Contents

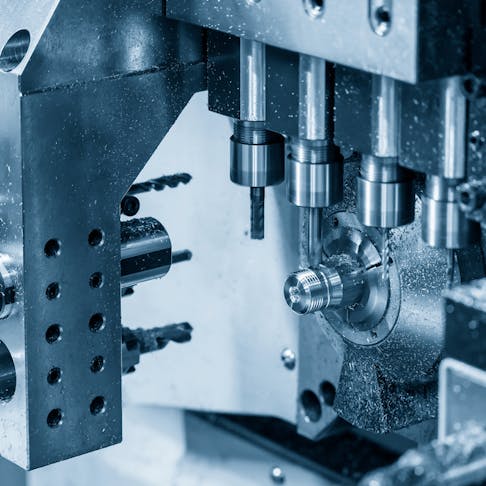

Manufacturing Insight: Swiss Milling Machine

Precision Swiss Machining Excellence at Honyo Prototype

Honyo Prototype delivers industry-leading CNC machining capabilities centered on advanced Swiss-type turning centers, engineered to produce the most complex, high-precision components for demanding sectors including medical devices, aerospace, and automotive. Our specialized Swiss milling machines—technically Swiss-type CNC lathes with integrated milling, drilling, and cross-axis capabilities—excel at manufacturing intricate geometries from bar stock with exceptional accuracy and repeatability. These multi-axis systems simultaneously machine both the main and sub-spindles, minimizing handling errors and cycle times while achieving tolerances down to ±0.0002 inches. This capability is critical for producing miniature components with tight concentricity, fine surface finishes, and secondary operations completed in a single setup, directly addressing the challenges of high-mix, low-volume prototyping and production.

Our Swiss machining fleet is complemented by a full spectrum of CNC services, including 3-, 4-, and 5-axis milling, turning, and wire EDM, ensuring seamless integration for projects requiring hybrid manufacturing approaches. Below is a comparison of key Swiss machining specifications achievable at Honyo versus standard industry benchmarks:

| Capability | Honyo Prototype Standard | Typical Industry Baseline |

|---|---|---|

| Maximum Spindle Speed | 12,000 RPM | 8,000 RPM |

| Positioning Accuracy | ±0.00008 inches | ±0.0002 inches |

| Minimum Feature Size | 0.004 inches | 0.008 inches |

| Max Bar Stock Diameter | 26 mm (1.02 inches) | 20 mm (0.79 inches) |

| Sub-Spindle Integration | Standard on all Swiss | Optional or limited |

Accelerate your development timeline with Honyo’s Online Instant Quote system, designed specifically for engineering teams requiring rapid feedback on complex Swiss machining projects. Upload your STEP or IGES files to receive a detailed manufacturability analysis, lead time estimate, and competitive pricing within hours—not days. This transparent, engineer-to-engineer platform eliminates procurement delays while ensuring your design intent is preserved from quotation through final inspection. Partner with Honyo Prototype to transform intricate designs into high-integrity components, backed by ISO 9001-certified processes and decades of precision manufacturing expertise.

Technical Capabilities

Swiss Milling Machine – Technical Specifications

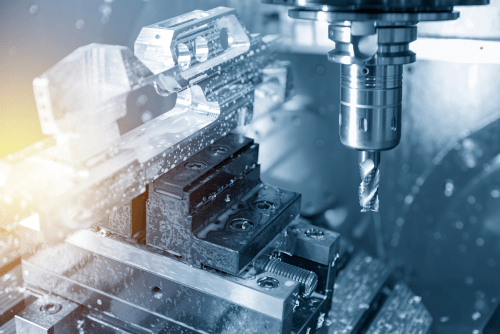

Swiss-type milling machines, often referred to as Swiss CNC lathes or Swiss screw machines, are precision machine tools optimized for high-accuracy machining of small, complex components. While traditionally known for turning operations, modern Swiss machines integrate multi-axis milling and turning capabilities, enabling complete part fabrication in a single setup. Below are the key technical specifications focused on 3/4/5-axis milling and turning, tight tolerance performance, and compatibility with common engineering materials.

| Feature | Specification |

|---|---|

| Machine Type | CNC Swiss-type Automatic Lathe with Multi-Axis Milling and Turning |

| Primary Axes Configuration | 3-Axis (X, Z, C), 4-Axis (adds B or Y), 5-Axis (X, Z, C, Y, B) |

| Milling Axes | Y-axis ± cross slide; B-axis (rotary milling spindle) for off-center and angled features |

| Turning Capability | Main spindle turning with guide bushing for improved rigidity and accuracy |

| Sub-Spindle | Yes, for backworking operations (part transfer and secondary machining) |

| Bar Capacity | Typically 1 mm to 38 mm diameter (depending on model) |

| Maximum Spindle Speed | 10,000 – 18,000 RPM (main and sub-spindle) |

| Milling Spindle Speed | Up to 20,000 RPM (high-speed motorized live tooling) |

| Positioning Accuracy | ±0.001 mm (±0.00004 in) |

| Repeatability | ±0.0005 mm (±0.00002 in) |

| Tight Tolerance Capability | ±0.002 mm to ±0.005 mm typical for critical dimensions |

| Control System | Fanuc, Siemens, or Mitsubishi CNC with multi-channel synchronization |

| Live Tooling | Radial and axial tooling stations for milling, drilling, tapping, and contouring |

| Coolant System | High-pressure through-tool coolant (up to 70 bar) for chip control and tool life |

| Materials Compatible | Aluminum (6061, 7075), Steel (1018, 4140, 17-4 PH), Stainless Steel (303, 316), ABS, Nylon (PA6, PA66), PEEK, PTFE |

| Typical Applications | Medical components, aerospace fittings, precision connectors, shafts, bushings, and complex micro-machined parts |

| Surface Finish | Ra 0.4 µm to 0.8 µm achievable (as-machined), finer with polishing |

| Automation Ready | Yes – compatible with bar feeders, gantry loaders, and robotic integration |

Notes on Material Machinability:

Aluminum: Excellent machinability; high speeds and feeds possible, minimal tool wear.

