Introduction: Navigating the Global Market for sublimation printing on metal

Sourcing quality sublimation printing on metal can be a complex challenge for B2B buyers navigating a rapidly evolving global market. As businesses increasingly seek innovative ways to enhance their branding and product offerings, understanding the nuances of sublimation printing becomes essential. This guide provides a comprehensive overview of the sublimation printing process on metal, detailing various types of metals suitable for printing, their specific applications, and the advantages they offer.

We will delve into the intricacies of selecting the right supplier, including criteria for vetting potential partners and assessing their capabilities. Additionally, we will explore cost considerations and ROI factors that can significantly impact your purchasing decisions. Whether you are in Africa, South America, the Middle East, or Europe, this guide is designed to empower you with the knowledge needed to make informed decisions that align with your business objectives.

From understanding the technical specifications of sublimation printing to uncovering market trends and best practices, this resource serves as a valuable tool for international buyers. By leveraging the insights shared in this guide, you can confidently navigate the complexities of sublimation printing on metal, ensuring that your investment yields high-quality, durable products that resonate with your target audience.

Understanding sublimation printing on metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Sublimation Printing | Lightweight, corrosion-resistant, versatile | Signage, promotional products, awards | Pros: Cost-effective, durable. Cons: Requires a polyester coating for best results. |

| Stainless Steel Sublimation Printing | High strength, excellent heat retention, durable | High-end signage, kitchenware | Pros: Long-lasting, easy to clean. Cons: Poor adhesion without pre-treatment. |

| ChromaLuxe Metal Prints | High-definition, vibrant colors, archival quality | Art displays, photography, décor | Pros: Superior durability, scratch-resistant. Cons: Higher initial investment. |

| Galvanized Metal Sublimation | Rust-resistant, suitable for outdoor use | Outdoor signage, industrial applications | Pros: Durable, versatile. Cons: Limited color vibrancy compared to aluminum. |

| Specialty Coated Metals | Custom coatings for enhanced adhesion and color | Customized products, niche markets | Pros: Tailored solutions, high aesthetic value. Cons: Potentially longer lead times. |

What Are the Characteristics of Aluminum Sublimation Printing?

Aluminum sublimation printing is characterized by its lightweight nature and corrosion resistance, making it an ideal choice for various applications. This type is particularly suitable for signage, promotional items, and awards due to its versatility and ability to retain vibrant colors. B2B buyers should consider the initial need for a polyester coating to achieve optimal adhesion, which can add to setup costs but ultimately results in a durable product.

How Does Stainless Steel Sublimation Printing Stand Out?

Stainless steel sublimation printing is known for its high strength and durability, making it a popular choice in high-end applications such as kitchenware and premium signage. Its excellent heat retention allows for effective printing, though B2B buyers must be aware of the need for pre-treatment to ensure proper ink adhesion. While it offers easy maintenance and a long lifespan, the initial investment can be higher due to pre-treatment costs.

What Makes ChromaLuxe Metal Prints Unique?

ChromaLuxe metal prints provide high-definition results with unmatched color brilliance and archival qualities. These prints are particularly suited for artistic displays and photography, where visual impact is paramount. For B2B buyers, the significant benefits include superior durability and scratch resistance, though the initial investment can be higher compared to standard options. However, the long-term value and visual appeal often justify this cost.

Why Choose Galvanized Metal for Sublimation Printing?

Galvanized metal sublimation is known for its rust-resistant properties, making it an excellent choice for outdoor signage and industrial applications. While it provides durability and versatility, buyers should note that it may not achieve the same level of color vibrancy as aluminum. This type is suitable for B2B buyers looking for cost-effective solutions for outdoor environments, balancing performance with affordability.

What Are the Benefits of Specialty Coated Metals?

Specialty coated metals are designed for enhanced adhesion and color reproduction, making them ideal for customized products and niche markets. This type allows for tailored solutions that can meet specific aesthetic or functional requirements. B2B buyers should consider the potential for longer lead times due to customization, but the resulting high-quality prints can significantly enhance brand visibility and customer engagement.

Key Industrial Applications of sublimation printing on metal

| Industry/Sector | Specific Application of sublimation printing on metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Signage and Branding | Custom metal signs and promotional displays | Enhances brand visibility with vibrant, durable prints | Sourcing high-quality aluminum or stainless steel; UV-resistant coatings for outdoor use |

| Home Décor | High-definition metal prints for artwork | Offers unique, long-lasting decorative options | Requires specialized sublimation equipment and inks; attention to color fidelity and finish |

| Manufacturing | Customized metal parts and components | Provides branding and design flexibility for products | Need for precision in sublimation process; compatibility with various metal substrates |

| Promotional Products | Personalized gifts and corporate merchandise | Creates memorable, customized products for clients | Consideration of order quantities; ability to handle small batch production efficiently |

| Automotive Industry | Custom metal badges and interior components | Enhances aesthetics and brand recognition in vehicles | Requires durable finishes; must withstand high temperatures and environmental factors |

How Is Sublimation Printing on Metal Used in Signage and Branding?

Sublimation printing is extensively utilized in the signage and branding sector to create custom metal signs and promotional displays. The process allows for high-quality, vibrant graphics that are resistant to fading and scratching, ensuring long-lasting visibility. For international buyers, especially those in Africa and South America, sourcing high-quality aluminum or stainless steel is crucial, as these materials enhance the durability of outdoor signage. Additionally, UV-resistant coatings are important for applications exposed to sunlight, ensuring the colors remain vivid over time.

What Role Does Sublimation Printing Play in Home Décor?

