Introduction: Navigating the Global Market for throttle body plate

In an increasingly competitive global landscape, sourcing the right throttle body plate can pose significant challenges for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, including emerging markets like Vietnam and Saudi Arabia. With diverse applications ranging from automotive to industrial machinery, understanding the nuances of throttle body plates—such as material specifications, sizes, and compatibility with various systems—is crucial for optimizing performance and ensuring reliability.

This comprehensive guide delves into the multifaceted world of throttle body plates, covering essential topics including types, applications, supplier vetting processes, and cost considerations. Each section is designed to empower international buyers with the insights needed to make informed purchasing decisions, helping them navigate the complexities of sourcing high-quality throttle body plates that meet their specific requirements.

By equipping B2B buyers with practical knowledge and actionable strategies, this guide not only addresses common pain points but also fosters stronger supplier relationships and enhances overall procurement efficiency. As you embark on this journey through the global market for throttle body plates, you’ll gain the confidence to select the best solutions that align with your operational goals and industry standards.

Understanding throttle body plate Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Throttle Plates | Typically made of aluminum, various sizes, simple design | OEM vehicle replacements, standard performance builds | Pros: Cost-effective, widely available. Cons: Limited performance enhancement. |

| High-Performance Throttle Plates | Enhanced airflow design, larger diameters, lightweight | Racing, high-performance vehicles | Pros: Improved throttle response, higher power output. Cons: Higher cost, may require modifications. |

| Electronic Throttle Plates | Integrated sensors, electronically controlled, precise | Modern vehicles, electric and hybrid applications | Pros: Greater accuracy, better fuel efficiency. Cons: More complex, potential for electronic failure. |

| Nitrous Throttle Plates | Designed for nitrous oxide systems, specific size and shape | Performance tuning, drag racing | Pros: Significant power boosts, tailored for nitrous use. Cons: Requires careful installation, potential engine strain. |

| Custom Throttle Plates | Tailored dimensions and materials to specific needs | Specialty builds, custom automotive projects | Pros: Perfect fit for unique applications. Cons: Longer lead times, potentially higher costs. |

What are the Characteristics of Standard Throttle Plates?

Standard throttle plates are typically made from aluminum and come in various sizes, featuring a simple design that allows for straightforward installation and operation. These plates are primarily used as OEM replacements in vehicles, making them highly accessible and cost-effective for businesses looking to maintain standard performance levels. When considering standard throttle plates, buyers should note their limitations in terms of performance enhancement, as they are not designed for high-output applications.

How Do High-Performance Throttle Plates Differ?

High-performance throttle plates are engineered with enhanced airflow capabilities, often featuring larger diameters and lightweight materials. These plates are ideal for racing and high-performance vehicles where improved throttle response and higher power output are critical. B2B buyers should weigh the benefits of increased performance against the higher costs and potential need for modifications to fit these plates into existing systems.

What are the Benefits of Electronic Throttle Plates?

Electronic throttle plates incorporate integrated sensors and are controlled electronically, providing precise throttle control that enhances fuel efficiency and performance in modern vehicles, including electric and hybrid models. For B2B buyers, the advantages include improved accuracy and efficiency; however, the complexity and potential for electronic failures may pose challenges in maintenance and repair.

When Should Businesses Consider Nitrous Throttle Plates?

Nitrous throttle plates are specifically designed for use with nitrous oxide systems, featuring tailored sizes and shapes to maximize performance in drag racing and other performance tuning applications. These plates can deliver significant power boosts, but they require careful installation and consideration of engine strain. Businesses should assess the specific needs of their performance projects to determine the suitability of nitrous throttle plates.

Why Opt for Custom Throttle Plates?

Custom throttle plates offer tailored dimensions and materials to meet unique specifications, making them ideal for specialty builds and custom automotive projects. While they provide a perfect fit for specific applications, B2B buyers should be aware of the longer lead times and potentially higher costs associated with custom orders. This option is best suited for businesses that require specialized solutions for unique performance needs.

Key Industrial Applications of throttle body plate

| Industry/Sector | Specific Application of throttle body plate | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Integration in high-performance vehicles | Enhances engine responsiveness and performance | Consider material specifications, compatibility with existing systems, and volume discounts. |

| Aerospace | Use in aircraft engine throttle control systems | Ensures precise control for safety and efficiency | Focus on lightweight materials and stringent quality certifications. |

| Agricultural Equipment | Application in agricultural machinery engines | Improves fuel efficiency and reduces emissions | Evaluate durability under harsh conditions and availability of replacement parts. |

| Marine Industry | Utilization in boat and marine engine systems | Boosts throttle response for better maneuverability | Check for corrosion resistance and compliance with marine standards. |

| Industrial Machinery | Implementation in heavy machinery for operational control | Increases operational efficiency and reliability | Assess compatibility with existing machinery and after-sales support for maintenance. |

How is the throttle body plate utilized in automotive manufacturing?

