Introduction: Navigating the Global Market for tin coating services

In today’s competitive landscape, international B2B buyers face the daunting challenge of sourcing reliable tin coating services that enhance product durability and performance. As manufacturers across Africa, South America, the Middle East, and Europe strive to elevate their offerings, understanding the nuances of tin coating becomes crucial. This comprehensive guide delves into the various types of tin coating services available, their diverse applications, and the essential criteria for selecting the right suppliers. By exploring aspects such as coating technology, cost structures, and quality assurance, buyers can make informed decisions that align with their operational goals.

The guide is tailored to empower B2B buyers with actionable insights, ensuring they navigate the global market effectively. Whether you are operating in sectors like automotive, aerospace, or consumer goods, understanding the intricacies of tin coating can significantly impact your supply chain and product lifecycle. From identifying reputable suppliers to evaluating the cost-benefit of different coating options, this resource equips you with the knowledge needed to optimize your sourcing strategy. As we venture deeper into the world of tin coating services, you will discover how to leverage these coatings not just for enhanced product performance, but also for gaining a competitive edge in your market.

Understanding tin coating services Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tin Plating | Electrolytic or hot-dip process; provides corrosion resistance | Electronics, automotive, packaging | Pros: Cost-effective, good corrosion resistance. Cons: Limited hardness compared to other coatings. |

| Tin-Nickel Coating | Enhanced corrosion resistance and solderability | Electrical connectors, automotive parts | Pros: Improved wear resistance, excellent solderability. Cons: Higher cost than tin plating. |

| Tin Alloy Coatings | Various alloy combinations (e.g., tin-lead) for specific properties | Aerospace, military, electronics | Pros: Tailored properties for specific applications. Cons: Environmental regulations may restrict usage. |

| Tin Coating with PVD | Physical vapor deposition for enhanced durability | Cutting tools, molds, medical devices | Pros: High hardness, customizable thickness. Cons: More expensive, requires specialized equipment. |

| Tin Coatings with Biocompatible Properties | Safe for medical applications, non-reactive | Medical devices, dental instruments | Pros: Biocompatible, reduces friction. Cons: May be limited to specific applications. |

What Are the Characteristics of Tin Plating and Its Suitability for B2B Buyers?

Tin plating is a widely used coating method that involves either electrolytic or hot-dip processes to apply a thin layer of tin onto metal substrates. This coating provides excellent corrosion resistance, making it suitable for applications in the electronics, automotive, and packaging industries. B2B buyers should consider the cost-effectiveness of tin plating; however, they should be aware that it may not offer the same hardness as other coatings, potentially limiting its use in more demanding environments.

How Does Tin-Nickel Coating Enhance Performance in B2B Applications?

Tin-nickel coatings combine the properties of tin and nickel to enhance corrosion resistance and solderability, making them particularly useful in electrical connectors and automotive parts. This type of coating offers improved wear resistance and is well-suited for applications where soldering is critical. While the benefits are significant, buyers should note that the cost is higher compared to traditional tin plating, which may impact budget considerations.

What Advantages Do Tin Alloy Coatings Offer for Specialized Applications?

Tin alloy coatings, such as those combining tin with lead or other metals, provide tailored properties for specific applications, including aerospace and military sectors. These coatings can enhance performance characteristics such as hardness and resistance to wear. However, due to environmental regulations restricting lead usage, buyers must carefully evaluate compliance with industry standards when considering these coatings.

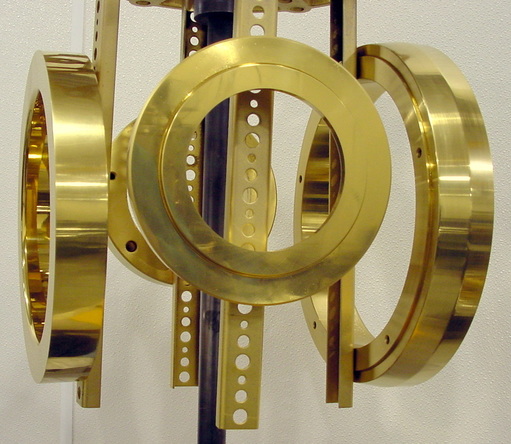

Why Choose Tin Coating with PVD for Durability?

Tin coatings applied through physical vapor deposition (PVD) offer exceptional durability and can be customized in thickness, making them ideal for cutting tools, molds, and medical devices. The PVD process results in high hardness and excellent adhesion properties. While these coatings are more expensive and require specialized equipment, they provide significant long-term benefits that can justify the investment for B2B buyers looking for superior performance.

What Are the Benefits of Tin Coatings with Biocompatible Properties?

Tin coatings designed for biocompatibility are essential in medical and dental applications, as they are non-reactive and safe for use in contact with bodily fluids. These coatings can reduce friction and improve the longevity of medical instruments. While the primary advantage is their safety and performance in medical settings, buyers should consider that their use may be limited to specific applications, potentially narrowing their options in other industries.

