Introduction: Navigating the Global Market for titanium anodising kit

In today’s competitive landscape, sourcing a reliable titanium anodising kit presents a significant challenge for international B2B buyers. Whether you are in Nigeria, Germany, or any part of the Middle East or South America, understanding the nuances of titanium anodising technology is essential to ensure high-quality finishes for your products. This comprehensive guide aims to equip you with the knowledge necessary to navigate the global market for titanium anodising kits, covering crucial aspects such as types of kits available, their various applications, supplier vetting processes, and cost considerations.

The anodising process enhances the aesthetic appeal and corrosion resistance of titanium, making it a popular choice in industries ranging from jewelry to medical devices. However, with numerous suppliers and varying specifications, selecting the right kit can be daunting. This guide empowers you to make informed purchasing decisions by providing in-depth insights into the features and functionalities of different anodising kits, as well as practical tips for evaluating suppliers based on their expertise and product offerings.

By addressing common pain points faced by B2B buyers—such as the need for precise control, environmental considerations, and compatibility with local electrical standards—this resource serves as your go-to reference for optimizing your anodising operations. With the right knowledge, you can confidently invest in a titanium anodising kit that meets your unique business needs and enhances your product offerings.

Understanding titanium anodising kit Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SMT Micro Anodizer | Solid state, 0-120 Volts, compact design, full digital control | Jewelry manufacturing, small parts | Pros: High precision, easy to use; Cons: Limited bath size. |

| Commercial Anodizer | Larger capacity, robust build, suitable for high-volume tasks | Mass production, body jewelry | Pros: Ideal for bulk anodizing; Cons: Higher initial investment. |

| Portable Anodizing Kit | Lightweight, user-friendly, battery-operated options available | Fieldwork, remote applications | Pros: Flexibility and mobility; Cons: May lack power for large jobs. |

| DIY Anodizing Kits | Cost-effective, customizable components | Hobbyists, small businesses | Pros: Affordable and adaptable; Cons: Requires technical knowledge. |

| Anodizing Accessory Kits | Complementary tools and materials for anodizing | Enhancing existing setups | Pros: Versatile; Cons: Additional costs for accessories. |

What are the Characteristics and Suitability of SMT Micro Anodizers?

The SMT Micro Anodizer is a compact and precise anodizing solution, ideal for small-scale operations in jewelry manufacturing. With a voltage range of 0-120 Volts and a solid-state design, it allows for fine control over the anodizing process. This kit is particularly suitable for businesses looking to create custom pieces or small batches. Buyers should consider the limited bath size, which may not accommodate larger items, but appreciate the high precision it offers for intricate designs.

How Does a Commercial Anodizer Cater to High-Volume Needs?

Commercial anodizers are built for efficiency and durability, making them perfect for high-volume anodizing tasks, such as body jewelry production. These machines typically feature larger bath capacities and robust construction, allowing for continuous operation. They are ideal for businesses that require consistent quality across large batches. However, potential buyers should be aware of the higher upfront costs and the need for more significant space and power supply, which may not suit smaller operations.

What Advantages Does a Portable Anodizing Kit Offer?

Portable anodizing kits are designed for flexibility, making them suitable for fieldwork or remote applications. They often come in lightweight designs with battery-operated options, allowing for easy transport. These kits are perfect for businesses that need to anodize components on-site or in various locations. However, buyers should keep in mind that while they offer mobility, they may lack the power and capacity necessary for larger anodizing jobs.

Why Choose a DIY Anodizing Kit for Small Businesses?

DIY anodizing kits provide a cost-effective solution for small businesses and hobbyists looking to enter the anodizing market. These kits often include customizable components that allow users to tailor their setup according to specific needs. While they are more affordable, buyers should consider the technical knowledge required to operate these kits effectively. They are best suited for those willing to invest time in learning the anodizing process.

How Can Anodizing Accessory Kits Enhance Existing Setups?

Anodizing accessory kits include tools and materials that complement existing anodizing systems. These kits can enhance the capabilities of a business’s anodizing setup by providing additional features such as specialized leads, baskets for small parts, and protective gear. While they add versatility to the anodizing process, buyers should factor in the additional costs associated with these accessories when planning their budget.

Key Industrial Applications of titanium anodising kit

| Industry/Sector | Specific Application of titanium anodising kit | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Anodizing surgical instruments and implants | Improves biocompatibility and corrosion resistance | Compliance with medical standards (e.g., ASTM F86) |

| Aerospace | Surface treatment for aircraft components | Enhances durability and reduces weight | Need for high-performance anodizing solutions |

| Jewelry and Fashion | Custom color finishing for titanium jewelry | Expands product offerings and aesthetic appeal | Demand for precision in color control and finish |

| Automotive | Anodizing parts for lightweight vehicles | Increases resistance to wear and tear | Consideration for large-scale production capabilities |

| Electronics | Anodizing heat sinks and casings | Improves thermal conductivity and aesthetic quality | Requirements for precise voltage control and safety |

How Is a Titanium Anodising Kit Used in Medical Devices?

In the medical sector, titanium anodising kits are crucial for enhancing the surface properties of surgical instruments and implants. The anodising process creates a thick oxide layer that improves biocompatibility, making devices safer for human use. International buyers, particularly from regions like Africa and Europe, must ensure that their anodising solutions comply with strict medical standards, such as ASTM F86, to avoid regulatory issues and ensure patient safety.

What Benefits Does Anodising Provide in Aerospace Applications?

Aerospace companies utilize titanium anodising kits to treat components that require exceptional durability and lightweight characteristics. The anodised layer not only increases resistance to corrosion but also reduces weight, which is vital for fuel efficiency. Buyers in this sector should consider sourcing high-performance anodising equipment capable of handling large volumes, as production demands can be significant.