In the automotive manufacturing sector, throttle body plates are critical components in high-performance vehicles. They regulate the airflow into the engine, significantly affecting engine responsiveness and overall performance. For B2B buyers in this industry, sourcing throttle body plates requires attention to material specifications, such as aluminum or composite materials, and compatibility with existing engine systems. Additionally, volume discounts can be advantageous for manufacturers producing vehicles at scale.

What role does the throttle body plate play in aerospace applications?

In the aerospace industry, throttle body plates are essential for the precise control of engine performance in aircraft. These plates ensure that the engines operate efficiently and safely, which is paramount in aviation. Buyers in this sector must prioritize lightweight materials that meet rigorous safety and quality standards. Furthermore, sourcing from suppliers with relevant certifications can help ensure compliance with industry regulations.

How does the throttle body plate enhance agricultural equipment?

In agricultural machinery, throttle body plates are used to optimize engine performance, leading to improved fuel efficiency and reduced emissions. This is particularly important in regions where environmental regulations are strict. Buyers need to consider the durability of throttle body plates, as they must withstand harsh operating conditions. Additionally, the availability of replacement parts is a crucial factor for maintaining equipment uptime.

Why is the throttle body plate important in the marine industry?

In the marine sector, throttle body plates are integral to the throttle control systems of boats and other marine vehicles. They enhance throttle response, which is vital for maneuverability and safety in watercraft. For international buyers in this industry, sourcing plates that offer corrosion resistance is essential due to the harsh marine environment. Compliance with maritime safety standards is also a key consideration.

What benefits does the throttle body plate provide in industrial machinery?

Throttle body plates are increasingly used in industrial machinery to enhance operational control and efficiency. By providing precise airflow regulation, they help improve the overall reliability of heavy machinery. B2B buyers in this sector should assess compatibility with existing systems and consider the after-sales support offered by suppliers for maintenance and repairs. This ensures that machinery remains operational with minimal downtime.

3 Common User Pain Points for ‘throttle body plate’ & Their Solutions

Scenario 1: Sourcing Quality Throttle Body Plates in Diverse Markets

The Problem: B2B buyers often struggle to find high-quality throttle body plates that meet specific performance standards and regulatory requirements in their regions. Discrepancies in manufacturing quality can lead to performance issues, increased downtime, and dissatisfaction among end customers. In regions like Africa and South America, where access to reliable suppliers can be limited, the risk of receiving subpar products is heightened. This challenge is compounded by the need for components that can withstand varied climatic conditions and local fuel qualities.

The Solution: To address this issue, B2B buyers should prioritize working with reputable suppliers who provide detailed specifications and certifications for their throttle body plates. It’s crucial to verify the material quality, such as the use of premium-grade aluminum or steel that can resist corrosion and wear. Establishing relationships with manufacturers that offer a comprehensive warranty and customer support can also mitigate risks. Additionally, buyers should consider conducting performance testing in local conditions before committing to large orders. Engaging in a thorough vetting process will help ensure that the products sourced will not only meet regulatory standards but also perform reliably in the intended applications.

Scenario 2: Managing Installation Challenges for Throttle Body Plates

The Problem: Installing throttle body plates can be a complex process, especially for businesses that lack specialized technical expertise. Misalignment during installation can lead to air intake issues, affecting engine performance and efficiency. For companies operating in regions with a shortage of skilled mechanics, this can result in increased service costs and extended vehicle downtimes, negatively impacting customer satisfaction and operational efficiency.

The Solution: To streamline the installation process, B2B buyers should seek out suppliers who offer comprehensive installation guides and support. Providing training sessions for in-house mechanics can significantly enhance the skill level of the team, ensuring that installations are performed correctly. Additionally, investing in specialized tools and equipment designed for throttle body plate installation can minimize the risk of misalignment. Buyers can also benefit from partnering with local service providers who specialize in engine components, as they can offer on-site assistance and troubleshooting support during the installation phase.

Scenario 3: Addressing Compatibility Issues with Throttle Body Plates

The Problem: Compatibility between throttle body plates and various engine models is a significant concern for B2B buyers. With numerous vehicle models and engine configurations, it is common for buyers to encounter challenges in ensuring that the throttle body plates they purchase will fit correctly and function as intended. This can lead to costly returns, delays in production, and potential damage to engines if incompatible parts are installed.

The Solution: To avoid compatibility issues, buyers should conduct thorough research on the specific requirements of the vehicles they service or manufacture. This includes understanding the bolt spacing, diameter, and design specifications of the throttle body plates compatible with different engine types. Collaborating with manufacturers that provide detailed fitment charts and cross-referencing compatibility with OEM specifications can greatly reduce the risk of errors. Additionally, establishing a communication channel with suppliers for real-time inquiries can help clarify any uncertainties before purchase, ensuring that the right parts are sourced for the intended applications. By adopting a proactive approach to compatibility, buyers can enhance operational efficiency and customer satisfaction while minimizing costly errors.