Key Industrial Applications of tin coating services

| Industry/Sector | Specific Application of Tin Coating Services | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Coating of engine components and fasteners | Enhanced corrosion resistance and extended service life | Need for high-performance coatings that meet OEM standards |

| Medical Devices | Surgical instruments and implantable devices | Improved biocompatibility and reduced friction | Compliance with health regulations and quality certifications |

| Electronics | Circuit boards and connectors | Increased conductivity and protection against corrosion | Ability to handle complex geometries and environmental factors |

| Packaging | Food and beverage cans | Improved shelf life and resistance to corrosion | Consideration of food safety standards and coating durability |

| Aerospace | Aircraft components and fasteners | Weight reduction and improved wear resistance | Strict adherence to aerospace standards and certifications |

How Are Tin Coating Services Used in the Automotive Sector?

In the automotive industry, tin coating services are primarily employed for coating engine components and fasteners. This application significantly enhances the corrosion resistance of parts exposed to harsh environmental conditions, thereby extending their service life. Buyers in this sector must ensure that the coatings meet OEM standards and provide the necessary performance under various operating conditions. Sourcing from suppliers with proven expertise in automotive applications is crucial for maintaining quality and reliability.

What Role Do Tin Coating Services Play in Medical Device Manufacturing?

Tin coatings are vital in the medical device sector, particularly for surgical instruments and implantable devices. These coatings enhance biocompatibility, reduce friction, and help maintain sharp edges, which is essential for surgical precision. International buyers, especially from regions with stringent health regulations, must prioritize suppliers who comply with quality certifications and can demonstrate a history of successful medical applications. This ensures that the coatings not only meet performance expectations but also adhere to safety standards.

How Are Tin Coating Services Beneficial for Electronics?

In the electronics industry, tin coating services are applied to circuit boards and connectors to improve conductivity and protect against corrosion. This is particularly important in environments where moisture and other corrosive elements are present. Buyers should seek suppliers that can handle complex geometries and provide coatings that can withstand thermal and electrical stresses. Understanding the specific requirements for electronics, including compliance with industry standards, is essential for sourcing effective tin coatings.

What Advantages Do Tin Coating Services Offer in Packaging?

Tin coatings are extensively used in packaging, particularly for food and beverage cans. The coatings improve shelf life by providing a barrier against corrosion, which is crucial for maintaining product integrity. Buyers from the packaging sector must consider food safety standards and the durability of the coatings to ensure they can withstand the rigors of distribution and storage. Sourcing from companies with a strong track record in food-grade coatings is essential for maintaining compliance and quality.

How Do Tin Coating Services Enhance Aerospace Applications?

In the aerospace industry, tin coating services are used for aircraft components and fasteners, providing weight reduction and enhanced wear resistance. These properties are critical for ensuring the longevity and safety of aerospace applications. Buyers in this sector must prioritize sourcing from suppliers who adhere to strict aerospace standards and certifications. This ensures that the coatings not only perform effectively but also contribute to the overall safety and efficiency of aerospace operations.

3 Common User Pain Points for ‘tin coating services’ & Their Solutions

Scenario 1: Inconsistent Coating Quality Impacts Tool Performance

The Problem: B2B buyers often encounter significant variations in the quality of tin coating services. Inconsistent coating thickness can lead to premature wear and tear on tools, resulting in increased downtime and higher operational costs. For manufacturers using coated tools in critical applications, such as medical device production, any inconsistency not only affects productivity but can also compromise product integrity and safety.

The Solution: To mitigate this issue, buyers should prioritize suppliers with established quality assurance protocols. When sourcing tin coating services, request detailed information about the supplier’s coating process, including the technologies used, temperature controls, and post-coating inspections. Look for suppliers that provide a coating thickness measurement report for each batch. Additionally, consider establishing a long-term partnership with a supplier that can offer consistent quality through regular audits and feedback mechanisms. This proactive approach ensures that your coating needs are met reliably, ultimately enhancing tool performance and durability.

Scenario 2: Difficulty in Selecting the Right Coating for Specific Applications

The Problem: Many B2B buyers struggle with choosing the appropriate tin coating for their specific applications. Different industries and tools may require unique properties such as enhanced hardness, corrosion resistance, or biocompatibility. This confusion can lead to suboptimal choices that fail to meet the performance requirements, increasing the risk of product failure and dissatisfaction.

The Solution: To address this challenge, buyers should engage in thorough consultations with coating service providers before making a decision. Create a detailed specification sheet outlining the intended use of the coated tools, including operational conditions, material compatibility, and desired performance characteristics. A reputable supplier will provide expert guidance on which tin coating options best suit your needs. Additionally, consider requesting sample coatings to evaluate performance in real-world conditions before committing to a larger order. This strategic approach minimizes the risk of selecting an unsuitable coating and optimizes tool performance.

Scenario 3: Long Lead Times Affecting Production Schedules

The Problem: Lengthy lead times for tin coating services can disrupt production schedules and delay time-to-market for critical products. B2B buyers often face challenges when suppliers are unable to meet tight deadlines, causing a cascading effect on production and inventory management. This issue is particularly pronounced for companies with just-in-time manufacturing processes where timing is crucial.

