Contents

Manufacturing Insight: Tensile Strength For Steel

Understanding Tensile Strength in Steel Components: Precision Machining for Critical Performance

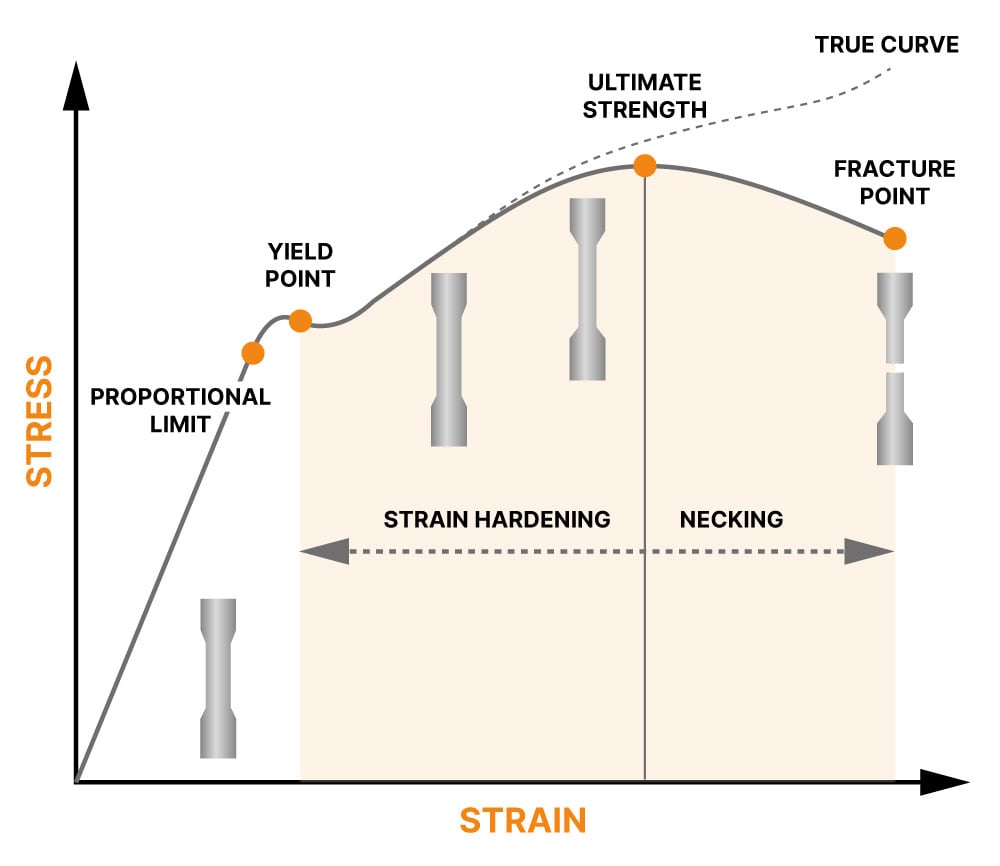

Tensile strength is a fundamental mechanical property defining the maximum stress steel can withstand while being stretched or pulled before failure. For engineered components in aerospace, automotive, and industrial applications, achieving the specified tensile strength—whether yield strength (where plastic deformation begins) or ultimate tensile strength (peak load capacity)—is non-negotiable. Variations in material composition, heat treatment, and crucially, machining processes, directly impact this performance threshold. Residual stresses induced during cutting, improper tool selection, or inadequate process control can compromise structural integrity, leading to premature fatigue or catastrophic failure in service.

At Honyo Prototype, our CNC machining services are engineered to preserve and validate the tensile properties of your steel components. We implement rigorous process protocols, including optimized cutting parameters, stress-relief cycles, and in-process metrology, ensuring machined parts meet exact material specifications per ASTM, ISO, or customer-defined standards. Our Haas and DMG MORI multi-axis CNC systems, paired with metallurgical expertise, deliver micron-level accuracy while maintaining the grain structure and mechanical integrity essential for high-stress applications. Every steel grade—from 4140 chrome-moly to 17-4 PH stainless—is processed with documented traceability from certified mill reports to final inspection.

Leverage Honyo Prototype’s precision manufacturing to transform your steel designs into functionally reliable parts. Validate your requirements and accelerate prototyping or low-volume production with our Online Instant Quote platform. Submit CAD files today to receive a detailed manufacturability analysis and competitive pricing within hours, backed by engineering support to optimize for tensile performance and cost efficiency.

Technical Capabilities

Tensile strength is a critical mechanical property that defines the maximum stress a material can withstand while being stretched or pulled before necking or breaking. In precision machining processes such as 3-axis, 4-axis, and 5-axis milling and turning—especially when targeting tight tolerances (±0.0005″ or tighter)—understanding the tensile strength of workpiece materials is essential for tool selection, feed and speed optimization, and maintaining dimensional accuracy.

