Introduction: Navigating the Global Market for swiss lathe machine

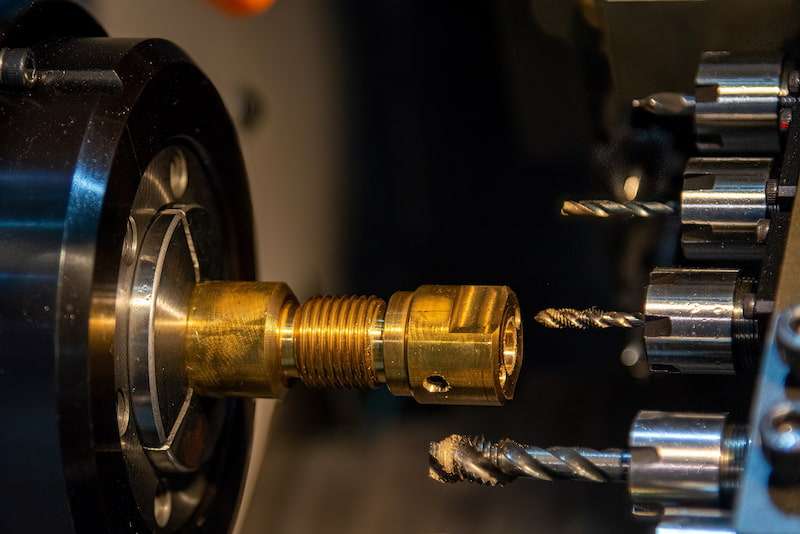

In the competitive landscape of precision manufacturing, sourcing a Swiss lathe machine can pose significant challenges for international B2B buyers. The demand for high-precision components across industries such as automotive, aerospace, and medical is driving the need for advanced machining solutions. Swiss lathes, renowned for their ability to produce intricate parts with exceptional accuracy and minimal waste, have emerged as a preferred choice for manufacturers aiming to enhance productivity while reducing operational costs.

This comprehensive guide will navigate the intricacies of the global market for Swiss lathe machines, covering essential topics such as various types of Swiss lathes, their applications in different sectors, and critical factors to consider when vetting suppliers. Additionally, we will explore cost considerations and financing options, equipping buyers with the knowledge to make informed purchasing decisions.

For international buyers from regions like Africa, South America, the Middle East, and Europe—where manufacturing demands are rapidly evolving—this guide serves as a valuable resource. By offering actionable insights and practical strategies, it empowers businesses to confidently invest in Swiss lathe technology that aligns with their production needs and market demands, ultimately driving growth and innovation in their operations.

Understanding swiss lathe machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Swiss Lathe | Uses a guide bushing for support, typically features 7-12 axes | Aerospace, automotive, medical device parts | Pros: High precision, reduced part deflection. Cons: Higher initial investment. |

| Opposed Gang Tool Lathe | Features multiple tool positions, allows simultaneous machining | High-volume production runs | Pros: Shorter cycle times, increased flexibility. Cons: More complex setup. |

| Sliding Headstock Lathe | Allows bar stock to be fed through a moving headstock | Short runs and prototypes | Pros: Quick changeovers, efficient for short runs. Cons: Limited to shorter workpieces. |

| CNC Swiss Lathe | Fully automated control with advanced programming capabilities | Complex geometries in various industries | Pros: High automation, versatile applications. Cons: Requires skilled operators. |

| Chucker Swiss Lathe | Operates without a guide bushing, suitable for larger diameter stock | General machining, larger parts | Pros: Greater flexibility, reduced remnant sizes. Cons: Less support for longer parts. |

What Are the Key Characteristics of Standard Swiss Lathes?

Standard Swiss lathes are characterized by their use of a guide bushing that supports the workpiece during machining, allowing for high precision and reduced part deflection. Typically equipped with 7 to 12 axes, these machines are ideal for producing intricate components in industries such as aerospace, automotive, and medical devices. Buyers should consider the initial investment versus the long-term benefits of precision and efficiency, as these machines can significantly enhance production quality.

How Do Opposed Gang Tool Lathes Enhance Production Efficiency?

Opposed gang tool lathes are designed to perform simultaneous machining operations, utilizing multiple tool positions to increase productivity. This type of lathe is particularly suited for high-volume production runs, making it a preferred choice in manufacturing environments where time efficiency is critical. While they provide shorter cycle times and greater flexibility in production scheduling, buyers should be aware of the complexity involved in setup and maintenance.

What Are the Benefits of Using Sliding Headstock Lathes?

Sliding headstock lathes feature a moving headstock that feeds bar stock through the machine, making them suitable for short runs and prototyping. This design allows for quick changeovers between different parts, which is advantageous for manufacturers dealing with diverse projects. However, these lathes are limited to shorter workpieces, which could restrict applications in industries requiring longer components.

Why Choose CNC Swiss Lathes for Complex Machining Needs?

CNC Swiss lathes offer advanced programming capabilities and full automation, making them ideal for producing complex geometries across various industries. Their versatility and ability to handle intricate designs enhance productivity and reduce manual labor requirements. Buyers should consider the need for skilled operators to manage these sophisticated machines, as well as the potential for high initial costs balanced against increased efficiency and output.

What Makes Chucker Swiss Lathes Unique?

Chucker Swiss lathes operate without a guide bushing, allowing for the use of larger diameter stock and providing greater flexibility in machining operations. This type is particularly effective for general machining tasks and larger parts, offering reduced remnant sizes and increased shop efficiency. While they present advantages in terms of operational flexibility, buyers must evaluate the trade-offs in support for longer workpieces, which could impact precision in certain applications.

