Introduction: Navigating the Global Market for tabletop water jet

In today’s competitive landscape, sourcing a reliable tabletop water jet can pose significant challenges for international B2B buyers. Whether you are in manufacturing, education, or creative industries, understanding the nuances of selecting the right water jet cutter is crucial for enhancing operational efficiency and reducing costs. This comprehensive guide delves into various types of tabletop water jets, their diverse applications, and essential factors for supplier vetting, pricing structures, and ongoing maintenance considerations.

By providing actionable insights and a clear framework for evaluating options, this guide empowers buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Brazil and Vietnam—to make informed purchasing decisions. The tabletop water jet market is evolving rapidly, and with the right knowledge, you can navigate this landscape effectively. From understanding the cutting capabilities of different models to evaluating the total cost of ownership, this guide serves as a valuable resource for ensuring that your investment aligns with your specific business needs and goals.

Equip yourself with the expertise necessary to select a tabletop water jet that not only meets your technical requirements but also provides long-term value and reliability for your operations.

Understanding tabletop water jet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| WAZER Pro | High cutting power, capable of cutting thick materials up to 1″ aluminum and 0.375″ stainless steel | Aerospace, Automotive, Manufacturing | Pros: Affordable, user-friendly, versatile. Cons: Higher initial investment. |

| WAZER Desktop | Compact design, suitable for smaller spaces, cuts various materials including metal and glass | Education, Small-scale Manufacturing, Prototyping | Pros: Space-efficient, lower cost. Cons: Limited cutting thickness compared to larger models. |

| Industrial Water Jet | Larger capacity, designed for high-volume production, cuts a wide range of materials | Heavy Manufacturing, Aerospace, Automotive | Pros: High throughput, robust performance. Cons: Requires more space and maintenance. |

| Portable Water Jet | Lightweight, mobile design, suitable for on-site cutting | Construction, Field Repairs, Custom Fabrication | Pros: Flexibility in location, easy transport. Cons: Limited cutting power compared to stationary models. |

| Multi-Function Water Jet | Combines waterjet cutting with other functions like engraving or milling | Signmaking, Custom Art, Prototyping | Pros: Versatile, saves on equipment costs. Cons: Potentially more complex operation. |

What Are the Key Features of WAZER Pro Tabletop Water Jet Cutters?

The WAZER Pro stands out for its remarkable cutting power, capable of slicing through thick materials such as 1″ aluminum and 0.375″ stainless steel. This model is ideal for industries like aerospace and automotive where precision and durability are paramount. When considering a WAZER Pro, buyers should evaluate their production needs against its upfront cost, while also recognizing its user-friendly interface that can benefit diverse teams.

How Does the WAZER Desktop Cater to Small Businesses?

Designed for smaller workspaces, the WAZER Desktop offers a compact solution without sacrificing cutting quality. It is capable of handling various materials, making it suitable for educational institutions and small-scale manufacturers. Buyers should consider the machine’s limitations in cutting thickness compared to larger counterparts but appreciate its affordability and ease of operation, making it a great entry point for businesses new to waterjet technology.

What Benefits Do Industrial Water Jets Provide for High-Volume Production?

Industrial water jets are engineered for high-volume production, making them indispensable in heavy manufacturing sectors. They can handle a broad range of materials and are built to operate continuously, which is crucial for businesses that require consistent output. However, potential buyers must assess their facility’s space and maintenance capabilities, as these machines typically demand more resources than smaller models.

Why Choose a Portable Water Jet for On-Site Applications?

Portable water jets bring the advantage of mobility, allowing businesses to perform cutting tasks directly at construction sites or during field repairs. Their lightweight design facilitates easy transport, making them ideal for custom fabrication projects. However, while they offer flexibility, buyers should be aware of their limited cutting power compared to stationary models, which might restrict their applications in more demanding environments.

What Makes Multi-Function Water Jets an Attractive Option?

Multi-function water jets integrate cutting with additional features like engraving or milling, providing exceptional versatility for businesses engaged in signmaking or custom art projects. This capability can lead to cost savings on equipment and increase operational efficiency. Buyers should consider the complexity of operation and training requirements, as these machines may require a steeper learning curve compared to simpler models.

Key Industrial Applications of tabletop water jet

| Industry/Sector | Specific Application of tabletop water jet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Rapid prototyping of aircraft components | Accelerates design iterations and reduces time-to-market | Look for precision cutting capabilities and material versatility. |

| Automotive | Custom parts manufacturing for vehicles | Enables production of lightweight, complex geometries | Ensure compatibility with various materials and ease of integration. |

| Glass Art | Intricate glass cutting for artistic designs | Automates labor-intensive tasks, increasing production efficiency | Consider machine size, cutting thickness, and software compatibility. |

| Education | Hands-on training for engineering students | Prepares students for real-world applications and modern technologies | Evaluate user-friendliness and support for educational institutions. |

| Manufacturing | On-demand production of custom components | Reduces lead times and inventory costs | Assess maintenance requirements and availability of parts. |

How is Tabletop Water Jet Used in Aerospace Applications?

In the aerospace industry, tabletop water jet technology is pivotal for rapid prototyping of aircraft components. Companies utilize this equipment to create precise, functional prototypes from various materials, including metals and composites. The ability to quickly iterate designs significantly enhances innovation and reduces time-to-market. International buyers should prioritize sourcing machines with high cutting accuracy and the capability to handle diverse materials, ensuring they meet stringent aerospace standards.

