Introduction: Navigating the Global Market for svg cnc files

In an increasingly interconnected world, sourcing high-quality SVG CNC files presents both opportunities and challenges for international B2B buyers. The demand for precision in manufacturing, coupled with diverse regional design preferences, makes it essential to navigate the global market effectively. This guide serves as a comprehensive resource for businesses seeking to acquire SVG CNC files, covering a wide range of topics including types of files available, their applications across various industries, best practices for supplier vetting, and insights into cost structures.

By understanding the nuances of SVG CNC files—from intricate designs suitable for laser cutting to versatile vector graphics used in diverse production environments—buyers can make informed purchasing decisions that align with their operational needs. This guide specifically targets B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Vietnam. It empowers these businesses to identify reliable suppliers, evaluate file quality, and optimize their procurement processes. Ultimately, this resource aims to streamline the sourcing journey, ensuring that companies can efficiently access the digital assets necessary for their manufacturing and creative projects.

Understanding svg cnc files Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2D SVG Files | Flat designs; suitable for laser cutting and engraving. | Signage, decorative items, and custom branding. | Pros: Easy to use and versatile. Cons: Limited to 2D applications. |

| 3D SVG Files | Multi-layered designs; creates depth in cut materials. | Prototyping, product design, and artistic sculptures. | Pros: Engaging and eye-catching. Cons: More complex to design and cut. |

| Vector Art SVG Files | High-quality, scalable graphics; maintain clarity at any size. | Crafting, promotional materials, and merchandise. | Pros: High resolution and detail. Cons: Requires design expertise. |

| Craft SVG Files | Themed designs for specific hobbies or crafts. | DIY projects, personal gifts, and home decor. | Pros: Niche appeal and creativity. Cons: May have limited market demand. |

| Custom SVG Files | Tailored designs specific to client needs or specifications. | Branding, promotional items, and specialized projects. | Pros: Unique and personalized. Cons: Higher cost and longer turnaround time. |

What Are the Characteristics of 2D SVG Files and Their B2B Suitability?

2D SVG files are characterized by their flat designs, making them ideal for applications like laser cutting and engraving. These files can be used to create signage, decorative items, and custom branding materials. For B2B buyers, the appeal lies in the simplicity and versatility of 2D SVG files. They can be easily manipulated and adapted for various projects, making them a cost-effective choice for businesses looking to enhance their marketing efforts or create unique products.

How Do 3D SVG Files Differ and What Are Their Key Applications?

3D SVG files stand out due to their multi-layered designs, which create a sense of depth in the finished products. These files are particularly useful for prototyping, product design, and artistic sculptures. For businesses, the ability to produce engaging, three-dimensional pieces can lead to innovative product offerings and enhanced customer experiences. However, these files may require more advanced design skills and cutting equipment, which could be a consideration for buyers with limited resources.

Why Choose Vector Art SVG Files for B2B Projects?

Vector art SVG files are known for their high-quality graphics that remain clear and detailed at any size. This makes them an excellent choice for crafting, promotional materials, and merchandise. B2B buyers benefit from the scalability and resolution of these files, which can enhance branding efforts and product appeal. However, working with vector art often necessitates design expertise, which could pose a challenge for businesses lacking in-house design capabilities.

What Makes Craft SVG Files Attractive for Specific B2B Markets?

Craft SVG files are themed designs tailored for specific hobbies or crafts, appealing to DIY enthusiasts and small businesses alike. These files are perfect for personal gifts, home decor, and unique projects that stand out in the market. For B2B buyers, the niche appeal of craft SVG files can foster creativity and attract a dedicated customer base. However, businesses should consider the potential limitations in market demand for specific themes.

How Do Custom SVG Files Provide Unique Value to Businesses?

Custom SVG files offer tailored designs that meet specific client needs or project requirements. They are often used in branding, promotional items, and specialized projects that require a unique touch. The primary advantage for B2B buyers is the ability to provide personalized products that resonate with their target audience. However, the higher cost and longer turnaround time associated with custom designs should be factored into purchasing decisions, especially for businesses with tight deadlines or budgets.

Key Industrial Applications of svg cnc files

| Industry/Sector | Specific Application of svg cnc files | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom Tooling and Fixtures | Enhances production efficiency and accuracy in manufacturing. | Seek high-quality, scalable SVG files compatible with CNC machines. |

| Signage and Advertising | Custom Signage Production | Allows for personalized branding and effective marketing. | Ensure files are optimized for various materials and cutting techniques. |

| Furniture Design | Laser-Cut Furniture Components | Facilitates intricate designs, reducing material waste. | Look for versatile SVG files that accommodate different wood types. |

| Automotive | Prototype Parts and Accessories | Speeds up product development and reduces costs. | Focus on files that meet automotive standards for precision and durability. |

| Arts and Crafts | Artistic Decor and Craft Projects | Provides unique design options for creative industries. | Consider the diversity of available designs and customization capabilities. |

How are SVG CNC Files Utilized in Manufacturing?

In the manufacturing sector, SVG CNC files are essential for creating custom tooling and fixtures. These files enable manufacturers to produce components with high precision, thus reducing errors and enhancing efficiency. For international buyers, especially in Africa and South America, sourcing high-quality SVG files that are compatible with various CNC machines is crucial. Additionally, understanding the specific requirements for different materials can significantly impact production outcomes.

What Role do SVG CNC Files Play in Signage and Advertising?

SVG CNC files are widely used in the signage and advertising industry to produce custom signage that enhances brand visibility. By utilizing these files, businesses can create intricate designs that stand out in competitive markets. International B2B buyers, particularly from Europe and the Middle East, should prioritize sourcing SVG files that are optimized for different substrates, ensuring durability and visual appeal. This is vital for effective marketing campaigns.