Key Industrial Applications of swiss lathe machine

| Industry/Sector | Specific Application of Swiss Lathe Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of precision components for aircraft | High accuracy and reduced weight of components | Need for certifications (e.g., AS9100) and material traceability |

| Medical Devices | Manufacturing intricate parts for surgical instruments | Enhanced precision and reliability in critical applications | Compliance with regulatory standards (e.g., ISO 13485) |

| Automotive | Creation of small, complex parts like fuel injectors | Increased efficiency and reduced cycle times | Ability to handle varied materials and tight tolerances |

| Electronics | Fabrication of components such as connectors and housings | High-volume production with minimal waste | Sourcing for versatility in tooling and quick changeovers |

| Defense | Manufacturing parts for military equipment | Assurance of durability and performance under stress | Need for robust supply chain and security clearances |

How Are Swiss Lathe Machines Used in the Aerospace Industry?

In the aerospace sector, Swiss lathe machines are employed to manufacture high-precision components such as turbine blades, fittings, and fasteners. These components often require stringent tolerances and lightweight materials to enhance fuel efficiency. The Swiss lathe’s ability to produce intricate geometries while minimizing material waste makes it an ideal choice for this industry. Buyers must consider sourcing machines that comply with aerospace certifications, such as AS9100, and ensure that materials used are traceable to meet industry standards.

What Role Do Swiss Lathes Play in Medical Device Manufacturing?

In the medical device industry, Swiss lathes are critical for the production of intricate parts used in surgical instruments, implants, and diagnostic devices. The high precision offered by these machines ensures that each component meets the strict reliability and safety standards required in medical applications. International buyers should prioritize suppliers that adhere to ISO 13485 regulations, ensuring quality management systems that can meet the unique demands of the medical field.

Why Are Swiss Lathes Essential for the Automotive Sector?

Swiss lathes are extensively used in the automotive industry to manufacture small, complex components such as fuel injectors, valve bodies, and transmission parts. The ability to perform multiple machining operations in a single setup significantly reduces cycle times and enhances productivity. For buyers, it’s crucial to consider machines that can handle diverse materials and maintain tight tolerances, as automotive components often face rigorous performance tests.

How Do Swiss Lathes Benefit Electronics Manufacturing?

In electronics, Swiss lathe machines are utilized to fabricate components like connectors, housings, and small mechanical parts. Their precision allows for high-volume production with minimal waste, which is essential in a sector where cost efficiency and speed are paramount. When sourcing Swiss lathes for electronics applications, buyers should look for flexibility in tooling and quick changeover capabilities to adapt to varying production needs.

What Are the Advantages of Using Swiss Lathes in Defense Manufacturing?

Swiss lathe machines are instrumental in the defense sector for producing durable and reliable parts used in military equipment and weapon systems. The precision and robustness of these machines ensure that components can withstand extreme conditions. Buyers in this field need to ensure that their suppliers have a robust supply chain and can meet security clearance requirements, as defense contracts often involve sensitive materials and technologies.

3 Common User Pain Points for ‘swiss lathe machine’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision with Complex Parts

The Problem:

Many B2B buyers in manufacturing face challenges when producing complex parts with high precision. Industries such as aerospace and medical device manufacturing require components that meet stringent tolerances. Buyers often struggle with conventional lathes, which can lead to issues like part deflection and longer cycle times. This not only affects the quality of the parts but also increases production costs and time, jeopardizing project deadlines and client satisfaction.

The Solution:

To address these challenges, investing in a Swiss lathe machine is a strategic move. These machines are designed specifically for high-precision machining with minimal part deflection due to their unique design, which includes a guide bushing that supports the workpiece during the machining process. When sourcing a Swiss lathe, it’s essential to specify the required tolerances and the complexity of the parts to ensure the machine can handle your specific needs.

Opt for models with advanced features, such as multiple spindles and live tooling capabilities, which allow for simultaneous operations and reduce cycle time. Additionally, ensure that the machine has a robust control system like FANUC, which enhances precision and enables easy programming of complex geometries. Investing in training for operators on how to effectively use these machines will further enhance production quality and efficiency.

Scenario 2: High Operational Costs Due to Inefficient Setup

The Problem:

Buyers often encounter high operational costs associated with machine setup and changeover times, particularly when transitioning between different part runs. Conventional lathes can take considerable time for setup, which translates to increased downtime and reduced productivity. This inefficiency can be particularly detrimental in competitive markets where rapid response and flexibility are essential.

The Solution:

To mitigate these issues, consider acquiring a Swiss lathe with modular tooling capabilities, such as the Tsugami SS20. This type of machine allows for quick changeovers and setup adjustments, enabling manufacturers to switch between long and short runs with minimal downtime. When evaluating machines, look for features such as interchangeable tool holders and easy access to the work area for tool changes.

Additionally, implementing a robust inventory management system can help streamline workflows. By anticipating production needs and maintaining a well-organized tool inventory, you can further reduce setup times. Training staff to efficiently utilize the machine’s modular capabilities will ensure that your operations remain agile and cost-effective.

Scenario 3: Limited Knowledge About Material Compatibility

The Problem:

B2B buyers may find themselves limited by a lack of understanding regarding the materials compatible with Swiss lathes. While these machines excel in machining metals like stainless steel and brass, they can also handle specific plastics. Buyers who are not aware of these capabilities might miss out on opportunities to expand their product offerings, leading to lost business potential.