The Solution: To alleviate lead time concerns, buyers should prioritize working with coating service providers who offer expedited services or have the capacity for flexible production scheduling. When discussing timelines, clearly communicate your deadlines and the importance of timely delivery. Establishing a collaborative relationship with your supplier can lead to better communication and more efficient production planning. Additionally, consider implementing a just-in-case inventory strategy for critical tools, maintaining a buffer stock that can sustain production during unexpected delays. By actively managing your supply chain and maintaining open lines of communication with your coating service provider, you can minimize the impact of lead times on your production schedules.

Strategic Material Selection Guide for tin coating services

What Are the Key Materials Used in Tin Coating Services?

When selecting materials for tin coating services, it is essential to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials: steel, aluminum, brass, and titanium. Each material presents unique advantages and challenges that can significantly affect product performance and manufacturing processes.

How Does Steel Perform with Tin Coating Services?

Steel is one of the most widely used substrates for tin coating due to its strength and versatility. Key properties include high tensile strength and excellent wear resistance. Steel can withstand high temperatures, making it suitable for applications involving heat exposure.

Pros: Steel’s durability and cost-effectiveness make it a preferred choice for various applications, including automotive and industrial components. Its compatibility with tin coatings enhances corrosion resistance, extending the lifespan of the final product.

Cons: However, steel can be prone to rust if not properly coated, and the coating process may introduce complexities, such as the need for surface preparation to ensure adhesion.

Impact on Application: Steel’s compatibility with various media, including water and oils, makes it suitable for diverse environments. However, care should be taken in high-salinity environments where corrosion risks are elevated.

Considerations for International Buyers: Compliance with standards such as ASTM A653 for galvanized steel is crucial. Buyers in regions like Europe may also need to consider EU regulations on material safety.

What Are the Advantages of Aluminum in Tin Coating Services?

Aluminum is known for its lightweight and corrosion-resistant properties, making it an excellent candidate for tin coating. Its low density and high strength-to-weight ratio are key advantages.

Pros: The primary benefit of aluminum is its resistance to oxidation, which enhances the durability of the coating. It is also relatively easy to machine, making it suitable for intricate designs.

Cons: On the downside, aluminum can be more expensive than steel, and its lower melting point may limit its application in high-temperature environments.

Impact on Application: Aluminum is compatible with various media, including acidic and alkaline solutions, making it ideal for chemical processing applications.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B209 for aluminum sheet and plate. Additionally, preferences for aluminum alloys may vary by region, impacting sourcing decisions.

How Does Brass Compare in Tin Coating Services?

Brass, an alloy of copper and zinc, offers excellent corrosion resistance and a pleasing aesthetic finish. Its properties include good machinability and thermal conductivity.

Pros: The primary advantage of brass is its resistance to corrosion, particularly in marine environments. It is also less prone to galling, making it ideal for applications involving sliding components.

Cons: Brass can be more expensive than steel and aluminum, and its softness may limit its use in high-stress applications.

Impact on Application: Brass is particularly suitable for plumbing and electrical applications due to its conductivity and corrosion resistance.

Considerations for International Buyers: Compliance with standards such as ASTM B36 for brass is essential. Buyers in regions like South America should consider local preferences for brass grades in specific applications.

What Role Does Titanium Play in Tin Coating Services?

Titanium is a high-performance material known for its exceptional strength-to-weight ratio and corrosion resistance. Its properties include high melting point and biocompatibility.

Pros: Titanium’s primary advantage is its ability to withstand extreme conditions, making it suitable for aerospace and medical applications. The inert nature of titanium also enhances the performance of tin coatings.

Cons: However, titanium is significantly more expensive than other materials, and its machining can be complex, requiring specialized tools.

Impact on Application: Titanium’s compatibility with various media, including seawater and aggressive chemicals, makes it ideal for demanding environments.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM B348 for titanium. Additionally, preferences for titanium grades may vary across regions, impacting procurement strategies.

Summary Table of Material Selection for Tin Coating Services

| Material | Typical Use Case for tin coating services | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive parts, industrial components | High strength and durability | Prone to rust if not coated properly | Medium |

| Aluminum | Chemical processing, lightweight structures | Corrosion resistance and lightweight | Higher cost, lower melting point | Medium |

| Brass | Plumbing fixtures, electrical components | Excellent corrosion resistance | More expensive, softer material | High |

| Titanium | Aerospace, medical devices | Exceptional strength and biocompatibility | High cost, complex machining | High |

This guide provides valuable insights for international B2B buyers, helping them make informed decisions about material selection for tin coating services while considering compliance and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for tin coating services

What Are the Key Stages in the Manufacturing Process for Tin Coating Services?

The manufacturing process for tin coating services involves several critical stages that ensure the final product meets the required specifications and quality standards. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Tin Coating?

Material preparation is the first step in the tin coating process. It involves cleaning and treating the surface of the substrate to ensure optimal adhesion of the tin coating. Techniques such as chemical cleaning, abrasive blasting, or mechanical polishing are commonly employed. The goal is to remove any contaminants, such as oils, dirt, or oxidation, which could adversely affect the coating’s performance. For manufacturers, this step is vital as it lays the groundwork for a successful coating application.

What Forming Techniques Are Used in Tin Coating Services?

Once the material is prepared, the forming stage can commence. This stage can include processes such as stamping, machining, or molding, depending on the intended application of the coated product. In the context of tin coating, the substrate is often subjected to various forming techniques that shape the material into its final design before coating. For instance, if the coated product is intended for automotive parts, precision machining might be necessary to achieve the required tolerances.