Strategic Material Selection Guide for throttle body plate

What Are the Key Properties of Common Materials Used for Throttle Body Plates?

When selecting materials for throttle body plates, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. The most common materials used in the manufacturing of throttle body plates include aluminum, stainless steel, brass, and composite materials. Each of these materials has unique characteristics that impact their suitability for various applications.

How Does Aluminum Perform as a Material for Throttle Body Plates?

Aluminum is a popular choice for throttle body plates due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating up to 300°C and can withstand moderate pressure, making it suitable for most automotive applications.

Pros: Aluminum is cost-effective and easy to machine, which simplifies the manufacturing process. Its lightweight nature can contribute to improved vehicle performance and fuel efficiency.

Cons: However, aluminum may not be as durable as other metals under high-stress conditions. It can deform under extreme pressure, which may affect throttle response.

Impact on Application: Aluminum is compatible with a wide range of media, including gasoline and E85 fuels. However, it is crucial to ensure that the specific alloy used is appropriate for the intended application.

Considerations for International Buyers: Buyers in regions like Africa and South America should verify compliance with local standards, such as ASTM or JIS, to ensure quality and safety.

What Are the Benefits of Using Stainless Steel for Throttle Body Plates?

Stainless steel is known for its superior strength and corrosion resistance, making it suitable for high-performance applications. It can withstand temperatures exceeding 800°C and is highly resistant to oxidation.

Pros: The durability of stainless steel enhances the longevity of throttle body plates, making them ideal for demanding environments. Additionally, stainless steel can handle higher pressures without deformation.

Cons: The primary drawback is its higher cost compared to aluminum. Stainless steel is also more challenging to machine, leading to increased manufacturing complexity.

Impact on Application: Stainless steel plates are compatible with various fuels and can handle aggressive media, making them suitable for performance vehicles.

Considerations for International Buyers: Compliance with international standards is critical, especially in regions such as the Middle East, where extreme temperatures can affect material performance.

How Does Brass Compare as a Material for Throttle Body Plates?

Brass offers excellent machinability and corrosion resistance, particularly against saltwater and acidic environments. It generally operates well at temperatures up to 300°C.

Pros: Brass is relatively easy to work with and can provide a good balance between cost and performance. Its aesthetic appeal can also be a consideration for custom applications.

Cons: However, brass is less durable than aluminum and stainless steel, particularly under high-pressure conditions. It may not be suitable for high-performance applications.

Impact on Application: Brass is compatible with various fuels, but its lower strength limits its use in high-stress environments.

Considerations for International Buyers: Buyers should be aware of the specific alloy used, as different grades of brass can have varying properties. Compliance with regional standards is necessary for quality assurance.

What Role Do Composite Materials Play in Throttle Body Plate Applications?

Composite materials, such as carbon fiber or reinforced plastics, are becoming increasingly popular in throttle body plate applications due to their lightweight and high-strength properties.

Pros: These materials offer excellent resistance to corrosion and can be engineered to meet specific performance requirements. Their lightweight nature can significantly improve vehicle efficiency.

Cons: The primary limitation is the higher cost and complexity of manufacturing. Additionally, composites may not withstand extreme temperatures as well as metals.

Impact on Application: Composites are suitable for specific applications where weight reduction is critical, such as in racing or high-performance vehicles.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards and are suitable for the intended media.

Summary Table of Material Selection for Throttle Body Plates

| Material | Typical Use Case for throttle body plate | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General automotive applications | Lightweight and cost-effective | Deforms under high pressure | Low |

| Stainless Steel | High-performance vehicles | Superior strength and durability | Higher cost and machining complexity | High |

| Brass | Custom and low-stress applications | Good machinability and aesthetics | Less durable under high pressure | Medium |

| Composite | Racing and specialized applications | Lightweight and corrosion-resistant | Higher cost and thermal limitations | High |

This comprehensive analysis of materials will assist international B2B buyers in making informed decisions when selecting throttle body plates for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for throttle body plate

What Are the Main Stages of Manufacturing Throttle Body Plates?

The manufacturing process of throttle body plates involves several critical stages, each ensuring that the final product meets the required performance and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The process begins with the selection of high-quality materials, typically aluminum or stainless steel, which are favored for their durability and lightweight properties. The chosen material undergoes a thorough inspection to ensure it meets specifications regarding thickness, tensile strength, and corrosion resistance. After inspection, the materials are cut into manageable sizes for the subsequent processes. -

Forming:

Forming techniques such as stamping or CNC machining are commonly used to shape the throttle body plates. Stamping involves pressing the material into a die to create the desired shape, while CNC machining provides precision and allows for complex geometries. This stage is vital as it directly affects the throttle plate’s fit and function within the engine assembly. -

Assembly:

After forming, the throttle plates are assembled with other components, such as the throttle shaft and position sensors. This stage may involve welding or fastening techniques, depending on the design requirements. Proper alignment and fitting are crucial to ensure optimal performance and responsiveness of the throttle mechanism. -

Finishing:

The final stage involves surface treatments to enhance durability and reduce friction. Processes such as anodizing or powder coating are commonly applied to protect against corrosion and wear. The plates may also undergo polishing to improve their aesthetic appeal and performance characteristics.