The Solution:

To overcome this knowledge gap, it is crucial to engage with suppliers who can provide comprehensive information on the material capabilities of their Swiss lathe machines. Before making a purchase, conduct thorough research and request demonstrations that showcase the machine’s performance with various materials.

Utilize technical specifications and user manuals to understand the best practices for machining different materials. Consider establishing partnerships with suppliers who offer training sessions or workshops on material compatibility and machining techniques. By becoming well-informed about the capabilities of Swiss lathes, buyers can diversify their product lines and better meet the demands of their clients, ultimately driving growth and profitability.

Strategic Material Selection Guide for swiss lathe machine

What Materials Are Commonly Used in Swiss Lathe Machines?

When selecting materials for Swiss lathe machining, it’s crucial to consider their properties, advantages, and limitations. The choice of material directly impacts the performance, durability, and cost-effectiveness of the final product. Below, we analyze four common materials used in Swiss lathe applications.

How Does Carbon Steel Perform in Swiss Lathe Applications?

Key Properties: Carbon steel is known for its high tensile strength and hardness, making it suitable for high-stress applications. It can withstand elevated temperatures and has good wear resistance.

Pros & Cons: The durability of carbon steel is a significant advantage, particularly in applications requiring high precision. However, it is susceptible to corrosion if not properly treated, which can lead to increased maintenance costs. Carbon steel is generally more affordable than stainless steel but may require additional processes such as coating for corrosion resistance.

Impact on Application: Carbon steel is compatible with a wide range of media, making it versatile for various industries, including automotive and aerospace. However, its susceptibility to rust can limit its use in humid environments, which is a consideration for international buyers in regions like Africa and South America.

Considerations for International Buyers: Compliance with standards such as ASTM A36 is essential. Buyers should also consider the availability of carbon steel grades in their region to ensure a smooth supply chain.

What Role Does Stainless Steel Play in Swiss Machining?

Key Properties: Stainless steel is renowned for its corrosion resistance and ability to maintain strength at high temperatures. It typically contains chromium, which provides its anti-corrosive properties.

Pros & Cons: The main advantage of stainless steel is its durability and resistance to rust, making it ideal for applications exposed to moisture. However, it is generally more expensive than carbon steel and can be more challenging to machine due to its toughness.

Impact on Application: Stainless steel is widely used in medical devices and food processing equipment due to its hygienic properties. Its compatibility with various media ensures that it can be used in diverse applications across different industries.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM A276 and EN 10088. Countries in Europe and the Middle East often have stringent regulations regarding the use of stainless steel in certain applications.

How Do Aluminum Alloys Enhance Swiss Lathe Machining?

Key Properties: Aluminum alloys are lightweight and possess excellent corrosion resistance. They also have good thermal and electrical conductivity, making them suitable for specific applications.

Pros & Cons: The lightweight nature of aluminum alloys makes them easier to handle and machine, reducing cycle times. However, they are generally less durable than steel and may not withstand high-stress applications as effectively.

Impact on Application: Aluminum is often used in the aerospace and automotive industries for components that require a balance of strength and weight. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is important. Buyers in regions like South America and Europe should also consider the availability of specific aluminum grades to meet their application requirements.

What Advantages Do Plastics Offer in Swiss Lathe Applications?

Key Properties: Plastics, such as nylon and polycarbonate, are lightweight and resistant to corrosion and chemicals. They can be machined to tight tolerances, making them suitable for intricate designs.

Pros & Cons: The main advantage of plastics is their versatility and lower cost compared to metals. However, they may not be suitable for high-temperature applications and can have lower mechanical strength than metals.

Impact on Application: Plastics are commonly used in electrical components and consumer products due to their insulating properties. Their compatibility with various media makes them suitable for diverse applications.

Considerations for International Buyers: Compliance with standards such as ASTM D638 is essential. Buyers from regions like Africa and the Middle East should consider the availability of specific plastic grades to ensure they meet their application requirements.

Summary Table of Material Selection for Swiss Lathe Machines

| Material | Typical Use Case for Swiss Lathe Machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive components | High tensile strength | Susceptible to corrosion | Medium |

| Stainless Steel | Medical devices, food processing | Excellent corrosion resistance | Higher cost and machining difficulty | High |

| Aluminum Alloys | Aerospace components | Lightweight and easy to machine | Lower durability compared to steel | Medium |

| Plastics | Electrical components, consumer products | Versatile and cost-effective | Lower mechanical strength | Low |

This strategic material selection guide aims to provide B2B buyers with the necessary insights to make informed decisions regarding material choices for Swiss lathe machining, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for swiss lathe machine

What Are the Key Stages in the Manufacturing Process of Swiss Lathe Machines?

The manufacturing process for Swiss lathe machines involves several critical stages, each designed to ensure precision and quality. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

Material Preparation: How Is the Right Material Chosen?

Material preparation is the first step in the manufacturing process. Swiss lathes typically work with a variety of materials, including carbon steel, stainless steel, brass, and certain plastics. The choice of material is crucial, as it affects the machine’s performance and the quality of the finished parts.

Materials are selected based on factors such as tensile strength, machinability, and application requirements. Once chosen, the raw materials undergo a series of processes, including cutting to length and surface treatment, to ensure they meet the specifications necessary for subsequent machining operations.

Forming: What Techniques Are Employed in Machining?