How Does the Jewelry Industry Leverage Titanium Anodising Kits?

In the jewelry and fashion industry, titanium anodising kits are employed to create custom color finishes on titanium pieces. This process allows manufacturers to offer unique designs, enhancing the aesthetic appeal of their products. B2B buyers from South America and Europe should focus on suppliers that provide precise voltage control and a variety of electrolytic solutions to achieve consistent and vibrant color outcomes.

Why Is Anodising Important for Automotive Components?

The automotive industry relies on titanium anodising kits for treating lightweight vehicle parts, which enhances their resistance to wear and corrosion. This surface treatment is essential for maintaining performance and longevity in various automotive applications. Buyers should prioritize suppliers who can meet large-scale production demands while maintaining quality and safety standards.

How Do Electronics Manufacturers Benefit from Titanium Anodising?

Electronics manufacturers use titanium anodising kits for anodising heat sinks and casings, which significantly improves thermal conductivity and aesthetic quality. This is especially important in high-performance devices where heat management is crucial. Sourcing considerations for this sector include ensuring that anodising kits provide precise voltage control and comply with safety regulations to prevent any operational hazards.

3 Common User Pain Points for ‘titanium anodising kit’ & Their Solutions

Scenario 1: Navigating Inconsistent Color Results in Anodizing

The Problem: Many B2B buyers in the jewelry and manufacturing sectors face frustration with inconsistent color outcomes when using titanium anodizing kits. This issue often arises from variations in voltage, amperage, and electrolyte concentration. Buyers may find that their end products do not match customer expectations, leading to dissatisfaction and potential loss of business. The inconsistency can stem from a lack of proper training on the anodizing process, equipment calibration, or environmental factors that affect the anodizing bath.

The Solution: To achieve consistent color results, buyers should invest in comprehensive training for their staff on the anodizing process. This includes understanding the precise voltage and amperage settings needed for different colors and ensuring the electrolyte solution is mixed correctly. Additionally, utilizing kits that come with detailed instructional manuals and video tutorials can significantly enhance understanding. Regular calibration of equipment is crucial; buyers should schedule periodic checks of their anodizing machines to ensure they operate within specified parameters. Finally, conducting small test runs before mass production can help identify any potential issues without jeopardizing larger batches.

Scenario 2: Limited Understanding of Safety Protocols in Anodizing

The Problem: B2B buyers often overlook safety protocols when using titanium anodizing kits, leading to hazardous situations. The anodizing process involves chemicals and electricity, and without proper safety measures, there is a risk of chemical burns, electrical shock, or even fires. Companies may not have established safety guidelines or may fail to provide adequate personal protective equipment (PPE) to their employees, creating a significant liability risk.

The Solution: Establishing a robust safety protocol is imperative for any company using anodizing kits. Buyers should prioritize sourcing kits that include comprehensive safety guidelines and ensure that employees are trained in these protocols. This training should cover the handling of hazardous materials, the use of PPE such as gloves and goggles, and emergency procedures in case of accidents. Additionally, companies should regularly review and update their safety protocols to align with industry standards and regulations. Regular safety drills can also reinforce these protocols and ensure that all employees understand the importance of safety in the anodizing process.

Scenario 3: Difficulty Sourcing Quality Anodizing Supplies and Accessories

The Problem: Sourcing high-quality anodizing supplies and accessories can be a significant pain point for B2B buyers. Many buyers find that local suppliers do not stock the necessary components, such as electrolytes, cathodes, or specific anodizing machines, which can delay production timelines. This scarcity can lead to reliance on subpar products that compromise the quality of the anodizing process, ultimately impacting product integrity.

The Solution: To overcome sourcing challenges, buyers should establish relationships with multiple suppliers, including those that specialize in anodizing products. This diversification ensures a reliable supply chain and access to high-quality materials. Additionally, engaging in bulk purchasing agreements can help secure better pricing and availability. Buyers should also explore online platforms that connect them with international suppliers, which may offer a wider variety of anodizing kits and accessories. Keeping abreast of industry trends and supplier innovations can also guide buyers in selecting the best products to meet their needs. Regularly attending industry trade shows can facilitate direct connections with suppliers and provide insight into new products and technologies.

Strategic Material Selection Guide for titanium anodising kit

What Are the Key Materials Used in Titanium Anodising Kits?

When selecting materials for titanium anodising kits, it is crucial to consider their properties, advantages, and limitations in relation to specific applications. Below, we analyze several common materials used in these kits, focusing on their performance and suitability for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance and high tensile strength. It can withstand temperatures up to 870°C (1600°F) without losing its structural integrity, making it suitable for anodising processes that may involve elevated temperatures.

Pros & Cons:

The durability of stainless steel ensures a long lifespan for anodising components. However, it is relatively more expensive than other materials like aluminum. Manufacturing complexity can also be higher, requiring specialized tooling and processes.

Impact on Application:

Stainless steel is compatible with various anodising electrolytes, which enhances its versatility. Its resistance to corrosion ensures that it does not contaminate the anodising bath, preserving the quality of the anodised finish.

Considerations for International Buyers:

Buyers from regions such as Europe and Germany may prefer stainless steel due to stringent compliance with standards like DIN 17440, which governs the properties of stainless steel used in various applications.

2. Titanium

Key Properties:

Titanium itself is lightweight yet incredibly strong, with a melting point of approximately 1668°C (3034°F). It exhibits excellent corrosion resistance and is biocompatible, making it ideal for medical and jewelry applications.

Pros & Cons:

While titanium’s durability and performance are unmatched, it comes with a high price tag. The manufacturing process is complex, often requiring advanced techniques such as CNC machining or specialized welding.