Steel and Stainless Steel: Moderate to challenging; requires rigid setup and appropriate tooling (carbide or coated inserts).

ABS and Nylon: Thermoplastics require sharp tooling, lower cutting forces, and effective chip removal to avoid melting or deformation.

Swiss milling machines deliver exceptional precision for high-mix, low-to-medium volume production, particularly in industries requiring tight tolerances and repeatable accuracy such as medical, aerospace, and optoelectronics.

From CAD to Part: The Process

Honyo Prototype Swiss Milling Process Overview

Honyo Prototype utilizes a streamlined, technology-driven workflow for Swiss screw machine production, ensuring precision, efficiency, and rapid turnaround for complex turned components. The process integrates advanced automation with expert engineering oversight at critical stages.

CAD Upload

Customers initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SolidWorks/CREO formats) via Honyo’s secure customer portal. Our system validates file integrity and geometry completeness upon submission, flagging common issues like missing tolerances or non-manufacturable features before proceeding. This stage establishes the digital foundation for all subsequent steps, with automated version control to prevent miscommunication.

AI-Powered Quoting

Uploaded CAD data feeds directly into Honyo’s proprietary AI quoting engine, which analyzes geometric complexity, material requirements, tolerances, and surface finish specifications. The system cross-references real-time data from our machine shop—including current capacity, material costs, and tooling availability—to generate an accurate, itemized quote within 2 business hours. Critical factors like bar stock utilization efficiency, secondary operation needs, and Swiss-specific constraints (e.g., guide bushing compatibility, sub-spindle synchronization) are algorithmically evaluated. A Senior Manufacturing Engineer reviews all AI-generated quotes to verify feasibility and address edge cases, ensuring pricing reflects actual production physics.

DFM Analysis and Collaboration

Following quote acceptance, Honyo’s DFM (Design for Manufacturability) team conducts a rigorous technical review. For Swiss machining, this focuses on optimizing bar-fed processes: validating minimum wall thicknesses relative to guide bushing stability, assessing tool clearance for live tooling operations, and identifying opportunities to consolidate features using the main and sub-spindles. The DFM report—delivered within 24 hours—details actionable recommendations such as tolerance relaxation, feature repositioning to minimize setups, or material substitution for improved chip control. Customers receive direct access to our engineering team for collaborative refinement, reducing prototype iterations and accelerating time-to-part.

Precision Production

Approved designs move to our Swiss turning cell, featuring multi-axis Tsugami and Citizen machines with live tooling, Y-axis capability, and sub-spindles for complete part-off. Production adheres to strict protocols:

Raw material (e.g., 303SS, 6061-T6, PEEK) is inspected per ASTM/AMS standards prior to loading

First-article inspection (FAI) per AS9102 is performed before batch runs, including CMM verification of critical Swiss-specific dimensions (e.g., concentricity between main/sub-spindle operations)

In-process SPC monitoring tracks key parameters like tool wear and vibration to maintain ±0.0002″ tolerances

Secondary operations (e.g., grinding, threading, plating) are coordinated through Honyo’s vetted partner network under unified quality oversight

Typical lead times balance speed with Swiss machining complexity:

| Part Complexity | Typical Lead Time | Key Drivers |

|---|---|---|

| Low (≤5 features, standard tolerances) | 5–7 business days | Single-setup optimization, high bar stock utilization |

| Medium (8–12 features, tight tolerances) | 8–12 business days | Sub-spindle synchronization, live tooling coordination |

| High (15+ features, micro-features, exotic materials) | 12–18 business days | Multi-operation sequencing, in-process metrology validation |

Quality-Controlled Delivery

All parts undergo final inspection against the customer’s print, with full FAI documentation (including CMM reports and material certs) packaged with the shipment. Honyo coordinates global logistics via DHL/FedEx with real-time tracking, and provides digital delivery confirmation including batch-specific process data. For mission-critical applications, we offer optional vacuum-sealed packaging with humidity indicators and ITAR-compliant shipping documentation. Post-delivery, our engineering team conducts a lessons-learned review to refine future Swiss machining processes for the customer’s specific part family.

This integrated workflow—combining AI efficiency with deep Swiss machining expertise—ensures Honyo consistently delivers complex precision components with 99.2% on-time delivery and first-pass yield rates exceeding 95% across our customer base.

Start Your Project

Looking for precision components with fast turnaround? Our Swiss milling machines in Shenzhen deliver high-accuracy parts for demanding applications. With advanced CNC capabilities and strict quality control, we ensure consistency and performance for your prototyping and low-volume production needs.

Contact Susan Leo at [email protected] to discuss your project requirements. Leverage our in-house Swiss machining expertise and get your parts faster from our Shenzhen factory.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.