The forming stage is where the actual machining occurs. Swiss lathes utilize a unique sliding headstock and guide bushing system that provides support to the workpiece, allowing for high precision and reduced part deflection. This design enables Swiss lathes to perform multiple operations simultaneously, including turning, drilling, and tapping.

Machining techniques in this stage include CNC programming, where complex geometries can be achieved with high accuracy. The machines are equipped with various tooling options, allowing for quick changeovers between different part designs, which is particularly beneficial for manufacturers needing to switch between long and short production runs.

Assembly: How Are Components Brought Together?

Following the machining process, the assembly stage involves the integration of various components to create the final Swiss lathe machine. This includes fitting the main spindle, secondary spindles, and tool holders. The precision with which these components are assembled is vital, as any misalignment can lead to inaccuracies in machining.

Quality checks during assembly often involve visual inspections and the use of precision measurement tools to ensure that all parts fit together correctly. Some manufacturers may also employ automated assembly systems to enhance consistency and efficiency.

Finishing: What Processes Ensure Quality and Precision?

The finishing stage focuses on refining the machined parts to meet strict tolerances and surface finish requirements. This may involve processes like polishing, coating, or additional machining operations to remove any burrs or imperfections. Finishing is essential for ensuring that the parts meet the necessary specifications for their intended applications.

In this stage, manufacturers often utilize advanced technologies such as laser measurement systems to verify the dimensions and surface quality of the parts. This attention to detail is crucial for industries that demand high precision, such as aerospace and medical devices.

What Quality Assurance Practices Are Critical for Swiss Lathe Machines?

Quality assurance (QA) is an integral part of the manufacturing process for Swiss lathe machines. B2B buyers must understand the QA practices employed by suppliers to ensure they receive high-quality products.

What International Standards Should Buyers Look For?

Manufacturers of Swiss lathe machines should adhere to international quality standards such as ISO 9001, which outlines a framework for effective quality management systems. Compliance with ISO standards ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO certifications, industry-specific certifications such as CE marking for European markets and API standards for oil and gas applications are also significant. These certifications demonstrate a commitment to quality and safety, reassuring B2B buyers about the reliability of the machinery.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are vital throughout the manufacturing process to ensure that each component meets the required standards. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the machining process and detect any deviations in real-time.

- Final Quality Control (FQC): Once the assembly is complete, the final products undergo rigorous testing to confirm they meet all quality specifications before shipping.

By implementing these checkpoints, manufacturers can significantly reduce the risk of defects and ensure the reliability of their machines.

What Testing Methods Are Commonly Used?

Various testing methods are employed to verify the quality of Swiss lathe machines, including:

- Dimensional Inspection: Using tools such as calipers and micrometers to measure the dimensions of components against specified tolerances.

- Functional Testing: Assessing the operational performance of the machine to ensure it functions as intended.

- Material Testing: Conducting tests to evaluate the mechanical properties of the materials used in the machine.

These methods help manufacturers identify potential issues before the machines reach the market, thereby enhancing the overall quality.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, verifying the quality assurance processes of potential suppliers is crucial. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits can provide insight into a supplier’s manufacturing processes and quality control measures. Buyers should assess the implementation of quality standards and the effectiveness of QC checkpoints.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports and compliance certifications. These documents can help buyers evaluate the reliability of the supplier.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can offer an unbiased assessment of the supplier’s quality assurance practices. This is particularly valuable for international buyers who may be unable to perform on-site inspections.

-

Understand Certification Nuances: Different regions may have varying certification requirements. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local regulations and standards to ensure that suppliers meet necessary compliance.

By taking these steps, B2B buyers can mitigate risks associated with quality and make informed purchasing decisions when investing in Swiss lathe machines.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘swiss lathe machine’

Introduction

When sourcing a Swiss lathe machine, it’s essential to approach the process systematically to ensure that you select the right equipment for your manufacturing needs. This guide provides a step-by-step checklist that will help you identify your requirements, evaluate suppliers, and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications your Swiss lathe machine must meet. This includes the maximum bar stock diameter, number of axes, and the types of materials you will be machining.

– Considerations: Think about the complexity of parts you will produce, as Swiss lathes can handle intricate designs with high precision.

– Document Requirements: Create a detailed document that includes tolerances, cycle times, and any specific features like live tooling or dual spindles.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in Swiss lathe machines. Utilize industry directories, trade shows, and online forums to compile a list of manufacturers.

– Reputation Check: Look for suppliers with a proven track record in your industry and region.

– Technology Focus: Ensure they offer the latest technology and machine capabilities that align with your specifications.

Step 3: Evaluate Supplier Certifications

Verify the certifications and industry standards of your shortlisted suppliers. Certifications such as ISO 9001 indicate a commitment to quality management systems.

– Importance: Certifications not only assure quality but also signify that the supplier adheres to industry best practices.

– Additional Credentials: Look for other relevant certifications that may pertain to safety and environmental management, which could impact your operations.

Step 4: Request Detailed Quotations

Once you have narrowed down your suppliers, request detailed quotations that outline pricing, delivery timelines, and warranty information.

– Comparative Analysis: This will allow you to compare offers more effectively, considering both cost and value.

– Inclusions: Ensure that the quotation specifies all necessary accessories, tooling, and any potential shipping costs.

Step 5: Assess After-Sales Support

Evaluate the after-sales support and service options provided by the supplier. A reliable supplier should offer training, maintenance, and quick access to spare parts.

– Service Agreements: Inquire about service level agreements (SLAs) that guarantee timely support and repairs.