In the home décor industry, sublimation printing on metal is employed to produce high-definition prints of artwork and photographs. This technique allows for vibrant colors and intricate designs that can transform spaces. Buyers should prioritize specialized sublimation equipment and inks to achieve the best results. Furthermore, ensuring color fidelity and finish quality is essential for meeting customer expectations, particularly in competitive markets in Europe and the Middle East, where design aesthetics are paramount.

How Is Sublimation Printing Beneficial in Manufacturing?

Manufacturing industries leverage sublimation printing to customize metal parts and components, providing branding and design flexibility. This technique allows manufacturers to incorporate logos and designs directly onto parts, enhancing product appeal. Precision in the sublimation process is critical, and international buyers must consider the compatibility of sublimation with various metal substrates. Additionally, understanding the operational requirements for successful sublimation, such as temperature regulation and timing, is vital for achieving high-quality outputs.

In What Ways Are Promotional Products Enhanced by Sublimation Printing?

Sublimation printing is increasingly used for creating personalized gifts and corporate merchandise, offering businesses a unique way to stand out. This method allows for full-color images and designs that can be tailored to specific client needs, enhancing the memorability of promotional items. Buyers should consider order quantities, as sublimation printing is efficient for small batch production, making it ideal for companies looking to offer customized products without large upfront investments.

How Does Sublimation Printing Impact the Automotive Industry?

In the automotive sector, sublimation printing is utilized for creating custom metal badges and enhancing interior components. This process not only improves the aesthetic appeal of vehicles but also aids in brand recognition. Buyers in this sector must source materials that provide durable finishes capable of withstanding high temperatures and environmental factors. Additionally, understanding the specific sublimation requirements for automotive applications is crucial for maintaining quality and longevity in products.

3 Common User Pain Points for ‘sublimation printing on metal’ & Their Solutions

Scenario 1: High Initial Investment Costs in Sublimation Equipment

The Problem: Many B2B buyers, especially small to medium-sized enterprises (SMEs), are hesitant to invest in sublimation printing technology due to the high initial costs associated with sublimation printers and related equipment. These expenses can range from thousands to tens of thousands of dollars, making it difficult for businesses operating on tight budgets to justify the purchase. This concern is compounded by the fear of inadequate returns on investment if the market demand for sublimated metal products fluctuates or if they are unable to secure enough orders to cover the costs.

The Solution: To mitigate the financial burden, B2B buyers should consider a phased investment strategy. Start by researching and purchasing a mid-range sublimation printer that offers flexibility in production volume. Additionally, consider leasing equipment or exploring financing options that allow for manageable monthly payments. This approach enables businesses to test the market demand for sublimated metal products without committing to a significant upfront cost. Establish partnerships with suppliers who offer equipment rental programs or flexible payment terms to further ease the financial impact. Lastly, focus on niche markets or specialized products that can command higher prices, ensuring a quicker return on investment.

Scenario 2: Challenges with Material Selection for Sublimation Printing

The Problem: Selecting the appropriate metal substrate for sublimation printing can be a daunting task for B2B buyers. Not all metals are suitable for sublimation; thus, businesses often struggle with choosing the right material that offers both high-quality print results and durability. For instance, while aluminum is widely recognized for its sublimation compatibility, variations in coating quality can affect print adherence and longevity. This lack of clarity can lead to costly mistakes in sourcing materials that do not perform well in the sublimation process.

The Solution: To address this challenge, buyers should prioritize collaboration with suppliers who specialize in sublimation-friendly metal substrates. Request samples of different types of aluminum and stainless steel to conduct test prints, assessing factors such as color vibrancy, adhesion, and durability. It’s also beneficial to seek out suppliers that provide detailed specifications and technical data sheets on their products, allowing for informed decision-making. Additionally, establishing a relationship with a trusted distributor can provide access to expert advice on the best materials for specific applications, ultimately enhancing the quality of the final product.

Scenario 3: Difficulty in Achieving Consistent Print Quality

The Problem: One of the most significant pain points for businesses engaged in sublimation printing on metal is achieving consistent print quality across different production runs. Inconsistent color reproduction, variations in print clarity, and issues with image transfer can lead to customer dissatisfaction and increased returns. This inconsistency can stem from multiple factors, including improper temperature settings, inadequate pressure during the transfer process, or variations in the sublimation ink and paper used.

The Solution: To improve print consistency, businesses should implement a standardized production process that includes precise monitoring of temperature, pressure, and timing during sublimation. Investing in high-quality, compatible sublimation inks and papers is crucial, as these products directly impact print quality. Regular calibration of the heat press machine and conducting routine maintenance checks will also contribute to more reliable outputs. Additionally, establishing a quality control protocol that involves inspecting prints before and after production can help identify any issues early on. Providing ongoing training for staff on best practices in sublimation printing will further ensure that all team members are aligned in their approach, leading to enhanced consistency in the final products.

Strategic Material Selection Guide for sublimation printing on metal

When selecting materials for sublimation printing on metal, it is essential to consider various factors that influence product performance, durability, and suitability for specific applications. Below, we analyze four common materials used in sublimation printing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Aluminum for Sublimation Printing?

Aluminum is one of the most popular choices for sublimation printing due to its lightweight nature and corrosion resistance. It has excellent thermal conductivity, allowing for even heat distribution during the sublimation process. This property is crucial for achieving high-quality prints, as it ensures that the dye fully infuses into the surface.

Pros: Aluminum is cost-effective and widely available, making it an ideal option for small to medium production runs. Its ability to maintain bright colors and resist fading over time enhances its appeal for both decorative and functional applications.

