Contents

Manufacturing Insight: Thermoplastic Parts Are

Thermoplastic Parts Are Precision Solutions Engineered for Performance and Speed

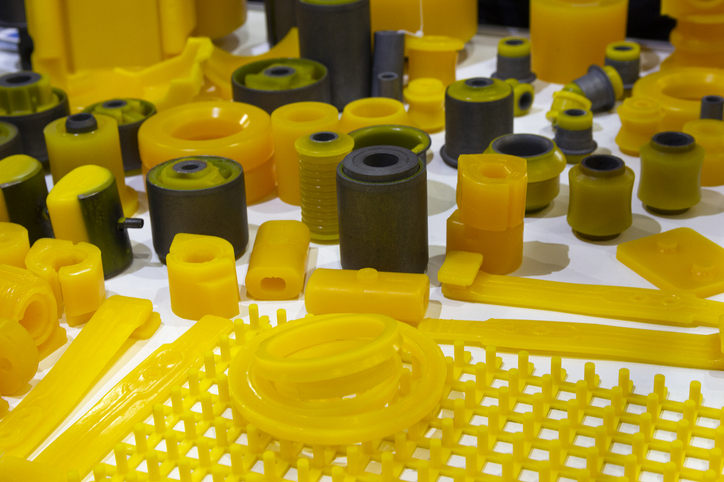

Thermoplastic parts are essential components across demanding industries due to their exceptional balance of mechanical properties, chemical resistance, and design flexibility. Achieving the required dimensional accuracy, superior surface finish, and material integrity for functional prototypes or low-to-medium volume production demands advanced manufacturing expertise. Honyo Prototype delivers this precision through our specialized CNC machining services, meticulously optimized for a wide range of engineering thermoplastics including ABS, Polycarbonate (PC), Acetal (POM), Nylon (PA), and PEEK.

Our state-of-the-art CNC milling and turning centers, operated by highly skilled technicians, consistently produce complex thermoplastic components meeting stringent tolerances down to ±0.005 mm. We understand the unique challenges of machining thermoplastics—managing heat generation, minimizing internal stresses, and preventing material deformation is critical. Honyo’s proven processes and deep material knowledge ensure parts maintain their intended mechanical properties and aesthetic quality, directly from the machine.

Accelerate your development cycle with Honyo Prototype. Leverage our Online Instant Quote system to receive a detailed, accurate cost and lead time estimate for your thermoplastic CNC machining project within minutes, not days. Simply upload your CAD file, specify materials and quantities, and proceed with confidence.

Technical Capabilities

Thermoplastic parts are commonly machined using 3-axis, 4-axis, and 5-axis CNC milling as well as CNC turning to achieve complex geometries and tight tolerances. These processes are also applicable to metals such as aluminum and steel, allowing for high-precision components in both prototyping and production environments. Below is a comparison of technical specifications and capabilities for thermoplastic and metal parts across key manufacturing processes.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Typical Materials | ABS, Nylon, Aluminum, Steel | ABS, Nylon, Aluminum, Steel | ABS, Nylon, Aluminum, Steel | ABS, Nylon, Aluminum, Steel | All listed materials |

| Max Complexity | Moderate (2D/2.5D features) | High (rotational indexing) | Very High (complex 3D contours) | Cylindrical and axial parts | High (±0.005 mm to ±0.025 mm) |

| Surface Finish (Typical) | 1.6–3.2 µm Ra | 1.6–3.2 µm Ra | 0.8–1.6 µm Ra | 0.8–3.2 µm Ra | <0.8 µm Ra (with finishing pass) |

| Material Removal Rate | High (metals), Medium (plastics) | Moderate to High | Moderate (due to complexity) | High (metals), Medium (plastics) | Varies by toolpath optimization |

| Fixturing Requirements | Standard vises, clamps | Rotary index table | Multi-axis rotary table | Collets, chucks | Dedicated fixtures for stability |

| Tolerance Range (General) | ±0.05 mm | ±0.025 mm | ±0.01 mm to ±0.025 mm | ±0.01 mm (diametrical) | ±0.005 mm achievable with process control |

| Thermal Sensitivity (Plastics) | Moderate (warp risk) | Moderate to High | High (long cycle times) | Low to Moderate | Requires slow feeds/special cooling |

| Tooling Considerations | Carbide for metals, sharp polished for plastics | Same as 3-axis with rotary compatibility | High-precision multi-axis tooling | Inserts for metals, sharp edges for plastics | Small diameter tools for fine features |

| Applications | Enclosures, brackets (ABS), aluminum housings | Multi-face features, jigs | Aerospace, medical, molds | Shafts, fittings, bushings | Metrology parts, sealing surfaces |

Note: When machining thermoplastics like ABS and Nylon, lower cutting forces and optimized spindle speeds are required to prevent melting or deformation. Metals such as aluminum and steel allow higher material removal rates but require rigid setups and appropriate tooling for tight tolerance work. 5-axis milling enables single-setup machining of complex parts, reducing cumulative error and improving precision. Tight tolerance production across all materials demands environmental control, in-process inspection, and skilled programming.

From CAD to Part: The Process

Honyo Prototype Thermoplastic Parts Manufacturing Process

Our streamlined workflow for thermoplastic parts ensures rapid, high-fidelity prototyping and low-volume production, prioritizing accuracy, cost efficiency, and engineering collaboration. The process begins when a client uploads a CAD model to our secure portal, supporting STEP, IGES, Parasolid, and native formats from major CAD suites. All data undergoes automated verification for geometry integrity and material compatibility against our thermoplastic database, which includes 50+ engineered resins (e.g., ABS, PC, Nylon, PEEK).