Impact on Application:

Titanium’s properties allow for a smooth anodised finish, which is essential for aesthetic applications like jewelry. Its compatibility with a variety of anodising solutions ensures consistent results.

Considerations for International Buyers:

In markets like Africa and South America, where cost sensitivity is higher, the premium price of titanium may be a barrier. However, its long-term benefits can justify the investment, especially for high-end products.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, particularly when anodised. It can withstand temperatures up to 660°C (1220°F) and is easy to machine, making it a popular choice for anodising kits.

Pros & Cons:

Aluminum is cost-effective compared to stainless steel and titanium, making it accessible for a broader range of businesses. However, its lower strength compared to titanium may limit its use in high-stress applications.

Impact on Application:

Aluminum anodising is widely used in various industries, including automotive and consumer electronics. The anodised layer provides a protective finish that enhances durability and aesthetic appeal.

Considerations for International Buyers:

Compliance with standards such as ASTM B580 is crucial for buyers in Europe and the Middle East. Understanding local regulations regarding aluminum use can help mitigate risks during procurement.

4. Plastic (Polypropylene or PVC)

Key Properties:

Plastics like polypropylene and PVC are resistant to many chemicals and can withstand temperatures up to 100°C (212°F). They are lightweight and non-conductive, making them suitable for certain anodising applications.

Pros & Cons:

The low cost of plastic makes it an attractive option for budget-conscious buyers. However, its lower durability and temperature resistance compared to metals may limit its application scope.

Impact on Application:

Plastics are often used for anodising containers and accessories, providing a non-reactive environment for anodising solutions. They are suitable for smaller-scale operations or educational purposes.

Considerations for International Buyers:

Buyers must ensure that the plastics used comply with local environmental regulations, especially in regions with strict waste management policies.

Summary Table of Material Selection

| Material | Typical Use Case for titanium anodising kit | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Anodising components and accessories | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Titanium | High-end jewelry and medical applications | Lightweight and strong | High cost and complex manufacturing | High |

| Aluminum | General anodising applications | Cost-effective and easy to machine | Lower strength compared to titanium | Medium |

| Plastic (PP/PVC) | Anodising containers and accessories | Low cost and lightweight | Limited durability and temperature resistance | Low |

This comprehensive analysis provides B2B buyers with actionable insights into the material selection for titanium anodising kits, facilitating informed purchasing decisions tailored to their specific operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for titanium anodising kit

When considering the procurement of a titanium anodising kit, B2B buyers must understand the intricate manufacturing processes involved, along with the quality assurance protocols that ensure product reliability and performance. This section provides a comprehensive overview of these aspects, focusing on the key stages of production, techniques employed, and the quality control measures that adhere to international standards.

What Are the Main Stages of Manufacturing a Titanium Anodising Kit?

Material Preparation: What Goes Into the Anodising Kit?

The manufacturing of a titanium anodising kit begins with meticulous material preparation. High-grade titanium, known for its strength and corrosion resistance, is selected as the primary material. Suppliers often perform thorough inspections to ensure that the titanium meets industry standards. This can include checking for impurities and ensuring consistent material properties.

Electrolytic solutions, such as TSP-PF, are also prepared during this stage. These solutions are crucial for the anodising process, requiring careful formulation to maintain effectiveness while adhering to environmental regulations. In some cases, suppliers may utilize recycled materials to promote sustainability, which can be an appealing factor for environmentally-conscious B2B buyers.

Forming: How Are Components Shaped?

Once materials are ready, the forming stage follows, involving various machining and fabrication techniques. Components such as anodisers, leads, and cathodes are often produced using CNC machining or die casting. These techniques allow for high precision, which is essential for ensuring that the anodising equipment functions correctly and produces consistent results.

For instance, the anodiser’s power supply must be manufactured with precision to handle varying voltage requirements (0-120 volts) and maintain a smooth DC output. This precision is crucial for achieving the desired color results during the anodising process, making it a focal point in production.

Assembly: What Does the Assembly Process Involve?

After forming, the assembly stage brings together all components into a complete anodising kit. This process may involve manual assembly or automated systems, depending on the scale of production. Quality checks are often integrated into this stage to ensure that all parts fit together correctly and function as intended.

Specialized tools, such as the Nb Magic Wand, are included in the kits to facilitate the anodising process. Ensuring that these tools are correctly assembled and tested is vital for the end-user experience, as improper assembly can lead to malfunction or safety hazards.

Finishing: How Is the Anodising Kit Finished?

The finishing stage encompasses surface treatments and coatings that enhance durability and aesthetics. For anodising kits, components may undergo treatments to improve resistance to corrosion and wear. This could involve anodizing the anodiser itself to enhance its longevity.

Packaging is also considered during this stage, as the kits need to be securely packed to prevent damage during transportation. Clear labeling with instructions and safety information is essential, especially for international shipments.

What Quality Assurance Protocols Are Applied to Titanium Anodising Kits?

Which International Standards Are Relevant for Quality Assurance?

Quality assurance in the production of titanium anodising kits is guided by several international standards. ISO 9001 is a fundamental standard for quality management systems, ensuring that manufacturers maintain consistent quality throughout their processes. Compliance with ISO standards demonstrates a commitment to quality, which is crucial for B2B buyers.

Additionally, specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the intended use of the anodising kit. These certifications indicate that products meet stringent safety and performance requirements, enhancing buyer confidence.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are critical throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Ensuring that materials meet specifications is essential to prevent issues down the line.

-

In-Process Quality Control (IPQC): Throughout manufacturing, continuous monitoring occurs at various stages to identify any deviations from quality standards. This includes checking the precision of machined components and the proper assembly of the anodising kit.

-

Final Quality Control (FQC): Before shipment, final inspections are conducted to verify that the completed kits meet all specifications and quality standards. This may include functional testing of the anodiser and verifying the integrity of all components.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are some strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should assess the supplier’s adherence to international standards and their internal quality control measures.