How are SVG CNC Files Transforming Furniture Design?

In furniture design, SVG CNC files facilitate the creation of laser-cut components that allow for intricate and modern designs. This application not only minimizes material waste but also supports sustainability initiatives. Buyers in this sector must focus on sourcing versatile SVG files that can adapt to various wood types and thicknesses, ensuring quality and longevity in their products. Understanding local regulations regarding material sourcing is also essential for international buyers.

What Benefits do SVG CNC Files Offer in Automotive Applications?

For the automotive industry, SVG CNC files are instrumental in producing prototype parts and accessories. This capability accelerates the product development cycle, allowing companies to innovate faster and reduce costs associated with traditional manufacturing methods. International buyers should look for SVG files that adhere to automotive standards, ensuring both precision and durability in their applications. Collaboration with suppliers that understand these requirements can lead to successful outcomes.

How do SVG CNC Files Enhance Arts and Crafts?

In the arts and crafts sector, SVG CNC files provide a plethora of unique design options for artistic decor and craft projects. These files empower creators to bring their visions to life with precision and creativity. For B2B buyers, especially those in Europe and Africa, it’s important to consider the diversity of available designs and the ability to customize files to meet specific artistic needs. This flexibility can significantly enhance product offerings in competitive markets.

3 Common User Pain Points for ‘svg cnc files’ & Their Solutions

Scenario 1: Difficulty Finding High-Quality SVG CNC Files for Specific Projects

The Problem: In a competitive manufacturing landscape, B2B buyers often struggle to locate high-quality SVG CNC files tailored to their specific project requirements. Many suppliers offer a wide range of files, but the quality can vary significantly. Poorly designed files can lead to wasted materials, increased production time, and ultimately, dissatisfied customers. For businesses in sectors like custom signage or intricate woodworking, the right SVG file is crucial for ensuring precision and quality in the final product.

The Solution: To overcome this challenge, buyers should focus on sourcing SVG CNC files from reputable suppliers that provide detailed previews and customer reviews. When evaluating potential sources, look for platforms that specialize in CNC files, such as CnCcraftSVG or 3axis.co, which offer a variety of high-quality options. Additionally, buyers should request sample files to assess the quality before making a bulk purchase. It’s advisable to establish relationships with trusted suppliers who can provide customization options, ensuring that the files meet the specific design requirements of each project. By prioritizing quality and establishing reliable partnerships, buyers can enhance their production efficiency and customer satisfaction.

Scenario 2: Compatibility Issues with CNC Machines

The Problem: Many B2B buyers face compatibility issues when using SVG CNC files with their machines. Different CNC machines support various file formats, and SVG files may not always be compatible with the software or hardware in use. This can lead to frustration, delays, and extra costs as companies may need to convert files or even redesign them to fit their equipment. Such complications can hinder productivity and impact timelines, especially for businesses managing multiple projects at once.

The Solution: To mitigate compatibility issues, buyers should conduct thorough research on the specifications of their CNC machines before purchasing SVG files. Understanding the file formats supported by the machine will help buyers select the right files from the outset. Additionally, it is beneficial to work with suppliers who provide files in multiple formats (e.g., DXF, AI, CDR) to ensure compatibility across various machines. Establishing a workflow that includes file testing on a smaller scale before full-scale production can also help identify any potential issues early in the process. By taking these proactive steps, businesses can streamline their operations and reduce the risk of costly setbacks.

Scenario 3: Lack of Customization Options in Pre-made SVG CNC Files

The Problem: In an era where personalization is key, B2B buyers often encounter limitations with pre-made SVG CNC files that do not fully meet their project specifications. Many available files are generic and may not cater to unique branding or design requirements. This lack of customization can lead to subpar products that do not resonate with the target audience, ultimately affecting sales and brand perception.

The Solution: To address this pain point, buyers should seek out suppliers that offer customization services for their SVG CNC files. Look for vendors who allow modifications or provide a collaborative design process. This approach enables businesses to tailor designs to their specific needs, ensuring that the final products align with their branding and customer expectations. Furthermore, investing in design software that allows for editing SVG files can empower buyers to make necessary adjustments in-house. By embracing customization and leveraging technology, businesses can create distinct offerings that stand out in the market, fostering customer loyalty and driving sales.

Strategic Material Selection Guide for svg cnc files

What Are the Key Properties of Common Materials for SVG CNC Files?

When selecting materials for SVG CNC files, understanding the properties of common materials is essential for optimizing performance and ensuring compatibility with various applications. Below are analyses of four widely used materials in the context of SVG CNC files.

1. Wood

Key Properties:

Wood is a versatile material known for its natural beauty and ease of machining. It has good strength-to-weight ratios and can be easily shaped into intricate designs. However, its performance can be affected by moisture content, which may lead to warping or splitting.

Pros & Cons:

Wood is relatively inexpensive and widely available, making it a popular choice for crafts and decorative items. Its aesthetic appeal is unmatched, but it may not be as durable as other materials like metal or plastic. Additionally, wood can be sensitive to environmental changes, which may affect long-term performance.

Impact on Application:

Wood is suitable for applications like furniture design, signage, and decorative crafts. It is compatible with various finishing techniques, enhancing its visual appeal. However, for outdoor applications, treated wood or alternative materials may be necessary to ensure longevity.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding sustainable sourcing and certifications, such as FSC (Forest Stewardship Council). Compliance with international standards for wood products is also essential, especially in markets like Europe.

2. Acrylic

Key Properties:

Acrylic, also known as PMMA (polymethyl methacrylate), is a lightweight, shatter-resistant material that offers excellent clarity and UV resistance. It can withstand moderate temperatures but may not be suitable for high-stress applications.

