Introduction: Navigating the Global Market for taig micro lathe

Navigating the complexities of the global market for Taig micro lathes presents a significant challenge for B2B buyers seeking precision machining solutions. As industries increasingly require high-quality, compact manufacturing equipment, sourcing a reliable Taig micro lathe becomes paramount. This guide serves as a comprehensive resource for international buyers, detailing various types of micro lathes, their diverse applications, and the essential factors to consider when vetting suppliers.

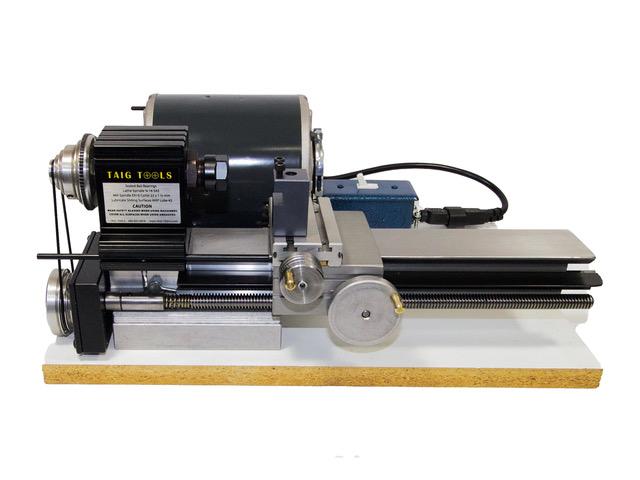

From the rugged construction of the Micro Lathe II to its impressive versatility in handling materials like steel and aluminum, understanding the specifications and capabilities of these machines is crucial for making informed purchasing decisions. This guide also delves into cost considerations, helping buyers navigate pricing structures and potential value-added services.

By empowering B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—with actionable insights, this resource aims to streamline the sourcing process. Whether you’re a manufacturer looking to enhance your production line or a workshop owner seeking reliable equipment, this guide is designed to facilitate your journey towards acquiring the right Taig micro lathe for your operational needs.

Understanding taig micro lathe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Micro Lathe II | Precision steel bed, sealed ball bearings, six-speed drive | Prototyping, small-scale production | Pros: High accuracy, versatile cutting capabilities. Cons: Limited bed length may restrict larger projects. |

| L1015 Micro Lathe II | Basic unit, automatic power feed, compact design | Education, hobbyist projects | Pros: Affordable entry point, easy to operate. Cons: Lacks advanced features for professional use. |

| L1015-5C Micro Lathe II | Enhanced capabilities with 5C collet system | Precision machining, jewelry making | Pros: Greater versatility with collet options. Cons: Higher cost compared to basic models. |

| M1015 Micro Lathe II | More robust construction, larger capacity | Small machine shops, custom fabrication | Pros: Increased durability and capacity. Cons: Requires more space and investment. |

| L1017 Micro Lathe II | Extended bed length, better for larger projects | CNC conversion, advanced prototyping | Pros: Suitable for larger workpieces, enhanced stability. Cons: More complex setup and maintenance. |

The Micro Lathe II is designed for precision and durability, featuring a machined steel bed and sealed bearings that ensure high accuracy. This model is ideal for businesses involved in prototyping and small-scale production, as it can handle both rough cuts and fine details. Buyers should consider its versatility, but the limited bed length may restrict larger projects.

The L1015 Micro Lathe II serves as an excellent entry-level option, equipped with an automatic power feed and a compact design, making it suitable for educational settings and hobbyist projects. Its affordability and ease of use are significant advantages, although it may not meet the demands of professional environments due to its basic features.

For those requiring more precision, the L1015-5C Micro Lathe II introduces a 5C collet system, enhancing its capabilities for precision machining and jewelry making. This model offers greater versatility than the standard L1015, allowing for various workpiece sizes. However, the increased functionality comes at a higher price point.

The M1015 Micro Lathe II is built with a more robust construction and larger capacity, catering to small machine shops and custom fabrication needs. Its durability and capacity make it a strong choice for businesses that require a reliable lathe for frequent use. However, buyers must be prepared for a larger investment and the need for additional space.

Lastly, the L1017 Micro Lathe II features an extended bed length, making it suitable for larger projects and advanced prototyping. This model is particularly beneficial for CNC conversion, offering enhanced stability during operation. While it provides significant advantages for larger workpieces, it also requires a more complex setup and ongoing maintenance, which may be a consideration for potential buyers.

Key Industrial Applications of taig micro lathe

| Industry/Sector | Specific Application of Taig Micro Lathe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace Manufacturing | Precision component fabrication | High accuracy and repeatability in part production | Need for robust performance and reliability in high-stress applications |

| Medical Device Production | Custom tooling and prototyping | Enables rapid prototyping and customization | Compliance with stringent medical regulations and standards |

| Automotive Engineering | Production of small engine components | Cost-effective small-batch production | Ability to handle various materials and precision requirements |

| Jewelry Making | Creating intricate designs and custom parts | Enhances creativity and product differentiation | Requires precision and the ability to work with delicate materials |

| Electronics Assembly | Manufacturing small electronic housings | Facilitates tight tolerances and efficient assembly | Compatibility with various electronic components and materials |

How Is the Taig Micro Lathe Used in Aerospace Manufacturing?

