Introduction: Navigating the Global Market for titanium anodizing kit

In the rapidly evolving world of metal finishing, sourcing a titanium anodizing kit can present significant challenges for international B2B buyers. Whether you are in the piercing industry in Saudi Arabia, the medical sector in Nigeria, or the manufacturing field in South America, understanding the nuances of anodizing technology is crucial. This comprehensive guide delves into the various types of titanium anodizing kits available, their applications across different industries, and the essential factors to consider when vetting suppliers.

From exploring the intricacies of anodizing processes to evaluating cost structures and sourcing high-quality materials, this guide equips you with the insights needed to make informed purchasing decisions. It addresses key questions such as: What are the best practices for achieving desired color outcomes? How can businesses ensure compliance with regional regulations? By providing actionable information tailored to the unique needs of buyers in Africa, Europe, and the Middle East, this resource empowers your business to enhance product offerings and meet customer demands effectively.

Navigating the global market for titanium anodizing kits has never been easier, and with this guide, you will be well-prepared to capitalize on the opportunities that lie ahead.

Understanding titanium anodizing kit Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Basic Titanium Anodizing Kit | Includes essential anodizing machine and accessories | Jewelry manufacturing, body piercing | Pros: Affordable entry point; Cons: Limited advanced features. |

| Advanced Commercial Anodizer | High voltage output, larger bath size | Mass production, dental and medical tools | Pros: Suitable for large-scale operations; Cons: Higher initial investment. |

| Portable Anodizing Kit | Compact size, easy to transport | On-site jewelry customization | Pros: Versatile for mobile businesses; Cons: May lack power for larger jobs. |

| Specialty Anodizing Kit | Includes unique tools for intricate designs | Artisans, custom jewelry makers | Pros: Allows for creative designs; Cons: More complex setup and learning curve. |

| Eco-Friendly Anodizing Kit | Uses environmentally safe electrolytes | Sustainable businesses, eco-conscious brands | Pros: Aligns with green practices; Cons: May be more costly than traditional options. |

What Are the Characteristics of Basic Titanium Anodizing Kits?

Basic titanium anodizing kits are designed for beginners or small businesses looking to enter the anodizing market. They typically include an anodizing machine, basic anodizing wands, and essential supplies such as electrolyte solutions and submersion containers. These kits are ideal for jewelry manufacturers and body piercing shops that want to offer colorful, custom body jewelry without a significant upfront investment. While they provide a cost-effective solution, buyers should be aware that they may lack advanced features, limiting their capabilities for larger or more intricate projects.

How Do Advanced Commercial Anodizers Differ from Other Kits?

Advanced commercial anodizers are built for high-volume production and can handle larger batches of materials. These machines often feature higher voltage outputs and larger bath sizes, making them suitable for industries such as dental and medical tool manufacturing, where precision and durability are paramount. While they enable mass production and consistent results, the initial investment can be substantial, requiring buyers to assess their production needs carefully.

What Are the Benefits of Portable Anodizing Kits?

Portable anodizing kits offer a compact solution for businesses that require mobility, such as on-site jewelry customization services. These kits are lightweight and easy to transport, allowing artisans to provide services at various locations. However, potential buyers should consider that while these kits are versatile, they may not deliver the same power output as larger systems, which could limit their effectiveness for larger jobs.

Why Should Artisans Consider Specialty Anodizing Kits?

Specialty anodizing kits are tailored for artisans and custom jewelry makers who wish to explore intricate designs and unique finishes. These kits often come with specialized tools that enable detailed work, enhancing the creative possibilities for users. While they allow for greater artistic expression, these kits may require a more complex setup and a steeper learning curve, making them less suitable for those just starting in anodizing.

What Makes Eco-Friendly Anodizing Kits Attractive to B2B Buyers?

Eco-friendly anodizing kits utilize environmentally safe electrolytes, appealing to businesses that prioritize sustainability. These kits align with green practices, making them an attractive option for eco-conscious brands looking to differentiate themselves in the market. However, buyers should be prepared for potentially higher costs compared to traditional anodizing solutions, necessitating a cost-benefit analysis to ensure alignment with their business goals.

Key Industrial Applications of titanium anodizing kit

| Industry/Sector | Specific Application of titanium anodizing kit | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Equipment | Anodizing surgical instruments and implants | Enhances corrosion resistance and biocompatibility | Compliance with medical standards; sourcing high-purity titanium |

| Jewelry Manufacturing | Custom anodized body jewelry designs | Offers unique, colorful options for clients | Need for versatile anodizing kits to achieve various color finishes |

| Aerospace | Anodizing components for aircraft and spacecraft | Increases durability while reducing weight | Requirement for high-performance anodizing machines with precise control |

| Automotive | Anodizing parts in performance vehicles | Improves aesthetic appeal and component longevity | Availability of specialized anodizing solutions for automotive applications |

| Electronics | Anodizing casings and components for electronic devices | Protects against corrosion and enhances appearance | Need for compact anodizing kits suitable for small parts |

How is a Titanium Anodizing Kit Used in Medical Equipment Applications?

In the medical industry, titanium anodizing kits are essential for enhancing surgical instruments and implants. The anodizing process provides a protective oxide layer that increases corrosion resistance and biocompatibility, crucial for devices that interact with human tissues. International buyers, particularly from regions like the Middle East and Europe, must ensure that the anodizing equipment meets stringent medical regulations and standards, while also sourcing high-purity titanium to avoid contamination.