Cons: While aluminum is durable, it can be prone to scratching if not handled carefully. Additionally, the initial investment in high-quality aluminum sheets can be higher compared to other materials.

Impact on Application: Aluminum is suitable for a variety of products, including signage, promotional items, and decorative panels. Its versatility makes it a preferred choice among manufacturers.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for aluminum quality and thickness, such as ASTM or ISO certifications, to guarantee product reliability.

How Does Stainless Steel Perform in Sublimation Printing?

Stainless steel is another viable option for sublimation printing, known for its strength and durability. It offers excellent corrosion resistance, making it suitable for outdoor applications. However, stainless steel requires a polyester coating to ensure proper adhesion of sublimation inks.

Pros: The durability of stainless steel makes it ideal for products that require longevity, such as kitchenware and industrial signage. It also provides a sleek, modern aesthetic that appeals to many consumers.

Cons: The need for pre-coating can increase manufacturing complexity and costs. Additionally, stainless steel retains heat longer, which may require careful handling during the sublimation process.

Impact on Application: Stainless steel is commonly used for high-end products, including awards, trophies, and custom signage. Its aesthetic appeal enhances brand image and product value.

Considerations for International Buyers: Buyers should be aware of regional standards regarding stainless steel grades and coatings, especially in the Middle East and Europe, where specific regulations may apply.

What Are the Benefits of Using Galvanized Metal for Sublimation Printing?

Galvanized metal, coated with zinc to prevent corrosion, is a less common but effective material for sublimation printing. Its durability and resistance to rust make it suitable for outdoor applications.

Pros: Galvanized metal is often more affordable than aluminum and stainless steel, making it a cost-effective option for larger production runs. It is also relatively lightweight and easy to handle.

Cons: The surface may require additional preparation to ensure proper adhesion of sublimation inks. If not treated correctly, the quality of the print may be compromised.

Impact on Application: This material is ideal for outdoor signage and promotional displays, where durability and cost-effectiveness are paramount.

Considerations for International Buyers: Compliance with local regulations regarding galvanized metal coatings is crucial, particularly in regions with strict environmental standards.

Why Consider Specialty Coated Metals for Sublimation Printing?

Specialty coated metals, such as those with a polymer coating specifically designed for sublimation, provide an excellent surface for high-quality prints. These coatings enhance adhesion and improve the overall durability of the print.

Pros: Specialty coated metals offer superior print quality and durability, making them ideal for high-end applications. They also allow for a broader range of finishes, from matte to glossy.

Cons: The cost of specialty coated metals is generally higher than standard metals, which may not be suitable for all budgets. Additionally, sourcing these materials may be more challenging in certain regions.

Impact on Application: These materials are perfect for premium products, including artwork displays and high-value promotional items.

Considerations for International Buyers: Buyers should verify the availability of specialty coated metals in their region and ensure compliance with relevant quality standards.

Summary Table of Material Selection for Sublimation Printing on Metal

| Material | Typical Use Case for sublimation printing on metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Signage, promotional items, decorative panels | Lightweight, cost-effective | Prone to scratching | Medium |

| Stainless Steel | Kitchenware, awards, custom signage | High durability, modern aesthetic | Requires pre-coating | High |

| Galvanized Metal | Outdoor signage, promotional displays | Affordable, lightweight | Surface preparation needed | Low |

| Specialty Coated Metals | Premium artwork displays, high-value promotional items | Superior print quality and durability | Higher cost, sourcing challenges | High |

This analysis provides valuable insights for B2B buyers in diverse international markets, helping them make informed decisions regarding material selection for sublimation printing on metal.

In-depth Look: Manufacturing Processes and Quality Assurance for sublimation printing on metal

What Are the Key Stages in the Manufacturing Process of Sublimation Printing on Metal?

Sublimation printing on metal involves a series of well-defined manufacturing stages that ensure quality and durability of the final product. The main stages include material preparation, forming, assembly, and finishing. Each stage plays a critical role in the overall quality assurance of the sublimated metal products.

How Is Material Prepared for Sublimation Printing?

Material preparation is the first step in the sublimation printing process. This involves selecting the right type of metal, typically aluminum or stainless steel, which are favored for their lightweight and corrosion-resistant properties. The metal sheets are often pre-treated with a polyester coating, which is essential for achieving proper adhesion of the sublimation inks.

During this stage, quality checks are performed to ensure that the surface of the metal is free from contaminants and defects. Any imperfections can affect the final print quality, leading to issues such as poor color reproduction or adhesion failures.

What Techniques Are Used in Forming and Assembly?

Once the materials are prepared, they undergo forming and assembly. This stage includes cutting the metal sheets to the desired dimensions and shapes, followed by any necessary bending or shaping processes. Advanced machinery, such as CNC machines, may be used to ensure precision in the cutting and shaping process.

In assembly, components may be combined, especially in products that require multiple parts. For instance, if a product includes a frame or mounting system, these elements are integrated at this stage. Quality assurance during assembly is critical, as any misalignment can lead to aesthetic and functional issues in the final product.

How Is Finishing Conducted in Sublimation Printing?

Finishing is the final stage in the manufacturing process. This involves applying the sublimation transfer paper onto the metal surface and then using a heat press to fuse the design into the metal. The heat and pressure must be carefully controlled to ensure a successful transfer; typical parameters include a temperature range of 350-400°F and a pressure level that can vary from low to medium.

After sublimation, the finished products are inspected for color accuracy, alignment, and overall quality. Any products that do not meet the established standards are set aside for rework or disposal.

