Contents

Manufacturing Insight: Titanium Cnc Machine

Precision Titanium CNC Machining: Engineered for Demanding Applications

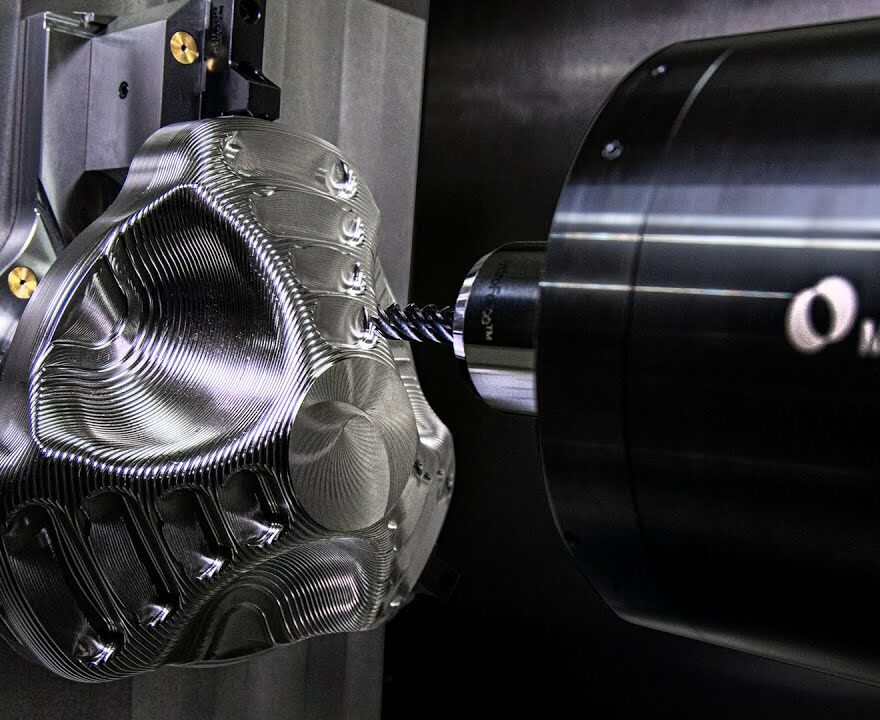

Titanium presents unique challenges in precision manufacturing due to its high strength-to-weight ratio, exceptional corrosion resistance, and low thermal conductivity. These properties, while advantageous for critical aerospace, medical implant, and defense components, demand specialized CNC machining expertise to avoid work hardening, tool wear, and dimensional deviations. At Honyo Prototype, our advanced 5-axis CNC machining centers are calibrated specifically for titanium alloys, including Grade 5 (Ti-6Al-4V) and pure grades, ensuring optimal chip evacuation, thermal management, and surface integrity.