Pros & Cons:

Acrylic is favored for its aesthetic qualities and ease of fabrication. It can be cut, engraved, and polished to achieve a high-gloss finish. However, it is more expensive than wood and can be prone to scratching and cracking under impact.

Impact on Application:

Acrylic is ideal for signage, displays, and decorative items due to its clarity and color options. It is compatible with various printing and engraving techniques, making it a versatile choice for creative projects.

Considerations for International Buyers:

Buyers should ensure compliance with safety standards for plastic materials, such as ASTM D638 for tensile strength. In regions like Europe, adherence to REACH regulations concerning chemical safety is crucial.

3. Metal (Aluminum)

Key Properties:

Aluminum is a lightweight metal known for its strength, corrosion resistance, and thermal conductivity. It can withstand higher temperatures and is suitable for various applications, including structural components.

Pros & Cons:

Aluminum’s durability makes it an excellent choice for long-lasting products. However, it is generally more expensive than wood and acrylic and may require specialized tools for cutting and engraving. The manufacturing complexity can also increase production time.

Impact on Application:

Aluminum is commonly used in industrial applications, signage, and custom parts. Its compatibility with various finishing processes, such as anodizing and powder coating, enhances its aesthetic and functional properties.

Considerations for International Buyers:

Understanding local standards for metal products, such as ASTM or DIN, is vital for ensuring compliance. Additionally, buyers should consider the availability of aluminum grades that meet specific performance requirements.

4. MDF (Medium-Density Fiberboard)

Key Properties:

MDF is an engineered wood product made from wood fibers and adhesives, providing a smooth surface for cutting and engraving. It has a uniform density and is less prone to warping compared to solid wood.

Pros & Cons:

MDF is cost-effective and easy to work with, making it suitable for intricate designs. However, it is not as strong as solid wood or metal and can be susceptible to moisture damage. Its surface may require sealing for certain applications.

Impact on Application:

MDF is ideal for furniture, cabinetry, and decorative items where a smooth finish is desired. It is compatible with various coatings and paints, enhancing its versatility.

Considerations for International Buyers:

Buyers should verify that the MDF meets local emissions standards, such as CARB in the U.S. or E1 in Europe, to ensure safety and compliance.

Summary Table of Material Selection for SVG CNC Files

| Material | Typical Use Case for svg cnc files | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, signage, decorative crafts | Aesthetic appeal and easy to work with | Sensitive to moisture and less durable | Low |

| Acrylic | Signage, displays, decorative items | Lightweight and shatter-resistant | Prone to scratching and higher cost | Medium |

| Metal (Aluminum) | Industrial applications, custom parts | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| MDF | Furniture, cabinetry, decorative items | Cost-effective and smooth finish | Susceptible to moisture damage | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for svg cnc files

What Are the Key Stages in the Manufacturing Process of SVG CNC Files?

The manufacturing process for SVG CNC files involves several critical stages that ensure the final product meets the required specifications and quality standards. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

Material Preparation: How Are SVG Files Created?

The first step in producing SVG CNC files is material preparation. This stage involves selecting the appropriate design software and tools for creating vector graphics. Designers typically use programs like Adobe Illustrator or CorelDRAW to create intricate designs that can be translated into SVG format. The output must be saved in a compatible format for CNC machines, often as DXF or AI files. Ensuring the correct scale and resolution is essential, as this will directly impact the quality of the final product.

Forming: What Techniques Are Used to Create SVG Designs?

Once the SVG file is prepared, the next stage is forming, where the design is translated into a physical medium. This process typically involves CNC (Computer Numerical Control) machines that read the SVG file and execute precise cuts or engravings on various materials such as wood, acrylic, or metal. Advanced techniques, including laser cutting and plasma cutting, are employed for different materials and desired finishes. The precision of these techniques is vital, as any deviations can lead to defects in the final product.

Assembly: How Are SVG Products Assembled?

In many cases, particularly with more complex designs, assembly may be required after the cutting process. This involves putting together multiple components that have been cut from the SVG files. Assembly can be straightforward, such as joining pieces to form a complete design, or more intricate, requiring adhesives or fasteners. Ensuring that all parts fit together perfectly is crucial for maintaining the integrity and aesthetic of the final product.

Finishing: What Are the Final Touches Applied to SVG Products?

The finishing stage involves applying any final touches to enhance the product’s appearance and durability. This can include sanding edges, applying paint or varnish, and ensuring that the surface is smooth and free of blemishes. Finishing not only improves the aesthetic appeal but also adds to the longevity of the product, particularly for items that will be used outdoors or in high-traffic areas.

How Is Quality Assurance Implemented in SVG CNC File Production?

Quality assurance (QA) is a vital aspect of the production process for SVG CNC files, ensuring that the final products meet international and industry-specific standards. For B2B buyers, understanding these QA measures can guide them in selecting reliable suppliers.

What International Standards Should B2B Buyers Consider?

B2B buyers should be aware of international quality standards such as ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with ISO standards ensures that suppliers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications, such as CE marking for products sold in Europe, can indicate compliance with safety and environmental standards.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are critical in maintaining product integrity throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): Ensures that raw materials meet predefined standards before production begins.

- In-Process Quality Control (IPQC): Monitors the manufacturing process to identify and rectify issues in real-time, minimizing waste and defects.

- Final Quality Control (FQC): Conducted on completed products to ensure they conform to specifications before shipping.

Implementing these checkpoints allows suppliers to identify potential problems early and ensure high-quality outcomes.

Which Testing Methods Are Commonly Used?