What Are the Key Quality Control (QC) Measures in Sublimation Printing?

Quality control is integral to the sublimation printing process, ensuring that products meet both international and industry-specific standards. The implementation of effective QC measures helps minimize defects and enhances customer satisfaction.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are crucial for ensuring consistent quality management systems. Adhering to these standards means that the manufacturing processes are regularly reviewed and improved. Additionally, certifications like CE mark (Conformité Européenne) are important for products sold in Europe, indicating compliance with safety and health regulations.

For products in specific industries, suppliers may also need to comply with standards such as API (American Petroleum Institute) for oil and gas sectors, which focuses on safety and reliability.

What Are the Common QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are established at various stages of the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks are performed during the manufacturing process to monitor compliance with quality standards. This may include visual inspections, dimensional checks, and functional tests.

- Final Quality Control (FQC): Once products are completed, they undergo a comprehensive inspection that verifies the final appearance, functionality, and adherence to specifications.

What Testing Methods Are Commonly Used for Quality Assurance?

Common testing methods in sublimation printing include:

- Color Fastness Tests: These tests assess the durability of the printed colors against fading from light exposure and abrasion.

- Adhesion Tests: Ensuring that the sublimated inks adhere properly to the metal surface is crucial, often performed using tape tests.

- Durability Tests: Products may undergo stress tests to evaluate their resistance to scratches, moisture, and temperature changes.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of potential suppliers.

What Are the Best Practices for Auditing Suppliers?

Conducting regular audits is one of the most effective ways to assess a supplier’s quality management system. Buyers should request to review quality management certifications and any audit reports that demonstrate compliance with international standards.

Additionally, on-site visits can provide insight into the manufacturing processes and quality control measures in place. During these visits, buyers should inquire about the specific QC checkpoints and testing methods utilized by the supplier.

How Important Are Third-Party Inspections for B2B Buyers?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These inspections can be conducted at various stages, from raw material acquisition to final product delivery, ensuring that the supplier adheres to the necessary quality standards.

What QC and Certification Nuances Should International B2B Buyers Consider?

For international buyers, understanding the nuances of quality control and certification is vital. Regulations and standards may vary significantly across different regions, particularly in Africa, South America, the Middle East, and Europe.

How Do Regional Standards Affect Purchasing Decisions?

Buyers must consider regional certifications that may be required for their specific markets. For instance, products sold in the European Union may need to comply with CE marking, while certain African countries may have unique local standards. Understanding these requirements can help avoid delays and complications in the supply chain.

In summary, the manufacturing processes and quality assurance measures for sublimation printing on metal are integral to producing high-quality products. B2B buyers must be diligent in evaluating suppliers, understanding international standards, and ensuring that rigorous QC practices are in place to meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sublimation printing on metal’

Introduction

This guide serves as a practical checklist for B2B buyers interested in sourcing sublimation printing services for metal products. As the demand for high-quality, durable, and aesthetically pleasing printed metals grows globally, especially in regions like Africa, South America, the Middle East, and Europe, it’s essential to understand the key steps involved in the procurement process. This checklist will help you navigate sourcing effectively, ensuring you make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for aligning your needs with supplier capabilities. Determine the types of metals you wish to print on (e.g., aluminum, stainless steel) and the dimensions required for your products. This clarity will aid in communicating your requirements to potential suppliers and ensuring they can meet your expectations.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers specializing in sublimation printing on metal. Look for companies with a proven track record and positive customer reviews. Utilize industry directories, online platforms, and trade shows to identify reputable suppliers who can cater to your regional needs.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that your shortlisted suppliers possess relevant certifications. Certifications such as ISO 9001 for quality management can indicate a supplier’s commitment to quality and reliability. Ensure they also comply with local and international standards, which is particularly important for buyers in diverse markets.

Step 4: Request Samples of Previous Work

Request samples to assess the quality of the sublimation printing. This step allows you to evaluate the vibrancy, durability, and overall aesthetic of the prints. Pay attention to the details, such as color accuracy and finish quality, as these factors will impact your own product’s marketability.

Step 5: Understand Production Capabilities and Turnaround Times

Inquire about the supplier’s production capabilities and typical turnaround times. Understanding their capacity to handle your order size and urgency is crucial, especially if you have tight deadlines. Discuss any potential bottlenecks in their production process to avoid delays in your supply chain.

Step 6: Review Pricing Structures and Terms

Analyze the pricing structures offered by each supplier, including any bulk order discounts or additional fees for customization. Ensure that you understand all terms related to payment, shipping, and any warranties provided for the printed products. A transparent pricing structure will help you make a more informed budget decision.

Step 7: Establish Communication and Support Channels

Establish clear communication channels with your chosen supplier. Ensure that they provide dedicated support for any inquiries or issues that may arise throughout the production process. Effective communication will facilitate a smoother transaction and enhance the overall partnership experience.

By following this checklist, B2B buyers can streamline the sourcing process for sublimation printing on metal, ensuring they partner with suppliers who meet their specific needs and quality standards.

Comprehensive Cost and Pricing Analysis for sublimation printing on metal Sourcing

What Are the Key Cost Components for Sublimation Printing on Metal?

Sublimation printing on metal involves several cost components that B2B buyers need to consider when sourcing from suppliers. Understanding these costs is crucial for accurate budgeting and long-term planning.

-

Materials: The primary materials include sublimation inks, transfer paper, and the metal substrate itself, often aluminum or stainless steel. The quality of these materials significantly impacts the final product’s durability and aesthetic. High-quality inks and substrates may have a higher initial cost but can lead to better customer satisfaction and repeat business.