– Training Programs: Ensure the supplier offers comprehensive training for your operators to maximize machine utilization.

Step 6: Request References and Case Studies

Ask for references from previous clients who have purchased similar machines. This will provide insights into the supplier’s reliability and the performance of their equipment.

– Industry Relevance: Focus on references from companies in your industry or with similar manufacturing needs.

– Performance Metrics: Inquire about the performance metrics of the machines supplied, such as uptime and productivity rates.

Step 7: Conduct Site Visits if Possible

If feasible, arrange site visits to the supplier’s facility or to existing clients using their machines.

– Hands-On Evaluation: This allows you to see the machines in action and evaluate their performance firsthand.

– Understanding Processes: Observe the quality of the parts produced and the efficiency of the machining processes to ensure they meet your expectations.

By following this checklist, you can confidently navigate the sourcing process for a Swiss lathe machine, ensuring that you select a solution that aligns with your operational goals and manufacturing needs.

Comprehensive Cost and Pricing Analysis for swiss lathe machine Sourcing

What Are the Key Cost Components in Sourcing Swiss Lathe Machines?

Understanding the cost structure of Swiss lathe machines is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences the final price. Swiss lathes are typically constructed from high-quality metals such as stainless steel and aluminum, which can drive up costs. Additionally, the availability of these materials in specific regions, such as Africa or South America, may affect pricing.

-

Labor: Labor costs vary by region and can impact the total expenditure on manufacturing Swiss lathes. Countries with higher labor costs, such as those in Europe, will generally see increased prices for these machines. Conversely, sourcing from regions with lower labor costs may provide cost advantages.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and equipment depreciation. Manufacturers in different regions may have varying overhead costs due to differences in infrastructure and operational efficiencies, which can translate into different pricing strategies.

-

Tooling: Swiss lathes often require specialized tooling to maintain their precision. The cost of these tools, which may need to be replaced or updated over time, should be factored into the overall pricing.

-

Quality Control (QC): Rigorous quality control processes are essential for ensuring the precision of Swiss lathes. The costs associated with QC can vary based on the manufacturer’s standards and certifications, influencing the overall price.

-

Logistics: Shipping and handling costs can be substantial, especially for international buyers. Factors such as distance, shipping method, and local tariffs can all impact the final cost of acquiring Swiss lathes.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the margin expectations of suppliers can aid in better negotiating prices.

What Influences the Pricing of Swiss Lathe Machines?

Several factors affect the pricing of Swiss lathes, including:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts, as suppliers often offer lower prices for larger orders. Buyers should assess their needs carefully to negotiate better terms.

-

Specifications and Customization: Custom-built Swiss lathes or those with advanced specifications may incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Machines built with premium materials and certifications will be priced higher due to their enhanced performance and reliability. Buyers should weigh the long-term benefits against the initial investment.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: The terms of shipping and delivery can significantly influence costs. Buyers should understand the implications of different Incoterms, such as FOB or CIF, as these can shift responsibility and costs between the buyer and seller.

How Can Buyers Optimize Costs When Sourcing Swiss Lathe Machines?

To enhance cost-efficiency when sourcing Swiss lathe machines, consider the following tips:

-

Negotiate Effectively: Develop a strong relationship with suppliers and leverage volume purchases to negotiate better pricing. Be prepared to discuss terms and conditions openly.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, tooling, and operational costs over the machine’s lifespan. This approach can reveal the true cost-effectiveness of different options.

-

Understand Pricing Nuances in International Markets: Different regions may have unique pricing structures due to local market conditions, tariffs, and currency fluctuations. Conduct thorough market research to identify the best sourcing options.

-

Request Detailed Quotations: Always ask suppliers for a breakdown of costs associated with the machine. This transparency can help identify areas for negotiation or adjustment.

-

Evaluate Multiple Suppliers: Compare offers from various suppliers to ensure competitive pricing. This not only helps in finding the best deal but also provides leverage during negotiations.

Disclaimer on Indicative Prices

Pricing for Swiss lathe machines can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure they receive the best value for their investment.

Alternatives Analysis: Comparing swiss lathe machine With Other Solutions

Exploring Alternatives to Swiss Lathe Machines in Precision Manufacturing

In the realm of precision manufacturing, selecting the right machinery is crucial for optimizing production efficiency, quality, and cost-effectiveness. While Swiss lathe machines are renowned for their high precision and capability to produce intricate components, several alternative solutions exist that may suit different manufacturing needs. Below, we compare Swiss lathe machines with two viable alternatives: conventional CNC lathes and multi-spindle machining centers.

| Comparison Aspect | Swiss Lathe Machine | Conventional CNC Lathe | Multi-Spindle Machining Center |

|---|---|---|---|

| Performance | High precision, short cycle times | Moderate precision, slower cycles | Very high throughput, moderate precision |

| Cost | Generally higher initial investment | Lower initial cost | Higher initial investment, but lower cost per part |

| Ease of Implementation | Moderate, requires skilled operators | Easier, more widely understood | Complex, requires specialized knowledge |

| Maintenance | High due to precision components | Moderate, simpler mechanics | High, due to multiple spindles and setups |

| Best Use Case | Producing complex, small parts | General-purpose machining | High-volume production of simpler parts |

In-Depth Look at Alternatives

What Are the Benefits and Drawbacks of Conventional CNC Lathes?