How Is Quality Assurance Implemented in Throttle Body Plate Production?

Quality assurance (QA) is a fundamental aspect of throttle body plate manufacturing, ensuring that each product meets international standards and customer expectations. Various quality control measures are implemented throughout the manufacturing process.

-

International Standards Compliance:

Many manufacturers adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, region-specific certifications such as CE marking in Europe or API standards for performance can be crucial for market acceptance. -

Quality Control Checkpoints:

Various checkpoints are established throughout the manufacturing process to monitor quality. These include:

– Incoming Quality Control (IQC): Inspection of raw materials before they are used in production.

– In-Process Quality Control (IPQC): Ongoing monitoring during manufacturing to identify any deviations from specifications.

– Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet performance criteria before shipment. -

Common Testing Methods:

Testing methods may include dimensional checks, pressure tests, and functional tests. Dimensional checks ensure that the throttle plates meet specified tolerances, while pressure tests evaluate the integrity of the assembly under operational conditions. Functional tests assess the responsiveness and accuracy of throttle control.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential for ensuring product reliability.

-

Supplier Audits:

Conducting on-site audits of potential suppliers allows buyers to assess manufacturing practices and quality control processes firsthand. During these audits, buyers can evaluate the supplier’s adherence to standards, equipment capabilities, and overall operational efficiency. -

Quality Reports and Documentation:

Requesting detailed quality reports, including inspection records and compliance certificates, can provide insights into the supplier’s commitment to quality. Buyers should look for documentation that outlines testing methods, results, and any corrective actions taken for non-conformities. -

Third-Party Inspections:

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. These organizations typically conduct comprehensive assessments and provide detailed reports, allowing buyers to make informed decisions based on objective data.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing throttle body plates from international suppliers, B2B buyers should be aware of specific nuances regarding quality control and certification that may vary by region.

-

Understanding Regional Standards:

Different regions may have varying standards for quality and safety. For example, while ISO certifications are globally recognized, certain markets may require additional certifications that align with local regulations. Buyers should familiarize themselves with the specific standards applicable in their target markets to ensure compliance. -

Cultural Considerations in Quality Practices:

Cultural differences can influence manufacturing practices and quality perceptions. For instance, suppliers in some regions may prioritize cost over quality, while others may have a more rigorous approach to quality assurance. Understanding these cultural nuances can help buyers navigate supplier relationships more effectively. -

Post-Purchase Support and Warranty:

Quality assurance does not end with the purchase. B2B buyers should also inquire about post-purchase support, warranty terms, and the supplier’s policy on handling defective products. A robust support system indicates a supplier’s commitment to quality and customer satisfaction.

Conclusion

In summary, the manufacturing processes and quality assurance for throttle body plates are intricate and essential for ensuring high-performance automotive components. B2B buyers must understand the manufacturing stages, quality control measures, and verification methods to ensure they partner with reliable suppliers. By being informed about international standards and regional nuances, buyers can make strategic decisions that enhance their supply chain and product offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘throttle body plate’

This guide serves as a practical checklist for B2B buyers seeking to procure throttle body plates. It provides essential steps to ensure a successful sourcing process, from defining specifications to evaluating suppliers. By following these steps, buyers can make informed decisions that align with their operational needs and quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental to sourcing the right throttle body plate. Consider factors such as size (bolt spacing), material (aluminum vs. steel), and design features (e.g., angle and thickness). This clarity will help you communicate your requirements effectively to potential suppliers and ensure compatibility with your existing systems.

Step 2: Research Market Options

Conduct thorough research to identify the range of throttle body plates available in the market. Explore different manufacturers and product offerings, focusing on specifications that meet your needs. Pay attention to product reviews and performance ratings from other businesses to gauge reliability and effectiveness.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Ensure they have experience in producing throttle body plates that meet the standards of your specific application. Look for suppliers with a proven track record of quality and reliability.

Step 4: Verify Supplier Certifications and Quality Standards

Ensure that your potential suppliers adhere to industry standards and possess relevant certifications. Look for ISO certifications or other quality assurance measures that demonstrate their commitment to maintaining high manufacturing standards. This step is critical in mitigating risks related to product quality and compliance.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the throttle body plates you are considering. Testing samples allows you to evaluate the product’s quality, fit, and performance under real-world conditions. This step is essential to confirm that the product meets your specifications and expectations.