What Role Does Tabletop Water Jet Play in Automotive Customization?

Automotive manufacturers leverage tabletop water jets for producing custom parts, particularly in lightweight and complex geometries. This technology allows for precise cutting of materials such as aluminum and composites, essential for modern vehicle design. By enabling in-house production, businesses can significantly cut lead times and reduce outsourcing costs. Buyers from regions like Africa and South America should consider machines that offer versatility in material compatibility and ease of integration into existing workflows.

How Does Tabletop Water Jet Enhance Glass Art Production?

In the realm of glass art, tabletop water jets facilitate intricate cutting designs that were previously labor-intensive. Artists and manufacturers can automate the cutting process, allowing for continuous production without the fatigue associated with manual labor. This capability not only increases efficiency but also opens up new creative possibilities. When sourcing, businesses should evaluate the machine’s cutting thickness and the software’s ability to handle complex designs, ensuring it aligns with artistic needs.

Why is Tabletop Water Jet Important in Educational Settings?

Tabletop water jets are increasingly utilized in educational institutions to provide students with hands-on experience in engineering and design. These machines allow students to engage with modern manufacturing technologies, preparing them for careers in various industries. When sourcing for educational purposes, it is essential to consider the machine’s user-friendliness and the availability of instructional support to facilitate effective learning experiences.

How Does Tabletop Water Jet Support Manufacturing Efficiency?

Manufacturers benefit from tabletop water jets by enabling on-demand production of custom components, which helps reduce lead times and inventory costs. This technology allows for accurate and repeatable cutting processes, making it ideal for various manufacturing applications. Buyers should assess the maintenance requirements and ensure the availability of replacement parts to minimize downtime and keep production running smoothly.

3 Common User Pain Points for ‘tabletop water jet’ & Their Solutions

Scenario 1: Navigating Material Limitations with Tabletop Water Jets

The Problem: Many B2B buyers are drawn to tabletop water jet cutters due to their versatility in cutting various materials. However, buyers often face challenges when they discover that not all machines can handle the thickness or type of materials they require. For instance, a manufacturer looking to cut 1-inch thick aluminum for a custom project may find that their chosen water jet is not equipped to handle such demands, leading to frustration and potential project delays.

The Solution: To address this issue, buyers should thoroughly evaluate the specifications of the tabletop water jet before purchase. Key considerations include the maximum material thickness and the types of materials that can be cut. Engaging with manufacturers directly can provide insights into the machine’s capabilities. Additionally, buyers should inquire about demo units or trial periods to test the machine’s performance with their specific materials. Leveraging customer reviews and case studies can also help in understanding how other businesses successfully utilized the equipment for similar applications. Ensuring the right fit not only enhances productivity but also mitigates the risk of costly operational downtime.

Scenario 2: Overcoming High Operational Costs and Maintenance

The Problem: A common concern among B2B buyers is the ongoing operational costs associated with tabletop water jet machines, particularly regarding maintenance and consumables like abrasives. Many businesses find themselves overwhelmed by the recurring expenses, which can impact their profit margins. For instance, a small workshop may struggle to manage the costs of abrasives and maintenance, especially if the equipment is not designed for efficiency.

The Solution: To combat high operational costs, buyers should conduct a comprehensive cost analysis before purchasing a tabletop water jet. Selecting models that are known for low maintenance and efficient use of abrasives can drastically reduce long-term costs. Buyers should also explore options for bulk purchasing of consumables to take advantage of discounts. Moreover, investing in training for staff on efficient operating procedures can help minimize waste and maximize the lifespan of the machine. Lastly, consider machines that offer features like automatic abrasive recycling systems, which can significantly lower the amount of abrasive used per cut.

Scenario 3: Ensuring User-Friendly Operation for Diverse Skill Levels

The Problem: In many B2B environments, the workforce comprises individuals with varying skill levels. This presents a challenge when integrating complex machinery like tabletop water jets, which may be intimidating for less experienced operators. A common scenario is a small manufacturing firm where only a few employees are well-versed in CNC operations, while others struggle to operate the machine effectively, leading to inefficient production processes and errors.

The Solution: To ensure smooth operation across diverse skill levels, buyers should prioritize user-friendly machines that come with intuitive software and clear operational guidelines. Opting for a tabletop water jet that features a straightforward interface can facilitate easier training for new users. Manufacturers that provide comprehensive training programs and ongoing support are invaluable resources. Additionally, investing in supplementary training resources, such as online tutorials or workshops, can empower all employees to become proficient in using the equipment. Implementing a mentorship system, where skilled operators guide less experienced colleagues, can also foster a more collaborative and effective working environment. This approach not only enhances productivity but also builds a more competent workforce capable of maximizing the machine’s capabilities.

Strategic Material Selection Guide for tabletop water jet

When selecting materials for tabletop water jet applications, international B2B buyers must consider various factors that influence performance, cost, and suitability for specific projects. Below is an analysis of four common materials used in conjunction with tabletop water jets, focusing on their key properties, advantages, disadvantages, and implications for buyers in different regions.

What Are the Key Properties of Aluminum for Tabletop Water Jet Applications?

Aluminum is a lightweight metal known for its excellent corrosion resistance and high strength-to-weight ratio. It typically has a melting point of around 660°C and can withstand pressures up to 200 MPa, making it suitable for various applications.