-

Labor: Labor costs encompass the workforce involved in the design, setup, printing, and finishing processes. Skilled technicians may command higher wages, but their expertise can enhance quality and reduce waste during production.

-

Manufacturing Overhead: This includes costs related to equipment maintenance, utilities, and facility rent. Investing in advanced sublimation printing machines can lead to increased efficiency and lower operational costs over time.

-

Tooling: Tooling costs refer to the investment in specialized equipment necessary for sublimation printing, such as heat presses and cutting tools. These are typically one-time expenses but can be significant depending on the scale of operations.

-

Quality Control (QC): Implementing a robust QC process is essential to ensure that the printed products meet the required specifications. This may include additional labor or technology costs but is vital for maintaining product quality and minimizing returns.

-

Logistics: Shipping and handling costs can vary significantly based on distance, packaging requirements, and shipping methods. For international buyers, understanding Incoterms is crucial to determine who bears the shipping costs and responsibilities.

-

Margin: Suppliers typically build a profit margin into their pricing structure, which can vary widely based on market competition, product uniqueness, and supplier reputation.

How Do Price Influencers Affect Sublimation Printing Costs?

Several factors influence the pricing structure for sublimation printing on metal, especially for international B2B buyers.

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Larger orders often lead to bulk discounts, allowing buyers to reduce the per-unit cost.

-

Specifications and Customization: Customized designs or specific requirements can lead to increased costs due to additional labor and material usage. Buyers should clearly communicate their needs to get accurate quotes.

-

Materials: The choice of metal substrate (e.g., aluminum vs. stainless steel) can impact costs. Aluminum is generally more affordable and lighter, while stainless steel offers superior durability but at a higher price.

-

Quality and Certifications: Products that meet industry standards or certifications may come at a premium but can be necessary for certain markets. Buyers should weigh the cost against potential market advantages.

-

Supplier Factors: The supplier’s reputation, experience, and geographic location can all influence pricing. Suppliers with established reliability may command higher prices but can offer greater assurance of quality and service.

-

Incoterms: Understanding the terms of shipment is essential for international buyers to avoid unexpected costs. Different Incoterms indicate who is responsible for shipping, insurance, and duties, which can affect the total landed cost.

What Buyer Tips Can Help Optimize Costs?

-

Negotiate Effectively: Engaging in negotiations can yield better pricing, especially for larger orders. Building a relationship with suppliers can also lead to favorable terms over time.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as durability and maintenance costs to make informed purchasing decisions.

-

Understand Regional Pricing Nuances: Pricing can vary by region due to local economic conditions, tariffs, and shipping costs. Buyers from Africa, South America, the Middle East, and Europe should research local suppliers and market conditions to find the best deals.

-

Request Samples: Before committing to a large order, request samples to evaluate quality. This can prevent costly mistakes and ensure that the final product meets your expectations.

-

Stay Informed: Market trends can impact pricing. Keeping abreast of industry developments can help buyers anticipate changes and make timely purchasing decisions.

By understanding these cost components, price influencers, and practical tips, B2B buyers can make informed decisions when sourcing sublimation printing services on metal, ultimately leading to more successful and profitable outcomes.

Alternatives Analysis: Comparing sublimation printing on metal With Other Solutions

Exploring Alternatives to Sublimation Printing on Metal

In the realm of metal printing, sublimation printing offers unique benefits, but it’s essential for B2B buyers to consider other viable alternatives that may better align with their specific needs. Each printing method has distinct characteristics that could influence performance, cost, ease of implementation, and maintenance. Below, we compare sublimation printing on metal with two other popular methods: screen printing and UV printing.

| Comparison Aspect | Sublimation Printing On Metal | Screen Printing | UV Printing |

|---|---|---|---|

| Performance | High durability and color vibrancy; suitable for intricate designs. | Good for solid colors and large areas; less detail in fine designs. | Excellent color fidelity and detail; quick curing time. |

| Cost | Higher initial investment in equipment; low operational costs. | Lower initial cost; cost-effective for large runs. | Moderate to high initial investment; cost-effective for small runs. |

| Ease of Implementation | Requires specialized equipment; training needed. | Relatively easy setup; minimal training required. | Requires specialized UV printers; can be complex. |

| Maintenance | Low maintenance; occasional printer upkeep needed. | Moderate maintenance; screens need regular cleaning. | Higher maintenance; requires care for UV lamps and systems. |

| Best Use Case | Ideal for custom, small-batch items with high detail. | Best for large quantities of simple designs; cost-effective for bulk orders. | Suited for high-detail graphics and short runs; excellent for diverse substrates. |

What Are the Advantages and Disadvantages of Screen Printing?

Screen printing is a traditional method that involves pushing ink through a mesh screen onto the substrate. This method is particularly advantageous for large production runs, as it allows for cost-effective printing of designs with solid colors. However, it may struggle with intricate designs and fine details, as the process is better suited for simpler graphics. Additionally, screen printing requires a series of screens for each color, which can lead to increased setup time and costs for multi-colored designs.

How Does UV Printing Compare?

UV printing utilizes ultraviolet light to cure or dry the ink as it is printed. This method is known for its exceptional color fidelity and ability to print on a wide variety of substrates, including metals. The quick curing process allows for faster production times and immediate handling post-printing. However, the initial investment for UV printing equipment can be high, and the maintenance of UV systems can require more attention compared to sublimation. UV printing is an excellent choice for businesses that require high-detail graphics and flexibility in materials.