Step 6: Assess Pricing and Payment Terms

Compare pricing structures among different suppliers while considering the overall value offered. Be sure to clarify payment terms, including any potential discounts for bulk orders or long-term contracts. Understanding the financial aspects will help you stay within budget while securing the best deal.

Step 7: Establish a Communication Plan

Effective communication with your suppliers is vital for a smooth procurement process. Establish clear lines of communication, including regular updates on order status, shipping timelines, and potential issues. A good communication plan will foster a collaborative relationship and ensure that any concerns are addressed promptly.

By following these steps, B2B buyers can navigate the sourcing process for throttle body plates with confidence, ensuring they select products that meet their technical requirements and quality standards.

Comprehensive Cost and Pricing Analysis for throttle body plate Sourcing

What Are the Key Cost Components in Sourcing Throttle Body Plates?

When sourcing throttle body plates, understanding the cost structure is essential for B2B buyers. The main cost components include:

-

Materials: The choice of materials significantly affects the price. Common materials include aluminum and steel, with aluminum generally being lighter and more cost-effective. Prices for aluminum throttle plates can range from $24 to $34, while premium steel components may incur higher costs due to their durability and strength.

-

Labor: Labor costs involve the wages of workers involved in manufacturing, assembly, and quality control. Regions with lower labor costs, such as parts of Africa and South America, may offer competitive pricing, while European countries may have higher labor expenses.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, ultimately impacting the final price.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs or specialized specifications. Buyers should factor in these costs when considering unique throttle body plate configurations.

-

Quality Control (QC): Ensuring that throttle body plates meet required specifications and certifications can add to the cost. Quality assurance processes, including testing and compliance with international standards, are crucial for reliability.

-

Logistics: Transportation and shipping costs can vary widely depending on the origin of the product and destination. Buyers must consider the total logistics costs, especially for international shipments, which may include tariffs and import duties.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the expected margins in different regions can aid in negotiations.

How Do Price Influencers Affect Throttle Body Plate Sourcing?

Several factors influence the pricing of throttle body plates:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to cost savings. Suppliers may offer discounts based on volume, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom throttle body plates tailored to specific applications can incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-grade materials and certified products typically command higher prices. Buyers should assess whether the added cost aligns with their performance needs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge premium prices but offer better quality assurance and service.

-

Incoterms: Understanding the terms of delivery, including who is responsible for shipping costs and risks, is crucial. Incoterms can significantly impact the final pricing structure.

What Buyer Tips Can Help Negotiate Better Pricing?

For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are key:

-

Negotiation Strategies: Leverage volume purchasing to negotiate better rates. Be prepared to discuss alternative materials or specifications that can lower costs without compromising quality.

-

Cost-Efficiency Considerations: Evaluate the total cost of ownership (TCO) instead of just the upfront price. This includes maintenance costs, longevity, and potential downtime due to failures.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and shipping costs when importing throttle body plates. Establish relationships with local suppliers to mitigate risks associated with international sourcing.

-

Disclaimer on Indicative Prices: Prices for throttle body plates can vary based on the above factors. It’s crucial to seek updated quotes and ensure that all costs are transparent before finalizing any agreements.

By understanding these elements, B2B buyers can make informed decisions that optimize their sourcing strategies for throttle body plates, ensuring cost-effectiveness and quality assurance.

Alternatives Analysis: Comparing throttle body plate With Other Solutions

Exploring Alternatives to Throttle Body Plates for Enhanced Performance

In the automotive and industrial sectors, selecting the right component for controlling airflow is crucial for optimizing performance. While throttle body plates are a popular choice, various alternative technologies exist that can also achieve similar goals. This section will analyze these alternatives, focusing on performance, cost, ease of implementation, maintenance, and their best use cases.

Comparison Table

| Comparison Aspect | Throttle Body Plate | Electronic Throttle Control (ETC) | Carburetor |

|---|---|---|---|

| Performance | High airflow control | Precise and responsive | Good for older engines |

| Cost | Moderate ($24 – $800) | Higher upfront cost ($300 – $1,500) | Lower cost ($50 – $500) |

| Ease of Implementation | Relatively easy | Requires specialized knowledge | Simple installation |

| Maintenance | Moderate (occasional cleaning) | Low (self-calibrating) | High (frequent adjustments) |

| Best Use Case | High-performance vehicles | Modern vehicles with electronic systems | Classic cars and simple builds |

Detailed Breakdown of Alternatives

What is Electronic Throttle Control (ETC) and How Does It Compare?

Electronic Throttle Control (ETC) replaces traditional mechanical systems with electronic sensors and motors. This technology allows for precise control over the throttle position, improving vehicle responsiveness and fuel efficiency. However, the higher upfront cost can be a deterrent for some buyers. While maintenance is minimal due to self-calibrating features, the complexity of installation may require specialized knowledge, making it less accessible for all users.