Pros: Aluminum is durable, easy to machine, and offers a good surface finish after cutting. Its lightweight nature makes it ideal for applications in aerospace and automotive sectors, where weight reduction is crucial.

Cons: While relatively affordable, aluminum can be more expensive than some plastics. Its thermal conductivity can lead to warping if not properly managed during cutting.

Impact on Application: Aluminum is compatible with various media, including water and abrasive mixtures, making it versatile for different cutting needs.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is essential. Buyers in regions like Africa and South America should also consider local availability and import duties.

How Does Stainless Steel Perform in Tabletop Water Jet Cutting?

Stainless steel is known for its high corrosion resistance and durability, with a melting point ranging from 1400°C to 1450°C. It can endure high-pressure applications, making it suitable for demanding environments.

Pros: Stainless steel is incredibly strong and resistant to rust, making it ideal for applications in the food processing and medical industries. It also provides a clean cut and is easy to maintain.

Cons: The material is more expensive than aluminum and can be challenging to cut due to its hardness. This may lead to increased wear on cutting tools.

Impact on Application: Stainless steel’s compatibility with various abrasive materials allows for precise cutting, but buyers must consider the potential for increased operational costs due to tool wear.

Considerations for International Buyers: Compliance with standards like ASTM A240 is critical. Buyers from the Middle East and Europe should ensure that the material meets local regulations regarding food safety and medical applications.

What Are the Benefits and Limitations of Glass in Water Jet Cutting?

Glass is a brittle material that can be cut into intricate designs using water jet technology. It is known for its aesthetic appeal and versatility in applications ranging from art to architecture.

Pros: Water jet cutting allows for precise and intricate designs without the risk of chipping or cracking, which is common with traditional cutting methods.

Cons: The brittleness of glass can lead to breakage during handling and cutting, making it less durable than metals. Additionally, it requires careful handling and storage.

Impact on Application: Glass is suitable for decorative applications and functional components like windows and panels. However, its fragility necessitates careful consideration in design and manufacturing processes.

Considerations for International Buyers: Compliance with safety standards such as ASTM C1036 for flat glass is important. Buyers in regions like Europe may also need to consider environmental regulations regarding glass recycling.

Why Choose Composites for Tabletop Water Jet Applications?

Composites, such as carbon fiber and fiberglass, are increasingly popular due to their lightweight and high-strength properties. They can withstand temperatures up to 200°C and are resistant to corrosion.

Pros: Composites offer excellent strength-to-weight ratios and can be tailored for specific applications. They are ideal for aerospace and automotive components where performance is critical.

Cons: Composites can be more expensive than metals and may require specialized cutting techniques to avoid delamination during the cutting process.

Impact on Application: Their compatibility with water jet cutting allows for complex shapes and designs, making them suitable for high-performance applications.

Considerations for International Buyers: Compliance with standards such as ASTM D3039 for tensile properties of composites is essential. Buyers from South America and Africa should be aware of local suppliers and potential import challenges.

Summary Table of Material Selection for Tabletop Water Jet

| Material | Typical Use Case for tabletop water jet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace, automotive components | Lightweight and corrosion-resistant | Can warp if not managed properly | Medium |

| Stainless Steel | Food processing, medical devices | High strength and corrosion resistance | Expensive and hard to cut | High |

| Glass | Decorative art, architectural panels | Allows for intricate designs without chipping | Brittle and requires careful handling | Medium |

| Composites | Aerospace, automotive high-performance parts | Excellent strength-to-weight ratio | More expensive and needs careful cutting | High |

This material selection guide provides B2B buyers with essential insights into the properties and considerations for using various materials with tabletop water jet technology. Understanding these factors can significantly impact the success of their applications and projects.

In-depth Look: Manufacturing Processes and Quality Assurance for tabletop water jet

What are the Main Stages in the Manufacturing Process of Tabletop Water Jets?

The manufacturing process of tabletop water jets involves several critical stages that ensure the final product is efficient, reliable, and meets industry standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in manufacturing a tabletop water jet is selecting and preparing the raw materials. Common materials used include high-grade stainless steel for the frame and components, as well as specialized composites for the cutting head. These materials must undergo rigorous quality checks to ensure they meet specifications, such as tensile strength and corrosion resistance. Suppliers often perform initial inspections (Incoming Quality Control, or IQC) to verify that the materials are free from defects.

-

Forming: Once the materials are prepared, they undergo forming processes. This may involve cutting, bending, and machining components to precise dimensions. CNC (Computer Numerical Control) machines are frequently used in this stage to achieve high precision. Advanced techniques like laser cutting or water jet cutting may also be employed to shape complex parts without compromising material integrity.

-

Assembly: After forming, the components are assembled into the final product. This process involves fitting together various parts, such as the water jet pump, cutting head, and control systems. Each component must be aligned correctly to ensure optimal performance. During assembly, manufacturers often conduct In-Process Quality Control (IPQC) checks to monitor the assembly process and identify any issues early on.

-

Finishing: The final stage involves surface finishing and testing. This may include treatments to enhance durability, such as anodizing or powder coating. Additionally, manufacturers will perform functional testing to ensure that the water jet operates according to specifications. This phase is crucial, as it verifies the machine’s ability to cut various materials effectively.

Which Quality Assurance Standards Should B2B Buyers Consider?