Common testing methods in the quality assurance of SVG CNC files include dimensional inspections, visual inspections, and functionality tests. Dimensional inspections verify that the cut parts match the specifications outlined in the SVG files, while visual inspections check for surface imperfections and finish quality. Functionality tests may be necessary for complex designs to ensure that assembled products work as intended.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks associated with product quality.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control measures. During an audit, buyers can review the supplier’s QMS, inspect production facilities, and evaluate compliance with international standards. Audits should be scheduled regularly and can be conducted by internal teams or third-party organizations specializing in quality assurance.

How Can Buyers Request Quality Reports?

Buyers should request detailed quality reports from suppliers that outline their QA processes, results from quality checks, and any corrective actions taken. This transparency helps build trust and assures buyers of the supplier’s commitment to quality.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct inspections at various stages of production, ensuring adherence to quality standards before products are shipped. This is particularly beneficial for buyers from regions with varying quality assurance practices, such as Africa and South America, as it provides an added layer of security.

What Are the Nuances of Quality Control for International Buyers?

Quality control processes can vary significantly across regions, and B2B buyers must be aware of these nuances when sourcing SVG CNC files.

How Do Regional Standards Affect Quality Assurance?

Different regions may have specific quality standards and regulations that suppliers must adhere to. For example, European suppliers often comply with CE marking requirements, while those in the Middle East may focus on GSO standards. Buyers should ensure that suppliers are knowledgeable about and compliant with the relevant standards for their target market.

What Should Buyers Know About Cultural Differences?

Cultural differences can impact communication and expectations regarding quality control. Buyers should be prepared to navigate these differences and establish clear guidelines and expectations with suppliers to ensure mutual understanding and satisfaction.

By understanding the manufacturing processes and quality assurance measures associated with SVG CNC files, B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘svg cnc files’

Introduction

This guide provides a systematic approach for B2B buyers seeking to procure high-quality SVG CNC files. SVG (Scalable Vector Graphics) files are essential for various applications, including laser cutting, engraving, and CNC machining. By following this checklist, you can ensure that your sourcing process is efficient and meets your technical requirements.

Step 1: Define Your Project Requirements

Before initiating the sourcing process, clarify your project specifications. This includes understanding the type of designs you need, such as intricate patterns or simple shapes, and the intended materials for processing (e.g., wood, acrylic, or metal). Precise project requirements will help you communicate effectively with suppliers and ensure that the files meet your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers of SVG CNC files. Utilize online platforms, industry forums, and social media to gather information about potential vendors. Look for suppliers that specialize in your required designs and have a strong reputation within your industry.

Step 3: Evaluate File Quality and Compatibility

Quality is paramount when sourcing SVG CNC files. Request sample files to test their compatibility with your CNC machinery and software. Ensure that the files are properly formatted and free from errors, as low-quality files can lead to production issues and wasted materials.

- Check for Standard Formats: Ensure that the files are available in standard formats like SVG, DXF, and AI, which are widely compatible with various cutting machines.

Step 4: Assess Supplier Experience and Expertise

Evaluate the experience and expertise of potential suppliers in the CNC file market. Look for suppliers who have worked with businesses similar to yours or who specialize in your specific industry sector. Their experience can provide insights into file customization and project-specific challenges.

- Request Case Studies: Ask for case studies or testimonials from past clients to gauge their reliability and service quality.

Step 5: Verify Licensing and Intellectual Property Rights

It’s crucial to ensure that the SVG files you purchase are properly licensed. Confirm that the supplier has the right to sell the designs and that you will have the necessary permissions for commercial use. This step helps avoid potential legal issues and protects your investment.

Step 6: Understand Pricing Structures

Discuss and understand the pricing models offered by suppliers. Some may charge per file, while others may offer subscription models or bulk purchase discounts. Ensure that the pricing aligns with your budget while considering the quality and uniqueness of the designs provided.

- Negotiate Terms: Don’t hesitate to negotiate terms or ask for volume discounts if you plan to order large quantities.

Step 7: Establish a Clear Communication Channel

Effective communication is vital throughout the sourcing process. Establish a clear line of communication with your supplier, specifying preferred methods and response times. This ensures that you can address any queries or issues promptly, facilitating a smoother procurement process.

By following these steps, B2B buyers can confidently navigate the sourcing of SVG CNC files, ensuring that their projects are supported by high-quality designs that meet their specific needs.

Comprehensive Cost and Pricing Analysis for svg cnc files Sourcing

What Are the Key Cost Components in Sourcing SVG CNC Files?

When sourcing SVG CNC files, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of digital materials is typically lower than physical materials, but the quality of the SVG files can vary significantly. High-resolution files that are optimized for various machines may command a higher price.

-

Labor: The skill level of the designers creating the SVG files impacts labor costs. More experienced designers may charge premium rates for complex or custom designs.

-

Manufacturing Overhead: Although this cost is less visible in digital products, it encompasses the expenses associated with the software and hardware used to create the SVG files, including maintenance and licensing fees.

-

Tooling: This refers to the software tools required to generate and edit SVG files. Depending on the complexity of the files and the software used, tooling costs can vary significantly.

-

Quality Control (QC): Ensuring that the SVG files meet specific quality standards can incur additional costs. This might include testing the files on different CNC machines to verify compatibility and performance.

-

Logistics: While digital files are easily distributed, logistics may also include the costs associated with the platforms used for hosting and selling these files.

-

Margin: Suppliers will factor in their profit margin, which can vary widely based on competition, demand, and target market.

How Do Price Influencers Affect the Cost of SVG CNC Files?

Several factors influence the pricing of SVG CNC files, and understanding these can help buyers make informed decisions.