-

Quality Reports: Requesting detailed quality reports, including IQC, IPQC, and FQC results, can help buyers understand the supplier’s commitment to quality. These reports should include data on testing methods and outcomes.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes. These inspections can be particularly beneficial for buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of specific quality control nuances when sourcing titanium anodising kits. Regulations can vary significantly between regions, impacting the requirements for certifications and testing. For example, European buyers may prioritize CE certification, while buyers in the Middle East might focus on compliance with local standards.

Furthermore, language barriers and cultural differences can affect communication regarding quality expectations. Buyers should ensure that all specifications are clearly outlined and understood by both parties to avoid potential disputes or misunderstandings.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with titanium anodising kits is crucial for B2B buyers. By evaluating suppliers based on their adherence to international standards, quality control checkpoints, and verification practices, buyers can make informed decisions that meet their specific needs and ensure product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘titanium anodising kit’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure a titanium anodizing kit. Understanding the complexities of anodizing technology and supplier capabilities is essential for making informed purchasing decisions. By following these steps, you can ensure that you select the right kit that meets your operational needs and quality standards.

Step 1: Define Your Technical Specifications

Establish clear technical requirements for your anodizing kit, including voltage range, amperage, and bath size. This step is vital as different applications may require different specifications, affecting both the performance and quality of the anodized finish. Consider factors such as:

– Material Types: Ensure compatibility with titanium and niobium.

– Production Volume: Determine if you need a kit suitable for small batches or larger production runs.

Step 2: Research Supplier Credentials

Conduct thorough research on potential suppliers to verify their credentials and industry experience. This is crucial to ensure you are dealing with reputable manufacturers who can deliver quality products and support. Look for:

– Certifications: Check for ISO certifications and compliance with international standards.

– Industry Reputation: Seek feedback from other businesses in your region or industry.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, vet them thoroughly to avoid future complications. Request detailed company profiles, case studies, and references from buyers in similar industries. Don’t just rely on their website; instead, assess:

– Product Range: Ensure they offer the specific anodizing kits and accessories you need.

– Customer Support: Evaluate their ability to provide technical support and after-sales service.

Step 4: Assess Product Features

Examine the features of the anodizing kits you are considering. Pay attention to essential components that can enhance your anodizing process, such as:

– Voltage Control: Look for kits with precise voltage control for better color options.

– Safety Features: Ensure the kit includes safety measures, such as spark guard mesh and proper insulation.

Step 5: Inquire About Material Quality

Quality of materials used in the anodizing kit directly impacts the durability and effectiveness of the anodizing process. Inquire about:

– Electrolyte Solutions: Ensure the electrolyte is environmentally friendly and effective for anodizing titanium.

– Cathode and Anode Materials: Verify that high-quality materials are used to prevent corrosion and enhance conductivity.

Step 6: Request Samples or Demonstrations

Whenever possible, request samples or demonstrations of the anodizing kit in action. This step is critical for assessing the performance and suitability of the kit for your specific applications. Pay attention to:

– Color Consistency: Evaluate the uniformity of anodized colors.

– Ease of Use: Assess the user-friendliness of the kit, including setup and operation.

Step 7: Compare Pricing and Warranty Options

Finally, gather quotes from multiple suppliers and compare pricing alongside warranty options. This will help you find the best value for your investment while ensuring that you have adequate protection in case of defects. Consider:

– Total Cost of Ownership: Factor in not just the purchase price but also maintenance and operational costs.

– Warranty Terms: Look for suppliers that offer comprehensive warranties, indicating confidence in their product quality.

By following this checklist, B2B buyers can navigate the procurement process for titanium anodizing kits more effectively, ensuring a successful investment that meets their operational needs.

Comprehensive Cost and Pricing Analysis for titanium anodising kit Sourcing

What Are the Key Cost Components for Sourcing a Titanium Anodizing Kit?

When considering the procurement of a titanium anodizing kit, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of materials used in anodizing kits significantly influences the overall cost. High-grade titanium, electrolytic solutions, and quality cathodes are essential for achieving optimal anodization results. Suppliers often provide different grades of materials, which can affect pricing.

-

Labor: Labor costs encompass both the manufacturing and assembly processes. Skilled technicians may be required to operate and maintain anodizing equipment, impacting the overall labor costs associated with the kit.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Manufacturers with advanced technology may have higher overhead costs but can offer better quality and efficiency.

-

Tooling: Specialized tooling is often necessary for anodizing processes. The investment in these tools can be significant and is typically factored into the pricing of the kit.

-

Quality Control (QC): Ensuring that all components meet industry standards requires rigorous QC processes, which can add to the cost. Certifications such as ISO or ASTM standards can also influence pricing, as they assure buyers of the product’s quality.

-

Logistics: Shipping costs can vary widely depending on the location of the supplier and the destination. International buyers should consider import duties, shipping fees, and potential delays when calculating total costs.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on supplier reputation, market demand, and the exclusivity of the products offered.

How Do Price Influencers Affect the Cost of Titanium Anodizing Kits?

Several factors can influence the price of titanium anodizing kits:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to reduced unit prices. Buyers should evaluate their needs against the potential savings from larger orders.

-

Specifications and Customization: Customized kits tailored to specific applications may incur additional costs. Buyers should assess whether standard kits meet their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials typically command higher prices. Moreover, certifications related to environmental standards or product safety can also affect costs.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is essential for determining who is responsible for shipping, insurance, and tariffs. This can significantly impact the final cost.

What Are the Best Practices for Negotiating Prices on Titanium Anodizing Kits?