For B2B buyers, understanding the quality assurance processes and standards that manufacturers adhere to is essential. International standards like ISO 9001 are critical, as they set the framework for consistent quality management systems. Companies certified under ISO 9001 demonstrate their commitment to quality in manufacturing and customer satisfaction.

In addition to ISO certifications, industry-specific standards may apply. For instance, CE marking is required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards. Similarly, API (American Petroleum Institute) certifications may be relevant for manufacturers supplying the oil and gas sector.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in the manufacturing of tabletop water jets typically includes several checkpoints to ensure compliance with established standards. These checkpoints include:

-

Incoming Quality Control (IQC): This initial step involves inspecting raw materials and components upon arrival. It ensures that all incoming parts meet predetermined specifications before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are performed at various stages. This may include verifying dimensions after machining or ensuring proper assembly techniques are followed. By catching defects early, manufacturers can reduce waste and rework.

-

Final Quality Control (FQC): Once the assembly is complete, final inspections are conducted. This involves testing the functionality of the water jet, ensuring it operates correctly, and meets performance standards. This stage often includes documentation of test results for transparency.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying the quality control measures of suppliers is crucial to ensure they receive a reliable product. Here are some effective strategies:

-

Audits: Conducting supplier audits can provide insights into their quality management systems. Buyers should request access to audit reports to assess compliance with relevant standards.

-

Documentation and Certifications: Buyers should ask for documentation that verifies compliance with international standards (e.g., ISO 9001, CE) and any industry-specific certifications. This documentation serves as proof of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These inspections can help identify potential issues before placing a large order.

What Are the Nuances of Quality Control for International B2B Buyers?

When sourcing tabletop water jets internationally, especially from regions like Africa, South America, the Middle East, and Europe, B2B buyers should be aware of specific nuances in quality control. These include:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers must understand local standards and ensure that their suppliers comply with them.

-

Cultural Differences: Cultural factors can impact business practices, including quality assurance. Understanding these differences can facilitate better communication and collaboration with suppliers.

-

Supply Chain Risks: International shipping introduces risks such as delays and damages. Buyers should consider suppliers with robust logistics and quality assurance processes to mitigate these risks.

-

Local Support and Service: Consider suppliers that offer local support, as this can enhance the post-purchase experience and facilitate quicker resolutions to any issues that arise.

Conclusion

The manufacturing processes and quality assurance measures for tabletop water jets are critical components that B2B buyers must understand. By familiarizing themselves with the stages of manufacturing, relevant quality standards, and verification strategies, buyers can make informed decisions that enhance their operational efficiency and product reliability. Whether sourcing from Europe, Africa, or South America, understanding these elements will empower buyers to establish strong partnerships with suppliers committed to quality and excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tabletop water jet’

In the competitive landscape of manufacturing, procuring a tabletop water jet can significantly enhance your operational capabilities. This guide provides a comprehensive checklist to assist international B2B buyers in sourcing the right equipment tailored to their specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure the water jet meets your operational requirements. Consider the types of materials you will be cutting, the maximum thickness, and the desired precision. Knowing these parameters will help you narrow down suitable models and avoid overspending on unnecessary features.

Step 2: Research Available Models

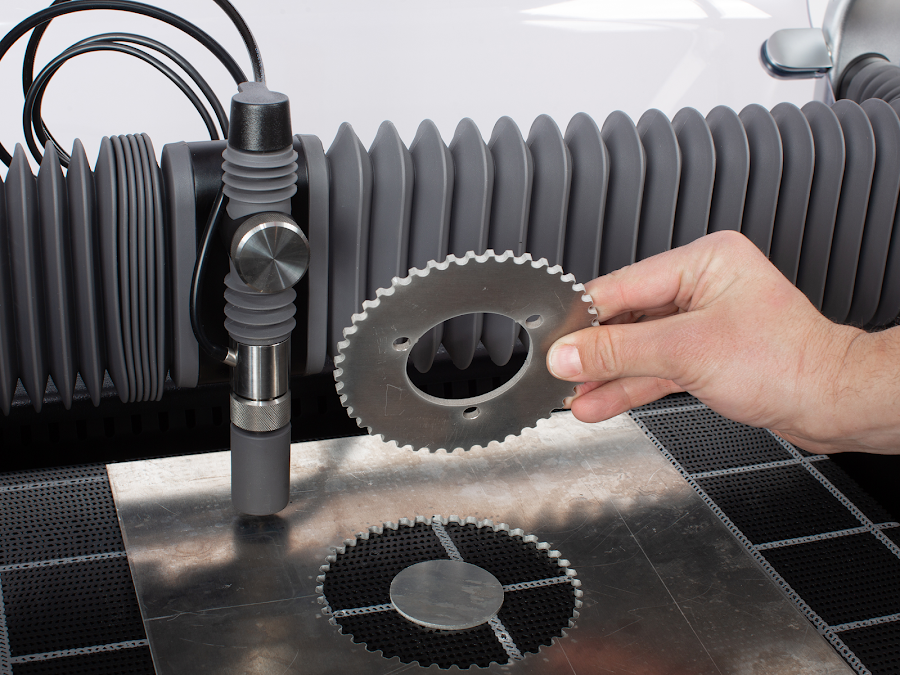

Take the time to explore various tabletop water jet models available in the market. Focus on their cutting capabilities, size, and user-friendliness. Pay particular attention to models like the WAZER Pro, which is designed for affordability without compromising on performance, allowing you to cut various materials including metals, glass, and composites.