Which Printing Solution Should B2B Buyers Choose?

Selecting the right printing solution depends on several factors including the specific requirements of the project, budget constraints, and production volume. For businesses focused on high-quality, customized designs with intricate details, sublimation printing on metal may be the best option despite its higher initial costs. Conversely, if the goal is to produce large quantities of simpler designs economically, screen printing could be more advantageous. For those needing versatility and rapid production with vibrant colors, UV printing stands out as a compelling alternative.

Ultimately, B2B buyers should evaluate their unique needs, including the intended use of the printed metal products, the desired aesthetic qualities, and their budget, to determine the most suitable printing method for their operations.

Essential Technical Properties and Trade Terminology for sublimation printing on metal

What Are the Essential Technical Properties for Sublimation Printing on Metal?

Understanding the technical specifications of sublimation printing on metal is crucial for B2B buyers to make informed decisions. Here are some key properties to consider:

1. Material Grade

Material grade refers to the quality and composition of the metal used for sublimation printing. Common grades include aluminum and stainless steel, both of which offer unique advantages. Aluminum is lightweight, corrosion-resistant, and highly versatile, making it ideal for various applications like signage and promotional items. Stainless steel provides excellent strength and durability, making it suitable for more rugged environments. Selecting the appropriate material grade ensures that the final product meets performance expectations and aesthetic requirements.

2. Coating Thickness

The coating thickness is a critical factor that affects adhesion during the sublimation process. A thicker polyester coating improves the bond between the ink and the metal, resulting in vibrant and long-lasting prints. For B2B buyers, understanding the optimal coating thickness is essential for ensuring print quality and durability, especially in demanding applications.

3. Temperature Tolerance

Temperature tolerance indicates the maximum temperature the metal can withstand during the sublimation process without warping or degrading. Metals like aluminum can handle high temperatures effectively, making them suitable for sublimation. Knowing the temperature tolerance helps businesses to optimize their printing processes and avoid costly mistakes, such as material failure during production.

4. Surface Finish

The surface finish of the metal affects both the aesthetic quality and the adhesion of the sublimation ink. Common finishes include gloss, matte, and clear coatings. Each finish has different visual impacts and may influence the final product’s market appeal. Buyers should consider the desired finish when selecting materials, as it can significantly affect customer satisfaction and product value.

5. Dimensional Tolerance

Dimensional tolerance refers to the acceptable limits of variation in the dimensions of the metal sheets. It is crucial for ensuring that printed designs align perfectly with the intended dimensions of the final product. For B2B buyers, understanding dimensional tolerances helps in planning production runs and maintaining quality control, especially when dealing with large-scale orders.

What Are Common Trade Terms in Sublimation Printing on Metal?

Familiarity with industry jargon can enhance communication and negotiation in B2B transactions. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that can be branded by another company. In sublimation printing, buyers may work with OEMs to source high-quality printing machines or materials. Understanding OEM relationships can help businesses ensure they are getting reliable products tailored to their specific needs.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to manage inventory and production costs effectively. Suppliers often set MOQs to ensure profitability, making it important for buyers to assess their demand before placing orders.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. It is a crucial part of the procurement process, allowing buyers to compare offers and negotiate terms. Utilizing RFQs can streamline purchasing decisions, ensuring that companies secure the best value for their investments.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms helps B2B buyers navigate the complexities of global trade, ensuring smooth transactions and minimizing misunderstandings.

5. Heat Press

A heat press is the machinery used in the sublimation process to transfer designs from sublimation paper to metal. Knowledge of heat press specifications, such as pressure and temperature settings, is crucial for achieving optimal results. B2B buyers should consider the capabilities of heat presses when investing in sublimation equipment.

By grasping these essential properties and trade terminology, B2B buyers in the sublimation printing industry can make informed decisions that enhance their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the sublimation printing on metal Sector

What Are the Current Market Dynamics and Key Trends in Sublimation Printing on Metal?

The sublimation printing on metal market is experiencing significant growth, driven by advancements in technology and the increasing demand for high-quality, customizable products. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are seeking innovative solutions that enhance brand visibility and consumer engagement. Key trends include the rise of personalized products, as businesses leverage sublimation technology to offer tailored solutions—from promotional items to bespoke signage.

Emerging technologies, such as advanced printing inks and improved heat press machines, are enhancing the quality and durability of prints, making sublimation an attractive option for various applications. Additionally, the integration of digital design tools allows for seamless transitions from concept to production, streamlining the workflow for B2B buyers. The market is also witnessing a shift towards eco-friendly materials, as companies aim to reduce their environmental impact while meeting consumer demand for sustainable products.

Moreover, competition among suppliers is intensifying, prompting businesses to seek cost-effective sourcing strategies. Global supply chain disruptions have emphasized the importance of diversifying supplier networks, especially for materials like aluminum and polyester-coated metals, which are crucial for the sublimation process. Buyers should remain vigilant and adaptable to these market dynamics to maintain a competitive edge.

How Can Sustainability and Ethical Sourcing Impact the Sublimation Printing on Metal Sector?

Sustainability is becoming a cornerstone of modern business practices, influencing sourcing decisions in the sublimation printing on metal sector. As global awareness of environmental issues rises, B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices. This includes the use of eco-friendly inks, recyclable materials, and energy-efficient manufacturing processes.

Ethical sourcing is equally critical, as companies strive to ensure that their supply chains are transparent and responsible. Buyers should look for certifications such as FSC (Forest Stewardship Council) for paper products or ISO 14001 for environmental management, which indicate a commitment to sustainability. By partnering with suppliers that prioritize ethical practices, businesses not only enhance their brand reputation but also contribute positively to the communities from which they source.