International B2B buyers should consider the following tips to enhance their purchasing strategy:

-

Conduct Thorough Market Research: Understanding the market landscape can provide leverage during negotiations. Compare prices from multiple suppliers to identify competitive offers.

-

Focus on Total Cost of Ownership (TCO): Evaluate not only the initial purchase price but also the long-term costs associated with maintenance, operation, and potential downtime.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow and reduce financial strain, especially for buyers operating in developing markets.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield additional benefits such as priority service or discounts.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import tariffs, and local regulations that can affect pricing. This is especially relevant for buyers in regions like Africa and South America, where such factors can vary significantly.

Conclusion: What Should Buyers Keep in Mind When Sourcing Anodizing Kits?

As you explore sourcing options for titanium anodizing kits, remember that prices can vary widely based on the factors outlined above. Always seek comprehensive quotes and assess the total cost, including logistics and potential tariffs. Additionally, consider the long-term implications of your purchase to ensure that you are making a cost-effective decision. While this analysis provides indicative pricing, actual costs may differ based on specific requirements and supplier negotiations.

Alternatives Analysis: Comparing titanium anodising kit With Other Solutions

Exploring Alternatives for Titanium Anodising Kits

When it comes to enhancing the surface properties of titanium, particularly in applications like jewelry and aerospace, various methods can be employed. Each option offers unique advantages and drawbacks. This comparison aims to provide B2B buyers with a clear understanding of how titanium anodising kits measure up against other viable solutions.

Comparison Table

| Comparison Aspect | Titanium Anodising Kit | Chemical Etching | Powder Coating |

|---|---|---|---|

| Performance | Provides vibrant colors and smooth finishes, enhancing corrosion resistance and aesthetic appeal. | Effective for creating intricate designs and textures, but less color variety. | Durable, thick coating that provides excellent protection and can be colored. |

| Cost | Moderate initial investment; costs can vary based on components and materials. | Generally lower upfront costs, but can incur additional costs for chemicals and safety measures. | Higher initial investment due to equipment and materials needed, but cost-effective for large batches. |

| Ease of Implementation | Requires some technical knowledge to operate the equipment correctly; involves multiple steps. | Relatively straightforward process but requires safety precautions due to chemicals. | More complex setup; requires specialized equipment and training for application. |

| Maintenance | Requires regular maintenance of equipment and careful handling of chemicals; ongoing costs for supplies. | Minimal maintenance, but proper storage of chemicals is crucial for safety and effectiveness. | Low maintenance once equipment is set up, but regular checks are necessary to ensure quality. |

| Best Use Case | Ideal for applications requiring high aesthetic quality, such as jewelry and medical implants. | Best for functional parts where surface texture is critical, such as in aerospace components. | Suitable for large-scale production where durability and color are essential, such as automotive parts. |

Detailed Breakdown of Alternatives

1. Chemical Etching

Chemical etching is a process that uses acids or other chemicals to remove material from the surface of titanium. This method is particularly effective for achieving intricate designs and textures, making it a popular choice in industries requiring detailed customization. However, while it is often more cost-effective upfront, the ongoing costs related to chemical procurement and safety measures can accumulate. Additionally, chemical etching does not provide the same range of vibrant colors as anodising, which can be a disadvantage for applications where aesthetics are paramount.

2. Powder Coating

Powder coating involves applying a dry powder to a surface and curing it under heat to form a hard, protective layer. This method offers superior durability and can withstand harsh environmental conditions, making it ideal for automotive and industrial applications. While powder coating can be more costly to set up due to specialized equipment, it is highly efficient for high-volume production runs. However, it may not achieve the fine details or the aesthetic qualities that anodising provides, particularly for intricate jewelry designs.

Conclusion: How to Choose the Right Solution

Selecting the appropriate surface treatment for titanium depends on the specific requirements of your application. For B2B buyers, understanding the trade-offs between performance, cost, and ease of implementation is crucial. If vibrant colors and a smooth finish are critical, a titanium anodising kit may be the best choice. Conversely, for applications focusing on durability or intricate designs, chemical etching or powder coating might be more suitable. Ultimately, buyers should assess their unique needs, budget constraints, and production scale to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for titanium anodising kit

What Are the Key Technical Properties of a Titanium Anodising Kit?

When considering a titanium anodising kit, understanding its technical properties is crucial for B2B buyers. Here are several critical specifications that influence performance and suitability for various applications:

-

Voltage Range (0-120 Volts)

The voltage range of an anodising kit is vital for achieving different colors and finishes on titanium. The ability to adjust voltage allows for greater control over the anodizing process, enabling users to customize the appearance of their products. For international buyers, especially those in regions with varying electrical standards, knowing the voltage compatibility is essential for operational efficiency. -

Current Output (0-1 Amp)

The current output is another important parameter that affects the anodizing process. A low amp output is generally sufficient for small parts, while larger batches or intricate designs may require higher outputs. Understanding this specification helps businesses select a kit that meets their production needs without compromising quality. -

Electrolyte Composition (TSP-PF)

The electrolyte used in anodising, such as TSP-PF, is critical for creating a stable anodic layer on titanium. Environmentally friendly electrolytes are increasingly preferred, as they reduce environmental impact while maintaining effective anodization. B2B buyers should consider the availability and compliance of these materials with local regulations. -

Bath Size (Up to 1.5 Quarts)

The size of the anodizing bath determines the volume of parts that can be processed simultaneously. A larger bath can accommodate multiple items, enhancing productivity for businesses with high throughput requirements. Buyers must assess their operational capacity and how it aligns with the bath size offered in the kit. -

Material Grade and Durability

The materials used in the anodising kit, including the cathodes and anodes, directly impact the longevity and reliability of the equipment. High-grade materials ensure consistent performance and reduce maintenance costs. Understanding material specifications is crucial for B2B buyers, especially in industries where durability is paramount. -

Portability and Weight (Approx. 15 lbs)

The weight and design of the anodising kit influence its portability and ease of use. A lighter, compact design is beneficial for businesses that may need to move equipment frequently or operate in limited spaces. Buyers should consider their operational environment and storage capabilities when evaluating this aspect.