AI-Powered Quoting Engine

Immediately after CAD validation, our proprietary AI engine generates a preliminary quote within 2 hours. The system analyzes 200+ geometric and process parameters—including part volume, wall thickness uniformity, draft angles, and undercuts—to predict manufacturability risks and cost drivers. Unlike generic quoting tools, it cross-references real-time data from 15,000+ prior builds, factoring in material waste, machine utilization, and regional energy costs. Clients receive a transparent cost breakdown with visual markers highlighting potential cost-saving design adjustments.

Engineer-Led DFM Analysis

All quotes trigger a mandatory Design for Manufacturability review by our in-house tooling engineers. This phase is not automated; it combines algorithmic insights with human expertise to resolve conflicts the AI flags. For example, if the AI detects sink marks in a thick rib section, the engineer proposes specific solutions: adjusting rib thickness to 60% of the nominal wall, adding gussets, or suggesting a material switch to a lower-shrinkage grade. Clients receive a DFM report within 24 hours with annotated CAD comparisons, tolerance stack-up analysis, and mold flow simulation snippets. We require client sign-off on DFM recommendations before proceeding, ensuring alignment on quality trade-offs.

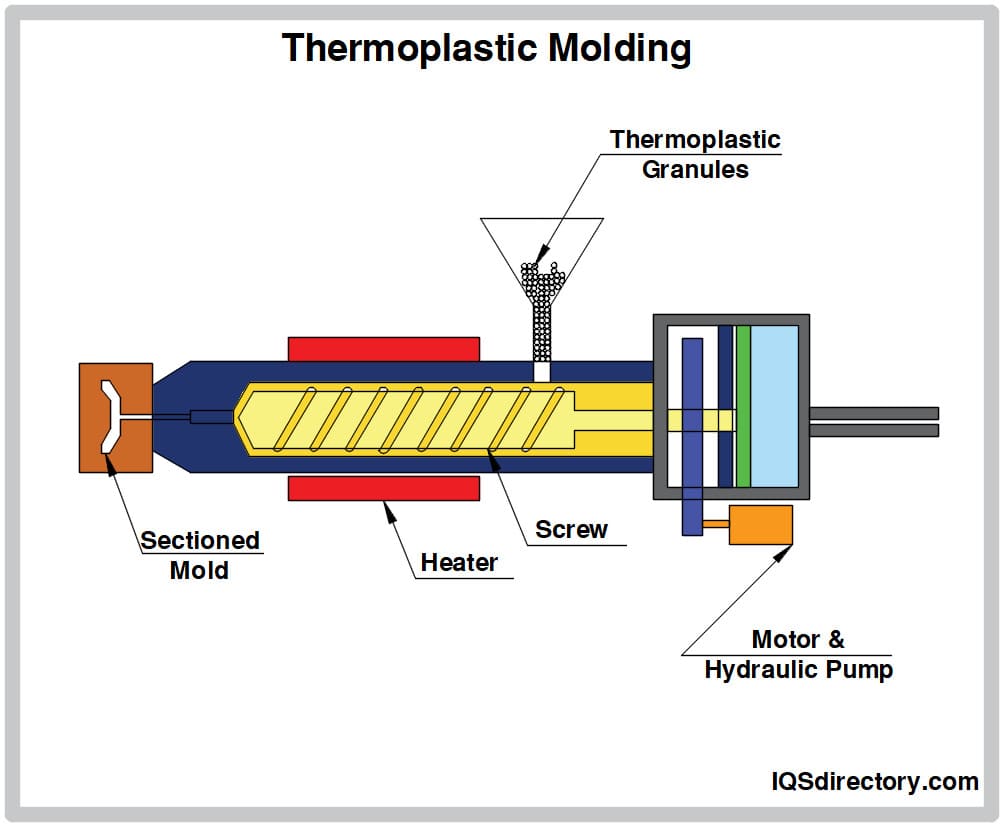

Precision Production Execution

Approved designs move to production in our climate-controlled facilities using electrically powered, all-electric injection molding machines (50–550 tons clamping force). Each thermoplastic batch undergoes rigorous pre-production validation:

Material drying per ISO 11357 standards (e.g., Nylon 66 dried at 80°C for 4 hours)

First-article inspection against ASME Y14.5 GD&T callouts

Real-time process monitoring with 0.1-second data logging

| Parameter | Control Tolerance | Measurement Method |

|---|---|---|

| Melt Temperature | ±3°C | In-line thermocouples |

| Cavity Pressure | ±1.5 bar | Piezoelectric sensors |

| Cycle Time | ±0.5 sec | Machine PLC analytics |

Parts are visually inspected per AQL 1.0 standards, with critical dimensions verified via CMM. For medical or aerospace projects, we provide full material traceability certificates and first-article reports (FAIRs).

Guaranteed Delivery and Post-Production Support

All orders include real-time logistics tracking from our hub in Shenzhen, with standard lead times of 7–10 days for tooling + 3 days for molding. We partner with DHL and FedEx for global shipments, providing climate-controlled packaging for hygroscopic materials. Post-delivery, clients receive a digital quality dossier including process validation data, and our engineering team remains available for assembly support or secondary operations (e.g., ultrasonic welding, pad printing). This closed-loop process reduces time-to-part by 40% versus industry averages while maintaining 99.2% first-pass yield rates for thermoplastic components.

Start Your Project

Thermoplastic parts are precision-engineered for high performance and repeatability in demanding applications. Manufactured in our Shenzhen facility, these components offer excellent durability, chemical resistance, and design flexibility for prototyping and low-to-mid volume production.

For expert support and custom solutions, contact Susan Leo at [email protected].

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.