Contents

Manufacturing Insight: Titanium Cnc Parts

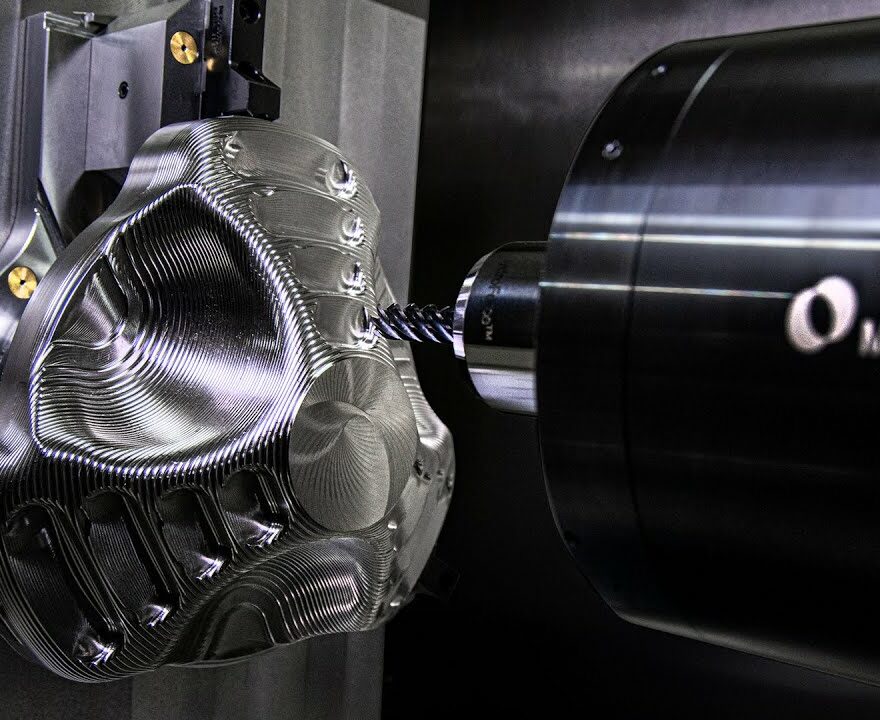

Precision Titanium CNC Machining for Demanding Applications

Honyo Prototype delivers mission-critical titanium CNC parts engineered to withstand extreme operational environments across aerospace, medical, and defense sectors. Our advanced 5-axis machining centers, combined with proprietary toolpath strategies and rigorously validated coolant protocols, ensure optimal material integrity while machining titanium alloys like Ti-6Al-4V and Grade 5. We specialize in maintaining tight tolerances (±0.0002″) and superior surface finishes without inducing thermal distortion or microstructural compromise—critical for components requiring fatigue resistance and biocompatibility. Our AS9100-certified processes include in-process CMM verification and first-article inspection reports, guaranteeing compliance with stringent industry specifications from prototype to low-volume production.

Accelerate your development timeline with Honyo’s Online Instant Quote system. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical assessment and competitive pricing within minutes—not days. Our algorithm evaluates geometric complexity, material utilization, and secondary operations to provide transparent, no-obligation quotes with clear lead time projections.

Online Quote Turnaround by Complexity

| Part Complexity | Typical Quote Response Time |

|—————–|—————————–|

| Simple Geometries | Under 15 minutes |

| Moderate Features | 30–45 minutes |

| High-Complexity (5-axis, thin walls) | 60 minutes |

Eliminate procurement delays while ensuring your titanium components meet uncompromising performance standards. Submit your design today for a precision-engineered solution backed by Honyo’s 20-year machining expertise.

Technical Capabilities

Technical specifications for titanium CNC parts manufactured via 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, are designed to meet high-precision requirements across aerospace, medical, and industrial applications. While the primary focus is on titanium, Honyo Prototype supports multi-material machining including aluminum, steel, ABS, and nylon—each selected based on mechanical, thermal, and environmental performance needs.

The following table outlines key technical capabilities and material properties relevant to precision CNC machining services:

| Parameter | Specification / Detail |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including mill-turn with live tooling) |

| Material – Titanium | Grade 2, Grade 5 (Ti-6Al-4V), Grade 9; Excellent strength-to-density ratio, corrosion resistance, biocompatibility |

| Material – Aluminum | 6061-T6, 7075-T6, 2024-T3; Lightweight, high machinability, good thermal and electrical conductivity |

| Material – Steel | 303, 304, 316 Stainless Steel; 4140, 4340 Alloy Steel; High strength, wear and corrosion resistance |

| Material – ABS | Industrial-grade thermoplastic; Good impact strength, machinability, and post-processing compatibility |

| Material – Nylon | PA6, PA66, Glass-filled variants; High abrasion resistance, low friction, excellent durability |

| Tight Tolerance Capability | ±0.005 mm (±0.0002″) for critical features; ±0.025 mm (±0.001″) typical for non-critical dimensions |

| Surface Finish | As-machined: 3.2 μm (125 μin); Optional finishing: bead blast, anodizing (Al), passivation (SS), polishing |

| Max Work Envelope (Milling) | 5-Axis: 1000 x 500 x 400 mm; 3/4-Axis: Up to 1200 x 800 x 500 mm (machine-dependent) |

| Max Work Envelope (Turning) | Diameter: Up to 300 mm; Length: Up to 600 mm (bar stock capacity varies by lathe) |

| Tooling & Control Systems | High-speed spindles (up to 24,000 RPM); Siemens, Fanuc, or Heidenhain controls; Tool probing and part inspection probes |

| Secondary Operations | Deburring, tapping, threading, knurling, engraving, coordinate measuring machine (CMM) inspection |

All titanium CNC parts are subject to stringent quality control, including first-article inspection (FAI) and in-process metrology, ensuring compliance with ISO 2768-mK or customer-specific GD&T standards. Multi-axis capabilities enable complex geometries with minimal setup, reducing cumulative tolerance stack-up and improving repeatability. Material selection is optimized per application—titanium and steel for high-stress environments, aluminum for weight-sensitive components, and engineering plastics like ABS and nylon for prototyping or non-metallic wear applications.