In aerospace manufacturing, the Taig Micro Lathe is utilized for fabricating precision components such as brackets, fittings, and housings. The lathe’s high accuracy, with tolerances as tight as 0.0005 inches, ensures that parts meet the rigorous demands of flight safety and performance. International buyers, particularly from regions like Europe and North America, must consider sourcing lathes that can withstand the high-stress environments typical in aerospace applications. The ability to produce both small and large batches efficiently adds significant value, allowing manufacturers to adapt quickly to changing project requirements.

What Role Does the Taig Micro Lathe Play in Medical Device Production?

In the medical device sector, the Taig Micro Lathe is essential for custom tooling and rapid prototyping of devices such as surgical instruments and diagnostic equipment. The lathe’s versatility allows for the creation of intricate designs that meet specific medical standards. Buyers from regions such as Africa and South America should focus on sourcing lathes that comply with international medical regulations, ensuring that the manufacturing processes meet the necessary safety and performance standards. The ability to quickly iterate designs and produce small batches can significantly reduce time-to-market for innovative medical solutions.

How Is the Taig Micro Lathe Applied in Automotive Engineering?

Automotive engineering leverages the Taig Micro Lathe for the production of small engine components, including bushings, pulleys, and other precision parts. Its capacity to handle various materials, including metals and plastics, makes it a valuable tool for manufacturers looking to optimize production costs and efficiency. Buyers, particularly in Brazil and Germany, should assess the lathe’s capability to produce consistent quality in small-batch runs, which is critical for maintaining competitive advantage in the fast-paced automotive market. The lathe’s robust design ensures longevity and reliability in demanding environments.

In What Ways Is the Taig Micro Lathe Beneficial for Jewelry Making?

Jewelry makers utilize the Taig Micro Lathe to create intricate designs and custom pieces, allowing for high levels of creativity and craftsmanship. The lathe’s precision capabilities enable jewelers to work with delicate materials such as gold and silver, ensuring that even the smallest details are captured flawlessly. Buyers in the jewelry sector, especially from Europe, should consider sourcing lathes that offer flexibility in tooling options and can accommodate various jewelry-making techniques. The ability to produce unique, customized pieces can significantly enhance a jeweler’s marketability and customer satisfaction.

How Does the Taig Micro Lathe Enhance Electronics Assembly?

In electronics assembly, the Taig Micro Lathe is used to manufacture small electronic housings and components, facilitating the assembly of intricate electronic devices. Its precision allows for tight tolerances, ensuring that components fit together seamlessly, which is vital for functionality and performance. Buyers from the Middle East and South America should prioritize sourcing lathes that can handle a variety of materials and are compatible with different electronic components. The efficiency and accuracy of the Taig Micro Lathe can lead to reduced assembly times and improved overall product quality.

3 Common User Pain Points for ‘taig micro lathe’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision Machining

The Problem:

B2B buyers often face challenges when it comes to maintaining precision during machining tasks with the Taig Micro Lathe. For instance, a manufacturer in Brazil might find that their components are not meeting the required tolerances, leading to increased waste and rework. This issue can stem from various factors such as improper setup, lack of understanding of the machine’s capabilities, or insufficient calibration of the lathe’s components. The repercussions of these challenges include dissatisfied customers, increased production costs, and a potential loss of market competitiveness.

The Solution:

To enhance precision, users should begin with thorough training on the machine’s specifications and operational nuances. It is essential to understand the lathe’s capabilities, including its maximum spindle speed of 7000 RPM and overall working accuracy of 0.0005 inches. Regular calibration and maintenance of the machine, including checking the alignment of the bed and ensuring the spindle is correctly set, can significantly improve precision. Furthermore, investing in high-quality cutting tools tailored to the materials being machined will also contribute to better results. For international buyers, sourcing these tools from reputable suppliers can make a significant difference in achieving the desired machining outcomes.

Scenario 2: Limited Knowledge of Accessory Compatibility

The Problem:

Buyers often struggle with selecting the right accessories and components for their Taig Micro Lathe, which can hinder their ability to perform various machining tasks effectively. For example, a user in Germany may purchase the Micro Lathe II but later realize they lack compatible accessories such as tool posts, chucks, or power feeds, which can limit functionality and productivity. This oversight can lead to delays in production and increased operational costs as the user scrambles to find compatible parts.

The Solution:

To avoid compatibility issues, it is critical for buyers to conduct thorough research on the available accessories and their specifications before making a purchase. The Taig Tools website provides a comprehensive list of compatible accessories, such as the adjustable tool post and various headstock options. Buyers should also consider purchasing starter kits that include essential components, ensuring they have everything needed to maximize their lathe’s capabilities from the start. Engaging with the Taig Tools community, including forums and customer support, can also offer insights into accessory compatibility and best practices for enhancing the lathe’s performance.

Scenario 3: Challenges in Sourcing Replacement Parts

The Problem:

International buyers often encounter difficulties in sourcing replacement parts for their Taig Micro Lathe, which can lead to prolonged downtime and hinder operational efficiency. For instance, a workshop in South Africa may require specific components like the spindle bearings or cross slide screws, but struggle to find reliable suppliers who can deliver these parts in a timely manner. This can cause significant disruptions to production schedules and impact the company’s bottom line.

The Solution:

To mitigate sourcing challenges, buyers should establish relationships with multiple suppliers who specialize in Taig Tools parts and accessories. Engaging directly with Taig Tools for parts procurement can often yield faster and more reliable service. Additionally, maintaining an inventory of critical spare parts is a proactive strategy that can help prevent production delays. Buyers can also explore local distributors or authorized service centers that can provide quick access to replacement parts. By staying informed about the machine’s maintenance needs and anticipating potential issues, companies can better manage their operations and reduce downtime.