What Common Trade Terms Should B2B Buyers Know When Purchasing a Titanium Anodising Kit?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms associated with purchasing anodising kits:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, knowing whether a supplier is an OEM can influence the quality and reliability of the anodising kit. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units that a supplier is willing to sell. This is particularly relevant for businesses looking to manage inventory costs effectively. Understanding MOQ can help buyers negotiate better terms and plan their purchasing strategy. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. This is an essential step in the procurement process, enabling buyers to compare costs and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and risk management. Familiarity with these terms helps B2B buyers understand their obligations and negotiate better shipping arrangements. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses that rely on timely deliveries for production schedules, understanding lead times is critical for effective supply chain management. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and its durability. Knowing the warranty terms can protect buyers from future costs associated with defects or failures, making it a key consideration in any purchase decision.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the titanium anodising kit Sector

What Are the Current Market Dynamics and Key Trends Influencing Titanium Anodizing Kit Sourcing?

The titanium anodizing kit market is experiencing robust growth, driven by increasing applications across various industries, including aerospace, automotive, medical, and jewelry manufacturing. The need for lightweight, corrosion-resistant materials has amplified the demand for titanium anodizing, particularly in regions such as Africa, South America, the Middle East, and Europe. For international B2B buyers, understanding these dynamics is crucial as they navigate sourcing decisions.

Key trends shaping the market include the rise of advanced anodizing technologies, such as digital voltage control systems, which enhance precision in color options and anodization quality. Suppliers are increasingly offering comprehensive kits that include not just anodizing machines but also essential accessories, such as electrolytic solutions and safety equipment. This trend reflects a shift towards providing end-to-end solutions for businesses, streamlining the procurement process for buyers.

Moreover, the growing emphasis on customization is evident, with many manufacturers offering tailored anodizing solutions that cater to specific industry needs. B2B buyers from diverse sectors are looking for suppliers who can provide not only the products but also technical expertise and educational support to optimize their anodizing processes. The rise of e-commerce platforms is facilitating easier access to these specialized kits, allowing buyers to compare products and prices more efficiently, a trend that is particularly beneficial for emerging markets.

How Is Sustainability Influencing Titanium Anodizing Kit Sourcing Decisions?

Sustainability is becoming a cornerstone of B2B purchasing decisions in the titanium anodizing kit sector. The environmental impact of anodizing processes, particularly concerning the disposal of chemicals and energy consumption, has prompted buyers to seek out suppliers who prioritize eco-friendly practices. Many companies are now adopting green certifications and using environmentally safe electrolytes in their anodizing kits, which reduce harmful emissions and waste.

Ethical sourcing is also gaining traction, with businesses increasingly scrutinizing their supply chains. Buyers are looking for manufacturers that adhere to sustainable practices, such as utilizing recycled titanium and minimizing water usage in their processes. The demand for transparency in sourcing is leading to partnerships with suppliers who can demonstrate their commitment to sustainable practices, thus enhancing brand reputation and customer loyalty.

Furthermore, the integration of renewable energy sources in anodizing operations is becoming a competitive advantage. Suppliers who invest in solar or wind energy to power their anodizing facilities are appealing to environmentally conscious buyers. This trend not only helps reduce operational costs but also aligns with the global push towards sustainability in manufacturing.

What Is the Historical Context of the Titanium Anodizing Kit Market?

The history of titanium anodizing can be traced back to the mid-20th century when advancements in materials science highlighted titanium’s unique properties, such as its strength and corrosion resistance. Initially, anodizing was primarily used in aerospace and military applications, where performance and reliability were paramount. Over the years, the process has evolved, with significant technological advancements that have made anodizing accessible to a broader range of industries.

As the jewelry and medical sectors began to adopt titanium for its biocompatibility and aesthetic appeal, the demand for anodizing kits surged. This evolution has led to the development of specialized anodizing machines and kits designed for both small-scale artisans and large manufacturing operations. Today, the market is characterized by a diverse range of products that cater to various applications, reflecting the growing importance of titanium anodizing in multiple sectors. Understanding this historical context allows B2B buyers to appreciate the innovations and trends that continue to shape the market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of titanium anodising kit

-

How do I choose the right titanium anodizing kit for my business needs?

Selecting the right titanium anodizing kit involves assessing your specific requirements, such as the types of products you will anodize, production volume, and color options desired. Consider the power supply specifications, bath size, and included accessories like Magic Wands and strainers. For businesses aiming for precision and diverse color finishes, look for kits with fine voltage control and digital meters. Additionally, evaluate the warranty and support offered by the supplier, as these factors can impact long-term operational efficiency. -

What is the best titanium anodizing kit for small-scale operations?

For small-scale operations, a compact anodizing kit with a bath size of 1.5 quarts and a voltage range of 0-120 volts is ideal. The SMT Micro Anodizer, for example, offers precision control, making it suitable for one-off projects or limited production runs. Look for kits that include essential accessories like color-coded leads and safety gloves. Ensure that the kit is user-friendly and comes with comprehensive instructions to facilitate ease of use, especially if you’re new to anodizing. -

What are the typical lead times for ordering titanium anodizing kits internationally?

Lead times for international orders of titanium anodizing kits can vary significantly based on the supplier’s location, your destination, and shipping methods. Typically, you can expect anywhere from 2 to 6 weeks for standard shipping. However, factors such as customs clearance and local regulations can also affect delivery times. To minimize delays, inquire about expedited shipping options and ensure that all necessary import documentation is prepared in advance. -

What should I consider when vetting suppliers for titanium anodizing kits?