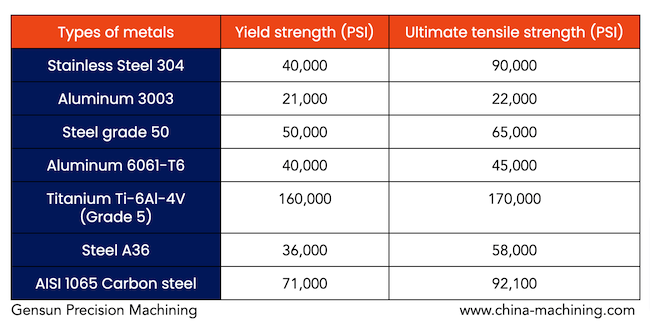

High tensile strength materials like steel require robust cutting strategies due to increased tool wear and cutting forces. Lower tensile strength materials such as aluminum, ABS, and nylon allow for higher material removal rates and longer tool life but demand attention to part rigidity and thermal deformation.

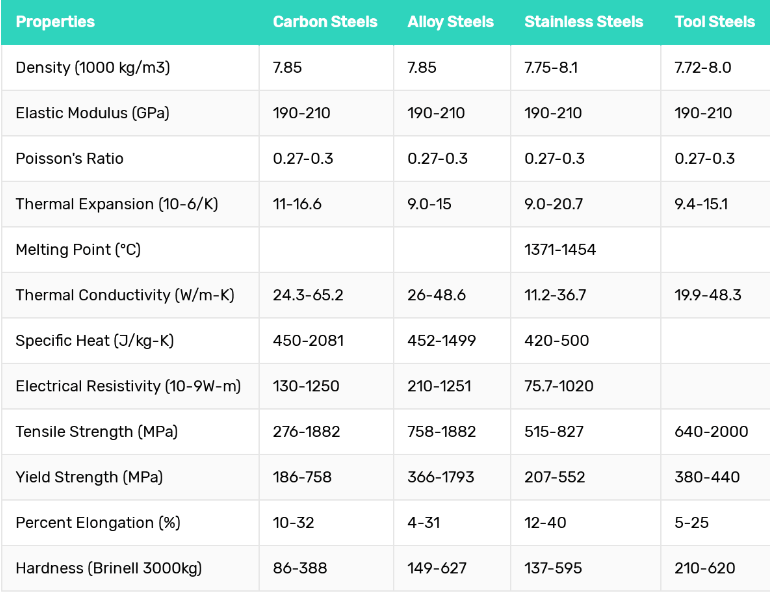

Below is a comparative table outlining the tensile strength and relevant machining characteristics for common materials used in high-precision CNC applications.

| Material | Tensile Strength (Ultimate) | Typical Applications in Precision Machining | Machinability Notes for 3/4/5-Axis Milling & Turning | Tight Tolerance Considerations |

|---|---|---|---|---|

| Steel (e.g., 4140, 1045) | 60,000 – 125,000 psi (414 – 862 MPa) | Structural components, tooling, aerospace fittings | High cutting forces; requires rigid setups, carbide or ceramic tooling; slower speeds; coolant recommended | Excellent dimensional stability; low thermal expansion beneficial for tight tolerance work |

| Aluminum (e.g., 6061-T6, 7075-T6) | 30,000 – 80,000 psi (207 – 552 MPa) | Aerospace enclosures, heat sinks, prototypes | High machinability; allows high spindle speeds and feeds; prone to built-up edge | High thermal expansion requires thermal management; excellent for tight tolerances with proper fixturing |

| ABS (Acrylonitrile Butadiene Styrene) | 4,000 – 6,000 psi (28 – 41 MPa) | Prototypes, jigs, non-structural parts | Low cutting forces; minimal tool wear; requires sharp tools to avoid melting or burring | Low stiffness; prone to deflection; use light passes and secure fixturing for precision |

| Nylon (Polyamide, e.g., PA6, PA66) | 8,000 – 12,000 psi (55 – 83 MPa) | Gears, bushings, insulating components | Soft and gummy; generates heat; needs sharp, polished tools; low feed rates | High moisture absorption affects dimensional stability; precondition material and control environment |

In 5-axis milling and turning operations, where complex geometries and minimal setup changes are leveraged, selecting appropriate cutting parameters based on tensile strength ensures surface finish quality and feature accuracy. For steel, a conservative approach with high-torque spindles and peck drilling strategies is often necessary. Aluminum benefits from high-speed machining (HSM) techniques, while polymers like ABS and nylon require attention to chip evacuation and thermal control to prevent deformation during tight tolerance machining.