What Role Does a Titanium Anodizing Kit Play in Jewelry Manufacturing?

Jewelry manufacturers utilize titanium anodizing kits to create custom designs with vibrant colors and finishes. The anodizing process allows for the transformation of titanium and niobium into unique pieces that cater to customers with metal allergies, as these materials are biocompatible. For B2B buyers in Africa and South America, sourcing kits that offer versatility and ease of use is vital for producing a diverse range of jewelry items that stand out in a competitive market.

How Does Anodizing Enhance Aerospace Components?

Aerospace applications benefit significantly from titanium anodizing kits, which are used to treat components of aircraft and spacecraft. The anodizing process not only provides enhanced corrosion resistance but also contributes to weight reduction, a critical factor in aerospace design. Buyers in this sector, especially in Europe and the Middle East, should prioritize sourcing advanced anodizing machines that offer precise control over the process to meet the high-performance standards required in aerospace engineering.

What Are the Benefits of Titanium Anodizing Kits in Automotive Industries?

In the automotive sector, titanium anodizing kits are employed to anodize parts of performance vehicles, enhancing their visual appeal and durability. The anodized finish protects against wear and environmental factors, contributing to longer-lasting components. For international buyers, particularly from regions like Saudi Arabia and Nigeria, it is essential to consider sourcing specialized anodizing solutions that can accommodate the unique requirements of automotive applications, including the ability to handle high volumes of production.

How Do Electronics Manufacturers Utilize Titanium Anodizing Kits?

Electronics manufacturers use titanium anodizing kits to anodize casings and components, protecting them from corrosion and enhancing their aesthetic appeal. This application is particularly relevant for devices exposed to harsh environments. Buyers from South America and Africa should focus on sourcing compact anodizing kits that are efficient for small parts, ensuring they can maintain quality while meeting production demands in the fast-paced electronics market.

3 Common User Pain Points for ‘titanium anodizing kit’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Color Results

The Problem: One common challenge faced by B2B buyers using titanium anodizing kits is achieving consistent color results across multiple pieces. This inconsistency can arise from variations in voltage settings, anodizing solutions, or even the surface preparation of the titanium. For businesses that rely on uniformity, such as jewelry manufacturers or dental labs, this can lead to customer dissatisfaction and potential loss of business. Clients may expect specific colors or finishes, and when the end product does not meet these standards, it can harm brand reputation.

The Solution: To overcome this challenge, it is essential to establish a standardized anodizing process. Start by meticulously documenting the settings used for different color outcomes, including the voltage, duration of anodization, and the specific electrolyte solution concentrations. Invest in a high-quality anodizing machine that allows for precise voltage control, such as those with digital meters. Additionally, perform thorough surface preparation by cleaning the titanium pieces with TSP-PF phosphate-free cleaners to remove any contaminants. By maintaining a consistent protocol and investing in reliable equipment, businesses can ensure uniform color results, leading to higher customer satisfaction.

Scenario 2: Limited Knowledge on Anodizing Techniques

The Problem: Many buyers entering the titanium anodizing market may lack the technical knowledge required to use anodizing kits effectively. This gap in understanding can lead to poor results, wasted materials, and frustration. For companies new to anodizing, the initial learning curve can be steep, resulting in lost opportunities to offer unique, customized products that appeal to their target market.

The Solution: To address this knowledge gap, companies should prioritize training and education. Start by sourcing comprehensive instructional materials from reputable suppliers, including detailed user manuals and video tutorials. Suppliers often offer workshops or online webinars that can provide hands-on experience and answer specific questions. Additionally, consider partnering with experienced anodizers for mentorship. Joining industry forums or social media groups can also be beneficial, allowing businesses to share insights and learn from others’ experiences. By investing in education and training, companies can enhance their anodizing capabilities, leading to better product offerings and improved operational efficiency.

Scenario 3: Equipment Maintenance and Reliability Issues

The Problem: A significant concern for B2B buyers is the maintenance and reliability of anodizing equipment. Anodizing machines can be complex, and without proper upkeep, they may fail during critical production periods, leading to costly downtime. This is especially problematic for businesses with tight production schedules or those that rely on anodizing as a core part of their offerings.

The Solution: To mitigate equipment reliability issues, establish a proactive maintenance schedule. Regularly inspect anodizing machines and components for wear and tear, and replace any worn parts promptly. Ensure that operators are trained in basic troubleshooting techniques to identify and address minor issues before they escalate. Furthermore, consider sourcing equipment from suppliers that provide robust customer support and warranty options, ensuring that help is readily available in case of malfunctions. Having a well-stocked inventory of essential spare parts, such as fuses and anodizer knobs, can also minimize downtime and keep production flowing smoothly. By prioritizing equipment maintenance and support, companies can enhance operational reliability and reduce the risk of disruptions.

Strategic Material Selection Guide for titanium anodizing kit

What Materials Are Commonly Used in Titanium Anodizing Kits?

When selecting materials for a titanium anodizing kit, it is essential to consider their properties, advantages, disadvantages, and compliance with international standards. Here, we analyze four common materials used in anodizing processes: titanium, niobium, stainless steel, and anodizing solutions.