Conventional CNC lathes are widely used in various industries for their versatility and lower initial investment costs. These machines are easier to set up and operate, making them a good choice for manufacturers who require flexibility in production. However, they generally offer lower precision than Swiss lathes and can be slower, particularly when producing intricate components. The lack of advanced features such as guide bushings may lead to part deflection, impacting overall quality for longer workpieces.

How Do Multi-Spindle Machining Centers Compare?

Multi-spindle machining centers excel in high-volume production environments, where speed and efficiency are paramount. They can simultaneously perform multiple operations, drastically reducing cycle times and lowering the cost per part. However, they are less suitable for complex or intricate parts that require high precision, as the technology typically sacrifices some accuracy for speed. Additionally, the complexity of operating and maintaining these machines can require a higher level of expertise, which may not be readily available in all manufacturing settings.

Making an Informed Decision: Which Solution is Right for Your Business?

When determining the most suitable manufacturing solution, B2B buyers must consider their specific needs, including production volume, part complexity, budget constraints, and available expertise. Swiss lathe machines are ideal for high-precision tasks involving small, intricate components, while conventional CNC lathes offer flexibility for varied production runs. On the other hand, multi-spindle machining centers are best for businesses focused on high-volume production of simpler parts.

Ultimately, the choice between these technologies hinges on a comprehensive understanding of operational requirements and long-term business goals. By aligning machinery selection with these factors, buyers can optimize their manufacturing processes and achieve competitive advantages in their respective markets.

Essential Technical Properties and Trade Terminology for swiss lathe machine

What Are the Essential Technical Properties of Swiss Lathe Machines?

When considering Swiss lathe machines for your production needs, understanding their technical properties is crucial for making informed purchasing decisions. Below are some of the key specifications that define the performance and suitability of these machines for various applications.

What Are the Key Specifications for Swiss Lathe Machines?

-

Maximum Bar Capacity

This refers to the largest diameter of bar stock that can be loaded into the lathe for machining. Common capacities range from 12mm to 38mm. Understanding the bar capacity is essential for B2B buyers as it directly affects the types of components that can be manufactured. If your operations require parts with larger diameters, selecting a machine with a sufficient bar capacity is critical to avoid production delays. -

Tolerances

Swiss lathes are renowned for their high precision, typically achieving tolerances of ±0.005 mm or better. Tolerance specifications are vital for industries that require intricate and tightly fitted components, such as aerospace and medical device manufacturing. Ensuring that your Swiss lathe meets the required tolerances can significantly influence product quality and compliance with industry standards. -

Number of Axes

Swiss lathes can feature between 6 to 13 axes, allowing for complex machining operations to be performed simultaneously. The number of axes is a key factor in determining a machine’s versatility and productivity. For buyers, selecting a machine with adequate axes can enhance operational efficiency by minimizing the need for secondary processes. -

Spindle Speed

The speed at which the main and sub-spindles operate can range from 200 to 10,000 rpm. Higher spindle speeds can lead to faster machining times and improved surface finishes. For B2B operations, understanding spindle speed capabilities can help you match the machine to your production requirements, especially for high-volume runs. -

Tool Positions

The number of tool positions available, typically ranging from 24 to 40, dictates the machine’s ability to perform multiple operations without manual tool changes. This characteristic is crucial for increasing productivity and reducing cycle times. Buyers should evaluate tool positions in relation to their production volume and complexity to optimize workflow. -

Material Compatibility

Swiss lathes are primarily designed to work with metals such as carbon steel, aluminum, and brass, as well as some plastics. Knowing the material compatibility is essential for buyers to ensure that the selected machine can handle the specific materials required for their product lines.

What Are Common Trade Terminology and Jargon Related to Swiss Lathes?

Understanding the trade terminology associated with Swiss lathe machines can help facilitate smoother negotiations and clearer communication with suppliers.

-

OEM (Original Equipment Manufacturer)

Refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Swiss lathes, knowing the OEM can provide insights into the quality and reliability of the machine. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for inventory management and cost calculations, especially when planning large-scale production runs. -

RFQ (Request for Quotation)

A document that solicits price and terms from suppliers. Submitting an RFQ is a standard practice for B2B buyers seeking competitive pricing and terms for Swiss lathe machines. -

Incoterms (International Commercial Terms)

A series of predefined commercial terms published by the International Chamber of Commerce (ICC). These terms clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers engaging in cross-border purchases of Swiss lathes. -

CNC (Computer Numerical Control)

Refers to the automation of machine tools via computers executing pre-programmed sequences of machine control commands. Understanding CNC is essential for buyers as it highlights the advanced technology behind Swiss lathes, which enhances precision and efficiency. -

Cycle Time

The total time taken to complete one cycle of production, from start to finish. For B2B buyers, a lower cycle time means higher productivity and efficiency, making it a crucial factor in the selection process for Swiss lathes.

By grasping these essential properties and terminologies, international B2B buyers can navigate the complex landscape of Swiss lathe machines more effectively, ensuring that they choose the right equipment for their specific manufacturing needs.

Navigating Market Dynamics and Sourcing Trends in the swiss lathe machine Sector

What Are the Key Market Trends Influencing Swiss Lathe Machine Sourcing?

The Swiss lathe machine sector is witnessing significant growth driven by the increasing demand for precision-engineered components across various industries, including automotive, aerospace, and medical devices. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance their manufacturing capabilities, they are gravitating towards Swiss lathes for their superior accuracy and efficiency. Key trends include the adoption of advanced CNC technologies, which allow for greater flexibility in manufacturing processes. This is particularly relevant for buyers looking to produce complex parts quickly and economically.