Strategic Material Selection Guide for taig micro lathe

What Are the Key Materials for Taig Micro Lathe Applications?

When selecting materials for the Taig Micro Lathe, it is essential to consider their properties, advantages, and limitations. The choice of material directly impacts the lathe’s performance, durability, and suitability for specific tasks. Here, we analyze four common materials used in the construction and operation of the Taig Micro Lathe: Steel, Aluminum, Brass, and Plastic.

How Does Steel Perform in Taig Micro Lathes?

Steel is a primary material for the bed and components of the Taig Micro Lathe, known for its strength and rigidity. Key properties include high tensile strength and excellent wear resistance, making it suitable for heavy-duty machining tasks. Steel can withstand high temperatures and pressures, which is crucial during prolonged operations.

Pros: Steel offers exceptional durability and longevity, making it ideal for rigorous industrial applications. It is also relatively cost-effective compared to other high-strength materials.

Cons: The manufacturing complexity can be higher due to the need for precise machining and heat treatment processes. Additionally, steel is prone to corrosion if not properly treated or maintained.

Impact on Application: Steel’s robustness allows it to handle a variety of media, including metals and plastics, making it versatile for different machining tasks.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for steel grades, such as ASTM or DIN. Understanding the availability of quality steel in their region is also critical to avoid supply chain disruptions.

What Role Does Aluminum Play in Taig Micro Lathes?

Aluminum is often used for components that require a lightweight yet strong material. It boasts excellent corrosion resistance and is easier to machine than steel, making it a popular choice for specific parts of the lathe.

Pros: Its lightweight nature reduces the overall weight of the machine, facilitating easier transport and setup. Aluminum is also less expensive than many high-strength alloys.

Cons: While aluminum is durable, it is not as strong as steel, which may limit its use in high-stress applications. It also has a lower temperature tolerance, which can be a factor in some machining environments.

Impact on Application: Aluminum is suitable for non-ferrous materials and applications where weight is a concern, such as in mobile workshops or educational settings.

Considerations for International Buyers: Buyers in Europe may prefer aluminum components due to EU regulations on weight and energy efficiency. Understanding the local availability of aluminum grades compliant with standards like JIS is crucial.

How Does Brass Enhance Taig Micro Lathe Functionality?

Brass is commonly used for fittings and components requiring good machinability and corrosion resistance. Its properties include excellent thermal conductivity and a low friction coefficient, making it ideal for parts like bushings and bearings.

Pros: Brass is highly machinable and offers a good balance of strength and weight. Its resistance to corrosion makes it suitable for various environments.

Cons: Brass can be more expensive than steel and aluminum, which may affect overall project budgets. Additionally, it is not as strong as steel, limiting its use in high-load applications.

Impact on Application: Brass components are particularly effective in applications involving precision and low-friction requirements, such as in the production of intricate parts.

Considerations for International Buyers: Buyers should be aware of the different brass alloys and their compliance with local standards, especially in regions like the Middle East, where specific material properties may be mandated.

What Are the Advantages of Using Plastic in Taig Micro Lathes?

Plastic is often utilized for non-load-bearing components or as protective covers. It is lightweight, resistant to corrosion, and can be molded into complex shapes.

Pros: The primary advantage of plastic is its versatility and low weight, which can enhance the overall design of the lathe. It is also cost-effective for non-structural parts.

Cons: Plastic lacks the strength and durability of metals, making it unsuitable for high-stress applications. It can also degrade under high temperatures.

Impact on Application: Plastic is best used in applications where weight savings are critical, and the components do not experience significant mechanical stress.

Considerations for International Buyers: Buyers should consider the types of plastics available in their regions and their compliance with international standards, especially in Europe, where material safety standards are stringent.

Summary Table of Material Selection for Taig Micro Lathe

| Material | Typical Use Case for Taig Micro Lathe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Bed and structural components | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight components | Easy to machine and corrosion-resistant | Lower strength than steel | Medium |

| Brass | Fittings and precision parts | Excellent machinability and low friction | More expensive than steel | High |

| Plastic | Non-load-bearing components | Lightweight and versatile | Not suitable for high-stress applications | Low |

This strategic material selection guide provides essential insights for B2B buyers considering the Taig Micro Lathe, helping them make informed decisions based on application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for taig micro lathe

What Are the Main Manufacturing Processes for Taig Micro Lathes?

The manufacturing of Taig micro lathes, particularly the Micro Lathe II, involves several key stages that ensure precision and durability. Understanding these processes can help international B2B buyers make informed purchasing decisions.

Material Preparation: What Materials Are Used and How Are They Processed?

The manufacturing process begins with the careful selection of materials. Taig Tools uses high-quality steel for the lathe bed, which is machined, ground, and stabilized. This preparation is crucial as it provides the necessary strength and rigidity required for precision machining. The components are often heat-treated to enhance their durability and resistance to wear.

To prepare the materials, they undergo cutting and machining processes to achieve the desired dimensions. This stage might also include surface treatments to improve corrosion resistance and overall finish quality.

How Are Components Formed and Assembled for Optimal Performance?

