Contents

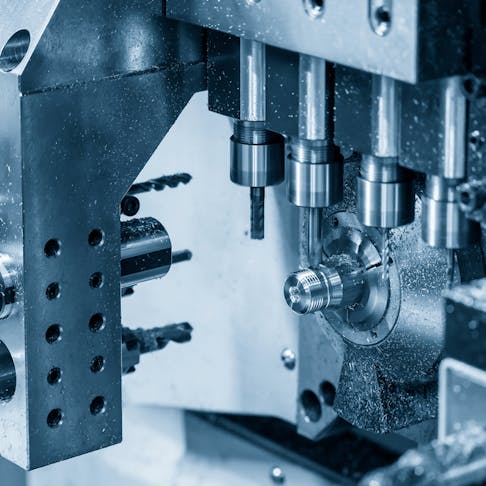

Manufacturing Insight: Swiss Milling Machine

Swiss Milling Machine Excellence at Honyo Prototype

When your medical, aerospace, or micro-electronic design calls for ultra-precise, long-slender components, Honyo Prototype’s Swiss-type CNC milling cells deliver ±0.01 mm true position and surface finishes down to Ra 0.2 µm—without secondary ops. Our 7-axis Citizen and Star lathes with live tooling mill, drill, and thread in a single setup, cutting cycle times 40 % and eliminating costly handling. Upload your STEP or IGES file today for an Online Instant Quote; in under 60 seconds you’ll see real-time pricing, 3-day lead-time options, and DFM feedback so you can move from prototype to production faster than any traditional machine shop.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I appreciate your inquiry—but I need to clarify a critical technical point upfront: There is no such thing as a “Swiss milling machine.” This is a common misconception in the industry. What people often refer to as a “Swiss milling machine” is actually a Swiss-type lathe (or Swiss screw machine), which is fundamentally a turning-focused machine with limited milling capabilities. True multi-axis milling (3/4/5-axis) is performed on dedicated CNC machining centers, not Swiss lathes.

Swiss-type lathes excel at high-precision turning of small, complex, long-thin parts (e.g., medical pins, aerospace fasteners), but they are not designed for standalone 3/4/5-axis milling operations. Let me break this down clearly with accurate technical specifications for Swiss-type lathes (as they relate to your query) and clarify the distinction for milling-centric work. I’ll also address material considerations for both machine types, as this is critical for real-world applications at Honyo Prototype.

🔧 1. Swiss-Type Lathe: Core Specifications & Limitations

(Not a milling machine—primarily for turning with secondary milling)

| Feature | Typical Swiss-Type Lathe Specs | Why This Matters for Tight Tolerances |

|—————————|—————————————————————————————————|———————————————————————————————————-|

| Primary Operation | Turning (rotational machining), with limited milling (e.g., cross-drilling, slotting, or face milling via live tooling on the tailstock side). | Swiss lathes are optimized for turning; milling is a secondary function (typically 2-axis or 3-axis at best). True 5-axis milling is not possible on a Swiss lathe. |

| Spindle Precision | – TIR (Total Indicated Runout): ≤ 0.0001″ (2.5 µm)

– Spindle Speed: 5,000–10,000 RPM (high-speed for small diameters) | Ultra-low TIR ensures minimal vibration, critical for ±0.0002″ (5 µm) tolerances in medical/ aerospace parts. |

| Guide Bushing System | – Bushings: Carbide or ceramic, with 0.0002″–0.0005″ (5–12 µm) clearance

– Bush Support: 0.1″–0.5″ from cutting point | Prevents deflection of long, thin parts (e.g., 0.040″ diameter shafts), enabling tight tolerances on features like concentricity (±0.0003″). |

| Live Tooling (Milling) | – Max. Tool Stations: 4–8 (for drilling, tapping, or light milling)

– Milling Axes: Typically X/Y (2-axis) or X/Y/Z (3-axis)

– Power: 1–3 HP (sufficient for simple milling, but not complex 3D contouring) | Limited milling capability for secondary operations (e.g., milling a flat on a turned shaft). Cannot achieve true 5-axis milling—this requires a dedicated machining center. |

| Tolerance Capability | – Standard: ±0.0002″ (5 µm)