-

Volume/MOQ: Bulk purchasing often leads to lower prices. Suppliers may offer discounts for larger orders, allowing buyers to reduce their per-unit cost significantly.

-

Specifications and Customization: Custom designs or specific file requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials: The choice of materials—such as the type of vector format—can affect pricing. For instance, files that require more complex vectorization may be priced higher.

-

Quality and Certifications: Higher-quality files that meet industry standards or certifications typically come at a premium. Buyers should assess their quality requirements against their budget.

-

Supplier Factors: The reputation and location of the supplier can influence pricing. Suppliers with a strong track record may charge higher prices due to perceived value.

-

Incoterms: Understanding the Incoterms related to digital file transactions can affect the final cost. Buyers should be aware of which costs are included in the quoted price and which are their responsibility.

What Are Essential Buyer Tips for Cost-Efficiency in SVG CNC Files Sourcing?

To maximize cost-efficiency, buyers should consider several strategies when sourcing SVG CNC files.

-

Negotiation: Always negotiate prices, especially for bulk orders. Suppliers may be willing to offer discounts or better payment terms.

-

Total Cost of Ownership (TCO): Evaluate the long-term implications of purchasing decisions. The initial cost of SVG files may be low, but if the files require extensive modifications or lead to production issues, the TCO can increase.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should consider factors like currency exchange rates, import duties, and local regulations, which can affect the overall cost.

-

Quality Assurance: Investing in high-quality SVG files can save costs in the long run by reducing errors and production delays. Consider asking for samples or trial files before making a large purchase.

-

Research and Compare: Use online platforms and marketplaces to compare prices and quality across different suppliers. This will help in making an informed decision and ensuring competitive pricing.

Disclaimer on Indicative Prices

Prices for SVG CNC files can vary widely based on the factors discussed above. The information provided serves as a guideline and may not reflect the actual prices encountered in the market. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing svg cnc files With Other Solutions

Understanding Alternatives to SVG CNC Files

In the realm of CNC machining, SVG files are a popular choice for their versatility and compatibility with various design and cutting tools. However, businesses must evaluate other viable options to determine the best fit for their specific needs. This analysis will compare SVG CNC files against two notable alternatives: DXF files and proprietary software solutions.

Comparison Table

| Comparison Aspect | SVG CNC Files | DXF Files | Proprietary Software Solutions |

|---|---|---|---|

| Performance | High compatibility with laser cutters and CNC machines. | Widely supported, especially in CAD applications. | Can offer advanced features tailored for specific industries. |

| Cost | Generally affordable, often available for free or low cost. | Usually free or low-cost, but may require additional software for editing. | Typically more expensive due to licensing and support fees. |

| Ease of Implementation | Simple to use; minimal setup required. | Requires CAD software for editing and conversion. | May have a steeper learning curve due to complex features. |

| Maintenance | Low maintenance; files can be easily updated or modified. | Requires occasional software updates; file compatibility issues may arise. | Regular updates and support needed; ongoing costs for maintenance. |

| Best Use Case | Ideal for quick projects, crafts, and personal use. | Best for professional CAD applications and detailed engineering designs. | Suitable for large enterprises needing custom solutions and support. |

Detailed Breakdown of Alternatives

What are DXF Files and How Do They Compare?

DXF (Drawing Exchange Format) files are a common alternative to SVG files, particularly favored in the architecture and engineering sectors. They are highly compatible with CAD software, making them ideal for detailed designs that require precision. However, while DXF files offer extensive capabilities, they often necessitate additional software for editing, which can complicate the workflow. For businesses that rely heavily on CAD applications, DXF may be the preferred choice, but this comes at the cost of increased complexity and potential compatibility issues.

Why Consider Proprietary Software Solutions?

Proprietary software solutions provide advanced features tailored to specific industries, such as custom tool paths, material optimization, and integration with other business systems. This can lead to increased efficiency and productivity. However, these solutions are often significantly more expensive due to licensing and support fees, which can be a barrier for small to mid-sized businesses. Moreover, the learning curve can be steep, requiring additional training for staff. While proprietary software may be beneficial for larger enterprises, it may not be cost-effective for smaller operations.

How Should B2B Buyers Choose the Right Solution?

When selecting between SVG CNC files, DXF files, and proprietary software, B2B buyers should consider their specific project needs, budget constraints, and the technical capabilities of their team. For quick and straightforward projects, SVG files offer a cost-effective and user-friendly option. If precision and detailed design are paramount, DXF files may be more suitable. Conversely, businesses with complex requirements and the budget for investment might find proprietary software to be the best long-term solution. Ultimately, the right choice will depend on a careful assessment of operational needs and resources.

Essential Technical Properties and Trade Terminology for svg cnc files

What Are the Key Technical Properties of SVG CNC Files?

Understanding the technical specifications of SVG CNC files is crucial for B2B buyers to ensure compatibility with various CNC machinery and to achieve the desired output quality. Here are some essential properties to consider:

-

File Format Compatibility

SVG (Scalable Vector Graphics) is a widely used format in CNC machining due to its scalability and precision. It can be easily modified without losing quality, making it suitable for intricate designs. Understanding compatibility with other formats such as DXF (Drawing Exchange Format) or AI (Adobe Illustrator) can help ensure the right choice for specific machinery. -

Resolution

The resolution of an SVG file affects the quality of the cut or engraving. High-resolution files contain more detail, which is essential for intricate designs or logos. Buyers should confirm that their SVG files are optimized for the intended application to avoid issues such as jagged edges or incomplete cuts. -

Layer Structure

SVG files can contain multiple layers, allowing for complex designs to be created and processed more efficiently. Each layer can be assigned different cutting speeds or tool types, which is particularly valuable in production settings. Understanding how to utilize layers can streamline the CNC operation and enhance the final product’s quality. -