Moreover, the trend towards automation and Industry 4.0 is reshaping sourcing strategies. Companies are now prioritizing machines that can integrate seamlessly with IoT technologies for real-time monitoring and predictive maintenance, thus minimizing downtime and improving productivity. Additionally, there is a growing emphasis on modularity and adaptability in machine design, enabling buyers to easily adjust their setups for both short and long production runs without incurring significant costs.

Another vital trend is the increasing importance of supply chain transparency. Buyers are now more inclined to source from manufacturers who can provide detailed insights into their production processes and material origins, ensuring alignment with quality standards and ethical practices.

How Are Sustainability and Ethical Sourcing Shaping the Swiss Lathe Machine Market?

Sustainability has emerged as a critical consideration for B2B buyers in the Swiss lathe machine sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to seek machines that minimize waste and energy consumption. For instance, Swiss lathes that utilize oil-based coolants instead of water not only enhance machining efficiency but also reduce tool wear and energy usage.

Furthermore, ethical sourcing is becoming increasingly important. Buyers are looking for suppliers who prioritize responsible manufacturing practices, including fair labor conditions and environmental stewardship. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming prerequisites in supplier selection.

In addition to certifications, the use of ‘green’ materials and processes is gaining traction. This includes sourcing from suppliers who utilize recycled materials or sustainable practices in their operations. By prioritizing sustainability and ethical sourcing, buyers not only align with global environmental goals but also enhance their brand reputation and customer loyalty.

What Is the Historical Context of Swiss Lathe Machines?

Swiss lathes trace their origins back to the 1870s, initially developed for the precision manufacturing of small components in the watchmaking industry. The invention of the Swiss-style lathe by Jakob Schweizer revolutionized the production of intricate parts, enabling manufacturers to achieve unprecedented levels of accuracy with minimal tolerances.

As industries evolved, the application of Swiss lathes expanded beyond watchmaking into sectors such as electronics and medical devices. By the 1960s, Swiss machining gained global recognition for its efficiency and precision, leading to its adoption in mass production environments. Today, the continual evolution of Swiss lathe technology, including the integration of CNC capabilities and automation, underscores its significance in modern manufacturing, making it an essential tool for international B2B buyers looking to stay competitive in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of swiss lathe machine

-

How do I choose the right Swiss lathe machine for my production needs?

Choosing the right Swiss lathe machine involves assessing your specific production requirements, such as part complexity, volume, and materials. Consider the maximum bar stock diameter and length-to-diameter ratio that your projects demand. Evaluate the machine’s capabilities for simultaneous machining, number of axes, and tool positions. Additionally, factor in the machine’s flexibility for both long and short runs, which can significantly impact productivity. Request demonstrations and consult with suppliers about customization options that align with your manufacturing goals. -

What are the advantages of Swiss lathes over conventional lathes?

Swiss lathes offer several advantages over conventional lathes, including higher precision and shorter cycle times. The segmented approach of Swiss machining allows for improved consistency and reduced part deflection, leading to tighter tolerances. Additionally, Swiss lathes can perform multiple operations in a single setup, which enhances productivity and minimizes the need for secondary processing. Their design also accommodates longer workpieces efficiently, making them ideal for complex parts and high-volume production. -

What is the typical lead time for ordering a Swiss lathe machine?

The lead time for ordering a Swiss lathe machine can vary significantly based on the manufacturer, model, and customization options. Generally, lead times range from a few weeks to several months. Factors influencing lead time include machine availability, the complexity of custom features, and shipping logistics. It’s advisable to discuss timelines with your supplier during the initial inquiry to set realistic expectations for delivery. -

What should I consider when vetting suppliers for Swiss lathe machines?

When vetting suppliers for Swiss lathe machines, consider their industry reputation, experience, and customer reviews. Assess their after-sales support, including warranty terms, maintenance services, and availability of spare parts. Ensure they have a robust quality assurance process to guarantee the machines meet international standards. Additionally, inquire about their capacity for customization and flexibility in addressing your specific needs, especially for complex or specialized parts. -

What are the common payment terms for purchasing Swiss lathe machines internationally?

Common payment terms for international purchases of Swiss lathe machines typically include options like a deposit followed by balance payment before shipment, or Letter of Credit (LC) arrangements. Some suppliers may also offer financing options or installment plans, especially for larger investments. Ensure to clarify payment terms upfront to avoid any misunderstandings and check if there are any additional fees related to currency exchange or international transactions. -

What is the minimum order quantity (MOQ) for Swiss lathe machines?

The minimum order quantity (MOQ) for Swiss lathe machines can vary based on the manufacturer and the type of machine. While some suppliers may offer single machine purchases, others might have higher MOQs, particularly for customized models. It is essential to communicate your needs clearly and discuss potential options with suppliers, especially if you are looking for a specific configuration or additional tooling. -

How does quality assurance work for Swiss lathe machines?

Quality assurance for Swiss lathe machines typically involves rigorous testing and inspection processes during manufacturing. Reputable suppliers will conduct checks for precision, functionality, and durability, ensuring machines meet established industry standards. Request documentation on quality control procedures, including certifications and test results. Additionally, inquire about the supplier’s policies for post-sale support and warranty coverage in case any issues arise after purchase. -

What logistics considerations should I keep in mind when importing Swiss lathe machines?