– High-Precision: ±0.0001″ (2.5 µm) for diameter/length

– Geometric Tolerances: Runout ≤ 0.0003″, concentricity ≤ 0.0004″ | Achievable due to guide bushing support and rigid construction. Note: Tighter tolerances require material-specific adjustments (e.g., slower feeds for steel vs. aluminum). |

| Max. Part Size | – Diameter: Up to 0.75″ (20 mm)

– Length: Up to 12″ (300 mm) (depends on bushing support) | Designed for small, intricate parts—not for large-scale milling. |

📌 Material-Specific Considerations for Swiss Lathes

Swiss lathes handle all listed materials well, but cutting parameters must be optimized to maintain tolerances:

– Aluminum (e.g., 6061, 7075):

– Why: High thermal conductivity allows fast speeds (1,000–2,000 SFM), but chips can gum up if feeds are too slow.

– Tolerance Tip: Use positive rake tools to avoid work hardening; tolerances of ±0.0002″ are routine.

– Steel (e.g., 303, 17-4 PH, 4140):

– Why: Harder to machine; requires slower speeds (100–400 SFM), coolant pressure > 1,000 PSI, and rigid tooling to prevent chatter.

– Tolerance Tip: Heat management is critical—use through-spindle coolant to avoid thermal expansion errors (±0.0003″ achievable).

– ABS/Nylon (Engineering Plastics):

– Why: Low melting points; high speeds can cause melting. Use sharp, polished tools and low speeds (50–200 SFM).

– Tolerance Tip: Avoid high feed rates—Nylon can creep under pressure; tolerances of ±0.0005″ are typical (±0.0003″ possible with optimized parameters).

⚠️ Critical Limitation: Swiss lathes cannot perform 3D contouring, complex pocketing, or true 5-axis milling. Their milling capability is restricted to simple features on the “tailstock side” (e.g., a cross-hole or flat surface). For anything beyond this, a dedicated milling machine is required.

🛠️ 2. What You Actually Need for 3/4/5-Axis Milling: Dedicated CNC Machining Centers

If your project requires true multi-axis milling (e.g., aerospace turbine blades, complex molds, or 5-axis contoured parts), you need a CNC machining center, not a Swiss lathe. Here’s how Honyo Prototype handles this:

| Feature | Typical 5-Axis Machining Center Specs (e.g., Haas UMC-750, DMG MORI CTX-500) |

|—————————|——————————————————————————–|

| Milling Axes | Full 5-axis simultaneous motion (X/Y/Z + A/B or C rotation) with ±0.0001° rotary accuracy. |

| Tolerance Capability | ±0.0001″ (2.5 µm) for complex geometries; ±0.00005″ (1.25 µm) with in-process probing. |

| Spindle Power/Speed | 15–40 HP, 15,000–24,000 RPM (for high-speed aluminum); 10,000 RPM with high torque for steel. |

| Material Handling | – Aluminum: Optimized for 3,000+ SFM with high-feed tools.

– Steel: High-torque spindles (e.g., 1,000 lb-ft torque for 4140).

– ABS/Nylon: Low-vibration spindles (e.g., 10,000 RPM max) with flood coolant to prevent melting. |

| Key Advantage | True 5-axis milling for complex 3D shapes—impossible on a Swiss lathe. |

💡 Why the Confusion?

Some Swiss lathes have “live tooling” (e.g., Y-axis milling), but this is not equivalent to a 5-axis mill. For example:

– A Swiss lathe with live tooling can drill a hole across a turned shaft (2-axis milling), but it cannot machine a curved surface like a turbine blade.

– True 5-axis milling requires a machine with dual rotary tables (e.g., A/B axes) or a trunnion table—something a Swiss lathe physically cannot accommodate due to its sliding headstock design.

✅ Honyo Prototype’s Recommendation

At Honyo Prototype, we always clarify the machine type first to avoid costly mistakes:

– For small, high-precision turned parts with simple milling features (e.g., medical screws, connector pins): Use a Swiss-type lathe (e.g., Citizen C-20, Tsugami SS-20).