Path Precision

The paths defined in SVG files dictate how the CNC machine moves during the cutting process. Precise paths are critical for achieving the desired shapes and details. Buyers should look for files that are optimized for path efficiency, minimizing unnecessary movements that can slow down production and increase wear on machinery. -

Scalability

One of the key advantages of SVG files is their ability to scale without loss of quality. This property allows businesses to adapt designs for various sizes and applications, from small decorative items to large signage. It is particularly beneficial for companies looking to diversify their product offerings without incurring additional design costs. -

Material Compatibility

Different materials require specific settings for cutting or engraving, and the SVG file should provide guidance on the optimal parameters for various materials such as wood, acrylic, or metal. Buyers should ensure that the SVG files they procure include notes on material compatibility to avoid costly mistakes in production.

What Are Common Trade Terms Related to SVG CNC Files?

Familiarity with industry terminology is essential for effective communication and decision-making in B2B transactions. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for high-quality SVG files tailored for specific CNC machines. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory and budget effectively, especially when ordering SVG files for large-scale production. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. For SVG files, an RFQ can include specifications on file types, quantities, and delivery timelines, facilitating competitive pricing and informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international trade. Understanding these terms can help buyers navigate shipping and delivery logistics for SVG files sourced from different countries. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For SVG files, this includes design preparation, production, and shipping. Knowing the lead time helps buyers plan their projects and manage expectations with clients. -

Customization

Customization refers to the ability to modify SVG files to meet specific requirements, such as size, design alterations, or material considerations. Buyers should look for suppliers that offer customization options to ensure the final product aligns with their branding or project needs.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing SVG CNC files, ultimately leading to more successful projects and satisfied customers.

Navigating Market Dynamics and Sourcing Trends in the svg cnc files Sector

What Are the Current Market Trends Influencing the SVG CNC Files Sector?

The SVG CNC files sector is experiencing significant growth driven by technological advancements, increasing demand for customization, and the rise of small-to-medium enterprises (SMEs) in manufacturing and crafting. Global drivers such as the digital transformation of industries and the proliferation of CNC machinery have made it easier for businesses in Africa, South America, the Middle East, and Europe to incorporate SVG files into their production processes. The rise of e-commerce has also facilitated access to a wider variety of SVG designs, allowing companies to source materials that cater to niche markets.

Emerging trends include the integration of artificial intelligence (AI) and machine learning in design software, which is enhancing the efficiency and accuracy of file creation. Furthermore, the growing popularity of DIY culture and personalized products has led to an increase in demand for unique SVG designs, particularly in the crafting community. This trend is particularly pronounced in regions like Europe and North America, where consumers are seeking distinctive, locally sourced products.

International B2B buyers should be aware of the need for reliable suppliers who can provide high-quality SVG files that are compatible with various CNC machines. As competition intensifies, businesses that can offer superior customer support and flexible sourcing options will have a competitive edge. The emphasis on speed-to-market, along with the ability to adapt to changing consumer preferences, will be crucial for success in this dynamic sector.

How Is Sustainability Shaping the Sourcing of SVG CNC Files?

Sustainability has become a focal point for international B2B buyers, particularly as environmental awareness rises among consumers. The SVG CNC files sector is not exempt from this trend, as businesses are increasingly scrutinizing the environmental impact of their sourcing practices. Buyers are encouraged to prioritize suppliers that adopt sustainable practices, such as using eco-friendly materials and minimizing waste in the design process.

The importance of ethical supply chains cannot be overstated. Companies that demonstrate a commitment to sustainability are more likely to build trust and loyalty among their customer base. This includes sourcing SVG files from designers and manufacturers that adhere to ethical labor practices and environmental standards. Certifications for ‘green’ materials, such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management, are becoming essential for suppliers in this space.

Moreover, the shift towards digital files like SVG allows for reduced material waste during production, as designs can be optimized for efficiency. This not only benefits the environment but also enhances the overall cost-effectiveness of projects. Buyers should actively seek out suppliers who can provide evidence of their sustainability efforts, ensuring that their sourcing aligns with both business goals and environmental responsibilities.

What Is the Evolution of SVG CNC Files in the B2B Landscape?

The evolution of SVG CNC files can be traced back to the broader digitalization of manufacturing processes. Initially, CNC machines operated primarily with proprietary file formats, limiting accessibility and interoperability. However, as technology progressed, the SVG format emerged as a versatile and widely accepted option due to its scalability and compatibility with various design software.

In the early days, SVG files were primarily used for simple vector designs; however, advancements in software capabilities have allowed for more intricate designs and applications. Today, SVG files are integral in various sectors, from woodworking to metal fabrication, and are increasingly utilized in the crafting community. This evolution has enabled businesses, particularly SMEs, to innovate and offer customized solutions tailored to specific market needs.

As the industry continues to grow, the integration of SVG files into automated production systems is anticipated to further streamline processes, reduce lead times, and enhance product quality. B2B buyers should remain informed about these developments to capitalize on the opportunities presented by the evolving SVG CNC files landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of svg cnc files

-

How can I ensure the SVG CNC files I purchase are of high quality?

To ensure high-quality SVG CNC files, verify the supplier’s reputation through reviews and testimonials from other buyers. Look for files that are compatible with your specific CNC machine and software, and check if the supplier provides a sample file or a portfolio of their work. Additionally, inquire about the design resolution and whether the files have been tested for cutting accuracy. Engaging with suppliers who offer guarantees or revisions can also help mitigate risks. -

What is the best platform for purchasing SVG CNC files for my business?