The environmental impact of sublimation printing can be mitigated through the adoption of ‘green’ materials and processes. For instance, utilizing aluminum that is recycled or produced with lower carbon footprints can significantly reduce the overall ecological impact. As sustainability becomes a key differentiator in the marketplace, B2B buyers who prioritize these values will likely find greater success in attracting environmentally conscious consumers.

What Is the Brief Evolution of Sublimation Printing on Metal?

Sublimation printing has evolved significantly since its inception in the early 1980s. Initially used for textiles, the technology quickly expanded to include various substrates, with metal becoming a popular choice due to its durability and aesthetic appeal. The process involves transferring dye onto a coated metal surface using heat and pressure, resulting in vibrant, long-lasting images.

Over the years, advancements in printing technology have improved the quality and efficiency of sublimation processes. The introduction of specialized sublimation inks and high-precision printers has enabled businesses to produce intricate designs with greater accuracy. Today, sublimation printing on metal is widely used across multiple industries, including advertising, interior design, and custom merchandise, making it an essential tool for B2B buyers looking to enhance their product offerings.

As the market continues to evolve, staying informed about the latest technologies and trends will be crucial for businesses aiming to leverage sublimation printing effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of sublimation printing on metal

-

How do I choose the right supplier for sublimation printing on metal?

When selecting a supplier, consider their experience in sublimation printing, especially on metal substrates. Look for suppliers who can demonstrate a portfolio of past work, ideally with references from clients in your industry. Evaluate their production capabilities, including the types of metals they can print on and their technology. Additionally, assess their quality control processes to ensure durability and aesthetic standards. Communicating with potential suppliers about their timelines and responsiveness can also provide insight into their reliability. -

What are the minimum order quantities (MOQs) for sublimation printing on metal?

Minimum order quantities can vary significantly between suppliers. Some may offer flexibility for smaller orders, especially for custom designs, while others may have strict MOQs to cover production costs. Generally, MOQs can range from 10 to 100 units depending on the complexity and customization involved. It’s advisable to discuss your specific needs with potential suppliers to negotiate terms that suit your business requirements. -

How can I ensure quality assurance during the sublimation printing process?

To ensure quality assurance, request samples before placing larger orders. This allows you to evaluate the print quality, color accuracy, and durability of the sublimated metal products. Inquire about the supplier’s quality control measures, such as inspections at various stages of the printing process. Establish clear specifications and requirements in your contract, and consider implementing a third-party quality audit if working with suppliers in different regions. -

What payment terms should I expect when sourcing sublimation printing on metal?

Payment terms can vary widely by supplier and region. Common terms include a deposit upfront (often 30-50%) with the balance due upon completion or delivery. Some suppliers may offer net terms (e.g., net 30, net 60) for established clients. It’s important to discuss and negotiate payment terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods or escrow services for large transactions to mitigate risks. -

What types of metals are suitable for sublimation printing?

The most commonly used metals for sublimation printing include aluminum and stainless steel due to their excellent thermal properties and ability to retain print quality. Aluminum is lightweight, corrosion-resistant, and versatile, making it ideal for various applications. Stainless steel is durable and easy to maintain, but it may require a polyester coating for optimal adhesion of sublimation inks. Always confirm the compatibility of the chosen metal with your supplier’s printing process. -

How does international shipping affect my sublimation printing orders?

International shipping can significantly impact lead times and costs for sublimation printing orders. Factors to consider include customs regulations, shipping methods, and potential tariffs or duties. Ensure your supplier can provide details on shipping options and estimated delivery times. It may be beneficial to work with logistics partners experienced in international shipping to navigate these complexities effectively. -

What customization options are available for sublimation printing on metal?

Customization options can include various sizes, shapes, finishes (such as gloss or matte), and the ability to print full-color designs. Many suppliers also offer additional services, such as cutting, coating, or mounting options. When discussing your project, be clear about your design requirements and inquire about any limitations in the customization process. This will help ensure that the final product meets your expectations. -

How do I handle issues with sublimation print quality or defects?

In the event of quality issues or defects, promptly contact your supplier to discuss the problem. Document the defects with photos and specific details about the order. Most reputable suppliers will have a return or replacement policy for defective items. Establishing clear communication and understanding the supplier’s policies beforehand will facilitate a smoother resolution process. Consider incorporating quality checks on your end as well to minimize future discrepancies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Sublimation Printing On Metal Manufacturers & Suppliers List

1. KDM Fab – Sublimation Printing Solutions

Domain: kdmfab.com

Registered: 2022 (3 years)

Introduction: Sublimation printing is a technique used to print on fabrics and metals, offering a convenient and cost-effective solution. Key details include: 1. Advantages: Smart choice for mini production, durability, ability to withstand high temperatures, aesthetic value, resistance to damage, easy maintenance, and multiple finishes available. 2. Drawbacks: High initial investment and impractical recycling….