When vetting suppliers, prioritize their experience and reputation in the anodizing equipment market. Check for certifications and quality assurance processes that ensure product reliability and safety. Request references or case studies from previous clients to gauge their service quality. Additionally, assess their customer support options, including technical assistance and warranty policies. It’s also wise to compare pricing and terms to ensure you receive a competitive offer that aligns with your budget and operational needs. -

Can I customize my titanium anodizing kit to fit specific requirements?

Many suppliers offer customization options for titanium anodizing kits to meet specific business needs. This can include adjustments to the anodizer’s voltage range, bath size, and included accessories. If your business requires unique features or additional components, communicate these needs during the ordering process. Some suppliers may also provide tailored training or support services to help you effectively utilize the customized kit. -

What are the minimum order quantities (MOQ) for titanium anodizing kits?

Minimum order quantities for titanium anodizing kits can vary by supplier. Some may have no MOQ, allowing you to purchase a single kit, while others might require bulk orders, especially for wholesale pricing. It’s advisable to discuss your purchasing plans with suppliers to understand their MOQ policies. If your business expects to scale production in the future, negotiating for favorable terms on larger quantities may also be beneficial. -

What payment terms should I expect when sourcing titanium anodizing kits?

Payment terms for titanium anodizing kits can differ widely among suppliers. Common terms include full payment upfront, a deposit with the balance due upon delivery, or net payment terms allowing payment within a specified period after receipt of goods. Always clarify these terms before finalizing an order, and consider using secure payment methods to protect your financial interests. Establishing a good relationship with your supplier may also provide leverage for more favorable terms in future transactions. -

How can I ensure quality assurance when purchasing titanium anodizing kits?

To ensure quality assurance, request detailed product specifications and certifications from the supplier, such as ISO standards. Review their quality control processes, including pre-shipment inspections and testing of equipment. Many reputable suppliers provide warranties that cover defects or malfunctions, which can be an indicator of their confidence in product quality. Additionally, consider requesting samples or trial runs to evaluate the kit’s performance before committing to larger orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Titanium Anodising Kit Manufacturers & Suppliers List

1. Caswell Plating – 20 Gallon Anodizing System

Domain: caswellplating.com

Registered: 1997 (28 years)

Introduction: This company, Caswell Plating – 20 Gallon Anodizing System, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. {choices:[{finish_reason:content_filter,index:0,logprobs:null,message:{annotations:[],refusal:null,role:assistant}}],created:1752441211,id:chatcmpl-BsyIlR4OYxzfwiqjHmdXzfCRXMB3E,model:gpt-4o-mini-2024-07-18,object:chat.completion,system_fingerprint:fp_efad92c60b,usage:{completion_tokens:12,completion_tokens_details:{accepted_prediction_tokens:0,audio_tokens:0,reasoning_tokens:0,rejected_prediction_tokens:0},prompt_tokens:66,prompt_tokens_details:{audio_tokens:0,cached_tokens:0},total_tokens:78}}

Domain: painfulpleasures.com

Registered: 1999 (26 years)

Introduction: Professional Anodizing Machines & Equipment for Titanium & Niobium.