The best platform for purchasing SVG CNC files depends on your specific needs, such as file variety, pricing, and customer service. Established marketplaces like Etsy, specialized websites like CNC Craft SVG, and dedicated vector art sites are excellent options. Ensure the platform offers secure payment options, user-friendly navigation, and a robust filtering system to help you find the specific designs you need quickly. Additionally, consider platforms that offer bulk purchase discounts for B2B transactions. -

Can I customize SVG CNC files for my specific projects?

Yes, many suppliers offer customization options for SVG CNC files to meet your unique project requirements. When contacting suppliers, specify your desired modifications, such as size adjustments, design alterations, or branding elements. Discuss the additional costs and turnaround times associated with custom requests. It’s beneficial to work with suppliers who have a flexible approach to customization, as this can enhance your project’s uniqueness and relevance. -

What are the minimum order quantities (MOQs) for purchasing SVG CNC files?

Minimum order quantities can vary significantly among suppliers. Some may offer single file purchases, while others might have MOQs, especially for bulk orders. When sourcing files, inquire about the supplier’s policy on MOQs and whether they offer discounts for larger orders. Understanding these terms upfront can help you plan your purchases effectively and ensure that you meet your project needs without excess expenditure. -

What payment terms should I expect when buying SVG CNC files internationally?

Payment terms for international purchases of SVG CNC files can differ widely based on the supplier’s policies and your location. Common options include credit card payments, PayPal, and wire transfers. Many suppliers may require upfront payment, especially for custom designs. Always clarify the payment process, currency exchange implications, and any additional fees for international transactions to avoid surprises. Additionally, consider using secure payment platforms to protect your financial information. -

How can I vet suppliers of SVG CNC files for reliability?

Vetting suppliers involves researching their history, customer reviews, and portfolio of work. Look for suppliers with a proven track record in the industry and positive feedback from previous clients. Engage in direct communication to assess their responsiveness and willingness to address your concerns. Additionally, check if they provide clear terms of service, return policies, and customer support to ensure a smooth purchasing experience. -

What quality assurance measures should I look for in SVG CNC files?

When sourcing SVG CNC files, quality assurance measures should include clear design specifications, compatibility with various CNC machines, and testing by the supplier. Ask if the files have been tested for cutting accuracy and if there are any guarantees regarding their performance. Additionally, some suppliers may offer a satisfaction guarantee or revision policy, which can provide peace of mind in case the files do not meet your expectations. -

What logistics considerations should I keep in mind when purchasing SVG CNC files?

Logistics for digital products like SVG CNC files typically involve considerations such as file delivery method and download availability. Ensure that the supplier offers immediate access to files upon purchase, preferably in multiple formats compatible with your CNC software. Check their policy on file storage duration and whether you can re-download files if needed. Additionally, consider the supplier’s responsiveness to any technical issues you may encounter post-purchase, which can impact your project’s workflow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Svg Cnc Files Manufacturers & Suppliers List