How Is the Assembly Process Handled in Tin Coating?

After forming, the assembly stage may be necessary, particularly for complex products that consist of multiple components. During this stage, parts are assembled according to specific design requirements. It is crucial that all components are aligned correctly to avoid issues during the coating process and to ensure functionality in the final product. Manufacturers must adhere to strict assembly guidelines to maintain quality and performance standards.

What Finishing Techniques Are Commonly Applied in Tin Coating?

The finishing stage is where the tin coating is applied. Various methods can be utilized, including electroplating, hot-dip galvanizing, or chemical vapor deposition (CVD). Each method has its advantages and is selected based on the desired properties of the final coating, such as thickness, adhesion, and corrosion resistance. For example, electroplating provides a uniform coating with excellent adhesion, while hot-dip galvanizing offers superior corrosion protection. The choice of finishing technique is critical for meeting the performance expectations of the end-user.

What Quality Assurance Measures Are Essential for Tin Coating Services?

Quality assurance (QA) is a crucial aspect of the tin coating service process. Adhering to international standards and implementing robust QA measures ensures that the coated products meet customer specifications and regulatory requirements.

Which International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 are essential benchmarks for quality management systems in manufacturing. Certification to ISO 9001 indicates that a company has established processes to ensure consistent quality in its products and services. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for oil and gas applications can also be critical for ensuring compliance with safety and performance standards.

What Are the Key Quality Control Checkpoints in Tin Coating?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Typical QC checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Monitoring various stages of production to identify any deviations from quality standards. This may involve regular inspections during the coating process.

- Final Quality Control (FQC): Conducting thorough inspections and tests on finished products to verify they meet all quality and performance specifications.

Each of these checkpoints plays a vital role in ensuring that defects are identified and rectified before products reach the market.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods for tin-coated products include:

- Adhesion Testing: Assessing how well the tin coating adheres to the substrate, which can involve tape tests or scratch tests.

- Thickness Measurement: Using tools like micrometers or X-ray fluorescence (XRF) to ensure the coating is within specified thickness ranges.

- Corrosion Resistance Testing: Conducting salt spray tests or other corrosion tests to determine the durability of the coating in various environments.

- Surface Roughness Measurement: Ensuring the surface finish meets the required specifications for performance and aesthetics.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance. Buyers can take several steps to assess supplier quality:

- Audits: Conducting on-site audits of the supplier’s facilities can provide valuable insights into their manufacturing practices and quality management systems.

- Quality Reports: Requesting quality control reports and documentation can help buyers understand the supplier’s QC processes and any issues that may have arisen during production.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s capabilities and adherence to quality standards.

What Are the Unique QC Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Cultural differences, regulatory requirements, and varying quality expectations can all impact the purchasing process. It’s vital for buyers to communicate their quality expectations clearly and to ensure that suppliers are familiar with relevant standards applicable to their markets.

Additionally, establishing strong partnerships with suppliers who have a proven track record of quality assurance can mitigate risks associated with international procurement. By prioritizing quality at every stage of the manufacturing process, B2B buyers can ensure they receive high-quality tin-coated products that meet their specific needs and enhance their operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tin coating services’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure tin coating services. Understanding the nuances of sourcing these services is critical to ensuring quality, compliance, and cost-effectiveness. By following this step-by-step checklist, you can streamline your procurement process and enhance your manufacturing capabilities.

Step 1: Define Your Technical Specifications

Clearly outline the specifications required for your tin coating project. This includes details such as the desired thickness, hardness, and environmental resistance. Providing precise specifications helps suppliers understand your needs and enables them to offer tailored solutions that meet your operational requirements.

- Consider application: Identify whether the coating will be used for tools, medical devices, or other applications, as this influences the coating type.

- Specify performance criteria: Define expectations for wear resistance, friction reduction, and thermal stability.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in tin coating services. Look for companies with a proven track record in your industry and those that have the necessary certifications, such as ISO or NADCAP.

- Evaluate supplier reputation: Check online reviews and testimonials to gauge customer satisfaction.

- Assess industry experience: Prefer suppliers with experience in your specific application area to ensure they understand the unique challenges you face.

Step 3: Evaluate Supplier Capabilities

Before making a commitment, assess the capabilities of potential suppliers. This includes evaluating their technology, equipment, and production processes.

- Check coating technologies: Ensure the supplier uses advanced techniques like Physical Vapor Deposition (PVD) for high-quality coatings.

- Review quality control measures: Inquire about their quality assurance processes to ensure consistent coating performance.

Step 4: Request Samples and Case Studies

Ask suppliers for samples of their previous work and relevant case studies. This will help you assess the quality of their coatings and their ability to meet your specifications.

- Inspect sample quality: Analyze the samples for thickness, adherence, and overall finish.

- Learn from past projects: Review case studies to understand how the supplier has addressed similar challenges faced by other clients.

Step 5: Verify Certifications and Compliance

Ensure that the suppliers you are considering have the necessary certifications and compliance with industry standards. This is essential for guaranteeing product quality and safety, particularly in regulated industries like medical and aerospace.