Once the materials are prepared, they move on to the forming stage. This involves several techniques, including CNC machining, to create precise components such as the spindle, carriage, and cross slide. The use of Computer Numerical Control (CNC) technology ensures that every component is manufactured to exact specifications, minimizing tolerances and enhancing performance.

After forming, the assembly process begins. Each micro lathe is carefully assembled with attention to detail. Critical components such as the sealed ball bearings in the spindle are installed to ensure smooth operation. The lathe includes features like adjustable tool posts and depth stops, which are calibrated during assembly to ensure maximum functionality.

What Finishing Techniques Are Used to Ensure Quality?

Finishing is the final stage of the manufacturing process. It typically includes polishing, coating, or painting to enhance the aesthetic appeal and protect the machinery from environmental factors. Taig Tools employs rigorous finishing techniques to ensure that each micro lathe not only performs optimally but also looks professional.

Quality is a top priority, and any imperfections identified during the finishing process are addressed immediately. This attention to detail contributes to the overall quality and longevity of the micro lathes.

How Is Quality Assurance Implemented in Taig Micro Lathe Manufacturing?

Quality assurance (QA) is critical in the manufacturing of Taig micro lathes. It ensures that the products meet both international standards and customer expectations.

What International Standards Guide Quality Assurance Practices?

Taig Tools adheres to several international standards, including ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO 9001 ensures that Taig Tools maintains consistent quality in its manufacturing processes and products. Additionally, certifications such as CE (Conformité Européenne) signify that the micro lathes meet European health, safety, and environmental protection standards.

For B2B buyers, understanding these certifications can provide confidence in the product’s quality and safety.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are integrated into various stages of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet specified standards before they enter production.

-

In-Process Quality Control (IPQC): During assembly, components are frequently measured and tested to ensure they meet design specifications. This includes checks on spindle runout and overall dimensional accuracy.

-

Final Quality Control (FQC): Once assembly is complete, each micro lathe undergoes a thorough inspection. This final inspection includes testing the operational capabilities of the lathe, ensuring that it meets performance standards.

What Common Testing Methods Are Employed for Quality Assurance?

Taig Tools employs various testing methods to validate the quality of their micro lathes. These may include:

-

Functional Testing: Each lathe is operated to verify performance metrics such as spindle speed and accuracy.

-

Dimensional Inspection: Precision measuring tools are used to ensure that all components meet the required tolerances.

-

Durability Testing: Components may be subjected to stress tests to assess their performance under load.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control measures of suppliers is essential. Here are some actionable steps to ensure that suppliers adhere to high standards:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify quality control processes. Buyers should:

-

Request Documentation: Ask for quality management system documentation, including certifications and quality assurance reports.

-

Conduct On-Site Audits: If feasible, visit the manufacturing facility to observe processes firsthand. This allows buyers to assess the quality of materials, manufacturing practices, and overall operational efficiency.

-

Review Test Reports: Request samples of testing reports from the supplier to understand the quality levels of the products being manufactured.

How Do Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further enhance the verification process. These independent organizations conduct thorough evaluations of manufacturing practices, ensuring compliance with international standards. This adds an extra layer of assurance for B2B buyers, particularly in regions with varying quality control norms.

What Are the QC Considerations for International Buyers from Diverse Markets?

When purchasing from suppliers in different regions, B2B buyers should be aware of certain nuances:

-

Cultural Differences: Different regions may have varying standards for quality assurance. Understanding these differences can help in negotiating quality expectations.

-

Regulatory Compliance: Ensure that the supplier complies with local regulations in addition to international standards. This is particularly important for buyers in regions like Africa and the Middle East, where regulations may differ significantly.

-

Communication: Maintain open lines of communication with suppliers to address any quality concerns promptly. This collaboration can help mitigate risks associated with international transactions.

By understanding the manufacturing processes and quality assurance practices of Taig micro lathes, B2B buyers can make informed decisions and ensure they are investing in high-quality machinery that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘taig micro lathe’

When sourcing a Taig Micro Lathe, especially for B2B procurement, having a structured approach can significantly enhance your decision-making process. This checklist is designed to guide you through the necessary steps, ensuring you select the right machine and supplier for your needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, outline the specific technical requirements for your Taig Micro Lathe. Consider factors such as maximum turning diameter, spindle speed, and the materials you will be machining.

– Example Specifications: If you need to work with mild steel, ensure the lathe can handle the required cuts and speeds.

– Customization Needs: Determine if you need any special features or accessories, like a power feed or specific tooling setups.

Step 2: Research Reputable Suppliers

Identifying reliable suppliers is crucial for a successful purchase. Look for manufacturers with a strong track record in the industry, particularly those specializing in precision tools like Taig Tools.

– Check Reviews and Testimonials: Look for customer feedback that highlights the quality of the lathe and the supplier’s service.

– Certifications: Ensure the supplier has relevant certifications, such as ISO standards, which can indicate quality assurance.

Step 3: Evaluate Product Options

Explore the various models of Taig Micro Lathes available. Each model may offer different capabilities and configurations that can cater to your specific machining needs.

– Comparative Analysis: Create a comparison chart of models like the L1015 and L1017, noting their specifications, pricing, and features.

– Accessories and Parts Availability: Ensure that the necessary parts and accessories are readily available to support your operations post-purchase.

Step 4: Request Quotes and Pricing

Once you have narrowed down potential suppliers and models, request detailed quotations. This step is essential for budget planning and understanding the total cost of ownership.

