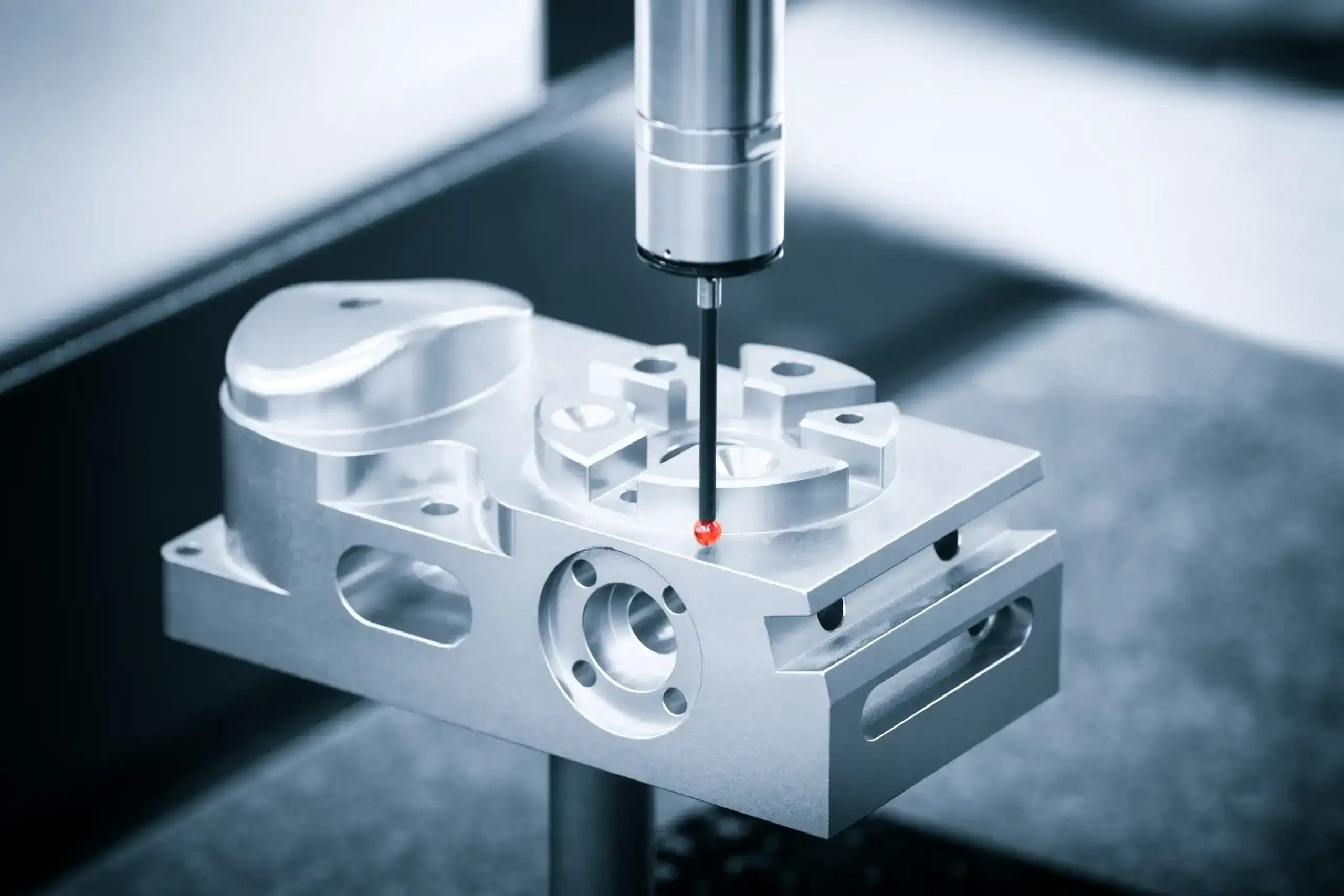

Tolerance Control: Thermal expansion of both workpiece and tool must be monitored. In-process probing and thermal compensation systems are recommended in precision environments.

While titanium is significantly more challenging to machine than aluminum, steel, ABS, or nylon, its performance in aerospace, medical, and high-performance applications justifies the increased cost and complexity in CNC operations.

From CAD to Part: The Process

Honyo Prototype’s titanium machining process integrates material-specific expertise at every stage of our streamlined workflow to address titanium’s unique challenges including low thermal conductivity, work hardening tendency, and chemical reactivity. Our proven sequence ensures optimal results while mitigating common titanium machining risks.

Upon CAD file upload, our system immediately identifies titanium alloy specifications (e.g., Ti-6Al-4V Grade 5) and flags critical parameters requiring special handling. The AI quoting engine cross-references real-time material costs, historical machining data for titanium grades, and calculates premium factors for extended cycle times, specialized tooling requirements, and mandatory post-process stress relief. This transparent quoting includes explicit justification for titanium-specific cost drivers such as 30-50% longer machining times versus aluminum and elevated scrap rate allowances.

During DFM analysis, our engineers apply titanium-specific protocols: verifying minimum wall thicknesses to prevent chatter-induced work hardening, optimizing toolpath strategies to maintain continuous chip formation, enforcing strict RPM limits to avoid thermal runaway, and mandating high-pressure coolant systems for heat dissipation. We reject designs with sharp internal corners prone to stress concentration and recommend controlled depth-of-cut parameters typically between 0.5-1.5mm to manage cutting forces below 65% of machine capacity.

Production execution occurs in dedicated titanium cells with isolated tooling to prevent contamination. We deploy carbide end mills with polished flutes and specialized PVD coatings (AlTiN), maintain spindle speeds 30-40% lower than steel equivalents, and implement rigid tapping with through-spindle coolant at 1,000+ PSI. In-process inspections verify dimensional stability after roughing to detect early-stage distortion, with mandatory stress-relief annealing before final finishing for critical aerospace components.

Delivery includes full material traceability documentation (mill test reports), first-article inspection reports with CMM data on critical features, and surface integrity verification including microhardness testing to confirm absence of alpha-case layer formation. All titanium parts undergo post-machining cleaning per ASTM F86 standards to remove embedded particles before shipment in anti-corrosion packaging with humidity indicators.

This integrated approach reduces titanium project failure rates by addressing material-specific failure modes at each workflow stage, delivering machined components that meet stringent aerospace and medical industry requirements on time and within budget.

Start Your Project

For expert insights on titanium machinability and precision manufacturing solutions, contact Susan Leo at [email protected]. Our advanced production facility in Shenzhen is equipped to handle complex titanium machining projects with tight tolerances and high repeatability. Partner with Honyo Prototype for reliable, high-quality results delivered on time.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.