When importing Swiss lathe machines, consider logistics factors such as shipping methods, customs duties, and insurance. Discuss with your supplier about the best shipping options that balance cost and transit time. Understand the documentation required for customs clearance, which may include commercial invoices, packing lists, and certificates of origin. Lastly, ensure you have a reliable logistics partner to manage the transportation and delivery of the machine to your facility, especially for heavy and complex equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Swiss Lathe Machine Manufacturers & Suppliers List

1. Fractory – Swiss Machining Solutions

Domain: fractory.com

Registered: 2000 (25 years)

Introduction: Swiss machining, also known as Swiss turning, is a high-precision CNC machining process performed on Swiss lathes designed for small and intricate parts. Key features include:

– High precision with incredibly small tolerances.

– Shorter cycle times compared to conventional lathes.

– Segmented machining approach that eliminates part deflection and increases accuracy.

– Typically uses one or two…

2. Tsugami – SS20 Swiss Type CNC Lathe

Domain: tsugamiamerica.com

Registered: 2020 (5 years)

Introduction: {“model”:”Tsugami SS20″,”type”:”Swiss Type CNC Automatic Lathe”,”maximum_bar_stock”:”20 mm”,”number_of_axes”:”6″,”sliding_headstock_with_guide_bushing”:”YES”,”convertible”:”YES (run without guide bushing with optional chucker kit)”,”max_headstock_stroke_with_guide_bushing”:”220 mm (8.66 in)”,”max_headstock_stroke_without_guide_bushing”:”45 mm (1.77 in)”,”tool_positions”:”24/40 (std/max)”,”live_too…

3. Star CNC – Swiss-type Automatic Lathes

Domain: starcnc.com

Registered: 1997 (28 years)

Introduction: Star CNC offers a range of Swiss-type Automatic Lathes designed for small, complex, and precise metal components machining. Key models include: SB-12R Type G, SB-16R Type G, SB-20R Type G, SD-26 Type S, SK-51 Type A, SL-10, SP-20, SR-10J, SR-20JII Type A/B, SR-20R IV Type A/B, SR-32JIII Type A/B, SR-38 Type B, ST-20, ST-38, SV-20R, SW-12R II, SW-20, SX-38 Type A/B. The SD-26 Type S features double…

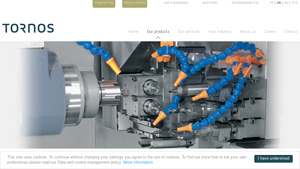

4. Tornos – Swiss-type Lathes

Domain: tornos.com

Registered: 2000 (25 years)

Introduction: Swiss-type lathes and sliding headstock lathes from Tornos include various models with specific features:

1. **SwissDECO** – Maximum bar capacity: Ø 36 mm, Number of axes: 11

2. **EvoDECO** – Multiple configurations:

– EvoDECO 10/10: Ø 10 mm, 10 axes

– EvoDECO 10/8: Ø 10 mm, 8 axes

– EvoDECO 16/10: Ø 16 mm, 10 axes

– EvoDECO 20: Ø 25.4 mm, 10 axes

– EvoDECO 32: Ø 32 mm, 10 a…

5. TSUGAMI – Swiss Lathe

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: {“product_type”:”Swiss Lathe”,”condition”:”Used”,”brands”:[“TSUGAMI”,”GANESH”,”STAR”,”CITIZEN”,”HANWHA”,”HAAS”,”MAZAK”,”OKUMA”,”DOOSAN”,”MORI SEIKI”,”DMG MORI SEIKI”,”DAEWOO”,”ACCUWAY”,”AMADA WASINO”,”ANNN YANG”,”BULOVA”,”CHALLENGER”,”CHARTER OAK AUTOMATION”,”CHEVALIER”,”COLCHESTER”,”CUBIC”,”DMG”,”EMAG”,”EUROTECH”,”FEMCO”,”GEMINIS”,”GOODWAY”,”HACO”,”HARDINGE”,”HAUSHU”,”HURCO”,”HWACHEON”,”HYUNDAI”,…

6. Citizen – CNC Swiss-Type Turning Centers

Domain: citizenmachines.com

Registered: 1997 (28 years)

Introduction: Citizen CNC Swiss-Type Turning Centers are widely accepted for manufacturing various products including medical instruments, electronics, fiber optics, automobiles, business machines, aerospace, defense, firearms, tools, valves, and fasteners. They utilize sliding headstock technology and guide bushing for enhanced material support, eliminating vibration and harmonics for precise machining. The ma…

Strategic Sourcing Conclusion and Outlook for swiss lathe machine

How Can Strategic Sourcing Enhance Your Swiss Lathe Machine Procurement?

In summary, strategic sourcing for Swiss lathe machines offers significant advantages to international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By understanding the unique benefits of Swiss machining—such as enhanced precision, reduced cycle times, and the ability to produce complex parts efficiently—companies can make informed decisions that optimize their manufacturing capabilities.

Investing in high-quality Swiss lathes not only improves production efficiency but also minimizes the need for secondary operations, ultimately leading to cost savings. The modular designs of modern Swiss machines allow for flexibility in production runs, making them suitable for both high-volume and short-run jobs.

As the global market continues to evolve, embracing advanced manufacturing technologies will be crucial for maintaining competitive advantage. B2B buyers should proactively engage with reputable suppliers, assess the latest innovations, and consider the long-term benefits of integrating Swiss lathe technology into their operations. This proactive approach will ensure that businesses are well-positioned to meet future demands and capitalize on new opportunities in the manufacturing landscape.