– Inquire About Bulk Discounts: If you plan to purchase multiple units, check if the supplier offers discounts for bulk orders.

– Clarify Shipping and Handling Costs: Understand all associated costs, including shipping, taxes, and potential customs fees, especially for international transactions.

Step 5: Verify Warranty and Support Options

Before finalizing your purchase, investigate the warranty terms and after-sales support offered by the supplier. A robust warranty can protect your investment and reduce long-term costs.

– Duration and Coverage: Look for warranties that cover parts and labor for a reasonable period.

– Technical Support: Ensure that the supplier provides accessible technical support in case you encounter any issues with the machine.

Step 6: Confirm Delivery and Payment Terms

Finally, clarify the delivery timeline and payment terms with your chosen supplier. This step is crucial for planning your operations effectively.

– Delivery Schedule: Confirm how long it will take to receive the lathe after placing the order.

– Payment Methods: Discuss acceptable payment methods, including options for credit terms or financing if needed.

By following this checklist, you can streamline the sourcing process for a Taig Micro Lathe, ensuring that you make an informed and strategic purchasing decision tailored to your operational needs.

Comprehensive Cost and Pricing Analysis for taig micro lathe Sourcing

What Are the Key Cost Components in Sourcing a Taig Micro Lathe?

When considering the procurement of a Taig micro lathe, it’s essential to understand the various cost components that contribute to the total expense. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The primary materials for the Taig micro lathe include high-quality steel for the bed and components, which impacts both durability and performance. Higher-grade materials typically result in a higher initial cost but can offer superior longevity and reliability.

-

Labor: Labor costs cover both the assembly and the skilled craftsmanship required in manufacturing the lathe. As the production involves precision engineering, skilled labor is essential, which can contribute to elevated costs.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these overheads, ultimately benefiting the buyer.

-

Tooling and QC: Tooling costs are necessary for creating the precision parts of the lathe, while quality control measures ensure that each unit meets the stringent performance specifications. Investing in robust QC processes can prevent costly defects and improve customer satisfaction.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and customs fees can significantly affect the overall cost.

-

Margin: Supplier margins vary widely based on the brand reputation, perceived value, and market competition. Understanding these margins can aid in negotiating better pricing.

How Do Price Influencers Affect the Cost of Taig Micro Lathes?

Several factors influence the pricing of Taig micro lathes, particularly for international buyers.

-

Volume/MOQ (Minimum Order Quantity): Buying in bulk can lead to significant discounts, reducing the per-unit cost. International buyers should consider consolidating orders with other businesses to meet MOQ requirements for better pricing.

-

Specifications and Customization: Customized lathes tailored to specific operational needs can increase costs. Buyers should clearly define their specifications to avoid unnecessary expenses.

-

Materials and Quality Certifications: Machines made with premium materials and certified for quality (e.g., ISO certifications) will typically command higher prices. Buyers should assess the balance between cost and quality to ensure they meet their operational requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their products due to perceived quality and service levels.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the final cost and responsibilities for both parties.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Taig Micro Lathes?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, adopting a strategic approach can lead to significant savings.

-

Negotiation: Always engage in negotiations to lower the price. Suppliers may offer discounts for larger orders or may be willing to adjust prices based on competitive offers.

-

Total Cost of Ownership (TCO): Consider the total cost of ownership, which includes initial purchase price, maintenance, operational costs, and potential downtime. A lower initial cost may not always equate to savings in the long run.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates and import tariffs, which can affect the overall cost of sourcing. It may be beneficial to lock in prices or negotiate terms that accommodate these variables.

-

Research Local Market Conditions: Understanding local market conditions and competitor pricing can empower buyers to make informed decisions and negotiate effectively.

Disclaimer on Indicative Prices

The prices mentioned for the Taig micro lathe and its accessories are indicative and may vary based on supplier, location, and market conditions. International buyers should seek specific quotes and confirm current pricing with suppliers to ensure accuracy in their budgeting and procurement planning.

Alternatives Analysis: Comparing taig micro lathe With Other Solutions

When considering the acquisition of a precision lathe, B2B buyers must evaluate various options to identify the best fit for their operational needs. The Taig Micro Lathe is a popular choice due to its rugged construction and precision capabilities. However, other alternatives may offer different advantages depending on the specific requirements of a business, including performance, cost, and ease of use. Below, we compare the Taig Micro Lathe with two viable alternatives: the Sherline Lathe and the Grizzly G8688 Mini Metal Lathe.

| Comparison Aspect | Taig Micro Lathe | Sherline Lathe | Grizzly G8688 Mini Metal Lathe |

|---|---|---|---|

| Performance | High precision (0.0005 in.) | Moderate precision (0.001 in.) | Good precision (0.001 in.) |

| Cost | $345.10 | $700.00 | $599.00 |

| Ease of Implementation | User-friendly, compact | Requires learning curve | Straightforward setup |

| Maintenance | Low maintenance | Moderate maintenance | Low maintenance |

| Best Use Case | Small, precise machining | Hobbyist and small projects | General purpose machining |

What Are the Advantages and Disadvantages of the Sherline Lathe Compared to the Taig Micro Lathe?

The Sherline Lathe is known for its compact design and versatility, making it suitable for hobbyists and small-scale manufacturers. While it offers moderate precision, it may not reach the high accuracy levels of the Taig Micro Lathe. The initial cost is higher, which may deter budget-conscious buyers. However, Sherline’s machines come with a broader range of accessories that can enhance functionality. The learning curve for operating Sherline lathes is steeper, which may require additional training or familiarization time.