1. Titanium

Key Properties:

Titanium is known for its exceptional strength-to-weight ratio, high corrosion resistance, and biocompatibility. It can withstand high temperatures, making it suitable for various anodizing applications.

Pros & Cons:

The durability of titanium is a significant advantage, as it does not corrode easily, ensuring longevity in anodized products. However, titanium can be expensive compared to other metals, which may deter smaller businesses or startups. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Impact on Application:

Titanium’s compatibility with anodizing processes allows for vibrant color variations, enhancing the aesthetic appeal of products. This is particularly beneficial in industries like jewelry and medical devices, where appearance and biocompatibility are crucial.

Considerations for International Buyers:

Compliance with standards such as ASTM F136 for titanium used in medical applications is vital. Buyers from regions like the Middle East and Africa should ensure that their suppliers adhere to these standards to avoid regulatory issues.

2. Niobium

Key Properties:

Niobium exhibits excellent corrosion resistance and is highly ductile, which allows for intricate designs in anodized products. Its melting point is relatively high, making it suitable for high-temperature applications.

Pros & Cons:

The primary advantage of niobium is its ability to produce vibrant colors during anodization, appealing to the jewelry market. However, its cost can be a drawback, as niobium is typically more expensive than aluminum and may not be as readily available in all markets.

Impact on Application:

Niobium is particularly favored in the body jewelry industry due to its hypoallergenic properties, making it suitable for individuals with metal allergies. This compatibility enhances its marketability in regions with a high demand for body jewelry.

Considerations for International Buyers:

Buyers should be aware of the varying availability of niobium in different regions and ensure that their suppliers can provide consistent quality. Compliance with local regulations regarding materials used in body jewelry is also crucial.

3. Stainless Steel

Key Properties:

Stainless steel is known for its strength, corrosion resistance, and ease of fabrication. It is often used in anodizing applications due to its durability and aesthetic appeal.

Pros & Cons:

While stainless steel is less expensive than titanium and niobium, it does not anodize as effectively, resulting in limited color options. However, its lower cost and widespread availability make it an attractive option for budget-conscious businesses.

Impact on Application:

Stainless steel is commonly used in various applications, including medical instruments and kitchenware, where durability and corrosion resistance are essential. However, its limited anodization capabilities may restrict its use in the jewelry sector.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A240 for stainless steel used in food and medical applications. Awareness of local preferences for stainless steel grades can also influence purchasing decisions.

4. Anodizing Solutions

Key Properties:

Anodizing solutions typically consist of sulfuric acid or phosphoric acid mixed with distilled water. These solutions are crucial for the anodization process, affecting the final product’s quality and appearance.

Pros & Cons:

The primary advantage of using specialized anodizing solutions is their ability to enhance the anodization process, resulting in better color and finish. However, handling these chemicals requires safety precautions and compliance with environmental regulations.

Impact on Application:

The choice of anodizing solution can significantly impact the durability and aesthetic quality of the anodized surface. This is particularly important in industries where product appearance is critical, such as fashion and electronics.

Considerations for International Buyers:

Buyers must ensure that their suppliers provide environmentally friendly anodizing solutions that comply with local regulations. Understanding the chemical composition and safety data sheets is crucial for safe handling and compliance.

Summary Table

| Material | Typical Use Case for titanium anodizing kit | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Medical devices, jewelry | High corrosion resistance | High cost, complex manufacturing | High |

| Niobium | Body jewelry | Produces vibrant colors | Higher cost, availability issues | High |

| Stainless Steel | Medical instruments, kitchenware | Cost-effective, durable | Limited anodization color options | Medium |

| Anodizing Solutions | Anodizing process | Enhances anodization quality | Requires safety precautions | Low |

This analysis provides B2B buyers with a comprehensive understanding of material options for titanium anodizing kits, enabling informed purchasing decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for titanium anodizing kit

What Are the Key Manufacturing Processes for a Titanium Anodizing Kit?

The production of a titanium anodizing kit involves several critical stages, each contributing to the final quality and functionality of the equipment. Understanding these stages can assist B2B buyers in evaluating potential suppliers and ensuring they receive high-quality products.

How Is Material Prepared for Titanium Anodizing Kits?

The first step in manufacturing titanium anodizing kits is material preparation. This involves sourcing high-grade titanium and other metal components, which are typically selected for their biocompatibility and durability. The materials undergo initial inspections to verify their chemical composition and mechanical properties, ensuring they meet industry standards.

After sourcing, the materials are cleaned and prepped to remove any contaminants. This may involve ultrasonic cleaning or chemical baths to ensure that the surfaces are free from oils, dust, or residues that could affect the anodizing process. Proper preparation is crucial, as any impurities can lead to inconsistent anodization results, impacting the aesthetic and functional properties of the final products.

What Techniques Are Employed in Forming and Assembly?

Once the materials are prepared, the forming process begins. This typically includes cutting, shaping, and machining the components that will make up the anodizing kit. Advanced techniques such as CNC machining may be employed to achieve precise dimensions and tolerances, which are vital for ensuring that all parts fit together correctly and function as intended.

Assembly involves integrating various components, including anodizing machines, power supplies, and accessories such as anodizing wands and baskets. Each component is carefully assembled to ensure reliability and ease of use. During assembly, manufacturers may utilize jigs and fixtures to maintain precision and consistency across multiple units, which is particularly important for meeting international quality standards.