Step 3: Evaluate Supplier Credentials

Before committing to a purchase, it’s critical to vet suppliers thoroughly. Look for certifications that demonstrate compliance with international standards and quality assurance processes. Request company profiles, case studies, and references from buyers in similar industries or regions to assess reliability and support.

Step 4: Consider Maintenance and Support Services

Understanding the maintenance requirements and support services offered by the supplier is vital. Inquire about warranty terms, availability of spare parts, and access to technical support. A reliable supplier will provide comprehensive maintenance packages, ensuring minimal downtime for your operations.

Step 5: Request Demonstrations or Samples

Whenever possible, request a demonstration of the water jet cutter in action or ask for a sample cut. This firsthand experience will give you insights into the machine’s performance, ease of use, and the quality of cuts it produces. Observing the machine in operation can significantly influence your purchasing decision.

Step 6: Assess Total Cost of Ownership

Beyond the initial purchase price, consider the total cost of ownership, which includes operational costs such as water and abrasive materials, maintenance, and energy consumption. A more efficient machine may have a higher upfront cost but could save you money in the long run through reduced operational expenses.

Step 7: Finalize Your Purchase and Negotiate Terms

Once you’ve identified a suitable model and supplier, finalize your purchase by reviewing the terms of sale. Don’t hesitate to negotiate pricing, payment options, and delivery timelines. Establishing clear terms upfront can prevent misunderstandings and ensure a smooth transaction.

By following these steps, B2B buyers can confidently navigate the sourcing process for a tabletop water jet, ensuring they choose the best equipment for their specific needs.

Comprehensive Cost and Pricing Analysis for tabletop water jet Sourcing

What Are the Key Cost Components in Tabletop Water Jet Sourcing?

When analyzing the costs associated with sourcing tabletop water jets, several critical components come into play. These include:

-

Materials: The choice of materials significantly impacts the overall cost. For instance, high-grade stainless steel or specialized alloys used in water jets can increase manufacturing expenses. Additionally, the abrasives, such as garnet, required for cutting also contribute to material costs.

-

Labor: Skilled labor is essential for both the manufacturing and operational phases. The cost of labor can vary widely based on geographic location and the availability of skilled technicians, particularly in regions like Africa or South America.

-

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and indirect labor. Efficient manufacturing processes can help mitigate these costs, but they must be factored into the pricing structure.

-

Tooling: Tooling costs involve the creation of specialized tools required for production. High-quality tooling can lead to better precision and efficiency, but it also represents a significant upfront investment.

-

Quality Control (QC): Investing in robust QC processes ensures that the water jets meet industry standards and customer specifications. This may involve additional inspection and testing phases, thereby adding to the overall cost.

-

Logistics: Transportation and shipping costs can fluctuate based on the distance between the manufacturer and buyer, as well as the chosen Incoterms. For international buyers, understanding these logistics is vital to avoid unexpected expenses.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. This margin can vary depending on the supplier’s positioning in the market and the demand for tabletop water jets.

How Do Price Influencers Impact Tabletop Water Jet Sourcing?

Understanding the factors that influence pricing can help buyers make informed decisions. Key influencers include:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to lower per-unit costs. Buyers should assess their needs to determine whether they can commit to higher volumes for better pricing.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to manage expectations around pricing and delivery timelines.

-

Materials: The choice of materials affects not only the initial cost but also long-term performance. Higher-quality materials may have a higher upfront cost but can lead to lower maintenance and replacement costs over time.

-

Quality Certifications: Products that meet international quality standards may come at a premium. Buyers should weigh the benefits of certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better service and support.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding these terms can help buyers anticipate total costs and avoid misunderstandings.

What Are Some Effective Buyer Tips for Sourcing Tabletop Water Jets?

To navigate the complexities of sourcing tabletop water jets, buyers can utilize several strategies:

-

Negotiate Smartly: Approach negotiations with a clear understanding of your budget and requirements. Be open to discussing volume discounts or long-term agreements that may benefit both parties.

-

Focus on Cost Efficiency: Assess the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, operation, and potential downtime costs. This holistic view can lead to better purchasing decisions.

-

Consider International Pricing Nuances: International buyers must account for fluctuations in currency exchange rates, tariffs, and import duties. Building relationships with local suppliers can also mitigate costs and simplify logistics.

-

Request Samples: Before committing to a purchase, request samples to evaluate the quality and performance of the water jet. This can prevent costly mistakes and ensure that the product meets your specifications.

-

Stay Informed: Keep up with market trends and technological advancements in water jet cutting. This knowledge can empower you to make better sourcing decisions and leverage competitive pricing.