How Does the Grizzly G8688 Mini Metal Lathe Stack Up Against the Taig Micro Lathe?

The Grizzly G8688 Mini Metal Lathe is a solid alternative for those seeking a balance between cost and performance. It offers good precision and is suitable for general-purpose machining. Priced competitively, it provides a good entry point for businesses looking to explore metalworking without significant investment. However, it does not match the Taig Micro Lathe in terms of high-precision capabilities. The setup is relatively straightforward, making it accessible for new users. Nevertheless, some users report that its build quality may not be as robust as that of the Taig.

Conclusion: How Can B2B Buyers Determine the Right Lathe for Their Needs?

In selecting the right lathe, B2B buyers should assess their specific operational needs, budget constraints, and the types of materials they will be working with. The Taig Micro Lathe excels in precision and build quality, making it ideal for applications requiring high accuracy. Alternatively, the Sherline Lathe provides versatility at a higher price point, suitable for hobbyists or small workshops. The Grizzly G8688 offers a budget-friendly solution for general machining tasks, albeit with some compromises in precision and build quality. Ultimately, understanding the unique requirements of your business will guide you toward the best lathe solution to enhance productivity and efficiency.

Essential Technical Properties and Trade Terminology for taig micro lathe

What Are the Essential Technical Properties of a Taig Micro Lathe?

When considering the purchase of a Taig Micro Lathe, understanding its technical properties is vital for making informed decisions. Here are some critical specifications:

-

Overall Working Accuracy (0.0005 in.)

This measurement indicates how precisely the lathe can produce parts. A tighter tolerance is crucial for industries requiring high precision, such as aerospace or medical device manufacturing. It ensures that components fit together correctly and function as intended. -

Maximum Spindle Speed (7000 RPM)

The spindle speed determines how quickly the lathe can operate. Higher speeds allow for faster material removal, which can significantly improve productivity. For businesses in competitive markets, this efficiency can be a decisive factor in meeting production deadlines and reducing costs. -

Maximum Turning Diameter (4.5 in., extendable to 6.5 in.)

This specification defines the largest diameter of the workpiece that can be machined. Understanding the capacity helps businesses assess whether the lathe can accommodate their typical project sizes, ensuring it meets their operational needs. -

Carriage Travel (9.0 in.)

Carriage travel indicates how far the cutting tool can move along the lathe. A greater travel distance provides flexibility for machining larger parts or multiple parts in one setup, which is especially valuable for companies looking to maximize their machining capabilities without investing in additional equipment. -

Material Grade and Construction

Taig Micro Lathes are constructed from heat-treated alloy steels and feature machined, ground, and stabilized steel beds. This material choice enhances durability and performance under heavy use. For B2B buyers, investing in quality materials translates to lower maintenance costs and longer machine life. -

Sealed Precision Ball Bearings

The use of sealed ball bearings in the spindle reduces friction and wear, leading to smoother operation and increased longevity. This is particularly important for businesses that rely on their equipment for continuous production, as it minimizes downtime and repair costs.

What Are Common Trade Terms Related to Taig Micro Lathes?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are some common terms used in the trade:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help businesses identify quality suppliers and ensure compatibility with existing machinery. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to manage inventory costs and ensure they meet production requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for a specific quantity of goods or services. For B2B buyers, issuing an RFQ is a strategic way to gather competitive offers and negotiate better terms. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses understand shipping costs, risks, and obligations, which is critical for smooth cross-border operations. -

Lead Time

Lead time refers to the period from the placement of an order until its delivery. Understanding lead times allows companies to better plan their production schedules and inventory management, ensuring that they can meet customer demands promptly. -

CNC (Computer Numerical Control)

CNC refers to the automation of machine tools through computer programming. This technology enhances precision and repeatability in manufacturing processes. B2B buyers should consider CNC capabilities when evaluating lathes, especially for high-volume production runs.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions about investing in Taig Micro Lathes, ensuring they choose the right equipment for their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the taig micro lathe Sector

What Are the Current Market Dynamics and Key Trends in the Taig Micro Lathe Sector?

The taig micro lathe sector is experiencing significant growth driven by the rising demand for precision machining tools across various industries. Key markets in Africa, South America, the Middle East, and Europe (notably Brazil and Germany) are witnessing an uptick in small-scale manufacturing and DIY projects, fueled by the growing trend of entrepreneurship and innovation in these regions. The increasing accessibility of advanced manufacturing technologies is enabling local businesses to utilize high-quality tools like the Micro Lathe II, leading to enhanced productivity and competitive advantages.

Emerging B2B tech trends, such as the integration of CNC capabilities with traditional lathe machines, are reshaping the sector. Companies are increasingly seeking versatile equipment that can accommodate both manual and automated processes, which is a hallmark of the Micro Lathe II. Furthermore, the shift towards digital platforms for sourcing and procurement is allowing international buyers to access a broader range of suppliers and products, streamlining the purchasing process and reducing lead times.

The market dynamics are also influenced by the growing emphasis on customization and flexibility in manufacturing. Businesses are looking for micro lathes that can easily adapt to different materials and production requirements, a feature that the taig micro lathe offers with its robust design and precision capabilities. As a result, suppliers must remain agile and responsive to the evolving needs of their B2B clients to maintain a competitive edge.