What Finishing Processes Are Applied to Ensure Quality?

Finishing is the final stage of manufacturing, where the anodizing kit undergoes treatments to enhance its performance and aesthetics. This may include anodizing the metal components to provide a protective oxide layer that improves corrosion resistance and wearability. Additionally, surface treatments may be applied to ensure that the finished product is not only functional but also visually appealing.

At this stage, quality checks are implemented to identify any defects in the finished products. Common practices include visual inspections, dimensional checks, and functionality tests to confirm that all components meet the required specifications before they are packaged and shipped.

What Quality Assurance Measures Are In Place for Titanium Anodizing Kits?

Quality assurance is a vital aspect of the manufacturing process for titanium anodizing kits. Implementing rigorous QA protocols helps ensure that products meet both international standards and industry-specific regulations, which is particularly important for B2B buyers looking to maintain compliance in their respective markets.

Which International Standards Should Buyers Consider?

International standards such as ISO 9001 play a crucial role in establishing quality management systems for manufacturers. This standard emphasizes a process approach to enhance customer satisfaction by meeting regulatory and statutory requirements. For titanium anodizing kits, adherence to ISO 9001 assures buyers that the manufacturer is committed to continuous improvement and effective quality management.

In addition to ISO 9001, other certifications may be relevant depending on the target market. For instance, the CE marking is essential for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards. Similarly, for suppliers targeting the medical or dental industries, certifications from organizations like the American National Standards Institute (ANSI) or the American Society for Testing and Materials (ASTM) may be required.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically implemented throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring and testing are conducted to identify and rectify issues in real-time, minimizing the risk of defects in the final product.

- Final Quality Control (FQC): Before shipment, the finished anodizing kits undergo comprehensive testing, including performance checks and visual inspections, to ensure they meet all quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control measures employed by their suppliers. Conducting audits of manufacturing facilities can provide insight into the supplier’s adherence to quality standards and practices. Buyers should request quality control reports that detail testing methods, results, and any corrective actions taken in response to identified issues.

Additionally, seeking third-party inspections can provide an unbiased assessment of the supplier’s quality assurance processes. This is particularly beneficial for international buyers, as it helps to mitigate risks associated with sourcing from overseas manufacturers.

What Are the Unique Quality Control Considerations for International Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, there are unique considerations to bear in mind when assessing quality control. Understanding local regulations and market expectations is critical. Buyers should ensure that their suppliers are familiar with the specific quality standards applicable in their target regions.

Moreover, international shipping and logistics can introduce additional risks. Buyers should inquire about the manufacturer’s practices regarding packaging and handling to prevent damage during transport. Ensuring that the supplier has robust quality control measures in place throughout the supply chain is essential for maintaining product integrity and meeting customer expectations.

By understanding the manufacturing processes and quality assurance measures associated with titanium anodizing kits, B2B buyers can make informed decisions that align with their business needs and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘titanium anodizing kit’

When sourcing a titanium anodizing kit, it’s essential to follow a structured approach to ensure you select the right equipment and supplies for your business needs. This checklist will guide you through the key steps in the procurement process, helping you make informed decisions and achieve optimal results in anodizing operations.

Step 1: Define Your Technical Specifications

Before you start sourcing, clarify the technical requirements for your anodizing kit. Consider factors such as the size of the parts you will anodize, the desired color range, and the volume of production.

– Key Considerations: What voltage and amperage do you need? What type of anodizing solutions are compatible with your materials?

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in anodizing equipment and materials. Look for companies with a strong track record in the industry, particularly those that cater to businesses in your target regions, such as Africa, South America, the Middle East, and Europe.

– What to Look For: Customer reviews, case studies, and testimonials from other B2B buyers. Ensure that the supplier has experience with titanium anodizing specifically.

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers. Certifications can indicate adherence to industry standards and quality assurance processes.

– Important Certifications: Look for ISO certifications and any specific industry-related certifications that ensure the safety and reliability of the anodizing equipment.

Step 4: Request Detailed Product Information

Once you have shortlisted suppliers, request detailed product specifications for the anodizing kits they offer. This information should include materials used, operational guidelines, and any warranty or support services.

– Focus Areas: Ensure that the anodizing kit includes necessary components such as anodizing machines, wands, solutions, and safety equipment.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare their pricing structures. Be sure to consider not just the upfront costs but also shipping fees, warranty terms, and any ongoing support or training they provide.

– Cost Factors: Look out for bulk purchase discounts or free shipping offers, which can significantly affect your overall expenditure.

Step 6: Assess After-Sales Support

Evaluate the after-sales support offered by potential suppliers. Robust support can be invaluable, particularly if you encounter issues during the anodizing process.

– Support Services: Inquire about training programs, technical assistance, and availability of replacement parts to ensure you can maintain your anodizing operations effectively.

Step 7: Finalize Your Purchase

After thorough evaluation, select the supplier that best meets your criteria and finalize your purchase. Ensure that all terms are clearly outlined in a purchase agreement.

– Final Checks: Confirm delivery timelines and installation services, if applicable, to avoid disruptions in your operations.

By following this checklist, you can streamline the procurement process for your titanium anodizing kit, ensuring that you invest in the right tools and resources to enhance your business capabilities and meet customer demands effectively.