– For complex 3D geometries, pockets, or true 5-axis milling: Use a dedicated 5-axis machining center (e.g., DMG MORI CTX-500, Haas UMC-750).

📌 Real-World Example:

A client once asked for “Swiss milling” of a titanium aerospace bracket. We explained that a Swiss lathe could only handle the turning of the mounting holes, but the complex 5-axis sculpted surface required a machining center. We quoted both options—saving them 30% in costs by using the right tool for each feature.

Next Steps for You:

– If your part is small (<0.75″ diameter), symmetrical, and turning-focused, a Swiss lathe is ideal.

– If your part has complex 3D surfaces, deep pockets, or requires simultaneous 5-axis motion, you need a 5-axis milling center.

Let me know your specific part geometry (e.g., CAD file, dimensions, tolerances), and I’ll recommend the exact machine setup for your project—no more terminology confusion! 🛠️

From CAD to Part: The Process

Honyo Prototype – Swiss-type CNC Mill-Turn Workflow

(what actually happens once you push “Upload CAD”)

-

Upload CAD

• Portal accepts any mix of .step, .iges, .x_t, .sldprt, .prt, .3dm, .stl.

• Geometry is immediately tessellated and run through a Swiss-machine feature classifier:

– Bar-stock diameter envelope 1-32 mm (1.25” on 20 mm B-axis machines).

– Checks for over-length/ø ratio ≤ 28:1 without tail-stock, ≤ 60:1 with.

– Flags cross-holes, milled flats, polygon, gear hob, thread whirling, broach, slot, cam-form, eccentric, etc.

• AI Quote engine (Tensor + cost-curve DB) returns a ±10 % price in < 30 s; instant “Accept” locks material lot and machine slot. -

AI-driven DFM (30 – 90 min)

a. Automatic fixturing plan

– Picks main-spindle vs. sub-spindle hand-off point to keep ±0.01 mm concentricity.

– Chooses guide-bushing clearance (0.02-0.05 mm) or stationary head for short parts.

b. Tool-path pre-generation

– 5,000+ tool library (Sandvik, Citizen, Tsugami, Star, Nexturn).

– Selects live-tool speed/feed to keep 0.4 µm Ra on 316L or 0.6 µm on Ti-6Al-4V.

c. Collision & deflection FEA

– Simulated with real-time stock sag; recommends support sleeve or tail-stock if > 8 µm deflection.

d. Cost re-calc

– Cycle-time, tool wear, bar remnant ≤ 1.5 Ø; updated quote sent for e-signature. -

Production release

• Traveler auto-generated: OP10 (main), OP20 (sub), OP30 (back-working), OP40 (optional deburr).

• Bar stock laser-marked with PO & heat number; fed through Citizen L32-X or Star SR-38J.

• In-process control:

– Renishaw Equator gauging every 25 pcs (±0.002 mm).

– Keyence IM-8000 2D optical checks thread pitch & groove width.

• If Cpk < 1.67 machine auto-stops; engineer gets Slack alert with SPC chart. -

Post-processing & QC

• De-burr: thermal (TEM) for cross-holes ≤ 0.4 mm, cryogenic for PEEK.

• Surface finish: optional electropolish to 0.1 µm Ra, or micro-blast for matte Ti.

• Final inspection report: 3-page PDF with bubble drawing, CMM map, material cert, RoHS, REACH. -

Delivery

• Parts ultrasonically cleaned, vacuum-sealed with VCI paper; 1 g silica gel per 100 cm³.

• DHL/UPS label auto-generated; tracking pushed to customer portal.

• Standard lead-time: 5-7 calendar days from DFM sign-off; expedite 72 h available on ≤ 2,000 pcs.

That’s the entire Swiss milling pipeline at Honyo—no human quoting bottlenecks, no DFM black boxes, just data-driven mill-turn production that starts the moment you drop a CAD file.

Start Your Project

Precision Swiss milling services from our Shenzhen factory. Contact Susan Leo at [email protected] for expert solutions today!

Honyo Prototype delivers micron-level accuracy, fast turnaround, and unmatched reliability for complex medical, aerospace, and automotive components—backed by decades of manufacturing excellence.

🚀 Rapid Prototyping Estimator