How Does a Carburetor Function as an Alternative?

Carburetors are traditional devices that mix air and fuel for internal combustion engines. They are generally simpler to install and maintain compared to throttle body plates and ETC. While they may be more affordable, especially for older vehicles, carburetors require regular adjustments and tuning to maintain performance. Their performance may not match that of throttle body plates or ETC, particularly in high-performance applications, making them less suitable for modern vehicles designed for efficiency and power.

Making the Right Choice: What Should B2B Buyers Consider?

When evaluating throttle body plates against alternatives like Electronic Throttle Control and carburetors, B2B buyers should carefully consider their specific needs. For high-performance applications where precision and responsiveness are paramount, throttle body plates or ETC systems may be the best fit. Conversely, for simpler, cost-effective solutions in older or classic vehicles, carburetors could be an ideal choice. Assessing factors such as the intended application, budget constraints, and installation capabilities will help buyers make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for throttle body plate

What Are the Key Technical Properties of Throttle Body Plates?

When sourcing throttle body plates, B2B buyers must understand several critical specifications that can significantly impact performance and compatibility. Here are essential properties to consider:

-

Material Composition

– Throttle body plates are typically made from aluminum or other lightweight alloys. Aluminum is favored for its strength-to-weight ratio, corrosion resistance, and ease of machining. Understanding the material helps buyers assess durability and performance in various environmental conditions, which is crucial for applications in different regions, such as Africa or the Middle East. -

Thickness

– The thickness of the throttle body plate, often measured in inches or millimeters, affects airflow characteristics and overall strength. For example, plates may range from .062″ to .091″ in thickness. Thicker plates can withstand higher pressures and temperatures, making them suitable for high-performance engines. Buyers should match the thickness to their specific engine requirements to ensure optimal functionality. -

Bolt Spacing

– Bolt spacing, commonly referred to as center-to-center (c-c) distance, is vital for compatibility with intake manifolds. Standard measurements include 1.0″ or 1.5″. Proper bolt spacing ensures a secure fit, preventing air leaks and maintaining engine efficiency. Buyers must verify compatibility with their specific vehicle models to avoid installation issues. -

Angle of Operation

– The angle at which the throttle plate opens, typically around 14 degrees, is crucial for controlling airflow into the engine. This specification influences engine response and performance. Buyers should consider how the angle aligns with their engine’s design and intended use, particularly in high-performance or modified applications. -

Surface Finish

– The surface finish of the throttle body plate can impact airflow and fuel atomization. A smoother finish can reduce turbulence, enhancing engine efficiency. Buyers should assess whether a polished or anodized finish is necessary based on their performance goals and the specific demands of their market.

What Are Common Trade Terms Used in the Throttle Body Plate Industry?

Understanding industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts that may be marketed by another manufacturer. In the throttle body plate market, OEM products are often seen as high-quality and reliable, making them a preferred choice for many buyers. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This is crucial for buyers to understand, as it can affect inventory management and cash flow. Buyers should negotiate MOQs based on their specific needs and market demands. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. It is an essential part of the procurement process, allowing buyers to compare offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms is vital for understanding shipping responsibilities, risks, and costs, especially for international buyers in regions like South America and Europe. -

Lead Time

– This term refers to the time taken from placing an order to the delivery of goods. Understanding lead time is crucial for buyers to plan their inventory and production schedules effectively, especially in industries with tight timelines. -

Aftermarket

– The aftermarket refers to parts and accessories that are not supplied by the original manufacturer. Buyers looking for throttle body plates may explore aftermarket options for enhanced performance or customization, which can be particularly appealing in competitive markets.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing throttle body plates, ensuring compatibility and performance for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the throttle body plate Sector

What Are the Key Market Dynamics and Trends Influencing the Throttle Body Plate Sector?

The global throttle body plate market is witnessing significant growth, driven by the increasing demand for fuel-efficient and high-performance vehicles. As automotive manufacturers focus on enhancing engine performance and reducing emissions, the demand for innovative throttle body solutions is on the rise. Key trends influencing this market include the shift towards electronic throttle control systems, which offer better responsiveness and efficiency compared to traditional mechanical systems. Additionally, the integration of advanced materials such as lightweight aluminum and composites is enhancing the performance characteristics of throttle body plates.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly leveraging digital technologies for sourcing. Platforms that facilitate direct manufacturer connections and provide transparent pricing models are becoming essential tools for procurement. Moreover, the trend towards just-in-time manufacturing is prompting suppliers to maintain flexible inventories, allowing buyers to minimize holding costs while ensuring a steady supply of throttle body plates.

Emerging markets are also becoming crucial players in the throttle body plate sector. For instance, countries like Vietnam and Saudi Arabia are investing in automotive manufacturing capabilities, leading to increased local demand for throttle body components. As these markets evolve, international buyers should stay informed about regional regulations and standards that could impact sourcing strategies.