Comprehensive Cost and Pricing Analysis for titanium anodizing kit Sourcing

What Are the Key Cost Components in Sourcing a Titanium Anodizing Kit?

When evaluating the cost structure of a titanium anodizing kit, it’s essential to consider several key components that contribute to the overall pricing. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary materials involved in anodizing kits are titanium or niobium metals, anodizing solutions (like TSP-PF), and various ancillary items such as anodizing wands and brushes. The quality of these materials can significantly affect pricing, with higher-grade metals commanding a premium.

-

Labor: Skilled labor is required to assemble anodizing kits and ensure they meet quality standards. Labor costs may vary based on the geographical location of the supplier and the complexity of the manufacturing process.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment depreciation. In regions with higher operational costs, such as Europe, these expenses can lead to increased pricing.

-

Tooling: Specialized tools and machinery are necessary for the anodizing process. The initial investment in tooling can be substantial, impacting the pricing of the kits.

-

Quality Control: Ensuring that the anodizing kits meet safety and performance standards requires robust QC processes. This can involve testing materials and finished products, adding to the overall cost.

-

Logistics: Shipping and handling costs can vary significantly depending on the destination. For international buyers, these costs can become substantial, especially if the products require special handling or expedited shipping.

-

Margin: Suppliers typically add a markup to cover their operational costs and generate profit. This margin can vary based on market competition and demand for anodizing kits.

How Do Price Influencers Affect the Cost of Titanium Anodizing Kits?

Several factors can influence the pricing of titanium anodizing kits, particularly for international B2B buyers.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often come with discounts, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Customization options, such as specific color finishes or sizes, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice of materials, such as the grade of titanium or niobium used, impacts pricing. Higher-quality materials typically lead to better performance and durability but come at a higher cost.

-

Quality and Certifications: Products that meet international quality standards or come with certifications (like ISO) may be priced higher due to the assurance of quality and reliability.

-

Supplier Factors: Established suppliers with a strong reputation may charge more due to their reliability and service quality. Conversely, emerging suppliers might offer competitive pricing to build their market presence.

-

Incoterms: The choice of Incoterms (international commercial terms) influences the cost structure, as they define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs.

What Are the Best Negotiation Tips for International B2B Buyers of Titanium Anodizing Kits?

When sourcing titanium anodizing kits, international buyers should employ strategic negotiation tactics to enhance cost-efficiency and maximize value.

-

Research and Benchmarking: Understand market prices and benchmark offers from multiple suppliers. This will provide leverage during negotiations.

-

Discuss Total Cost of Ownership: Emphasize the importance of total cost of ownership (TCO), which includes not just the initial price but also maintenance, operational costs, and potential downtime.

-

Highlight Long-term Relationships: Express willingness to establish long-term partnerships. Suppliers may offer better pricing or terms to buyers who commit to future orders.

-

Clarify Payment Terms: Negotiate favorable payment terms that align with your cash flow. Discuss options like partial payments or extended payment periods.

-

Consider Local Regulations: Understand the import regulations and potential tariffs in your region, as these can significantly affect the total cost of procurement.

Disclaimer on Indicative Prices

Prices for titanium anodizing kits can vary widely based on the aforementioned factors, and it is advisable for buyers to obtain detailed quotes tailored to their specific requirements. Always consider requesting samples or conducting pilot tests before finalizing large orders to ensure compatibility and quality.

Alternatives Analysis: Comparing titanium anodizing kit With Other Solutions

When evaluating the best options for enhancing the aesthetic and functional properties of titanium products, it’s essential to consider various alternatives to a titanium anodizing kit. These alternatives can offer different benefits and drawbacks depending on the specific needs of businesses, especially those in industries such as jewelry, medical, and aerospace.

| Comparison Aspect | Titanium Anodizing Kit | Chemical Coloring Process | Laser Etching and Marking |

|---|---|---|---|

| Performance | High durability and corrosion resistance; vibrant color options | Good color variety, but less durable than anodizing | Permanent markings; limited color options |

| Cost | Moderate initial investment; ongoing supply costs | Generally lower initial costs, but potential hidden costs in chemicals | Higher initial investment for equipment; low ongoing costs |

| Ease of Implementation | Requires training; straightforward setup for experienced users | Simpler for basic applications; may require safety precautions | Requires technical expertise for setup and operation |

| Maintenance | Regular maintenance of equipment and supplies needed | Minimal maintenance but requires safe disposal of chemicals | Low maintenance; periodic equipment calibration |

| Best Use Case | Ideal for jewelry and medical applications needing biocompatibility | Suitable for decorative applications where durability is not critical | Best for permanent identification or branding on titanium |

What are the Pros and Cons of Using Chemical Coloring as an Alternative to Titanium Anodizing Kits?

Chemical coloring processes involve applying various dyes or paints to the titanium surface. The advantages of this method include a lower initial investment and a simpler setup, making it accessible for smaller operations or beginners. However, the durability of the colors achieved through chemical coloring is often inferior to anodizing, and the colors may fade or wear over time, particularly in high-use applications. Additionally, businesses must be mindful of the environmental regulations associated with chemical disposal.

How Does Laser Etching and Marking Compare to Titanium Anodizing Kits?