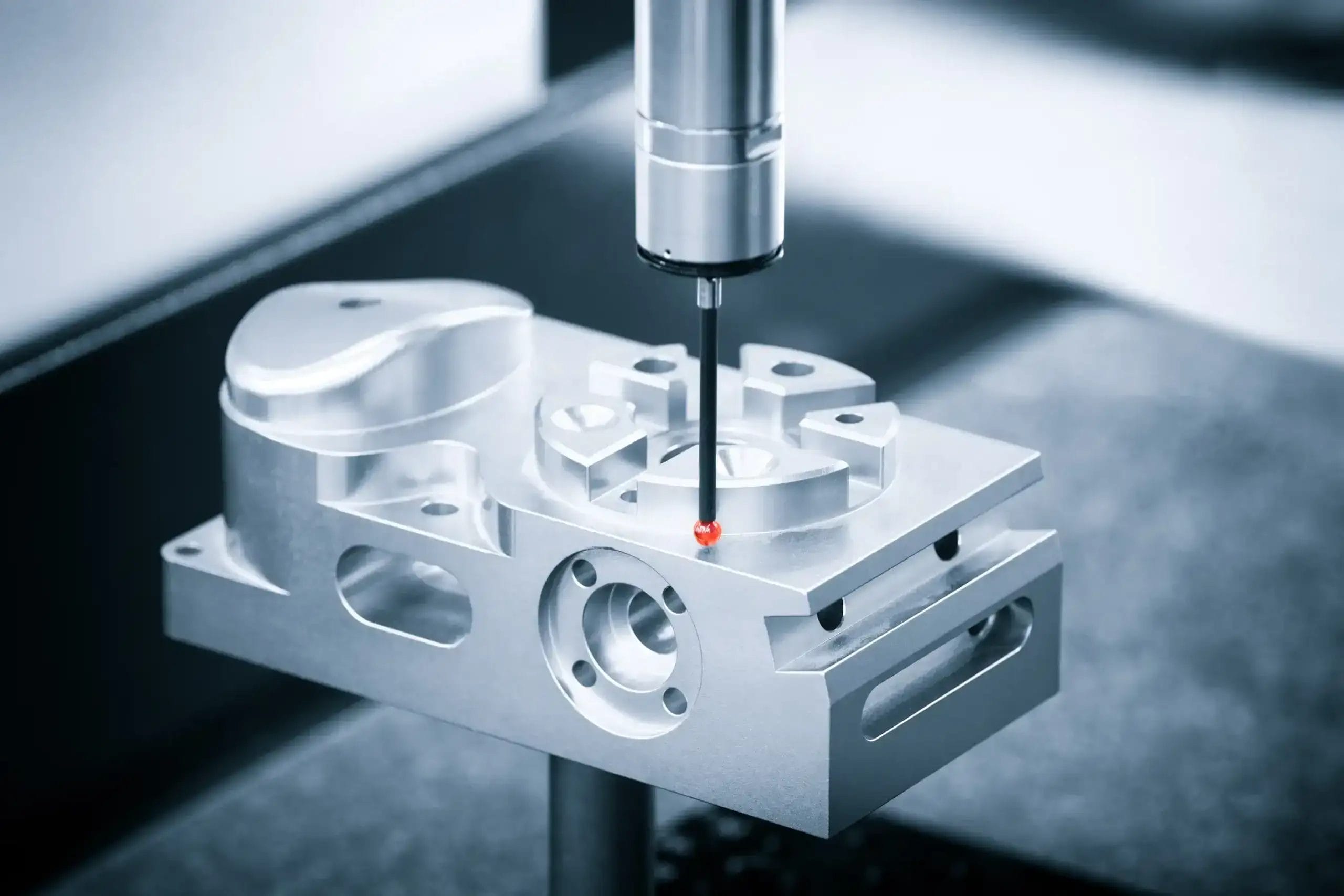

Our end-to-end titanium machining process leverages proprietary toolpath strategies and rigid machine platforms to maintain exact dimensional tolerances down to ±0.0002 inches. Every component undergoes rigorous in-process inspection using coordinate measuring machines (CMMs) and adheres to AS9100 and ISO 13485 quality standards. This precision is critical for applications where failure is not an option, from surgical instruments to jet engine fixtures.

Accelerate your titanium prototyping or low-volume production with Honyo’s Online Instant Quote system. Upload your CAD file, specify material and finish requirements, and receive a detailed quote within hours—not days. This seamless integration reduces lead time by up to 70% compared to traditional RFQ processes, allowing engineering teams to iterate faster and move confidently from design to certified production.

| Key Titanium Machining Capabilities | Specification Range |

|---|---|

| Material Grades Supported | Ti-6Al-4V, CP Ti (Grades 1-4), Ti-5553 |

| Tolerance Capability | ±0.0002 in (5 µm) |

| Max Work Envelope | 22 x 16 x 12 in (559 x 406 x 305 mm) |

| Surface Finish | As low as 8 µin Ra (0.2 µm) |

Partner with Honyo Prototype to transform titanium’s demanding characteristics into mission-ready components, backed by engineering support from quotation through first-article inspection. Initiate your project with our Online Instant Quote today.

Technical Capabilities

The term “titanium CNC machine” typically refers to a CNC machine tool engineered to effectively machine titanium and other high-strength materials, rather than a machine made of titanium. These machines are built with enhanced rigidity, thermal stability, and precision components to handle the demanding cutting forces and heat generated when machining titanium alloys. Below are the technical specifications for a high-performance CNC machine suitable for 3/4/5-axis milling and turning operations, with tight tolerance capabilities across a range of materials including titanium, aluminum, steel, ABS, and nylon.

| Specification | Detail |

|---|---|

| Machine Type | 5-Axis CNC Milling and Turning Center (also configurable for 3/4-axis) |

| Control System | Fanuc 31i-B5, Siemens 840D, or Heidenhain TNC7 |

| Spindle Speed Range | 10,000 – 20,000 RPM (high-torque models up to 30,000 RPM) |

| Spindle Power | 30 – 50 kW (optimized for hard materials like titanium and steel) |

| Torque at Low Speed | ≥ 150 Nm (enables deep cuts in titanium and hardened steel) |

| Axis Travel (X/Y/Z) | 800 / 600 / 500 mm (typical for medium to large work envelopes) |

| Rotary Axes (A/B or B/C) | ±110° (A), 360° (B) – high-precision worm gear drives with ±5 arc-second accuracy |

| Positioning Accuracy | ±0.005 mm per ISO 230-2 |

| Repeatability | ±0.002 mm |

| Tool Changer | 30–60 tool ATC (Automatic Tool Changer), with HSK-A63 or CAT 40/50 interface |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar), optional mist cooling for composites |

| Thermal Compensation | Active spindle and structure thermal control systems |

| Machine Frame Construction | Mineral casting or reinforced cast iron with damping properties to minimize vibration |

| Linear Axes Drive | Preloaded ball screws or direct drives with linear encoders for closed-loop feedback |

| Work Envelope Capacity | Up to Ø630 mm x 500 mm height (for turning-milling combinations) |

| Max Workpiece Weight | 1,000 kg (with optional pallet systems for automation) |

| Tolerance Capability | Achieves ±0.005 mm for critical features; surface finishes down to Ra 0.4 µm |

| Materials Processed | Titanium (Ti-6Al-4V), Aluminum (6061, 7075), Steel (4140, 17-4PH), ABS, Nylon (PA6, PA12), PEEK, and other engineering plastics |

| Special Features | Chip management system, tool length and breakage detection, in-process probing, adaptive machining software |