How Does Sustainability and Ethical Sourcing Impact the Taig Micro Lathe Sector?

Sustainability is becoming a critical consideration for B2B buyers, particularly in regions where environmental regulations are tightening. The taig micro lathe sector is not exempt from these pressures; thus, manufacturers are increasingly focusing on reducing their environmental impact through sustainable practices. This includes the responsible sourcing of materials, reducing waste during production, and ensuring energy-efficient manufacturing processes.

Ethical supply chains are gaining importance as businesses strive to enhance their corporate social responsibility profiles. Buyers are more inclined to partner with suppliers who demonstrate a commitment to ethical labor practices and environmental stewardship. For example, taig tools are manufactured using high-quality, durable materials that minimize the need for frequent replacements, thereby reducing overall resource consumption.

Moreover, certifications that validate a product’s environmental impact and ethical sourcing practices are becoming essential for international buyers. Certifications such as ISO 14001 for environmental management systems or adherence to the Sustainable Manufacturing Initiative can bolster a supplier’s reputation and appeal. B2B buyers are advised to evaluate potential suppliers based on these criteria, as they not only align with global sustainability goals but also enhance long-term operational efficiencies.

What Is the Evolution of the Taig Micro Lathe in the B2B Context?

The evolution of the taig micro lathe can be traced back to the increasing demand for compact yet powerful machining tools in the late 20th century. Originally designed for hobbyists, these lathes have transitioned into essential equipment for small-scale manufacturers and educational institutions. The introduction of features such as precision ball bearings, adjustable tool posts, and CNC compatibility has positioned the taig micro lathe as a versatile solution for various machining tasks.

As the manufacturing landscape continues to evolve, the taig micro lathe has adapted to meet the needs of modern B2B buyers. Its robust construction and high precision have made it a preferred choice for industries ranging from aerospace to automotive, where accuracy and reliability are paramount. The focus on continuous improvement and innovation ensures that the taig micro lathe remains relevant in a competitive market, catering to the diverse requirements of international buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of taig micro lathe

1. How do I solve common issues with the Taig Micro Lathe?

Common issues with the Taig Micro Lathe, such as misalignment or inconsistent cutting, can often be resolved through proper setup and maintenance. Ensure the machine is level and securely mounted to prevent vibration. Regularly check and adjust the alignment of the tailstock and headstock, and ensure all components are clean and lubricated. If you experience unusual noises or performance issues, inspect the bearings and belts for wear. For technical support, contact the manufacturer or your supplier for assistance.

2. What is the best Taig Micro Lathe model for precision machining?

The best model for precision machining often depends on your specific requirements. The L1015 Micro Lathe II is highly regarded for its rugged construction and precision capabilities, with an overall working accuracy of 0.0005 inches. It features a steel bed, sealed ball bearings, and a six-speed drive system, making it suitable for various materials. For more demanding applications, consider the M1015ER model, which offers enhanced features for CNC compatibility. Evaluate your machining needs to select the most suitable option.

3. What are the payment terms when purchasing Taig Micro Lathes internationally?

Payment terms for international purchases typically vary by supplier. Common options include advance payment, letters of credit, or payment upon delivery. It’s crucial to discuss these terms upfront with your supplier to ensure clarity and mutual agreement. Consider using secure payment methods like PayPal or bank transfers to safeguard your transaction. Always confirm the supplier’s credibility and review their payment policies to avoid potential issues.

4. How can I vet a supplier for Taig Micro Lathes?

Vetting a supplier for Taig Micro Lathes involves several key steps. Start by researching the supplier’s reputation through online reviews and testimonials from other B2B buyers. Verify their business credentials, including registration and certifications, to ensure they are legitimate. Request references from previous customers to assess their experience with product quality and customer service. Additionally, consider visiting their facility if possible or request a virtual tour to evaluate their operations and quality control processes.

5. What is the minimum order quantity (MOQ) for Taig Micro Lathes?

The minimum order quantity (MOQ) for Taig Micro Lathes can vary by supplier and the specific model. Generally, smaller suppliers may have flexible MOQs, while larger manufacturers may require bulk orders to justify production runs. Discuss your purchasing needs with potential suppliers to see if they can accommodate smaller orders, especially if you are testing the market or starting a new project. Always confirm the MOQ in writing to avoid misunderstandings.

6. Can I customize my Taig Micro Lathe order?

Yes, many suppliers offer customization options for Taig Micro Lathes. Customizations may include specific tooling, additional accessories, or modifications to suit unique operational requirements. When discussing your order, clearly outline your customization needs to the supplier. Be aware that customization may affect pricing and lead times, so factor these into your planning. Always request a detailed quote that includes any additional costs associated with customizations.

7. What quality assurance measures should I expect from Taig Micro Lathes?

Quality assurance measures for Taig Micro Lathes typically include rigorous testing and inspection processes before shipment. Expect suppliers to provide certifications that demonstrate compliance with industry standards. Look for features such as precision manufacturing, use of high-quality materials, and post-production inspections. Request documentation of the quality assurance process from your supplier to ensure the lathe meets your operational requirements and standards.