From CAD to Part: The Process

Honyo Prototype’s Integrated Process for Steel Tensile Strength Verification

Honyo Prototype ensures steel tensile strength compliance through a closed-loop engineering workflow, starting from design input to certified delivery. Tensile strength is not an isolated step but a critical quality attribute validated across multiple phases, with explicit verification during production. Our process begins when a customer uploads a CAD file specifying material requirements, including minimum tensile strength per standards like ASTM A36 or ISO 6892-1. The AI Quote engine immediately cross-references the geometry and stated material grade against our metallurgical database, flagging potential conflicts—such as thin sections in high-stress areas that could compromise tensile performance—and providing real-time feasibility feedback.

During DFM (Design for Manufacturability) analysis, our engineers rigorously assess how manufacturing choices impact tensile properties. This includes evaluating heat treatment requirements, weld zone integrity, and grain structure implications. For instance, if the design uses 4140 steel but lacks callouts for quenching and tempering, DFM will mandate adjustments to achieve the required 655–1035 MPa tensile range. We simulate residual stresses from machining or forming that could reduce effective tensile strength, ensuring the final part meets functional loads.

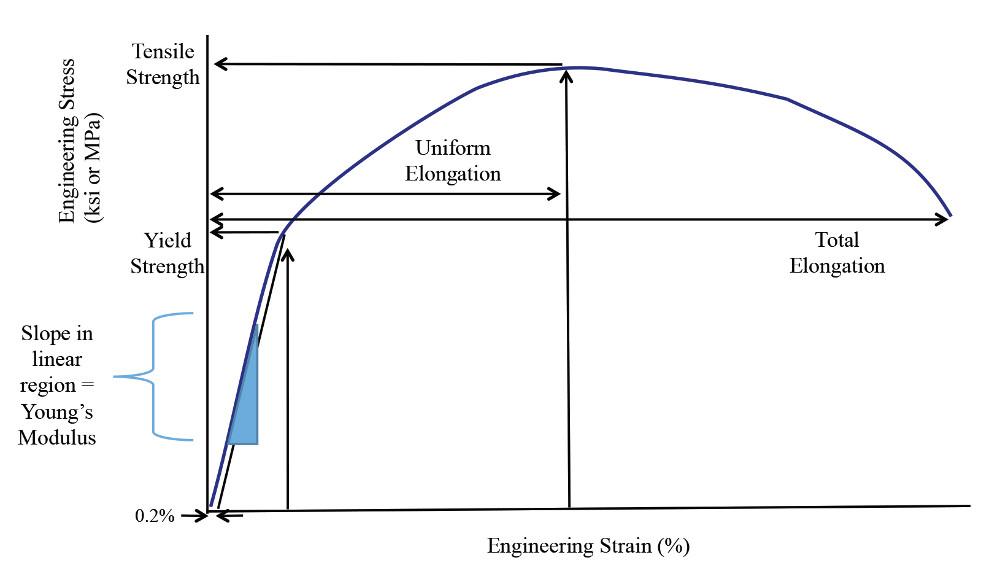

Tensile strength validation occurs exclusively in the Production phase through destructive testing of sacrificial samples. We follow ASTM E8/E8M standards, extracting test coupons from the same heat lot as the production run. Testing is performed in our ISO 17025-accredited lab using calibrated universal testing machines. Critical parameters are recorded:

| Test Parameter | Standard | Honyo Protocol |

|---|---|---|

| Specimen Geometry | ASTM E8 Annex A1 | Sub-size coupons matching part thickness |

| Strain Rate | 0.0005–0.005/s | 0.0015/s (mid-range for consistency) |

| Reporting | Yield Strength (Rp0.2), UTS, Elongation | Full stress-strain curve with 3-sample average |

Results are compared against the material specification and design requirements. If values fall outside tolerance—e.g., UTS below 500 MPa for ASTM A572 Gr 50—we initiate root-cause analysis, which may involve reprocessing the heat lot or adjusting post-weld heat treatment.

Delivery includes a Certificate of Conformance (CoC) with traceable tensile test data, heat numbers, and lab accreditation details. This documentation satisfies aerospace (AS9100), automotive (IATF 16949), and industrial compliance needs. Crucially, Honyo does not rely on mill certificates alone; we verify tensile properties in-house to ensure production processes did not degrade material performance. This integrated approach guarantees that every steel component shipped meets the tensile strength requirements defined at the CAD upload stage.

Start Your Project

For detailed specifications on tensile strength for steel used in your prototyping and production projects, contact Susan Leo directly at [email protected]. Honyo Prototype’s engineering team in Shenzhen ensures precise material testing and compliance with international standards, providing you with reliable mechanical property data for all steel grades. Partner with a manufacturer that prioritizes accuracy and transparency in every prototype.

Contact:

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

Let us support your next project with certified material performance and fast turnaround.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.