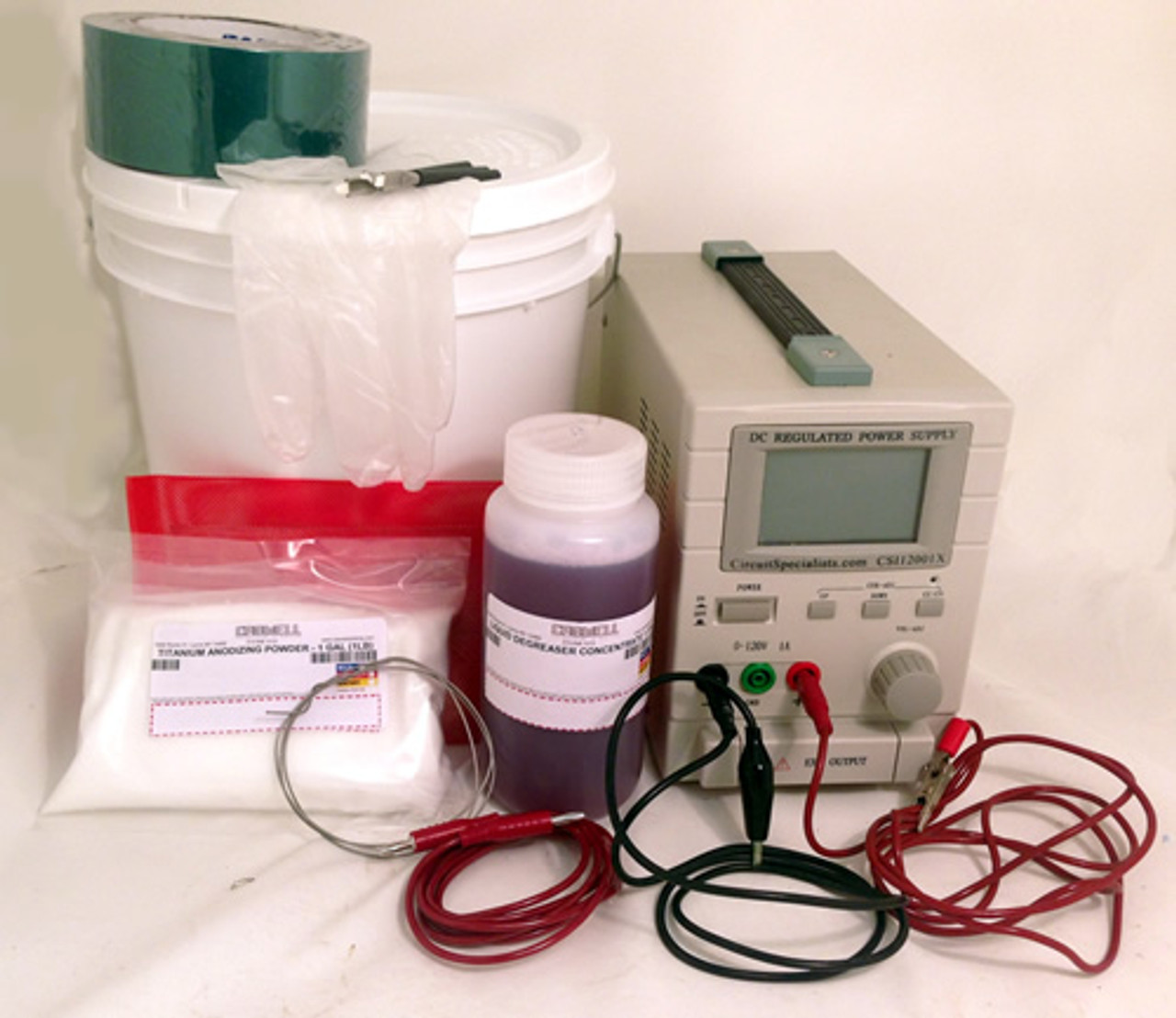

3. Metal Mafia – Titanium Anodizing Machine Kit

Domain: metalmafia.com

Registered: 2002 (23 years)

Introduction: Product Name: Titanium Anodizing Machine Kit

SKU: SMTKIT

Price: $335.45

Description: This anodizing kit is perfect for changing color options and providing precision anodization.

Contents of the Kit:

– 1 anodizer machine

– 1 TSP-PF electrolytic solution (1lb box)

– 1 small anodizing bath bowl with cover

– 1 Metal Mafia black towel (16 x 24)

– 1 Magic Wand

– 2 mesh strainers (4″ and 5.5″)

S…

4. Piercers – Anodizer 220V

Domain: piercers.com

Registered: 1999 (26 years)

Introduction: Anodizer 220V

– Power supply for anodizing body jewelry

– Voltage range: 0 to 120 Volts

– Full digital voltage and amperage meters

– Extremely fine controls for more color options and precision

– Anodizes titanium parts before sterilization and wear, rendering the surface smoother and passive

– Removes microscopic particulate matter missed by other cleaning methods

– Includes: two sets of color co…

5. Reddit – Anodizing Titanium Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Anodizing Titanium tutorial covering the process, surface finish influence on color, tips and tricks for achieving results, and a comprehensive guide for beginners.

6. Best Technology Inc – Titanium Anodizing Equipment

Domain: besttechnologyinc.com

Registered: 2001 (24 years)

Introduction: Titanium anodizing equipment delivers improved surface finish for titanium parts. It offers Type 2 (wear coat) and Type 3 (color) anodizing. The equipment line consists of 10 polypropylene tanks, each with a 30-gallon capacity, featuring a 160-volt, 100-amp rectifier. Custom-built designs allow for left-to-right or right-to-left workflow, and L-shaped configurations are available. Typical features…

7. NineSafe – ASTM F136 Titanium Anodizing Machine Kit

Domain: ninesafe.com

Registered: 2018 (7 years)

Introduction: Product Name: ASTM F136 Titanium Anodizing Machine Anodizing Kits AM-3

Contents: 1 Titanium Wand, 1 Tweezer, 1 Alligator Clip Set, 1 Anodizer Chart with instructions, 1 Cups, 1 Steel Sheet Cathode, 1 Plastic Submersion Container, 1 Nylon Mesh Strainer, 2 Fuse, 1 Plastic Spoon

Price: $14.00 USD

SKU: AM-3

Shipping Origin: China

Packing: 12PCS

Rating: 5.0 (no reviews yet)

Manufacturer: Nine Safe Pier…

Strategic Sourcing Conclusion and Outlook for titanium anodising kit

In navigating the complex landscape of titanium anodizing kits, strategic sourcing emerges as a critical factor for B2B buyers. By understanding the diverse offerings, such as the precision control capabilities and environmentally safe electrolytes, businesses can optimize their procurement strategies to enhance product quality and operational efficiency. The growing demand for customized anodizing solutions, particularly in sectors such as jewelry and medical devices, underscores the importance of investing in high-quality anodizing equipment.

As international markets evolve, suppliers must prioritize service excellence, technical support, and educational resources to empower their clients. For buyers in regions like Africa, South America, the Middle East, and Europe, forging partnerships with reputable manufacturers can facilitate access to advanced technologies and market insights.

Looking ahead, businesses that proactively adapt to industry trends and invest in innovative anodizing solutions will be well-positioned to capitalize on emerging opportunities. Engage with suppliers who not only provide products but also foster a collaborative approach to address your unique challenges. By doing so, you can ensure a competitive edge in the titanium anodizing market, paving the way for sustainable growth and success.

![{choices:[{finish_reason:content_filter,index:0,logprobs:null,message:{annotations:[],refusal:null,role:assistant}}],created:1752441211,id:chatcmpl-BsyIlR4OYxzfwiqjHmdXzfCRXMB3E,model:gpt-4o-mini-2024-07-18,object:chat.completion,system_fingerprint:fp_efad92c60b,usage:{completion_tokens:12,completion_tokens_details:{accepted_prediction_tokens:0,audio_tokens:0,reasoning_tokens:0,rejected_prediction_tokens:0},prompt_tokens:66,prompt_tokens_details:{audio_tokens:0,cached_tokens:0},total_tokens:78}}](https://www.hyproto.com/wp-content/uploads/2025/07/painfulpleasures-com-5454.jpg)