How Does Sustainability Influence Sourcing Decisions for Throttle Body Plates?

Sustainability is becoming an integral aspect of sourcing decisions in the throttle body plate sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to seek suppliers who prioritize eco-friendly practices. This includes the use of recycled materials and energy-efficient manufacturing techniques that minimize carbon footprints.

Ethical sourcing is equally important, as buyers look to establish transparent supply chains. This involves assessing suppliers for compliance with labor laws and environmental regulations, ensuring that the sourcing practices align with corporate social responsibility goals. Certifications such as ISO 14001 for environmental management and the use of eco-labels can help buyers identify suppliers committed to sustainable practices.

In the throttle body plate market, the adoption of “green” materials—such as bio-based composites or recyclable aluminum—can enhance the appeal of products. B2B buyers who prioritize sustainability not only contribute to environmental conservation but also gain a competitive edge by appealing to environmentally conscious end consumers.

What Is the Historical Context of the Throttle Body Plate Market Development?

The throttle body plate has evolved significantly since its inception in the early automotive industry. Initially, these components were primarily mechanical, relying on a cable-driven system to control airflow into the engine. However, advancements in technology led to the development of electronic throttle control systems in the late 20th century, marking a pivotal shift in how throttle bodies function.

This transition has been driven by the need for improved engine performance, reduced emissions, and enhanced drivability. As automotive technology continues to advance, the throttle body plate is expected to undergo further transformations, integrating smart technologies such as sensors and IoT capabilities to optimize vehicle performance.

In summary, understanding the current market dynamics, sustainability considerations, and historical developments in the throttle body plate sector is crucial for international B2B buyers. These insights can inform strategic sourcing decisions, enabling companies to remain competitive in a rapidly evolving automotive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of throttle body plate

-

How do I ensure the quality of throttle body plates when sourcing from international suppliers?

To ensure quality, conduct thorough supplier vetting. Check certifications such as ISO 9001 and request samples before placing bulk orders. Utilize third-party inspection services to verify product quality before shipment. Engage with suppliers who have a proven track record in the industry and positive customer reviews. Establish clear quality assurance criteria and communicate these with your suppliers to minimize discrepancies. -

What are the key specifications I should look for in a throttle body plate?

Key specifications include bolt spacing, material type (aluminum or steel), and thickness. Ensure the design fits your engine requirements, including airflow capacity and pressure ratings. Consider features such as whether the plate is compatible with nitrous systems or supports E85 fuel. Understanding these specifications will help you select the right throttle body plate for your application. -

What is the typical lead time for custom throttle body plates?

Lead times for custom throttle body plates typically range from 4 to 12 weeks, depending on the complexity of the design and the supplier’s production capacity. It is advisable to communicate your requirements early in the sourcing process and confirm the timelines with the supplier. Factors such as material availability and shipping logistics can also influence lead times. -

How do I negotiate payment terms with international suppliers for throttle body plates?

Negotiating payment terms involves establishing trust and understanding the supplier’s policies. Common terms include a deposit upon order confirmation and the balance upon shipment. Consider using letters of credit or escrow services to mitigate risk. Always clarify terms regarding late payments and penalties to avoid misunderstandings and ensure a smooth transaction. -

What is the minimum order quantity (MOQ) for throttle body plates?

MOQs for throttle body plates can vary significantly by supplier and product type. Generally, MOQs range from 50 to 500 units for standard products, while custom designs may have higher MOQs. Discuss your needs with potential suppliers and inquire about flexibility in MOQs, especially if you are a smaller buyer or testing new markets. -

How can I assess the reliability of a supplier in the throttle body plate market?

Assess supplier reliability by reviewing their business history, customer feedback, and industry reputation. Request references from previous clients and check their response times to inquiries. Additionally, consider visiting their manufacturing facilities if possible or utilizing third-party audits. A reliable supplier should also provide clear communication and transparency throughout the sourcing process. -

What logistics considerations should I keep in mind when importing throttle body plates?

When importing throttle body plates, consider shipping methods, customs clearance, and local regulations. Determine the best shipping option based on cost and delivery time. Ensure that all documentation, including invoices and packing lists, is accurate to prevent delays at customs. Familiarize yourself with import duties and taxes in your region to avoid unexpected costs. -

Can throttle body plates be customized for specific applications?