- Check for industry-specific certifications: Look for relevant certifications such as ISO 9001 or FDA compliance, depending on your industry.

- Inquire about environmental standards: Confirm that the supplier adheres to environmental regulations and sustainability practices.

Step 6: Assess Pricing and Terms of Service

Once you have narrowed down your options, request quotes from potential suppliers. Compare pricing structures, terms of service, and delivery timelines.

- Consider total cost of ownership: Look beyond initial pricing; factor in potential long-term savings from improved tool life and performance.

- Negotiate terms: Discuss payment terms, warranty conditions, and service support to ensure a mutually beneficial agreement.

Step 7: Establish a Communication Plan

Effective communication is vital for successful collaboration with your chosen supplier. Establish a clear communication plan to manage expectations and facilitate ongoing dialogue.

- Set regular check-ins: Schedule periodic updates to monitor progress and address any issues that may arise.

- Designate points of contact: Assign specific contacts on both sides to streamline communication and decision-making processes.

By following this checklist, B2B buyers can enhance their sourcing strategies for tin coating services, ensuring they select the best suppliers to meet their specific needs.

Comprehensive Cost and Pricing Analysis for tin coating services Sourcing

What are the Key Cost Components in Tin Coating Services?

When sourcing tin coating services, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The cost of tin and any additional materials used in the coating process can vary significantly based on purity, source, and market demand. High-quality materials typically command a premium but may result in better performance and durability.

-

Labor: Skilled labor is essential for the application of tin coatings. Labor costs will vary depending on the region, expertise required, and the complexity of the job. High labor costs can often be justified by improved quality and efficiency in the coating process.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Overhead can be a significant portion of the total cost and often varies with the scale of production.

-

Tooling: Initial setup and tooling costs can be substantial, especially for custom projects that require specialized equipment. These costs can be amortized over larger production runs, making it beneficial to negotiate bulk orders.

-

Quality Control (QC): Ensuring the coating meets industry standards necessitates rigorous QC processes. The costs associated with testing and certification can affect the overall pricing, particularly for industries like medical or aerospace, where compliance is mandatory.

-

Logistics: Transportation of materials and finished products can add to the overall cost. International shipping, tariffs, and customs duties are particularly relevant for buyers in Africa, South America, and the Middle East, impacting the total cost.

-

Margin: Finally, suppliers will include a profit margin in their pricing. This margin can fluctuate based on competition, market conditions, and supplier reputation.

How Do Volume and Customization Impact Pricing for Tin Coating Services?

Pricing for tin coating services is heavily influenced by factors such as order volume and the level of customization required.

-

Volume/MOQ: Many suppliers offer tiered pricing structures, where larger orders result in lower per-unit costs. Minimum Order Quantities (MOQ) can also affect pricing; buyers should negotiate to find a balance between their needs and the supplier’s requirements.

-

Specifications and Customization: Custom coatings, which may involve unique formulations or processes, typically incur higher costs. Buyers should clearly outline their specifications to receive accurate quotes and avoid unexpected charges.

-

Quality and Certifications: High-quality coatings that meet international standards often come at a premium. Certifications, especially in industries like medical and aerospace, can add to the cost but are essential for compliance and reliability.

What Are the Key Buyer Tips for Cost-Efficiency in Tin Coating Services?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, cost-efficiency can be achieved through strategic sourcing and negotiation.

-

Negotiation Strategies: Engage suppliers in discussions about pricing based on your volume and long-term needs. Building a good relationship can lead to better terms and discounts.

-

Understanding Total Cost of Ownership (TCO): Evaluate the long-term implications of your coating choices. While a lower initial price may be attractive, consider the durability and performance of the coating, which can affect replacement and maintenance costs.

-

Pricing Nuances for International Buyers: Be mindful of pricing variations due to local economic conditions, currency fluctuations, and trade policies. Additionally, understanding Incoterms (International Commercial Terms) can help clarify responsibilities regarding shipping and insurance, impacting overall costs.

What Are the Important Disclaimers Regarding Indicative Prices?

It’s essential to note that indicative prices for tin coating services can vary widely based on the aforementioned factors. Prices are subject to change based on market conditions, material availability, and supplier pricing strategies. Always request detailed quotes and conduct thorough due diligence before finalizing contracts to ensure you are receiving competitive and fair pricing for your specific needs.

Alternatives Analysis: Comparing tin coating services With Other Solutions

Introduction: Exploring Alternatives to Tin Coating Services

In the realm of industrial coatings, tin coating services are recognized for their durability and corrosion resistance. However, various alternatives exist that may suit specific operational needs better. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their unique applications and business objectives.