Disclaimer on Indicative Prices

Prices mentioned in this analysis are indicative and can vary based on numerous factors, including market conditions, supplier pricing strategies, and specific buyer requirements. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing tabletop water jet With Other Solutions

Exploring Alternatives to Tabletop Water Jets for Precision Cutting

In the realm of precision cutting, tabletop water jets stand out for their versatility and efficiency. However, various alternatives can also meet specific cutting needs. This analysis compares tabletop water jets against laser cutting machines and CNC milling machines, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Tabletop Water Jet | Laser Cutting Machine | CNC Milling Machine |

|---|---|---|---|

| Performance | Excellent for a variety of materials, including metals, plastics, and glass. | Best for thin materials, particularly metals and plastics, with high precision. | Versatile in material types but generally suited for harder materials and complex shapes. |

| Cost | Starting at $9,999 for entry-level models. | Ranges from $15,000 to over $100,000 depending on power and features. | Typically starts around $20,000, with higher-end models exceeding $100,000. |

| Ease of Implementation | Requires minimal setup and training; intuitive software for design. | More complex setup with potential need for additional ventilation and safety measures. | Requires skilled operators and more extensive training to set up and program. |

| Maintenance | Low maintenance with minimal wear parts; easy to service. | Moderate maintenance; optics may require regular cleaning and replacement. | Higher maintenance due to mechanical parts and potential for wear and tear. |

| Best Use Case | Ideal for prototyping, custom parts, and artistic applications. | Best for production runs of thin materials and detailed designs. | Suited for manufacturing complex parts and high-volume production runs. |

Detailed Breakdown of Alternatives

Laser Cutting Machines

Laser cutting machines utilize focused light beams to slice through materials with precision. They excel in cutting thin sheets of metal and plastics, making them ideal for applications requiring intricate designs. However, their effectiveness diminishes with thicker materials, and they are less suitable for softer substances like foam or rubber. Additionally, laser cutting equipment can be significantly more expensive and requires safety measures due to the high energy involved.

CNC Milling Machines

CNC milling machines are capable of machining a variety of materials, including metals, plastics, and wood. They are ideal for creating complex three-dimensional shapes and can achieve high precision with proper setup. However, the cost and need for skilled operators can be prohibitive, especially for smaller businesses. CNC milling is also more time-consuming compared to water jet cutting, particularly for intricate designs, as it typically involves multiple passes.

Conclusion: How to Choose the Right Solution for Your Cutting Needs

Selecting the appropriate cutting technology depends on various factors, including the type of materials you work with, your budget, and the required precision for your projects. Tabletop water jets offer a balance of versatility and ease of use, making them suitable for a wide range of applications, from prototyping to artistic endeavors. Conversely, if your operations focus on high-volume production of thin materials, laser cutting may be more advantageous. On the other hand, CNC milling is a robust option for complex, high-precision parts but may require a greater initial investment and skill set. By carefully assessing your specific needs and constraints, you can make an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for tabletop water jet

What Are the Key Technical Properties of Tabletop Water Jets?

When considering a tabletop water jet for your business, understanding its technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Compatibility

Tabletop water jets can cut a wide range of materials, including metals (like aluminum and stainless steel), plastics, glass, rubber, and composites. This versatility allows businesses in various sectors—such as aerospace, automotive, and manufacturing—to use a single machine for multiple applications. Assessing material compatibility helps ensure that the water jet can meet your specific production needs.

2. Cutting Thickness

The cutting thickness capacity indicates the maximum material thickness the water jet can effectively cut. For example, many tabletop models can handle up to 1 inch of aluminum or 0.375 inches of stainless steel. Knowing the cutting thickness is essential for businesses that work with varied material sizes, as it directly affects production capabilities and project feasibility.

3. Precision and Tolerance

Precision refers to the machine’s ability to produce cuts with minimal deviation from the desired dimensions. Tolerance, often measured in millimeters or inches, indicates how closely the finished product matches the intended design. High precision and tight tolerances are critical in industries like aerospace and automotive, where even minor discrepancies can lead to significant operational issues.

4. Cutting Speed

Cutting speed measures how quickly the water jet can make cuts through materials, typically expressed in inches per minute (IPM). Faster cutting speeds increase productivity and reduce lead times, making it a vital consideration for businesses with tight schedules or high-volume production demands.

5. Maintenance Requirements

Maintenance refers to the routine care needed to keep the water jet operating efficiently. A system that requires less maintenance can save time and costs over its lifespan. Understanding the maintenance needs helps businesses budget appropriately and minimizes downtime due to repairs or servicing.

6. Power Consumption

Power consumption is a measure of the energy required to operate the water jet. Efficient power use is crucial for controlling operational costs, especially in regions where energy prices are high. Evaluating power consumption can help businesses assess long-term cost implications.

What Are Common Trade Terms Related to Tabletop Water Jets?

Familiarity with industry jargon can streamline negotiations and enhance communication with suppliers and manufacturers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of water jets, understanding OEM relationships can help businesses identify reliable suppliers and assess product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for businesses that may not require large quantities of water jets or parts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. This process is vital for B2B buyers as it allows for comparison of costs, ensuring competitive pricing and informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms helps businesses navigate global transactions, ensuring clarity regarding costs and responsibilities.

5. CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools and 3D printers by a computer. Understanding CNC is essential for businesses as it relates to the precision and efficiency of water jet cutting processes.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding tabletop water jets, ensuring they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the tabletop water jet Sector

What Are the Current Market Dynamics and Key Trends in the Tabletop Water Jet Sector?

The tabletop water jet sector is experiencing transformative growth, driven by several global factors. Increasing demand for precision cutting in various industries, including aerospace, automotive, and manufacturing, is propelling the market forward. The emergence of advanced technologies, such as computer numerical control (CNC) integration and cloud-based design software, is enhancing operational efficiency and reducing turnaround times. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking compact and affordable water jet solutions, such as the WAZER Pro and WAZER Desktop, which offer high performance without the need for extensive space or investment.