Yes, throttle body plates can often be customized to meet specific application requirements. Many suppliers offer design modifications, such as adjustments in size, bolt patterns, and material choice. When requesting customization, provide detailed specifications and any necessary drawings to the supplier. Be clear about your performance expectations to ensure the final product aligns with your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Throttle Body Plate Manufacturers & Suppliers List

1. Kinsler – Set of 16 Screws

Domain: kinsler.com

Registered: 1997 (28 years)

Introduction: [{‘name’: ‘Set of 16 Screws’, ‘description’: ‘8-32 x 2.50″ long, button head socket head cap screw, premium steel’, ‘price’: ‘$14.15’}, {‘name’: ‘Throttle plate’, ‘description’: ‘1.0″ c-c bolt spacing, .062″ aluminum, 14-degree’, ‘price_range’: ‘$24.05 – $27.65’}, {‘name’: ‘Throttle plate’, ‘description’: ‘1.5″ c-c bolt spacing, .071″ aluminum, 14-degree’, ‘price_range’: ‘$24.05 – $31.20’}, {‘name…

2. Reddit – Automotive Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Automotive Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Nitrous Outlet – GM LSX 92mm Dry Plate System

Domain: nitrousoutlet.com

Registered: 2002 (23 years)

Introduction: GM Nitrous Plate Systems for various models including Camaro, Corvette, CTS-V, Trailblazer, and more. Key products include: 1. GM LSX 92mm Dry Plate System – From $639.99 2. GM 90mm LSX Dry Plate System – From $650.99 3. Magnuson SC 90mm Nitrous Dry Plate System – From $651.99 4. GM 78mm Dry LSX Plate System – From $671.99 5. Holley Hi-Ram 102mm Throttle Body Hard-line Plate System (Drivers Side) …

4. Permatex – Throttle Body Cleaner

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Throttle Body Cleaner: Permatex Throttle Body, Carb & Choke Cleaner #80279; Tools/Supplies Needed: screwdriver, socket set, two clean rags or cloths, toothbrush, cotton swabs, penetrating oil; Vehicle Types: cable operated and electronic/fly by wire throttle bodies; Example Vehicle: 1984 BMW 733i; Procedure: Access throttle body by removing intake duct, clean with specific throttle body cleaner, e…

5. Nitrous Express – Throttle Body Plate Bolts

Domain: nitrousexpress.com

Registered: 1997 (28 years)

Introduction: This company, Nitrous Express – Throttle Body Plate Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

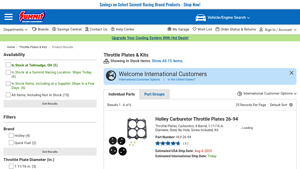

6. Summit Racing – Throttle Plates & Kits

Domain: summitracing.com

Registered: 1995 (30 years)

Introduction: Throttle Plates & Kits – In Stock

– Vendor: Summit Racing

– Free Shipping on Orders Over $109

– Savings on Select Summit Racing Brand Products

**Product Options:**

– **Brands:** Holley (4), Quick Fuel (2)

– **Throttle Plate Diameter:** 1 11/16 in. (3), 1 3/4 in. (2), 2 in. (1)

– **Throttle Plate Drilled:** No (5), Yes (1)

– **Throttle Plate Drilled Hole Size:** 0.093 in. (1)

– **Throttle Plate Ma…

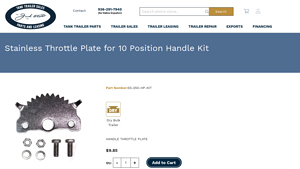

7. Olstaco – Stainless Throttle Plate for 10 Position Handle Kit

Domain: olstaco.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Stainless Throttle Plate for 10 Position Handle Kit”, “part_number”: “SS-250-HP-KIT”, “category”: “Dry Bulk Trailer”, “price”: “$9.85”, “shipping_info”: “FREE UPS Ground shipping on orders more than $500 and package weight less than 50 lbs.”}

8. ScienceDirect – Throttle Plate

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Throttle Plate is a component in automotive engineering that controls the airflow into the engine, thereby influencing engine power and torque output. It is linked mechanically to the accelerator pedal in conventional systems, allowing the driver to control the throttle angle and air intake. In modern systems, Electronic Throttle Control (ETC) replaces mechanical linkages with electronic sensors a…

Strategic Sourcing Conclusion and Outlook for throttle body plate

As the automotive industry continues to evolve, the importance of strategic sourcing for throttle body plates cannot be overstated. By focusing on quality, compatibility, and supplier reliability, international buyers can ensure that they procure components that not only meet performance standards but also enhance overall vehicle efficiency. The growing demand for high-performance throttle body plates, particularly in regions like Africa, South America, the Middle East, and Europe, presents significant opportunities for businesses willing to invest in robust supplier relationships.

In addition, understanding the nuances of different throttle plate specifications—such as materials, bolt spacing, and design—can lead to better decision-making and cost savings. Buyers should prioritize suppliers who offer a diverse range of products and customization options to meet unique market demands.

Looking ahead, the global market for throttle body plates is poised for growth, driven by advancements in automotive technology and increasing regulatory standards for vehicle emissions. B2B buyers are encouraged to leverage this momentum by exploring new partnerships and sourcing strategies that align with their long-term business goals. Engage with trusted suppliers today to stay ahead in this competitive landscape and ensure your operations are equipped for future success.