Laser etching and marking offer a unique solution for businesses looking to create permanent markings on titanium. This method is particularly advantageous for applications requiring precise, high-contrast markings for identification or branding purposes. While the initial investment in laser equipment can be significant, the ongoing costs are minimal, as there are few consumables involved. However, laser marking typically offers limited color options compared to anodizing and does not enhance the surface’s corrosion resistance. Therefore, it may not be suitable for applications where aesthetics and biocompatibility are paramount.

Conclusion: Which Solution is Best for Your Business Needs?

Choosing the right solution for titanium treatment ultimately depends on your specific application and business goals. If vibrant colors and enhanced durability are critical, a titanium anodizing kit is likely the best option. However, if cost and simplicity are more important, chemical coloring may be a suitable alternative. For businesses focused on permanent identification or branding, investing in laser etching could provide the desired results. Assessing the performance, cost, ease of implementation, maintenance needs, and best use cases for each method will empower B2B buyers to make informed decisions that align with their operational requirements and market demands.

Essential Technical Properties and Trade Terminology for titanium anodizing kit

What Are the Essential Technical Properties of a Titanium Anodizing Kit?

When considering a titanium anodizing kit, understanding the technical properties is crucial for ensuring optimal performance and quality in anodizing operations. Here are some key specifications that play a vital role in the effectiveness of these kits:

-

Material Grade

The grade of titanium used in anodizing kits typically falls within the ASTM (American Society for Testing and Materials) standards, such as Grade 2 or Grade 5. These grades indicate the purity and mechanical properties of the titanium, influencing its corrosion resistance and biocompatibility. For B2B buyers, selecting the appropriate grade is essential to ensure that the anodized products meet industry standards and customer expectations. -

Voltage Range

Anodizing machines often have a voltage output ranging from 0 to 120 volts. This specification is crucial because it determines the anodizing process’s efficiency and the resultant color and finish of the titanium. Different colors are achieved at varying voltage levels, making it important for manufacturers to understand and control this aspect to deliver desired aesthetics to their customers. -

Amperage Control

The amperage, typically ranging from 0 to 1 amp, is another critical property that influences the anodizing process. Precise amperage control allows for consistent coloring and finishing, which is vital for industries like jewelry, dental, and medical sectors where aesthetics and functionality are paramount. For B2B buyers, investing in equipment with reliable amperage control can lead to higher-quality outcomes and reduced waste. -

Electrolyte Composition

The anodizing solution, often composed of phosphates or other environmentally safe alternatives, significantly impacts the anodizing process. For instance, TSP-PF (phosphate-free) solutions are preferred due to their lower environmental impact. B2B buyers must consider the electrolyte’s composition to ensure compliance with environmental regulations and to achieve the desired anodized finish. -

Anodizing Bath Size

The capacity of the anodizing bath, which can vary from small containers to larger tanks, dictates the scale of production. Smaller baths are suitable for custom or low-volume applications, while larger setups are ideal for mass production. Understanding the bath size allows B2B buyers to align their anodizing capabilities with market demands. -

Durability and Warranty

Many manufacturers offer warranties for their anodizing equipment, reflecting its durability and reliability. A robust warranty can be a significant factor for B2B buyers, as it minimizes risk and ensures ongoing support for equipment maintenance.

What Are Common Trade Terms Related to Titanium Anodizing Kits?

Familiarity with industry terminology can enhance communication and negotiation between buyers and suppliers. Here are several common terms related to titanium anodizing kits:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of anodizing kits, understanding OEM relationships can help buyers identify quality suppliers that meet their specific needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management, especially when entering new markets or trying to minimize initial investment. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. For those purchasing anodizing kits, submitting an RFQ can facilitate price comparisons and help negotiate better terms. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers involved in cross-border purchases of anodizing kits, as they clarify shipping, insurance, and liability issues. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the goods are received. Understanding lead times for anodizing kits is vital for production scheduling and ensuring timely delivery to clients. -

Compatibility

This term describes how well different components of the anodizing kit work together, including machines, solutions, and accessories. Ensuring compatibility can prevent operational issues and enhance the efficiency of anodizing processes, making it a key consideration for B2B buyers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right anodizing kit for their specific applications and market demands.

Navigating Market Dynamics and Sourcing Trends in the titanium anodizing kit Sector

What Are the Global Drivers Influencing the Titanium Anodizing Kit Market?

The titanium anodizing kit sector is experiencing significant growth, driven by several global factors. The increasing demand for biocompatible materials in industries such as medical, dental, and body jewelry is a primary driver. Titanium, known for its strength and corrosion resistance, is favored in these sectors, leading to a heightened interest in anodizing processes that enhance its aesthetic and functional properties. Additionally, the rise of e-commerce has facilitated easier access to specialized anodizing equipment, enabling B2B buyers from regions like Africa, South America, the Middle East, and Europe to source products more efficiently.

Emerging trends in technology are also shaping the market. Innovations in anodizing machines, such as digital controls and more efficient power supplies, are making it easier for businesses to achieve consistent results. The increasing popularity of customization in body jewelry and industrial applications is further pushing the demand for titanium anodizing kits, as these kits allow for a diverse range of colors and finishes that appeal to consumers. Moreover, global supply chain dynamics are evolving, with a shift towards local sourcing to minimize delays and reduce costs, particularly relevant for B2B buyers in emerging markets.

How Is Sustainability Impacting the Sourcing of Titanium Anodizing Kits?