2. Pictorem – HD Sublimation Metal Print

Domain: pictorem.com

Registered: 2013 (12 years)

Introduction: Product Name: HD Sublimation Metal Print – ChromaLuxe

Formats Available: Custom formats from 8×8″ up to 60×40″

Pricing Examples:

– 16×12″ – $77

– 24×16″ – $124

– 30×20″ – $176

– 36×24″ – $241

– 48×36″ – $452

– 12×12″ – $65

– 24×24″ – $170

– 30×30″ – $250

– 36×36″ – $346

– 40×40″ – $421

Mounting Options: Metal Print only, Back frame mount, Floating Frame box

Features:

– Unmatched color brilliance…

3. Best Printer – Top Choices for Metal & Textile Sublimation Under $500

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Best printer under 500$ for metal / textile sublimation. Users are looking for options that can handle multiple materials, specifically for sublimation on metal/aluminum and textile clothing. It is noted that you do not need a special ‘sublimation’ printer; any tank-type inkjet printer can be used with sublimation ink. Epson is mentioned as a brand that makes multiple tank printers. The printer sh…

4. USA On Canvas – Metal & Wood Prints

Domain: usaoncanvas.com

Registered: 2008 (17 years)

Introduction: USA Metal & Natural Wood Prints – Dye Sublimation on Aluminum and Wood. Dye sublimation is a digital print technology that reproduces full color images on various surfaces. Metal prints are available in standard sizes with two finishes: Gloss White and Gloss Brushed/Silver. Wood photo panels feature a natural base look with bevelled edges and keyholes for easy hanging. Key features include a frame…

5. LongForte – Sublimation Metal Sheets

Domain: longforte.com

Registered: 2011 (14 years)

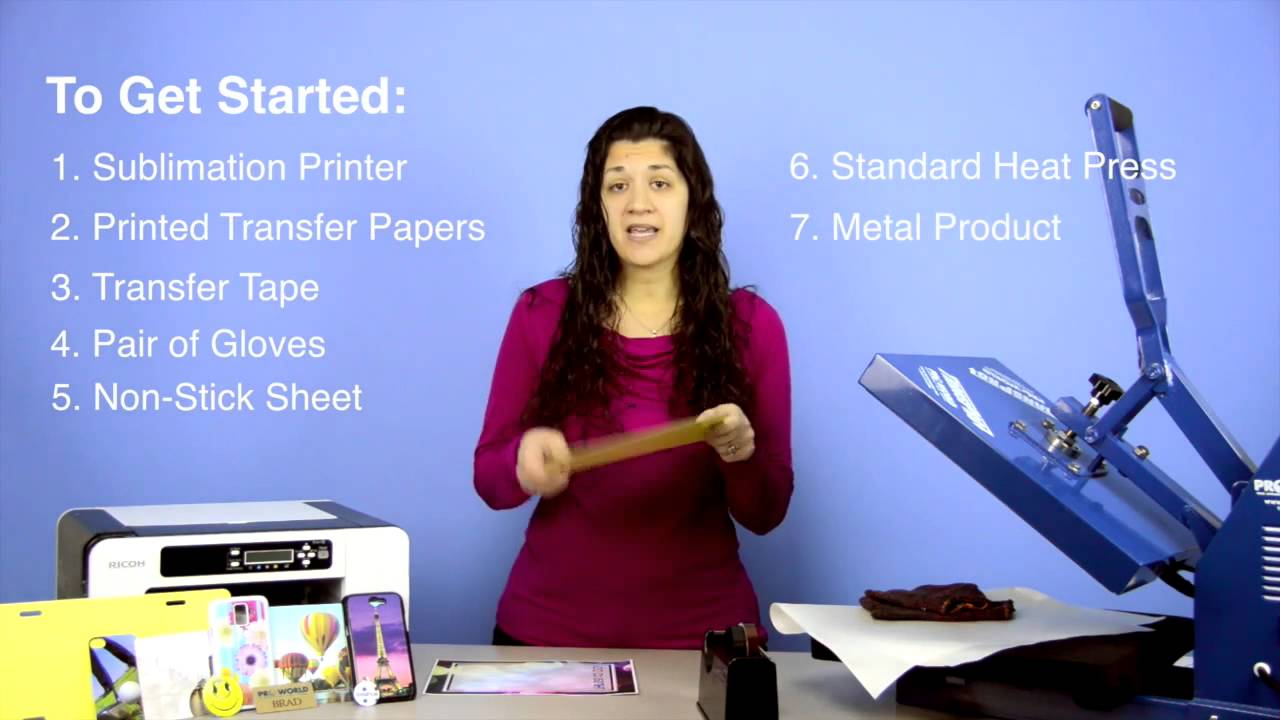

Introduction: Printing Sublimation Metal Sheets are versatile products suitable for indoor or outdoor signage and photographic wall prints. Key materials needed for printing include Sublimation Metal Sheets, Sublimation Paper, Sublimation Ink, a Heat Press, Protective Gloves, and Heat-Resistant Tape. The printing process involves designing an image, printing it as a mirror image on sublimation paper, preheating…

Strategic Sourcing Conclusion and Outlook for sublimation printing on metal

The strategic sourcing of sublimation printing on metal presents significant opportunities for international B2B buyers. By leveraging the advantages of this technology—such as durability, aesthetic appeal, and low operational costs—companies can enhance product offerings and meet diverse market demands. Notably, sublimation printing is not only ideal for small production runs but also provides an efficient solution for customization across various metal substrates, including aluminum and stainless steel.

Investing in high-quality sublimation equipment may involve a substantial initial outlay, but the long-term benefits—such as resistance to damage, ease of maintenance, and superior color fidelity—far outweigh these costs. Moreover, as markets in Africa, South America, the Middle East, and Europe evolve, the demand for high-definition, visually striking products continues to rise.

As you consider your sourcing strategies, prioritize suppliers who can provide both the technology and expertise necessary to maximize the potential of sublimation printing. Embrace this innovative printing method to differentiate your offerings and cater to an increasingly design-conscious consumer base. The future of sublimation printing on metal is bright; now is the time to invest and position your business for success.