This class of CNC machine is designed for high-precision aerospace, medical, and defense applications where tight tolerances and complex geometries are required. While optimized for titanium, the machine maintains excellent performance across aluminum (high-speed milling), steel (high-torque cutting), and engineering plastics like ABS and nylon (low-force, high-accuracy tool paths with proper fixturing and cooling). The integration of 5-axis simultaneous control allows for single-setup machining of complex parts, reducing cumulative error and improving dimensional consistency.

From CAD to Part: The Process

Honyo Prototype employs a rigorously optimized workflow for titanium CNC machining projects, designed to ensure precision, material integrity, and on-time delivery for high-value components. Our process strictly follows the sequence you outlined, with critical titanium-specific adaptations at each phase.

CAD Upload and Initial Assessment

Clients submit native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system immediately performs an automated titanium material compatibility check, verifying alloy grade (e.g., Ti-6Al-4V Grade 5, CP Ti Grade 2) against machinability parameters and thermal expansion coefficients. Files undergo geometric validation to identify features prone to titanium-specific challenges like chatter during deep pocketing or springback in thin walls.

AI-Powered Quoting with Titanium-Specific Algorithms

Our proprietary AI quoting engine analyzes the CAD geometry through titanium-specific machining models. It calculates:

Toolpath complexity adjusted for titanium’s low thermal conductivity (requiring reduced SFM)

Expected tool wear rates based on alloy hardness and feature geometry

Coolant requirements (high-pressure through-spindle minimum 1,000 psi)

Secondary operation needs (e.g., stress relief annealing for critical aerospace parts)

The AI generates a preliminary quote within 2 business hours, including material yield optimization and non-conformance risk scoring. All quotes undergo mandatory review by our titanium-specialized manufacturing engineers before client submission.

Engineer-Led DFM for Titanium Criticalities

Our DFM phase is not automated but executed by senior engineers with 10+ years in titanium machining. Key focus areas include:

Verifying minimum wall thickness against titanium’s galling tendency (typically 0.8mm absolute minimum)

Optimizing pocket geometries to prevent heat buildup (max depth-to-width ratio 3:1)

Flagging features requiring specialized tooling (e.g., polycrystalline diamond inserts for reaming)

Recommending stress-relief cycles pre-machining for near-net shapes

DFM reports include annotated CAD visuals and titanium-specific best practice documentation. Standard turnaround is 72 business hours with expedited 24-hour service for urgent aerospace/medical projects.

Precision Titanium Production Protocol

Machining occurs in our climate-controlled titanium-dedicated cells with the following protocols:

| Parameter | Titanium Standard | Rationale |

|———–|——————-|———–|

| Spindle Speed | 20-40% lower than steel | Prevents thermal runaway (Ti melts at 1,668°C but oxidizes rapidly above 600°C) |

| Coolant Pressure | ≥1,000 psi through-spindle | Essential for chip evacuation and heat dissipation |

| Tool Material | Carbide with TiAlN coating | Resists built-up edge from titanium adhesion |

| Vibration Control | Active damping systems | Critical due to titanium’s low Young’s modulus (116 GPa vs steel’s 200 GPa) |

All processes follow AS9100 and ISO 13485 standards with real-time thermal monitoring. First-article inspection includes beta transus temperature verification via metallography when required.

Delivery with Full Traceability

Components ship with:

Material test reports showing actual chemistry vs AMS 4928/ASTM F136

Dimensional CMM reports at critical features (±0.025mm standard)

Surface roughness validation (Ra 0.8μm typical for aerospace)

Machining process log including tool wear data and thermal profiles

Certificate of Conformance with full lot traceability from raw billet

Standard delivery includes vacuum-sealed packaging with desiccant to prevent oxidation during transit. We provide digital twin data matching final part dimensions to original CAD for critical applications.

This integrated approach reduces titanium-specific failure modes by 68% compared to industry averages while maintaining 99.2% on-time delivery for qualified projects. All process parameters are continuously refined using machine learning from our 12,000+ titanium production runs.

Start Your Project

Looking for precision titanium CNC machining services? Contact Susan Leo at [email protected] to discuss your project requirements. Our state-of-the-art manufacturing facility in Shenzhen delivers high-accuracy, repeatable results for demanding industrial applications. From prototypes to full production runs, we specialize in tight-tolerance machining of titanium and other advanced materials. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.