Comparison Table

| Comparison Aspect | Tin Coating Services | Titanium Nitride Coating | Zinc Coating |

|---|---|---|---|

| Performance | Good corrosion resistance; enhances tool life | Excellent hardness; wear-resistant | Moderate corrosion resistance; good for outdoor applications |

| Cost | Moderate cost, depending on application | Higher initial cost, but longer lifespan | Generally lower cost, but frequent maintenance may increase overall expense |

| Ease of Implementation | Requires specialized equipment; moderate complexity | Requires advanced technology and skilled operators | Easier to apply; can be done in-house or by a contractor |

| Maintenance | Low maintenance; long-lasting effects | Very low maintenance; high durability | Requires periodic maintenance and reapplication |

| Best Use Case | Ideal for cutting tools and electrical components | Best for high-performance tools and surgical instruments | Suitable for structural steel and outdoor applications |

Detailed Breakdown of Alternatives

Titanium Nitride Coating

Titanium nitride (TiN) coating is a physical vapor deposition (PVD) technique that produces a hard, wear-resistant surface. The primary advantage of TiN is its exceptional hardness, which significantly extends the lifespan of tools. However, the initial investment can be higher than tin coatings, and the application process requires specialized equipment and skilled personnel. TiN is particularly beneficial for high-stress applications, such as cutting tools in manufacturing and surgical instruments in the medical field, where durability and precision are paramount.

Zinc Coating

Zinc coating, often applied via galvanization, offers moderate corrosion resistance and is widely used in various industries, especially for outdoor applications. One of the primary benefits of zinc is its cost-effectiveness and the relative simplicity of application. However, while it provides a protective layer against corrosion, it may not perform as well as tin or titanium nitride coatings in high-wear environments. Regular maintenance and reapplication may be necessary to sustain its protective qualities, making it less suitable for applications requiring minimal downtime.

Conclusion: How to Choose the Right Coating Solution

When selecting a coating solution, B2B buyers should consider factors such as the specific application, required performance characteristics, and budget constraints. Tin coating services offer a balanced approach for many applications, particularly in the electrical and tooling sectors. Conversely, titanium nitride coatings may be the preferred choice for high-performance needs, while zinc coatings are ideal for cost-sensitive projects requiring outdoor durability. Ultimately, the right choice will depend on a thorough analysis of operational requirements and long-term maintenance considerations.

Essential Technical Properties and Trade Terminology for tin coating services

What Are the Key Technical Properties of Tin Coating Services?

When evaluating tin coating services, understanding the essential technical properties can significantly impact decision-making for B2B buyers. Here are some critical specifications to consider:

1. Coating Thickness

Coating thickness typically ranges from 2 to 5 microns for tin coatings. This specification is crucial because it affects the durability and performance of the coated item. A thicker coating can provide better protection against wear and corrosion, which is particularly important in high-stress applications like automotive and industrial components.

2. Hardness

The hardness of tin coatings can vary, but it is generally measured using the Vickers hardness scale, often ranging from 2400 to 2600 HV. Hardness is vital as it determines the coating’s resistance to scratching and wear. For B2B buyers, a harder coating translates into longer tool life and reduced maintenance costs.

3. Coefficient of Friction (COF)

The coefficient of friction for tin coatings typically falls around 0.6 when applied to steel alloys. A lower COF indicates better lubricity, which is essential for applications where components slide against each other. This property can lead to improved operational efficiency and reduced energy consumption in machinery.

4. Biocompatibility

Tin coatings are often biocompatible, meaning they do not react adversely with biological tissues. This property is crucial for industries such as medical devices and food processing, where safety and compliance with health standards are paramount. B2B buyers in these sectors must ensure that the coatings meet regulatory requirements.

5. Deposition Temperature

The deposition temperature for tin coatings typically ranges from 700°F to 800°F (approximately 370°C to 425°C). This factor is essential as it can affect the substrate material’s properties, including its structural integrity. Buyers should consider whether their materials can withstand the necessary temperatures without compromising performance.

What Are Common Trade Terms in Tin Coating Services?

Familiarity with industry jargon can facilitate smoother transactions and clearer communication with suppliers. Here are some common terms used in the tin coating services sector:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tin coating services, understanding whether a supplier is an OEM can help buyers determine if the coating meets specific industry standards and quality requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is particularly important for B2B buyers as it affects budgeting and inventory management. Knowing the MOQ helps companies plan their purchases and avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers for specific products or services. In tin coating, submitting an RFQ can ensure that buyers receive competitive pricing and clear specifications for their coating needs.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, such as who pays for shipping and insurance. Understanding Incoterms is crucial for B2B buyers dealing with international suppliers, as it clarifies the risks and costs associated with shipping coated products.

5. PVD (Physical Vapor Deposition)

PVD is a vacuum coating process used to produce thin films, such as tin coatings. This technology allows for precise control over coating thickness and material properties. Familiarity with PVD can help buyers understand the advantages of different coating methods and make informed choices based on their specific requirements.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting tin coating services, ensuring they choose the right solutions for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the tin coating services Sector

What Are the Current Market Dynamics and Key Trends in Tin Coating Services?

The tin coating services sector is experiencing significant growth driven by several global factors. Increased demand for corrosion-resistant materials in industries such as automotive, construction, and electronics is a primary driver. As manufacturers seek to extend the lifespan and performance of their products, tin coatings have become increasingly popular due to their excellent protective properties. Additionally, the ongoing trend toward lightweight materials in manufacturing is pushing the adoption of tin-coated substrates, particularly in the automotive and aerospace sectors.