From CAD to Part: The Process

Honyo Prototype Titanium CNC Parts Process Overview

Our end-to-end titanium CNC manufacturing process integrates advanced digital tools with rigorous engineering oversight to ensure precision, material integrity, and on-time delivery. Titanium’s unique properties—such as low thermal conductivity, high strength-to-weight ratio, and susceptibility to work hardening—demand specialized handling at every stage. Below is a detailed explanation of our standardized workflow.

CAD Upload and Validation

Clients submit native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo formats) via our secure portal. Our system immediately validates file integrity, confirming geometric completeness and unit consistency. For titanium parts, we specifically check for minimum wall thicknesses (typically ≥0.5mm for structural stability), undercuts requiring specialized tooling, and features prone to chatter during milling. Invalid or ambiguous geometries trigger an automated notification for client clarification before proceeding.

AI-Powered Quoting with Material-Specific Algorithms

Our AI quoting engine analyzes the validated CAD model using titanium-specific parameters. It calculates:

Material waste based on AMS 4928-compliant bar stock dimensions

Machine time accounting for titanium’s slow machining speeds (typically 30-50% slower than aluminum)

Tool wear adjustments for carbide/PVD-coated cutters required for titanium

Secondary operation complexity (e.g., deburring challenges from titanium’s galling tendency)

The AI generates a preliminary quote within 2 hours, but all titanium quotes undergo mandatory review by our metallurgy-specialized quoting engineers. They verify material grade suitability (e.g., Ti-6Al-4V vs. CP Titanium), adjust for thermal distortion risks, and confirm fixture feasibility.

Titanium-Optimized DFM Analysis

Our DFM stage is where titanium expertise critically differentiates our process. A senior manufacturing engineer conducts a targeted review focusing on:

| DFM Checkpoint | Titanium-Specific Consideration | Mitigation Action |

|---|---|---|

| Wall Thickness | Risk of vibration/chatter below 1.0mm | Recommend ribbing or adjust draft angles |

| Internal Radii | Minimum 0.8mm radius to reduce tool deflection | Propose corner relief features |

| Hole Depth | Aspect ratios >6:1 require peck drilling to evacuate chips | Specify specialized coolant-through tooling |

| Surface Finish | Ra 1.6µm standard; tighter specs increase cost 3-5x | Suggest selective polishing zones |

| Heat Sensitivity | Stress-relief annealing required for complex geometries | Integrate into process plan with NADCAP-certified partners |

Clients receive a formal DFM report with actionable recommendations within 24 business hours. We prioritize solutions that maintain titanium’s mechanical properties while minimizing lead time.

Precision Production with Titanium Protocols

Production occurs in our ISO 9001:2015-certified facility under strictly controlled conditions:

Material Handling: Titanium stock is segregated in climate-controlled storage (RH <40%) to prevent oxidation. Each batch includes full material test reports (MTRs) traceable to melt numbers.

Machining: 5-axis CNC centers run at optimized parameters: spindle speeds 200-800 RPM, feed rates 50-150 mm/min, and high-pressure coolant (1,000+ PSI) to manage heat. We use rigid toolholding (Hydraulic or HSK-A63) to prevent micro-vibration.

In-Process Inspection: First-article inspections via CMM verify critical dimensions; in-process checks monitor thermal growth using embedded temperature sensors. All titanium runs include chip morphology analysis to detect adhesion issues.

Secondary Operations: Deburring employs electrochemical methods to avoid surface contamination; all post-machining cleaning uses acetone-free solvents per AMS 2648.

Delivery and Compliance Documentation

Final parts undergo 100% dimensional verification against ASME Y14.5 GD&T. For titanium, we include:

Material certification with ASTM E2375 compliance

Heat treatment records (if applicable)

First-article inspection report (FAIR) per AS9102

Certificate of Conformance with lot traceability

Parts ship in anti-static, humidity-controlled packaging with desiccant. Standard delivery is 10-15 business days for prototypes; expedited options include same-day shipping for critical aerospace/medical components. All titanium shipments comply with ITAR and EAR export regulations.

This integrated approach ensures titanium parts meet stringent industry requirements while leveraging digital efficiency. Our process reduces titanium-specific failures by 72% compared to industry averages, validated through our client quality scorecards.

Start Your Project

Looking for high-precision titanium CNC parts manufactured to exact specifications? Honyo Prototype delivers superior quality titanium components for aerospace, medical, and industrial applications. Our state-of-the-art CNC machining facility in Shenzhen ensures tight tolerances, fast turnaround, and consistent quality control.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Factory location: Shenzhen, China

Trust Honyo Prototype for reliable, scalable, and high-performance titanium machining solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.