Sourcing trends are also evolving, with buyers prioritizing suppliers who can offer comprehensive support and training. The rise of e-commerce platforms is facilitating direct access to suppliers, allowing businesses to compare products and prices easily. Additionally, the trend toward customization is gaining momentum, as companies look for water jet systems that can handle a diverse range of materials, from metals to glass and composites, to meet specific project needs.

Moreover, sustainability is becoming a critical consideration, with manufacturers focusing on energy-efficient technologies and waste reduction practices. Buyers are now evaluating suppliers based on their commitment to sustainable practices, which can influence purchasing decisions significantly.

How Is Sustainability and Ethical Sourcing Addressed in the Tabletop Water Jet Industry?

Sustainability is increasingly at the forefront of purchasing decisions in the tabletop water jet sector. The environmental impact of manufacturing processes and the materials used is a significant concern for international B2B buyers. Companies are now more aware of their carbon footprints and are seeking suppliers that implement eco-friendly practices.

Ethical sourcing is crucial, as buyers are looking for manufacturers that prioritize transparency in their supply chains. This includes the responsible sourcing of materials, ensuring that they are not only high quality but also obtained in a manner that respects both environmental and social standards. Certifications such as ISO 14001 for environmental management systems can provide buyers with assurance regarding a supplier’s commitment to sustainability.

Furthermore, the use of ‘green’ materials, such as recycled composites and eco-friendly abrasives, is gaining traction. Water jet systems that utilize garnet abrasives, which are less harmful to the environment compared to traditional cutting methods, are becoming popular among companies aiming to reduce their environmental impact. By prioritizing sustainability and ethical sourcing, businesses can not only enhance their brand reputation but also appeal to a growing market segment that values corporate responsibility.

What Is the Evolution and Historical Context of the Tabletop Water Jet Technology?

The evolution of tabletop water jet technology can be traced back to the 1980s when water jet cutting was first introduced as a viable method for precision cutting in industrial applications. Initially, the technology was limited to large, industrial-grade machines that required significant space and investment, making it less accessible for smaller businesses or educational institutions.

In recent years, advancements in technology have led to the development of compact, user-friendly systems like the WAZER Desktop, which democratizes access to water jet cutting. These innovations have made it possible for a wider range of industries, including glass art, signmaking, and educational institutions, to incorporate water jet technology into their operations.

As the market continues to evolve, the focus is shifting towards affordability, ease of use, and versatility, ensuring that businesses of all sizes can leverage the precision and efficiency that water jet cutting provides. This historical context highlights the ongoing transformation of the tabletop water jet sector, making it a valuable tool for modern manufacturing and prototyping processes.

Frequently Asked Questions (FAQs) for B2B Buyers of tabletop water jet

-

How do I select the right tabletop water jet for my business needs?

Selecting the right tabletop water jet involves assessing your specific cutting requirements, including the materials you’ll work with (metal, glass, plastic, etc.), thickness, and volume of production. Consider the machine’s cutting speed, maintenance needs, and ease of use, especially if your team lacks technical expertise. Additionally, evaluate the software compatibility for design uploads and the machine’s footprint to ensure it fits within your workspace. Engaging with suppliers for demos or visiting existing installations can provide valuable insights into performance. -

What is the best tabletop water jet for small-scale manufacturing?

For small-scale manufacturing, the WAZER Desktop water jet stands out as a cost-effective solution. It is designed to handle various materials, including steel and glass, with a compact footprint ideal for limited spaces. With a starting price of $9,999, it balances affordability with industrial-grade capabilities, making it suitable for prototyping and small production runs. Additionally, its easy operation allows even non-experts to produce high-quality cuts, enhancing workflow efficiency without extensive training. -

What are the typical lead times for ordering and receiving a tabletop water jet?

Lead times for tabletop water jets can vary significantly based on the manufacturer and the specifications of the machine. Generally, you can expect a lead time ranging from 4 to 12 weeks. Factors influencing this timeline include production capacity, customization requests, and shipping logistics, especially for international orders. It’s advisable to communicate directly with suppliers to get accurate estimates and ensure timely delivery aligned with your project schedules. -

What are the minimum order quantities (MOQs) for tabletop water jets from suppliers?

Minimum order quantities (MOQs) for tabletop water jets can vary by supplier and depend on the machine type. Some manufacturers may offer individual units, while others may require orders in multiples to optimize production and shipping costs. When sourcing, inquire about MOQs to understand your purchasing flexibility. Additionally, negotiating terms may be possible, especially if you demonstrate potential for future orders. -

How can I vet suppliers for tabletop water jets effectively?

Vetting suppliers involves assessing their reputation, experience, and product quality. Start by checking customer reviews, testimonials, and case studies to gauge satisfaction. Request references from current clients, especially those in your industry or region. Additionally, verify certifications and compliance with international standards. Consider visiting manufacturing facilities or attending trade shows to evaluate quality firsthand and establish direct relationships with potential suppliers. -

What payment terms should I expect when purchasing a tabletop water jet?

Payment terms for purchasing a tabletop water jet can vary widely among suppliers. Common arrangements include upfront payments, installment plans, or letters of credit, especially for international transactions. Some suppliers may offer financing options to ease initial costs. Always clarify terms before finalizing a purchase to ensure they align with your budget and cash flow management. Understanding the total cost, including shipping and duties, is crucial for accurate budgeting. -

What quality assurance measures should I look for in tabletop water jets?