Emerging technologies, including advancements in physical vapor deposition (PVD) and chemical vapor deposition (CVD), are revolutionizing how coatings are applied. These processes allow for more precise application, better adhesion, and enhanced performance characteristics, such as improved hardness and wear resistance. As a result, international B2B buyers are increasingly seeking suppliers who can offer these advanced coating technologies. Furthermore, the rise of digital sourcing platforms is transforming how companies connect with coating service providers, making it easier to compare offerings and streamline procurement processes.

International buyers from regions such as Africa, South America, the Middle East, and Europe are particularly focused on sourcing from suppliers who can guarantee quality and consistency. As these regions continue to industrialize, the demand for reliable tin coating services is expected to rise, emphasizing the need for suppliers to meet rigorous international standards.

How Is Sustainability and Ethical Sourcing Influencing Tin Coating Services?

Sustainability is becoming a crucial consideration in the tin coating services sector, as businesses increasingly recognize the importance of environmentally responsible practices. The environmental impact of coatings, including the use of hazardous materials and waste generation, is under scrutiny. Buyers are now prioritizing suppliers who implement sustainable practices, such as using eco-friendly materials and processes that minimize waste and emissions.

Incorporating ‘green’ certifications and materials into the supply chain is also gaining traction. Certifications like ISO 14001 for environmental management systems and the use of non-toxic, biodegradable coatings can enhance a company’s reputation and appeal to environmentally conscious consumers. For B2B buyers, partnering with suppliers who prioritize sustainability can not only mitigate risk but also create opportunities for differentiation in a competitive marketplace.

Ethical sourcing is equally important, as buyers seek transparency in their supply chains. Understanding where materials come from and ensuring fair labor practices are essential for building trust with customers and stakeholders. As the demand for ethically sourced products grows, tin coating service providers must adapt to these expectations to remain competitive in the global market.

What Is the Evolution of Tin Coating Services in the B2B Context?

The evolution of tin coating services can be traced back to the industrial revolution when the need for protective coatings emerged alongside advancements in metalworking. Initially, coatings were applied manually, with limited technology and understanding of material science. Over the decades, the development of more sophisticated application techniques, such as electroplating and later PVD and CVD methods, has transformed the industry.

Today, the tin coating services sector is characterized by its focus on high-performance coatings that meet the demanding requirements of modern manufacturing. As industries evolve, so too do the technologies and techniques employed in coating applications. The shift towards automation and digitalization in sourcing and procurement processes reflects broader trends in the global economy, emphasizing efficiency, quality, and sustainability. This historical context underscores the importance of innovation and adaptability in meeting the ever-changing needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of tin coating services

-

How can I choose the right tin coating service for my business needs?

Selecting the appropriate tin coating service involves evaluating several factors. First, consider the specific requirements of your application, such as the type of materials you need coated and the desired properties (e.g., wear resistance, corrosion resistance). Research potential suppliers’ experience and capabilities, such as their coating thickness options and technological processes. It’s also beneficial to request samples or case studies demonstrating their work in similar industries. Finally, assess their customer service responsiveness and their ability to meet your deadlines. -

What are the advantages of using tin coatings in industrial applications?

Tin coatings offer numerous benefits, including excellent corrosion resistance, reduced friction, and enhanced surface hardness. They are ideal for protecting metal components in harsh environments, extending the lifespan of tools and equipment. Additionally, tin is biocompatible, making it suitable for medical and food-related applications. The coating can also improve the aesthetic appeal of products, which is beneficial for consumer-facing industries. Ultimately, these advantages can lead to lower maintenance costs and improved operational efficiency. -

What are the typical minimum order quantities (MOQs) for tin coating services?

Minimum order quantities for tin coating services can vary widely based on the supplier and the complexity of the coating process. Some suppliers may have MOQs as low as 100 units for standard applications, while more specialized coatings might require larger orders to be cost-effective. When sourcing suppliers, it is important to clarify their MOQs upfront, as this can significantly impact your purchasing decisions and inventory management strategies. Always discuss your specific needs to negotiate favorable terms. -

What payment terms should I expect when working with international tin coating suppliers?

Payment terms can differ significantly between suppliers and regions. Common arrangements include upfront deposits (usually 30-50% of the total cost), followed by the balance upon completion of the order or delivery. Letter of Credit (LC) is a popular method in international transactions, providing security for both parties. Ensure you discuss payment methods that suit your business model and financial capabilities. Additionally, consider the currency exchange rates and transaction fees that may apply when dealing with international suppliers. -

How can I ensure quality assurance in tin coating services?

To guarantee quality assurance in tin coating services, request certifications and quality control processes from potential suppliers. Look for industry-standard certifications such as ISO 9001 or specific coatings-related certifications. Inquire about their testing methods for coating adhesion, thickness, and performance under stress. Establish a clear communication channel for addressing quality concerns and consider conducting periodic audits or site visits. Lastly, ask for references or testimonials from other clients to validate their quality standards. -

What logistics considerations should I keep in mind when sourcing tin coating services internationally?

Logistics play a crucial role in international sourcing. Key considerations include shipping methods, lead times, and customs regulations that may impact delivery. Ensure that the supplier has experience with international shipping and can provide reliable timelines. Discuss who will be responsible for duties and tariffs, and consider using a freight forwarder to streamline the process. Additionally, confirm the packaging standards to prevent damage during transit, especially for delicate or precision-coated items. -

Can I customize my tin coating requirements?