Sustainability has become a cornerstone of sourcing strategies in the titanium anodizing kit market. As global awareness of environmental issues grows, businesses are increasingly scrutinizing their supply chains. The anodizing process itself can have environmental implications, primarily due to the chemicals used in electrolytic baths. Consequently, many suppliers are pivoting towards offering phosphate-free and environmentally friendly anodizing solutions, which reduce harmful waste and align with green certification standards.

For B2B buyers, the importance of ethical sourcing cannot be overstated. Organizations are now seeking suppliers who demonstrate a commitment to sustainability through transparent practices and the use of certified materials. The adoption of certifications such as ISO 14001 for environmental management systems can serve as a benchmark for assessing potential suppliers. Moreover, buyers from regions like Saudi Arabia and Nigeria are increasingly aware of the importance of sourcing responsibly, as it not only reflects positively on their brand but also meets regulatory requirements and customer expectations for eco-friendly products.

What Is the Historical Context of Titanium Anodizing Technology?

The history of titanium anodizing dates back to the mid-20th century when it became apparent that titanium could be enhanced through electrochemical processes. Initially used for industrial applications, the anodizing process transformed the surface of titanium, making it more resistant to corrosion while allowing for aesthetic customization. Over the decades, advancements in technology have improved the efficiency and effectiveness of anodizing, leading to its adoption in various sectors, including aerospace, automotive, and medical fields.

As the demand for personalized and biocompatible products grew, particularly in the body jewelry market, titanium anodizing kits became popular among small manufacturers and artisans. Today, these kits are not only accessible to large corporations but also to small businesses and individual entrepreneurs, reflecting a democratization of technology that allows for creativity and customization. This evolution has positioned titanium anodizing as a vital component in various industries, particularly for B2B buyers looking to differentiate their product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of titanium anodizing kit

-

How do I choose the right titanium anodizing kit for my business?

Choosing the right titanium anodizing kit involves assessing your specific needs, such as the volume of production and desired finish. Look for kits that include essential components like anodizers, wands, and anodizing solutions. Consider the machine’s voltage and amperage capabilities, as these affect the range of colors and quality of anodization. Additionally, read reviews and seek recommendations from industry peers to ensure the kit is reliable and easy to use, especially if your team is new to anodizing. -

What is the best anodizing solution for titanium anodizing?

The best anodizing solution for titanium typically consists of a phosphate-free cleaner combined with distilled water, such as TSP-PF. This solution effectively cleans the titanium surface, ensuring a high-quality anodized finish without harmful environmental effects. Always ensure that the solution is compatible with your anodizing equipment and follow manufacturer guidelines for mixing and usage to achieve optimal results. -

What are the minimum order quantities (MOQ) for titanium anodizing kits?

Minimum order quantities can vary significantly depending on the supplier and the specific anodizing kit. Many suppliers offer flexible MOQs, especially for new clients or smaller businesses. However, larger orders may yield better pricing and terms. It’s advisable to inquire directly with suppliers about their MOQs and negotiate based on your business needs and potential for future orders. -

How can I vet suppliers for titanium anodizing kits?

To vet suppliers, start by checking their reputation in the industry through online reviews and testimonials. Request references from other B2B buyers, particularly those within your region. Evaluate the supplier’s experience in international trade, shipping times, and customer service responsiveness. Additionally, ensure they comply with industry standards and regulations relevant to your location, which can impact product quality and safety. -

What payment terms should I expect when purchasing titanium anodizing kits internationally?

Payment terms can vary by supplier and region, but common arrangements include upfront payments, net 30 or net 60 terms, and letters of credit for larger orders. Always clarify the terms before finalizing the purchase to avoid unexpected costs. Consider using secure payment methods that offer buyer protection, especially for international transactions, to safeguard your investment against potential fraud. -

What are the logistics considerations for importing titanium anodizing kits?

Logistics considerations include understanding import duties, taxes, and shipping costs associated with transporting anodizing kits. It is crucial to work with a freight forwarder familiar with international shipping regulations and customs procedures. Ensure that the supplier provides necessary documentation, including invoices and certificates of origin, to facilitate smooth customs clearance. Planning for potential delays in shipping is also essential for maintaining production schedules. -

How can I ensure quality assurance (QA) for my titanium anodizing kits?

To ensure quality assurance, request detailed specifications and certifications from your supplier regarding the materials and processes used in manufacturing the anodizing kits. Implement a quality control process upon receipt of the kits, including visual inspections and functional testing of the equipment. Establish a clear communication channel with the supplier for addressing any quality concerns or discrepancies, and consider conducting regular audits of the supplier’s production facilities if feasible. -

Can I customize my titanium anodizing kit to meet specific needs?