8. How does logistics work for international shipping of Taig Micro Lathes?

Logistics for international shipping of Taig Micro Lathes involves several steps, including selecting a reliable freight forwarder and understanding customs regulations. Coordinate with your supplier to determine the best shipping method based on urgency and cost. Ensure that all shipping documents, such as invoices and packing lists, are accurate to facilitate smooth customs clearance. It’s advisable to discuss insurance options for your shipment to protect against potential damage or loss during transit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Taig Micro Lathe Manufacturers & Suppliers List

1. TAIG Tools – Micro Lathes

Domain: taigtools.com

Registered: 1999 (26 years)

Introduction: Micro Lathes for Precision Projects and Compact Workspaces. Micro Lathe II Machines (14) and Micro Lathe II Parts & Accessories (5). Contact: TAIG Tools, 12419 E. Nightingale Lane, Chandler, AZ 85286, Phone: (480) 895-6978.

2. Taig – Micro Lathe

Domain: blog.thehobbyistmachineshop.com

Registered: 2007 (18 years)

Introduction: Taig Micro Lathe is designed for small parts hobbyists and miniature model makers. It lacks powered feed and thread making ability, but a powered feed option has recently been added. The lathe is simple to use, customizable, and made of aluminum, suitable for micro parts. The Taig spindle operates at over 10,000 rpm with extreme side loads and does not overheat. The lathe has limitations typical o…

3. Otto Frei – TAIG Micro Lathe II

Domain: ottofrei.com

Registered: 2000 (25 years)

Introduction: Otto Frei TAIG Micro Lathe II, Completely Assembled & Pre-Wired

4. Taig – Power Feed Micro Lathe

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: Micro lathes discussed include Taig, Sherline, Proxxon, Unimat, Prazi, and Emco. Key features mentioned for Taig lathes: one with power feed, capable of great repeatable accuracy, limitations in size and no single point threading capability. Users express interest in comparisons of repeatable accuracy and elimination of taper among different micro lathes. Other lathes mentioned include Unimat SL 1…

5. Taig – Micro Lathe II

Domain: canadianhobbymetalworkers.com

Registered: 2015 (10 years)

Introduction: Taig Micro Lathe II

– Spindle: 3/4-16

– Motor: 1/4hp, 1725rpm

– Includes:

– Metal working carriage and cross slide

– Woodturning tool rest

– Drilling tail stock

– 1/4” drill chuck

– 1 front tool post

– 2 rear tool posts

– 4-jaw independent chuck

– Headstock wrench

– 7 cutting tools

– Asking price: $400

6. Taig – Vintage Micro Lathe 4500

Domain: modelenginemaker.com

Registered: 2012 (13 years)

Introduction: Vintage Taig Micro Lathe 4500; estate sale find; includes milling attachment; assortment of collets; 3 jaw and 4 jaw chucks; motor runs fine; condition: rusty and dusty but cleaned up well; previous sale price reference: approximately $550 for a similar setup in 2019; current basic setup price around $550; additional heads available for around $1100; noted as a capable machine for its size.

7. Carter Tools – Taig Micro Lathe II

Domain: cartertools.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “Taig Micro Lathe II”, “Specifications”: {“Assembled Components”: [“1150 tailstock”, “1050 3 jaw chuck”, “1097D tool bit”, “1023 mounting board”, “1162 pulley set”, “1092 drill chuck”], “Swing Over Bed”: “4.5 inch”, “Swing Over Crosslide”: “2.375 inch”, “Overall Length of Bed”: “15.5 inch”, “Overall Length of Lathe”: “16.5 inch”, “Bed Construction”: “Ground Steel Dovetailed Ways o…

8. Taig – Lathe Starter Set

Domain: modelcarsmag.com

Registered: 1999 (26 years)

Introduction: Taig Lathe Starter Set: Price – just over $450; Features – suitable for 1/24 scale models, capable for various tasks, full range of accessories available; Specifications – 4.5″ swing, 9-3/4″ between centers, overall length of 16-1/2″; Motor – 1/4 hp; Speed control – 6 speeds from 525-5200 rpm; Tailstock – extra cost option, operated with a non-calibrated lever; Comparison – heavier than Sherline, …

9. Taig – Micro Lathe 2 for Sale

Domain: rcgroups.com

Registered: 2001 (24 years)

Introduction: Taig Micro Lathe 2, in excellent condition, for sale at $375.00 USD (buyer pays shipping). Includes some tooling, two new end mills, and a professionally made milling attachment. Used mainly for making parts for RC helicopters and airplanes. Seller is moving to a larger lathe and is firm on price but open to discussing a trade for a larger lathe. Payment accepted via money order or personal check …

Strategic Sourcing Conclusion and Outlook for taig micro lathe

As the global market for precision machining tools continues to expand, the Taig Micro Lathe stands out as a cost-effective solution that meets the diverse needs of manufacturers and hobbyists alike. Its robust design, exceptional accuracy, and versatility make it an attractive option for businesses across various sectors, including metalworking, woodworking, and plastics. The Micro Lathe II’s ability to perform both heavy cuts and fine detailing positions it as a valuable asset for those looking to optimize their production capabilities.

Strategic sourcing of the Taig Micro Lathe not only enhances operational efficiency but also contributes to long-term cost savings and competitive advantage. By investing in reliable equipment like the Micro Lathe II, international buyers can ensure consistent quality in their outputs while minimizing downtime due to equipment failure.

Looking ahead, the demand for advanced machining solutions in regions such as Africa, South America, the Middle East, and Europe is set to rise. Companies are encouraged to leverage the benefits of the Taig Micro Lathe to stay ahead in a competitive landscape. Engage with suppliers today to explore how this precision tool can elevate your manufacturing processes and meet your specific production needs.