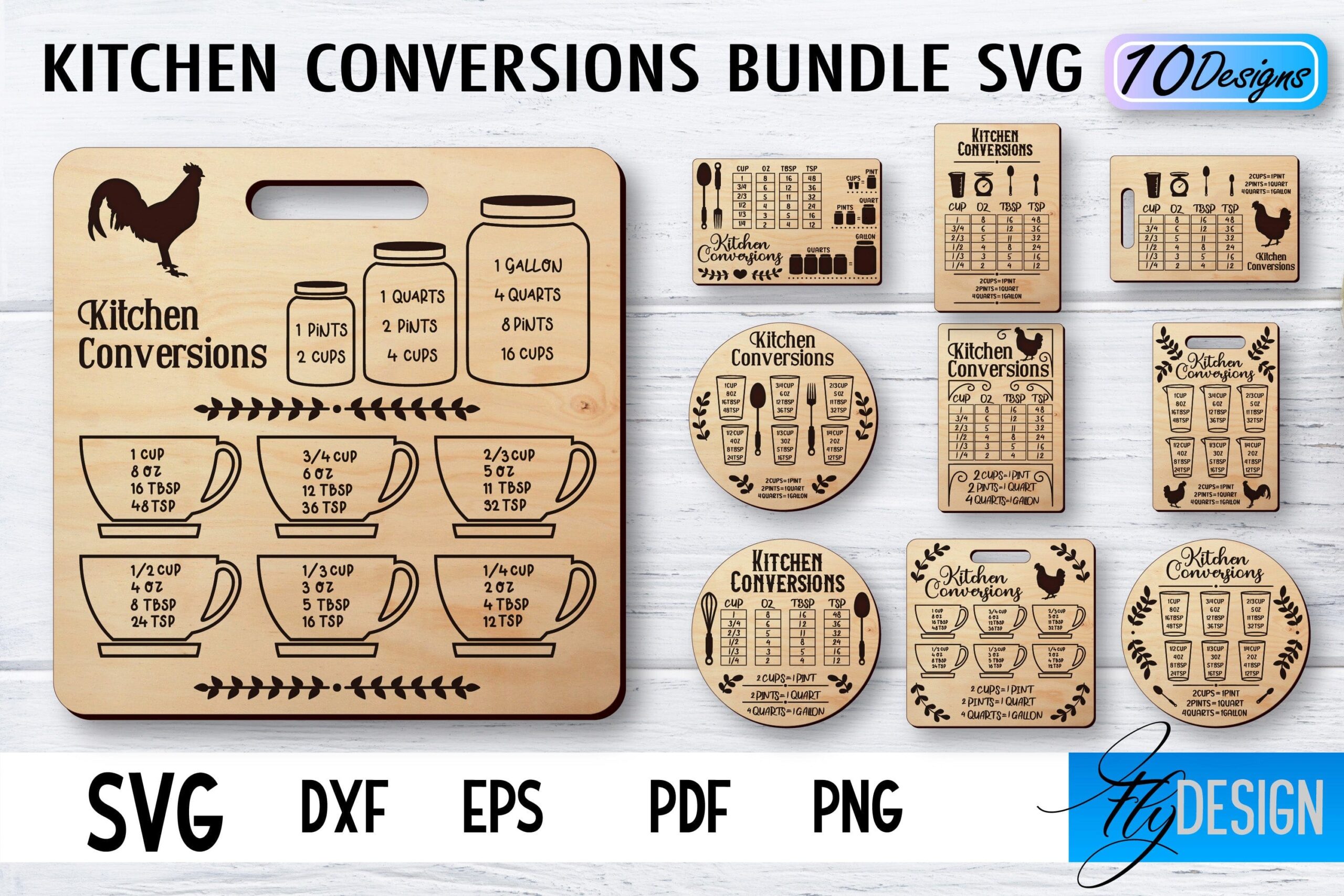

1. Etsy – CNC SVG Files

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – CNC SVG Files, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. CNC Craft SVG – Quality Cutting Files

Domain: cnccraftsvg.com

Registered: 2023 (2 years)

Introduction: Quality Lines and Cutting SVG Files for CNC. Includes various categories such as Fire Department Badge, Law Enforcement Badges, Military Badge & Insignia, Police Badge, Sheriff Badge, and State, County, City Seal/Logo. Products available in formats: SVG, DXF, PNG, and AI. Examples of products include: San Andreas State Patrol Badge SVG ($8.00), Memphis City Seal SVG ($5.00), Georgia State Patrol H…

3. Designs by Donnie – SVG File Collection

Domain: designsbydonnie.com

Registered: 2018 (7 years)

Introduction: [{‘name’: ‘Wine Rack’, ‘type’: ‘SVG FILE’, ‘price’: 48.0}, {‘name’: ‘Phone Holder’, ‘type’: ‘SVG FILE’, ‘price’: 48.0}, {‘name’: ‘Scroll Base’, ‘type’: ‘SVG FILE’, ‘price’: 48.0}, {‘name’: ‘Transformer’, ‘type’: ‘SVG FILE’, ‘price’: 40.0}, {‘name’: ‘Toilet Cloud Holder’, ‘type’: ‘SVG FILE’, ‘price’: 48.0}, {‘name’: ‘Spider Platter’, ‘type’: ‘SVG FILE’, ‘price’: 48.0}, {‘name’: ‘Taco Holder’, ‘type…

4. 3axis.co – CNC SVG & DXF Files

Domain: 3axis.co

Registered: 2017 (8 years)

Introduction: CNC SVG Free DXF Files & Vectors available at 3axis.co include 1138 CNC SVG, DXF, and vector files in formats such as CDR, EPS, PDF, BMP, DWG, and STL. The offerings include laser cut tools, boxes (e.g., gift boxes, jewelry boxes, tool boxes), 3D puzzles (e.g., animals, vehicles), wood cutouts (e.g., Christmas ornaments, decor), clocks, photo frames, and various decorations for events and occasion…

5. Pinterest – Free SVG & DXF Files for CNC and Crafts

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Free SVG files for CNC router, DIY projects, and crafts. Includes over 200 free SVG cut files for commercial use, perfect for various occasions like Valentine’s, weddings, and holidays. Offers free printable laser engraving templates and a collection of free DXF files tailored for CNC plasma tables. Features unique designs for fishing enthusiasts and home decor. Provides resources for making SVG f…

6. Freepik – CNC SVG Files & Design Tools

Domain: freepik.com

Registered: 2010 (15 years)

Introduction: Cnc Svg Files Images – Free Download on Freepik. Includes various tools and features such as AI Suite, AI Assistant, Image Generator, Video Generator, Image Upscaler, Background Remover, and more. Offers stock vectors, photos, illustrations, icons, templates, mockups, 3D videos, and audio. Provides options for premium content and various filters for sorting images by relevance, license, orientatio…

7. Carbide 3D – Free SVG/DXF Resources for CNC Projects

Domain: community.carbide3d.com

Registered: 2013 (12 years)

Introduction: The discussion revolves around sourcing “free” SVG/DXF files for CNC projects, specifically for users of Carbide Create and Shapeoko 3. Key points include: 1. Users seek reliable websites for quality SVG/DXF files to simplify the toolpath creation process. 2. Suggested resources include Carbide Create’s clipart library, CutRocket, CNCCookbook, Open Source Design, FreePatternsArea, The Noun Project…

Strategic Sourcing Conclusion and Outlook for svg cnc files

In summary, the strategic sourcing of SVG CNC files offers international B2B buyers significant advantages, including cost efficiency, high-quality designs, and access to a diverse range of applications. As the demand for customized solutions grows across industries, leveraging well-curated SVG files can streamline production processes and enhance product offerings. By prioritizing reliable suppliers, businesses can ensure they have access to the latest designs that meet their specific needs, from intricate vector art to functional templates.

Furthermore, as markets in Africa, South America, the Middle East, and Europe continue to evolve, the opportunities for innovation and collaboration are vast. Buyers are encouraged to explore partnerships that not only provide high-quality SVG files but also foster creativity and adaptability in their projects.

Looking ahead, embracing strategic sourcing will be crucial in maintaining a competitive edge. As the landscape of manufacturing and digital design continues to shift, proactive engagement with suppliers will empower businesses to stay ahead of trends and demands. Now is the time to invest in quality SVG CNC files that can elevate your production capabilities and inspire new avenues of growth.