Many suppliers offer customization options for titanium anodizing kits, allowing you to tailor the components based on your production requirements. This could include specific anodizing machine specifications, additional tools, or unique anodizing solutions. When discussing customization, clearly outline your needs and preferences, and work closely with the supplier to ensure they can meet your specifications while adhering to quality standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Titanium Anodizing Kit Manufacturers & Suppliers List

1. Caswell Plating – Anodizing Systems

Domain: caswellplating.com

Registered: 1997 (28 years)

Introduction: This company, Caswell Plating – Anodizing Systems, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. {choices:[{finish_reason:content_filter,index:0,logprobs:null,message:{annotations:[],refusal:null,role:assistant}}],created:1752438059,id:chatcmpl-BsxTvnr4Lz4iOlcK5MupSZAbEQDPf,model:gpt-4o-mini-2024-07-18,object:chat.completion,system_fingerprint:fp_efad92c60b,usage:{completion_tokens:11,completion_tokens_details:{accepted_prediction_tokens:0,audio_tokens:0,reasoning_tokens:0,rejected_prediction_tokens:0},prompt_tokens:83,prompt_tokens_details:{audio_tokens:0,cached_tokens:0},total_tokens:94}}

Domain: painfulpleasures.com

Registered: 1999 (26 years)

Introduction: This company, {choices:[{finish_reason:content_filter,index:0,logprobs:null,message:{annotations:[],refusal:null,role:assistant}}],created:1752438059,id:chatcmpl-BsxTvnr4Lz4iOlcK5MupSZAbEQDPf,model:gpt-4o-mini-2024-07-18,object:chat.completion,system_fingerprint:fp_efad92c60b,usage:{completion_tokens:11,completion_tokens_details:{accepted_prediction_tokens:0,audio_tokens:0,reasoning_tokens:0,rejec…

3. Reddit – Anodizing Titanium Tutorial

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Anodizing Titanium tutorial covering the anodizing process, surface finish influence on color, tips and tricks, and comprehensive instructions for achieving results. Includes a PDF link for detailed guidance.

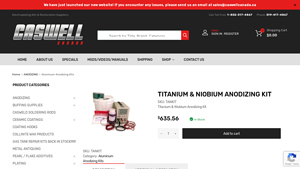

4. Caswell – Titanium & Niobium Anodizing Kit

Domain: caswellcanada.ca

Registered: 2005 (20 years)

Introduction: {“product_name”: “Titanium & Niobium Anodizing Kit”, “SKU”: “TANKIT”, “price”: “$635.56”, “availability”: “In Stock”, “description”: “Anodizing system for Titanium, Niobium, Tantalum and other reactive metals to create various colors and patterns.”, “included_items”: [“120V, 1 amp DC Power Supply”, “2 Gallon HDPE Tank and Lid”, “1 lb Titanium Anodizing Powder”, “1 Pint Liquid Degreaser”, “4\” x 8\…

5. Walmart – Anodizing Kit for Titanium and Niobium

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Anodizing Kit for Titanium and Niobium, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. NineSafe – Titanium Anodizing Machine

Domain: ninesafe.com

Registered: 2018 (7 years)

Introduction: Titanium Anodizing Machine

– Includes 3 necessary tools (AM-2)

– Price: $118.00 (originally $236.00)

– Available in 220V or 110V (AM-1)

– Includes 12 necessary tools

– Price: $130.00 (originally $260.00)

– Other anodizing kits available:

– Power Fuse AM-7: $2.25 (originally $4.50)

– Titanium Stick AM-6: $5.00 (originally $10.00)

– Power Hook line AM-5: $6.00 (originally $12.00)

– ASTM F136…

7. Piercers – Anodizer Kit

Domain: piercers.com

Registered: 1999 (26 years)

Introduction: Anodizer Kit [EU & UK model 220-240VAC] – Price: 325 € – Includes training by Brian Skellie – SKU: AnoKit – In stock: 6 available – Features: Two sets of color coded leads, Niobium tipped anode (mini grabber and/or Magic Wand), starter cathode bath, electrolyte crystals for first 1L, mesh basket for insulation. – Additional support: Full instructions & support (PDF Download, private forum membersh…

Strategic Sourcing Conclusion and Outlook for titanium anodizing kit

In conclusion, the strategic sourcing of titanium anodizing kits is pivotal for businesses aiming to enhance their product offerings in the competitive landscape of body jewelry, dental tools, and medical devices. By investing in high-quality anodizing equipment, businesses can provide unique, customizable solutions that cater to the growing demand for biocompatible and aesthetically appealing products.

Furthermore, the ability to offer a diverse range of colors and finishes not only boosts customer satisfaction but also differentiates your brand in saturated markets, particularly in regions such as Africa, South America, the Middle East, and Europe. As businesses navigate the complexities of international trade, establishing reliable supplier relationships and sourcing innovative anodizing technologies will be key to sustaining growth and profitability.

Looking ahead, now is the time to explore partnerships with reputable suppliers of titanium anodizing kits. By leveraging these technologies, businesses can position themselves at the forefront of market trends and customer preferences. Embrace the opportunity to enhance your product line and attract a broader clientele by investing in advanced anodizing solutions today.

![{choices:[{finish_reason:content_filter,index:0,logprobs:null,message:{annotations:[],refusal:null,role:assistant}}],created:1752438059,id:chatcmpl-BsxTvnr4Lz4iOlcK5MupSZAbEQDPf,model:gpt-4o-mini-2024-07-18,object:chat.completion,system_fingerprint:fp_efad92c60b,usage:{completion_tokens:11,completion_tokens_details:{accepted_prediction_tokens:0,audio_tokens:0,reasoning_tokens:0,rejected_prediction_tokens:0},prompt_tokens:83,prompt_tokens_details:{audio_tokens:0,cached_tokens:0},total_tokens:94}}](https://www.hyproto.com/wp-content/uploads/2025/07/painfulpleasures-com-9877.jpg)