When sourcing tabletop water jets, inquire about the manufacturer’s quality assurance (QA) processes. Look for certifications such as ISO or similar standards that ensure consistent production quality. Ask about testing procedures for performance, precision, and durability. Some manufacturers may offer warranties or service agreements, which can provide additional peace of mind regarding the longevity and reliability of the equipment. -

How does international shipping impact the purchase of a tabletop water jet?

International shipping can significantly affect the purchase process for tabletop water jets. Factors such as shipping costs, customs duties, and import regulations must be considered. Ensure your supplier can handle international logistics efficiently and provide all necessary documentation for customs clearance. It’s advisable to work with freight forwarders familiar with importing industrial machinery to minimize delays and ensure compliance with local regulations in your country.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Tabletop Water Jet Manufacturers & Suppliers List

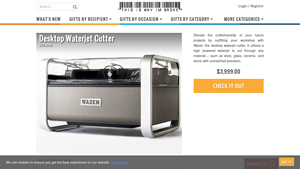

1. WAZER – Desktop Waterjet Cutting Machine

Domain: matterhackers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “WAZER Desktop Waterjet Cutting Machine”, “brand”: “WAZER”, “price”: {“WAZER Desktop”: “$9,999”, “WAZER Standup”: “$10,999”, “WAZER Starter Bundle”: “$11,999”}, “key_features”: [“Digitally-controlled high-velocity jet”, “Cuts a wide range of materials”, “Compact and contained design”, “Easy and safe to use”, “Utilizes cold cutting process”, “Quick learning curve”], “cutting_capabi…

2. Flow Waterjet – Waterjet Cutting Machines and Advanced Solutions

Domain: flowwaterjet.com

Registered: 2003 (22 years)

Introduction: Flow Waterjet offers a range of waterjet cutting machines including the Mach 150, Mach 200, Mach 200c, Mach 200s, Mach 300, Mach 500, Mach 700, EchoJet, and NanoJet. Their advanced solutions include software such as FlowMaster and FlowXpert, and pumps like HyPlex Prime, MotoJet, MotoJet X, and HyperJet. Cutting heads available are Standard Waterjet, Pivot+, Dynamic Waterjet, and Dynamic Waterjet X…

3. Grizzly – Wazer T34212 Benchtop Waterjet Cutter

Domain: grizzly.com

Registered: 1991 (34 years)

Introduction: {“model”:”Wazer T34212″,”type”:”Benchtop Waterjet Cutter”,”power_requirement”:”110V/60Hz”,”price”:”$9,999.00″,”cutting_area”:”12″ x 18″”,”kerf”:”0.044″”,”abrasive_rate”:”0.33 lbs./min.”,”maximum_working_pressure”:”4600 PSI”,”overall_dimensions”:”34″ W x 26″ D x 22″ H”,”included_items”:[“WAZER Desktop”,”WAM software license”,”Two 55-pound abrasive buckets”,”Two cut beds”,”Two water sensors”,”Access…

4. ProtoMAX – Compact Abrasive Waterjet System

Domain: omax.com

Registered: 1996 (29 years)

Introduction: ProtoMAX Abrasive Waterjet

– Designed for prototyping and low-volume cutting of materials up to 1″ thick.

– Compact, self-contained cutting system.

– Traverse speed: up to 100 in/min (2,540 mm/min).

– Linear positional accuracy: ±0.005″ (±0.127 mm).

– Electrical requirements: 230-240 VAC, single phase, 30A, 50/60 Hz.

– Dimensions: 39.5″ x 56.5″ x 41.5″ (1,004 mm x 1,435 mm x 1,054 mm).

– Cutting e…

5. Hornet Cutting Systems – Mini Hornet

Domain: hornetcs.com

Registered: 2016 (9 years)

Introduction: Hornet Cutting Systems manufactures high-performance CNC waterjet cutting machines with high cut speeds and precision. The machines can cut various materials, including wood and steel, and offer both pure water and abrasive water-jet cutting functionality. Key products include:

1. **Mini Hornet**:

– No assembly required, ready to use the same day.

– High performance with a small footprin…

6. This Is Why I’m Broke – High-Powered Waterjet Cutter

Domain: thisiswhyimbroke.com

Registered: 2011 (14 years)

Introduction: This company, This Is Why I’m Broke – High-Powered Waterjet Cutter, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for tabletop water jet

The integration of tabletop water jet technology represents a transformative opportunity for businesses across diverse industries. By leveraging the capabilities of machines like the WAZER Pro, companies can achieve high precision in cutting various materials, from metals to composites, all within their own facilities. This not only enhances production efficiency but also significantly reduces lead times, enabling firms to respond swiftly to market demands.

Strategic sourcing of tabletop water jets offers buyers the advantage of accessing cutting-edge technology that supports rapid prototyping, custom manufacturing, and educational applications. It is crucial for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, to consider the long-term benefits of investing in reliable and efficient water jet systems.

As global markets continue to evolve, the demand for versatile and affordable manufacturing solutions will grow. Now is the time to explore partnerships and procurement strategies that prioritize innovative technologies like tabletop water jets. Embrace the future of manufacturing and position your business for success by investing in tools that enhance productivity and creativity.