Yes, many tin coating service providers offer customization options to meet specific needs. This includes variations in coating thickness, adhesion properties, and surface finishes. Communicate your requirements clearly, including the intended application and performance expectations. Some suppliers may also provide tailored solutions based on unique materials or manufacturing processes. It’s advisable to collaborate closely with the supplier during the development phase to ensure the final product meets your specifications. -

What should I know about the environmental regulations related to tin coatings?

When sourcing tin coating services, it’s essential to be aware of environmental regulations that may affect your operations. Different countries have varying standards regarding the use of coatings, including restrictions on hazardous materials and waste disposal practices. Ensure that your chosen supplier complies with local and international environmental regulations, such as REACH in Europe or EPA standards in the U.S. Request documentation confirming their adherence to these regulations to avoid potential legal issues and align with your company’s sustainability goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Tin Coating Services Manufacturers & Suppliers List

1. Brazen Firearms – TiN & PVD Coating Services

Domain: brazenfirearms.com

Registered: 2015 (10 years)

Introduction: {“products”:[{“name”:”TiN & other PVD Coating – Handgun Barrel”,”price”:”From $50.00″},{“name”:”TiN and PVD Coating – Handgun Slide”,”price”:”From $80.00″},{“name”:”TiN Coating – AR Barrels”,”price”:”From $40.00″},{“name”:”TiN Coating – Battleworn”,”price”:”$115.00″},{“name”:”TiN Coating- Rifle/Shotgun Parts”,”price”:”From $50.00″},{“name”:”TiN & other PVD Coating – Small Parts”,”price”:”From $10….

2. Tincoat – TiN Coating Solutions

Domain: tincoat.net

Registered: 2001 (24 years)

Introduction: TiN (Titanium Nitride) Coating

– **Properties:**

– Thickness: .0001″ – .0002″ (2 to 5 microns)

– Hardness: 2400 – 2600 Hv (>80 Rc)

– Inert and Stable: Does not react with most materials, oxidizes at ~850°F

– Biocompatible: Suitable for medical, dental, and food applications

– Coefficient of Friction (COF): ~0.6 for steel alloys

– Deposition Temperature: 700 – 800°F

– Appearance: Dark…

3. Oerlikon – BALINIT Coatings

Domain: oerlikon.com

Registered: 1998 (27 years)

Introduction: BALINIT A: The world’s first wear protective PVD coating, launched in 1978, designed for various applications across multiple industries.

BALINIT B: Provides wear protection under extreme conditions, enhancing the performance and longevity of tools and components.

Both coatings reduce abrasion and adhesive wear.

4. Bunty LLC – TiN Coating Services

Domain: buntyllc.com

Registered: 2002 (23 years)

Introduction: TiN Coating Services provide high-quality titanium nitride (TiN) coatings for metal components. TiN coatings enhance physical properties such as color and electrical conductivity, offering a gold-colored, hard surface that is water-resistant and protects against erosion and surface abrasions. The TiN coating process utilizes physical vapor deposition (PVD) to create a thin, tightly bonded film on …

5. Beamalloy – IBED TiN-Plus Coating

Domain: beamalloy.net

Registered: 2004 (21 years)

Introduction: Beamalloy provides advanced IBED coating technology for various industries, focusing on production toll coating services. The coatings are applied in an ISO 9001/2015 and ISO 13485/2016 certified facility. Key offerings include: 1. IBED TiN-Plus coating for orthopedic implants, specifically approved by the FDA for Ti-6Al-4V knee femorals. 2. Coating thickness of 5 microns with a finish of 0.02 mic…

6. Vulcan Machine Werks – TiN Pistol Barrel Service

Domain: vulcanmachinewerks.com

Registered: 2017 (8 years)

Introduction: Product Name: TiN – Pistol Barrel Service

Price: $75.00

Coating Type: Titanium Nitride (TiN)

Description: TiN coating is a well-known physical vapor deposition (PVD) choice, recognized for its good mechanical properties and lustrous gold color. It is formed by combining nitrogen (a non-metallic element) with titanium (a transition metal), resulting in a refractory material. The service covers the …

Strategic Sourcing Conclusion and Outlook for tin coating services

As the global demand for tin coating services continues to rise, businesses must prioritize strategic sourcing to maximize value and ensure high-quality outcomes. The insights gathered from industry leaders illustrate that investing in advanced coating technologies not only enhances the performance of tools but also extends their lifespan, reducing overall operational costs. By leveraging services such as titanium nitride coatings, companies can achieve substantial improvements in wear resistance and friction reduction, making it a vital consideration for sectors ranging from manufacturing to medical devices.

International buyers, particularly those in Africa, South America, the Middle East, and Europe, should engage with multiple suppliers to explore diverse offerings and establish relationships that foster innovation. Collaborating with established providers can facilitate access to cutting-edge technologies and customized solutions tailored to specific industry needs.

Looking ahead, as technology evolves, the potential for enhanced coatings will expand, paving the way for new applications and efficiencies. Now is the time to act—evaluate your sourcing strategies, engage with reputable coating service providers, and position your business for success in a competitive global market. Embrace the future of tin coating services to drive performance and profitability.